BEAMEX MC5 Guide

For Main Firmware Version 1.90

Calibrating and Adjusting MC5 / 011912

Calibration and

Adjustment Instructions

for MC5 Multifunction Calibrator

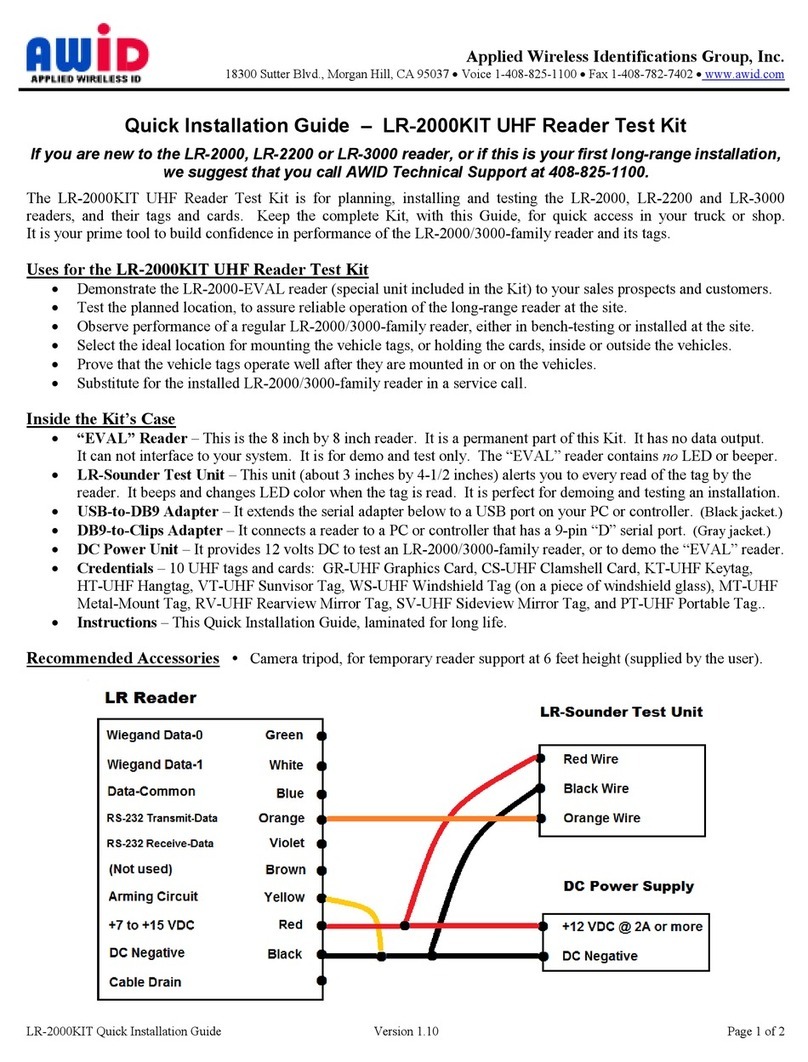

Enable Adjustment Mode

Select Quantity and Function/Port

Calibrate (Compare against a

more accurate instrument)

Adjustment required?

Store adjustment data

Enter reference values to

adjust a Quantity in the calibrator

More Quantities to calibrate?

Did one or

more Quantities in

all modules require

adjustment?

Enter the calibration date and

Calibration Laboratory data in

the Module Settings window

yes

no

no

yes

no

yes

Start

End

More Quantities to adjust?

no

yes

Calibration and Adjustment Instructions for MC5 Multifunction Calibrator For Main Firmware Version 1.90

Page 2/16

Contents

General.......................................................................................................... 3

Equipment Required for Performing the Calibration............................................................3

Recommended Calibration Points.......................................................................................4

E module......................................................................................................................................4

ET module ...................................................................................................................................4

Pressure modules........................................................................................................................4

Calibrating and Adjusting the Calibrator ................................................... 5

Enabling and Starting the Adjustment Mode.......................................................................5

Calibration ...........................................................................................................................5

Adjustment of Measurement Ranges..................................................................................6

Adjusting the Voltage Measurement in E Module (±50 V)...........................................................6

Adjusting the Low Voltage Measurement in E Module (±1 V)......................................................6

Adjusting the Current Measurement in E Module (±100 mA) ......................................................7

Adjusting the Frequency Measurement in E Module (±0.0027 … 50000 Hz)..............................7

Adjusting the Resistance Measurement in ET Module (0 … 4000 ohm).....................................8

Adjusting the Low Voltage Measurement in ET Module (±500 mV).............................................8

Adjusting the Pressure Measurement of a Pressure Module.......................................................9

Adjusting the Temperature Measurement of the Internal Reference Junction Module..............10

Adjustment of Generation/Simulation Ranges ..................................................................11

Adjusting the Current Generation in E Module (0 … 25 mA).....................................................11

Adjusting the Resistance Simulation in ET Module (0 … 4000 ohm) ........................................12

Adjusting the Low Voltage Generation in ET Module (±500 mV)...............................................13

Adjusting the Frequency Generation in ET Module (2.7 mHz … 50 kHz)..................................13

Adjusting the Voltage Generation in ET Module (±12 V)...........................................................14

Adjusting the Current Generation in ET Module (±25 mA) ........................................................15

Saving Adjustment Data....................................................................................................16

Setting the Calibration Date When No Adjustment Was Required ...................................16

Ending Adjustment Mode ..................................................................................................16

Calibration and Adjustment Instructions for MC5 Multifunction Calibrator For Main Firmware Version 1.90

Page 3/16

General

The tolerances, linearity errors and temperature factors of the components used in the Beamex

Calibrators have been carefully considered during the specification tests at the factory. All nec-

essary parameters have been saved into the EEPROM memory of each measurement module.

It is not necessary to renew the calibration if certain components in the analogy part of the cali-

brator are not replaced. Anyhow, some characteristics can deviate from the original values dur-

ing the time. The periodical calibration is thus necessary in order to maintain the full accuracy of

the calibrator. In the beginning of the calibrator’s life span, the recommended calibration period

is one year. When the calibration history has been established, the calibration period can be

extended.

The whole calibration procedure can be made without opening the calibrator. The calibration

procedure is made as easy as possible. The calibration requires, however, some very accurate

instruments. If You do not have all the necessary calibration instruments, send the device to

Beamex’s accredited calibration laboratory for calibration.

Equipment Required for Performing the Calibration

For the complete calibration you need the following equipment:

1) DC calibrator, capable of generating the

- currents, voltages and low voltages measured with the E module.

- low voltages measured with the ET module.

2) DC meter(s), capable of measuring the

- currents generated with the E module

- currents, voltages and low voltages generated with the ET module

- generated voltages in the calibration of the ET module's resistance simulation.

3) Frequency generator capable of generating the frequencies measured with the E module.

4) Frequency measurement meter, capable of measuring the frequencies generated with the

ET module.

5) Precision resistors, for calibrating the ET modules resistance measurement.

6) A good quality thermocouple of type E, J, K or T. The sensor wires should be continuous

without extension or plug. The error of the sensor output at the condition where the sensor is

in the used temperature reference and the reference junction in 20 to 30°C should be known

and taken into account in the calibration.

7) An ice bath or another known temperature reference. The combined uncertainty of the tem-

perature reference and the thermocouple together should be less than 0.05°C.

8) A dead weight tester with the accuracy of 0,02 % RDG or better for the generation of the

necessary testing pressures. Required for the different pressure modules used with the cali-

brator.

You can replace items 6 and 7 with a small size temperature sensor and measuring device with

calibrated accuracy better than 0.05°C. The sensor must be small enough to fit inside the RJ

module. It should not noticeably conduct heat to or from the environment.

The accuracy of the necessary equipment should be about three times better than the accuracy

specified for the calibrator (see the calibrator’s Technical Data Sheet). If the accuracy of the

calibration equipment are worse, the calibration period should be shorter.

Calibration and Adjustment Instructions for MC5 Multifunction Calibrator For Main Firmware Version 1.90

Page 4/16

Recommended Calibration Points

The calibration points presented here are mostly the same as on the Calibration Certificate de-

livered with the calibrator. As the heading indicates, these are recommendations, not the only

suitable calibration points.

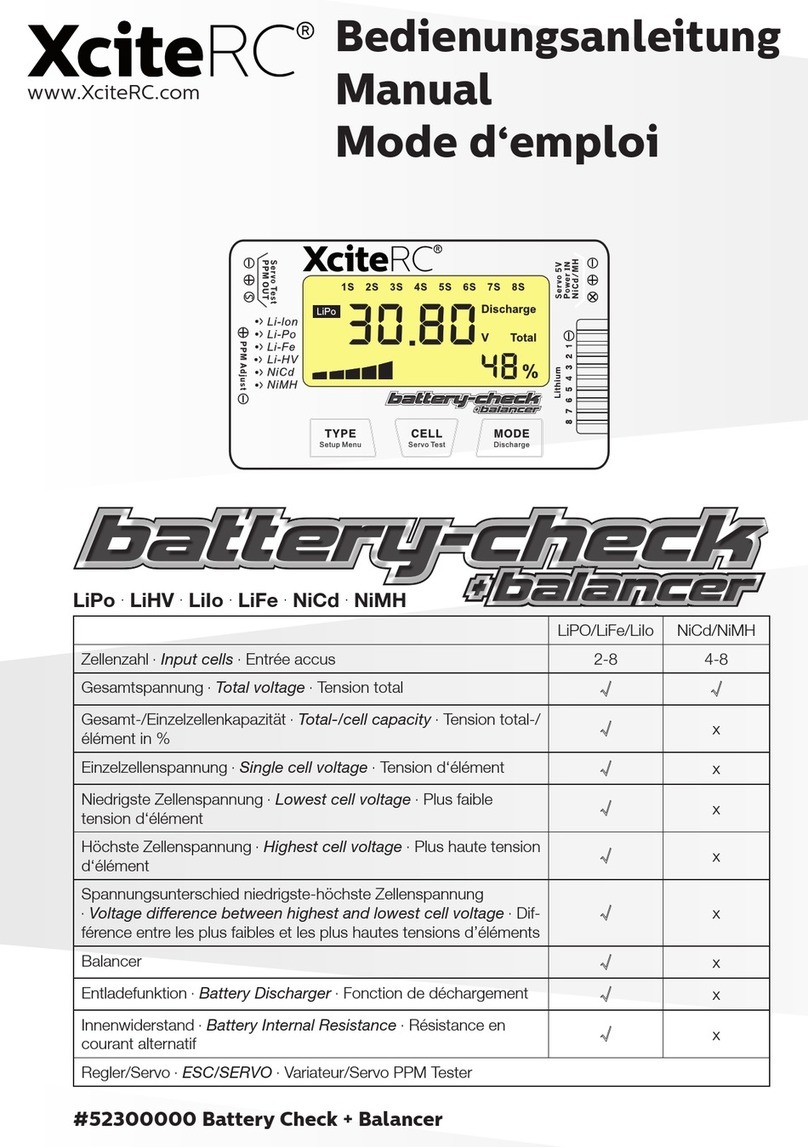

E module

Low Voltage

meas., V

(±1 V)

Voltage

meas., V

(±50 V)

Current

meas., mA

(±100 mA)

Current

generation, mA

(0 … 25 mA)

Frequency meas-

urement, Hz

(0.0027…50000 Hz)

-1.00000 -50.000 -100.000 0.000 1

0.00000 0.000 0.000 5.000 10

0.25000 10.000 4.000 10.000 100

0.50000 20.000 12.000 15.000 1000

0.75000 30.000 20.000 20.000 10000

1.00000 40.000 50.000 25.000 50000

50.000 100.000

ET module

Low Voltage

meas. & gen., mV

(±500 mV)

Voltage

gen., V

(±12 V)

Current gen.,

mA

(±25 mA)

Frequency genera-

tion, Hz

(2.7 mHz…50 kHz)

Resistance

meas., ohm

(0 … 4000 ohm)

Resistance

simul., ohm

(0 … 4000 ohm)

-500.00 -12.000 0.000 15.000 5.000

0.00 0.000 5.000 10 80.000 130.00

10.00 2.500 10.000 100 160.00 145.00

50.00 5.000 15.000 1000 320.00 270.00

250.00 7.500 20.000 10000 1000.00 290.00

500.00 10.000 25.000 50000 2000.00 540.00

12.000 4000.00 570.00

1050.00

1200.00

2100.00

2300.00

4000.00

Pressure modules

Barometric

module, kPa abs

(80…120 kPa)

Gauge

modules,

(0 … X kPa)

Combined modules with a

symmetrical range

(±X kPa)

Combined modules with

an asymmetrical range

(-100 … X kPa)

80.00 0 % of span 0 % of span 0 % of span

90.00 20 % of span 20 % of span 20 % of span

100.00 40 % of span 40 % of span 40 % of span

110.00 60 % of span 60 % of span 60 % of span

120.00 80 % of span 80 % of span 80 % of span

100 % of span 100 % of span 100 % of span

80 % of span 80 % of span 80 % of span

60 % of span 60 % of span 60 % of span

40 % of span 40 % of span 40 % of span

20 % of span 20 % of span 20 % of span

0 % of span 0 % of span 0 % of span

-20 % of span -20 kPa

- 40 % of span -40 kPa

- 60 % of span -60 kPa

- 80 % of span -80 kPa

- 100 % of span -99 kPa

Note. The exact values of the calibration

points may vary depending on the dead weight tester in use.

Calibration and Adjustment Instructions for MC5 Multifunction Calibrator For Main Firmware Version 1.90

Page 5/16

Calibrating and Adjusting the Calibrator

Calibration

Since adjusting the measurement ranges affect the generation ranges (via feedback measure-

ment), all Quantity and Function/Port settings should first be calibrated before making any

adjustments. Do the calibration in Basic Mode and use the recommended calibration points pre-

sented on page 4or any other suitable set of calibration points.

When all calibrations are done, prepare for enabling the adjustment mode by shutting down the

calibrator. To save the calibration date, you need to enable the adjustment mode even if no ad-

justment is required. For further information, see next chapter.

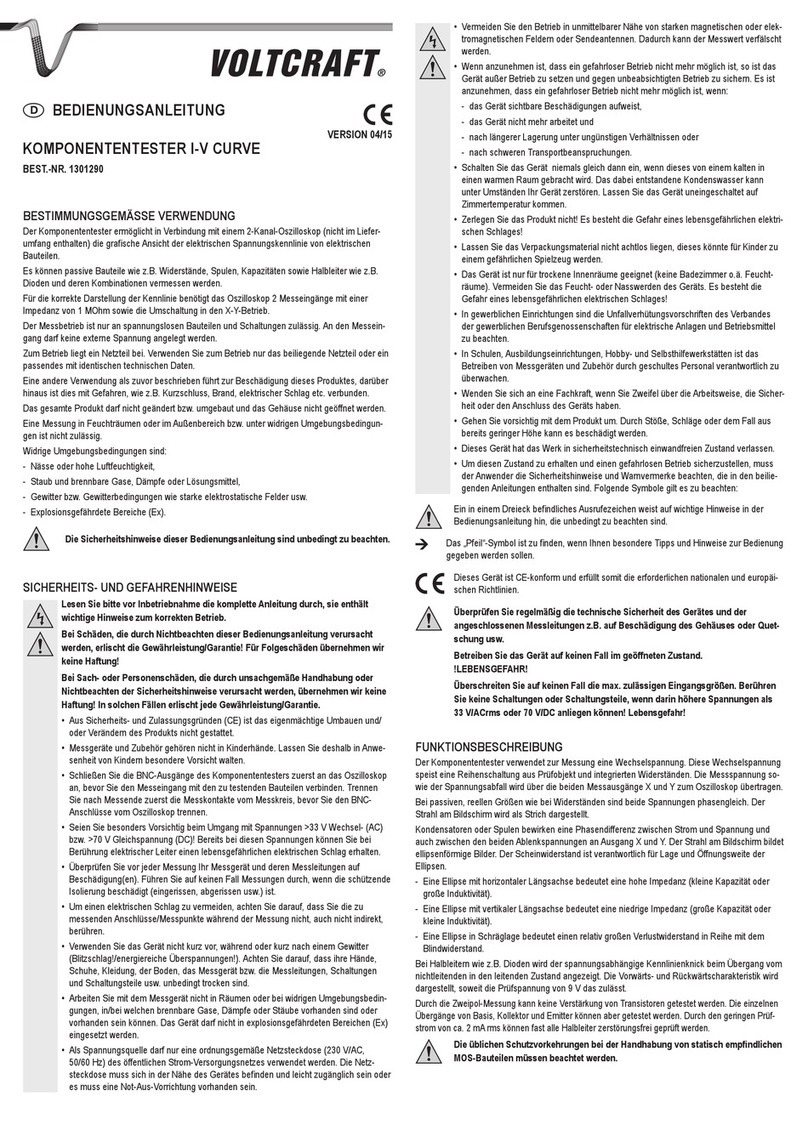

Enabling the Adjustment Mode

By default, the calibrator does not support adjustment of its

own measurement generation and simulation signals. This

prevents the calibrator from being accidentally adjusted.

To enable the Adjustment Mode, do as follows:

1. Start the calibrator. When the screen with the mod-

ule version numbers etc. appear, press the D/Wait

function key

Note.

Pressing the D/Wait function key is not needed if the calibrator's

calibration due date has expired. Then the calibrator beeps and

stops automatically on this screen and displays the message

"Calibrate soon".

Adjustment mode enabled

Wait

Serial number

E module version

Calibration due date

Main version

ET module version

23512365

1.50

20.03.2003

1.90

1.70

www.beamex.com

2. Press the key.

Check that the text "Adjustment Mode enabled" appears on the status bar.

Enabling the Adjustment Mode makes the Adjustment menus available.

To start adjusting the calibrator, select:

D/Menu, C/Others, 2/Maintenance, 2/Calibrator Adjustment and

1/Start Adjustments.

Notes:

The commands apply when the calibrator is in Basic State.

The measurement window of a Quantity is enlarged to indicate that calibration/adjustment is in progress.

If there is need for adjustment see chapters Adjustment of Measurement Ranges and

Adjustment of Generation/Simulation Ranges on pages 6and 11 respectively.

If no adjustment is needed, set the calibration date into the calibrator’s memory. To do that, see

chapter Setting the Calibration Date When No Adjustment Was Required on page 16.

Calibration and Adjustment Instructions for MC5 Multifunction Calibrator For Main Firmware Version 1.90

Page 6/16

Adjustment of Measurement Ranges

Adjusting the Voltage Measurement in E Module (±50 V)

Quantity: Voltage

Function/Port: E: Voltage Measurement

Use an accurate voltage source and connect it to the

calibrator’s terminals highlighted in the adjacent picture.

In case the accuracy of the voltage source is not good

enough, check the correct voltage using an accurate

Digital Multimeter.

Adjustment point ranges, mV

1: 9 … 12

2: 19 … 25

3: 39 … 50

Generate a voltage that is inside the limits of the first

adjustment point range. Enter the correct voltage seen

on the Digital Multimeter’s display to Span Reference

Value field in the calibrator. Continue through all the ad-

justment points

When all adjustment points are checked, select either

another Quantity and Function/Port combination or save

the adjustment result as described in chapter Saving

Adjustment Data on page 16.

Source/DMM V

10.00021

17.10.2002 10:21

Voltage

E: Voltage Measurement

V10.0001

Span Reference Value 10.00021

MENU

Calibration

Mode

MULTIFUNCTION CALIBRATOR

T/C, Low V 4-w meas

R, RTD

3 & 4-w meas

V, I,+24V Imeas/sink

Low V

HART®

T/C INT. RJ

T/C OR EXT

WIRES ONLY

2-w xmtr

V, ,

?

MEASURE

OUTPUTSENSOR MEASURE & SIMULATE

ET E

Max input:

60 VDC/30VAC

Adjusting the Low Voltage Measurement in E Module (±1 V)

Quantity: Voltage

Function/Port: E: Low Voltage Measurement

Use an accurate millivolt source and connect it to the

calibrator’s terminals highlighted in the adjacent picture.

In case the accuracy of the voltage source is not good

enough, check the correct voltage using an accurate

Digital Multimeter.

Adjustment point ranges, mV

1: 200 … 250

2: 400 … 500

3: 800 … 1000

Generate a voltage that is inside the limits of the first

adjustment point range. Enter the correct voltage seen

on the Digital Multimeter’s display to Span Reference

Value field in the calibrator. Continue through all the ad-

justment points

When all adjustment points are checked, select either

another Quantity and Function/Port combination or save

the adjustment result as described in chapter Saving

Adjustment Data on page 16.

Source/DMM mV

220.000 12

17.10.2002 9:25

Voltage

E: Low Voltage Meas.

mV219.999

Span Reference Value 220.00012

MENU

Calibration

Mode

MULTIFUNCTION CALIBRATOR

T/C, Low V 4-w meas

R, RTD

3 & 4-w meas

V, I,+24V Imeas/sink

Low V

HART®

T/C INT. RJ

T/C OR EXT

WIRES ONLY

2-w xmtr

V, ,

?

MEASURE

OUTPUTSENSOR MEASURE & SIMULATE

ET E

Max input:

60 VDC/30VAC

Calibration and Adjustment Instructions for MC5 Multifunction Calibrator For Main Firmware Version 1.90

Page 7/16

Adjusting the Current Measurement in E Module (±100 mA)

Quantity: Current

Function/Port: E: Current Measurement

Use an accurate current source and connect to the cali-

brator’s terminals highlighted in the adjacent picture. In

case the accuracy of the current source is not good

enough, check the correct current using an accurate

Digital Multimeter.

Adjustment point ranges, mA

1: 20 … 50

2: 80 …100

Generate a current that is inside the limits of the first

adjustment point range. Enter the correct current seen

on the Digital Multimeter’s display to Span Reference

Value field in the calibrator. Continue through all the ad-

justment points

When all adjustment points are checked, select either

another Quantity and Function/Port combination or save

the adjustment result as described in chapter Saving

Adjustment Data on page 16.

Source/DMM mA

24.996 72

17.10.2002 9:27

Current

E: Current Measurement

mA24.9997

Span Reference Value 24.99672

MENU

Calibration

Mode

MULTIFUNCTION CALIBRATOR

T/C, Low V 4-w meas

R, RTD

3 & 4-w meas

V, I,+24V Imeas/sink

Low V

HART®

T/C INT. RJ

T/C OR EXT

WIRES ONLY

2-w xmtr

V, ,

?

MEASURE

OUTPUTSENSOR MEASURE & SIMULATE

ET E

Max input:

60 VDC/30VAC

Adjusting the Frequency Measurement in E Module (±0.0027 … 50000 Hz)

Quantity: Frequency

Function/Port: E: Frequency Meas.

Use an accurate frequency source and connect to the

calibrator’s terminals highlighted in the adjacent picture.

In case the accuracy of the frequency source is not good

enough, check the correct frequency using an accurate

Digital Multimeter.

Adjustment point range, Hz

800 … 50000

Generate a frequency that is inside the limits of the ad-

justment point range. Enter the correct frequency seen

on the Digital Multimeter’s display to Span Reference

Value field in the calibrator.

Select either another Quantity and Function/Port combi-

nation or save the adjustment result as described in

chapter Saving Adjustment Data on page 16.

Source/DMM kHz

10.000 00

17.10.2002 10:30

Frequency

E: Frequency Meas.

Hz1000.00

Trigger Level [V]

Span Reference Value 1000.00000

Field MENU

Calibration

Mode

2.00

MULTIFUNCTION CALIBRATOR

T/C, Low V 4-w meas

R, RTD

3 & 4-w meas

V, I,+24V Imeas/sink

Low V

HART®

T/C INT. RJ

T/C OR EXT

WIRES ONLY

2-w xmtr

V, ,

?

MEASURE

OUTPUTSENSOR MEASURE & SIMULATE

ET E

Max input:

60 VDC/30VAC

Note.

The default trigger level is 2 V. Change it to a more suitable level, if needed.

Calibration and Adjustment Instructions for MC5 Multifunction Calibrator For Main Firmware Version 1.90

Page 8/16

Adjusting the Resistance Measurement in ET Module (0 … 4000 ohm)

Quantity: Resistance

Function/Port: ET: Resistance Meas.

Use precision resistors and connect them to the cali-

brator’s terminals highlighted in the adjacent picture. In

case the accuracy of the resistors are not good enough,

check the correct resistance using an accurate Digital

Multimeter. Also read the note below the picture.

Adjustment point ranges, ohm

1: 60 … 87

2: 120 … 175

3: 240 … 350

4: 700 … 1025

5: 1400 … 2050

6: 2800 … 4100

Select a precision resistor that is inside the limits of the

first adjustment point range. Enter the correct resistance

seen on the Digital Multimeter’s display to Span Refer-

ence Value field in the calibrator. Continue through all

the adjustment points

When all adjustment points are checked, select either

another Quantity and Function/Port combination or save

the adjustment result as described in chapter Saving

Adjustment Data on page 16.

MENU

Calibration

Mode

Precision Resistor

W

70.0000

17.10.2002 10:26

Resistace

ET: Resistance Meas.

W69.998

Span Reference Value 70.00012

MULTIFUNCTION CALIBRATOR

T/C, Low V 4-w meas

R, RTD

3 & 4-w meas

V, I,+24V Imeas/sink

Low V

HART®

T/C INT. RJ

T/C OR EXT

WIRES ONLY

2-w xmtr

V, ,

?

MEASURE

OUTPUTSENSOR MEASURE & SIMULATE

ET E

Max input:

60 VDC/30VAC

Note.

Do not connect both the calibrator and the

Digital Multimeter to the resistor simultane-

ously. The resistance measurement currents

of the calibrator and the Digital Multimeter

disturb each other resulting in unreliable

measurements.

Adjusting the Low Voltage Measurement in ET Module (±500 mV)

Quantity: Voltage

Function/Port: ET: Low V. Sensor Mea

Use an accurate millivolt source and connect to the cali-

brator’s terminals highlighted in the adjacent picture. In

case the accuracy of the millivolt source is not good

enough, check the correct voltage using an accurate

Digital Multimeter.

Adjustment point ranges, mV

1: 90 … 125

2: 150 … 250

3: 400 … 500

Generate a voltage that is inside the limits of the first

adjustment point range. Enter the correct voltage seen

on the Digital Multimeter’s display to Span Reference

Value field in the calibrator. Continue through all the ad-

justment points

When all adjustment points are checked, select either

another Quantity and Function/Port combination or save

the adjustment result as described in chapter Saving

Adjustment Data on page 16.

Source/DMM mV

499.97357

17.10.2002 9:42

Voltage

ET: Low V. Sensor Meas.

mV499.97

Span Reference Value 499.97357

Field MENU

Calibration

Mode

MULTIFUNCTION CALIBRATOR

T/C, Low V 4-w meas

R, RTD

3 & 4-w meas

V, I,+24V Imeas/sink

Low V

HART®

T/C INT. RJ

T/C OR EXT

WIRES ONLY

2-w xmtr

V, ,

?

MEASUREOUTPUTSENSOR MEASURE & SIMULATE

ET E

Max input:

60 VDC/30VAC

Calibration and Adjustment Instructions for MC5 Multifunction Calibrator For Main Firmware Version 1.90

Page 9/16

Adjusting the Pressure Measurement of a Pressure Module

(Measurement Range Varies Depending on the Pressure Module)

Quantity: Pressure

Function/Port: P1…, P2…, P3…, PB…, EXT…

(depending on the selected/available modules)

Use a dead weight tester and connect it to the pressure

module to be adjusted.

Adjustment Points

The span adjustment point range for all gauge pressure

modules is 60 … 100 % of span. The zero adjustment

point is zero.

Ensure that the input connector of the gauge pressure

module is not connected to anything. Move the field

pointer to Zero Reference Value field in the calibrator

and enter the zero point value.

Connect the dead weight tester and generate a pressure

near the maximum span value. Move the field pointer to

Span Reference Value field in the calibrator and enter

the span value.

When ready, select either another Quantity and Func-

tion/Port combination or save the adjustment result as

described in chapter Saving Adjustment Data on page

16.

Field MENU

Calibration

Mode

17.10.2002 10:40

Pressure

P2: INT20C/-100 ... 2068 kPa g

gauge

kPa1800.22

Zero Reference Value

Span Reference Value 0.00000

???????

Dead Weight Tester

kPa

1800.0820

T/C, Low V 4-w meas

R, RTD

3 & 4-w meas

V,

I,+24V Imeas/sink

Low V

HART®

T/C INT. RJ

T/C OR EXT

WIRES ONLY

2-w xmtr

V, ,

?

MEASUREOUTPUTSENSOR MEASURE & SIMULATE ET E

Max input:

60 VDC/30 VAC

MULTIFUNCTION CALIBRATOR

Adjustment Points for a Barometric Module

The barometric module's zero correction point range is 800 … 1200 mbar (11.6 … 17.4 psi). The

span correction point range is the same but there should be at least 200 mbar abs (approx.

2.9 psi abs) difference between the used zero adjustment and the used span adjustment point.

The connector for the Barometric Module is on the back side of the calibrator. The thread is M5.

Note.

Usually a one point trim is enough for adjusting the barometric module. This is done by comparing the atmospheric

pressure readout of the calibrator’s barometric module to the readout of a more accurate barometric pressure indicator.

When the correct barometric pressure is entered, the calibrator actually adjusts the zero point so that the readout for

the current atmospheric pressure is the same as the entered value.

Calibration and Adjustment Instructions for MC5 Multifunction Calibrator For Main Firmware Version 1.90

Page 10/16

Adjusting the Temperature Measurement of the

Internal Reference Junction Module

For obtaining best results when adjusting the Internal

Reference Junction Module, do the adjustment after the

calibrator has been shut down and not connected to a

charger overnight. Then the temperature inside the cali-

brator is stabilized to the same temperature as the envi-

ronment.

Quantity: T/C Temperature

Function/Port: ET: TCi(mea)

Connect an accurate thermocouple to the INT. RJ termi-

nals. Use an ice bath and place the thermocouple into

the bath.

Adjustment Point

Only the zero adjustment point need to be checked.

Enter the correct bath temperature to the Zero Refer-

ence Value field in the calibrator.

When ready, select either another Quantity and Func-

tion/Port combination or save the adjustment result as

described in chapter Saving Adjustment Data on page

16.

Temp. Bath °C

0.00

Field MENU

Calibration

Mode

07.11.2002 14:54

T/C-temperature

ET: T/C-Meas., Int RJ K NiCr/NiAl

°C (ITS90)0.02

Zero Reference Value

Span Reference Value 0.00

???????

RJ: Internal 23.02

MULTIFUNCTION CALIBRATOR

T/C, Low V 4-w meas

R, RTD

3 & 4-w meas

V, I,+24V Imeas/sink

Low V

HART®

T/C INT. RJ

T/C OR EXT

WIRES ONLY

2-w xmtr

V, ,

?

MEASURE

OUTPUTSENSOR MEASURE & SIMULATE

ET E

Max input:

60 VDC/30VAC

Calibration and Adjustment Instructions for MC5 Multifunction Calibrator For Main Firmware Version 1.90

Page 11/16

Adjustment of Generation/Simulation Ranges

The accuracy of a generation range depends on the accuracy of the respective measurement

range. Therefore the measurement range should be adjusted before trimming the generation

range. Trimming the generation range affects the overshoot and damping of the generated

value.

Several of the calibrators generation range adjustment windows include the feedback measure-

ment value. This can be used for trimming the generation range. Using an external Digital Mul-

timeter is optional for these measurement ranges.

Adjusting the Current Generation in E Module (0 … 25 mA)

Quantity: Current

Function/Port: E: Current Source/Sink

Power supply needed for the current generation can be

provided either from the calibrator or from an external

power supply unit. The connection depends on the used

power supply.

The lowermost measurement value in the current gen-

eration window is the calibrator’s own feedback meas-

urement of the generated current. It is accurate enough

for trimming the generated value. The Digital Multimeter

connected to the loop is optional.

Power Supplied from the Calibrator

The uppermost picture defines the connection when the

calibrator provides the power supply.

External Power Supply

The lowermost picture defines the connection when an

external device is used for power supply.

Adjustment Procedure

The adjustment procedure is the same for both connec-

tions.

Adjustment point ranges, mA

Low: 0.5 …5

High: 20 …25

Move the field indicator to the uppermost field and enter

a current generation value that is inside the limits of the

low adjustment point range. Enter the correct current

seen on the Digital Multimeter’s display to Span Refer-

ence Value field in the calibrator. Then generate a cur-

rent that is inside the high adjustment point range and

enter the correct value for that point too. Repeat the low

and high adjustments until the current generation is ac-

curate enough.

When ready, select either another Quantity and Func-

tion/Port combination or save the adjustment result as

described in chapter Saving Adjustment Data on page

16.

DMM mA

24.997 60

Field MENU

Calibration

Mode

17.10.2002 9:35

Current

E: Current Source/Sink

mA25.0000

Measurement mA

Span Reference Value 24.996

25.996

MULTIFUNCTION CALIBRATOR

T/C, Low V 4-w meas

R, RTD

3 & 4-w meas

V, I,+24V Imeas/sink

Low V

HART®

T/C INT. RJ

T/C OR EXT

WIRES ONLY

2-w xmtr

V, ,

?

MEASURE

OUTPUTSENSOR MEASURE & SIMULATE

ET E

Max input:

60 VDC/30VAC

Supply

DMM

V

mA

24.0

24.997 60

Field MENU

Calibration

Mode

17.10.2002 9:35

Current

E: Current Source/Sink

mA25.0000

Measurement mA

Span Reference Value 24.998

24.998

MENU

MULTIFUNCTION CALIBRATOR

T/C, Low V 4-w meas

R, RTD

3 & 4-w meas

V, I,+24V Imeas/sink

Low V

HART®

T/C INT. RJ

T/C OR EXT

WIRES ONLY

2-w xmtr

V, ,

?

MEASUREOUTPUTSENSOR MEASURE & SIMULATE

ET E

Max input:

60 VDC/30VAC

Calibration and Adjustment Instructions for MC5 Multifunction Calibrator For Main Firmware Version 1.90

Page 12/16

Adjusting the Resistance Simulation in ET Module (0 … 4000 ohm)

Quantity: Resistance

Function/Port: ET: Resistance Sim.

Connect an accurate Digital Multimeter to the calibra-

tor’s terminals highlighted in the adjacent picture.

The resistance simulation range is divided into

subranges that are adjusted as separate high and low

point pairs.

Adjustment points, ohm

Low 1: 1

High 1: 100

Low 2: 160

High 2: 250

Low 3: 300

High 3: 500

Low 4: 600

High 4: 1000

Low 5: 1200

High 5: 2000

Low 6: 2400

High 6: 4000

DMM W

70.00103

17.10.2002 10:27

Resistance

ET: Resistance Sim.

W70.00

Span Reference Value 70.00103

Field MENU

Calibration

Mode

MULTIFUNCTION CALIBRATOR

T/C, Low V 4-w meas

R, RTD

3 & 4-w meas

V, I,+24V Imeas/sink

Low V

HART®

T/C INT. RJ

T/C OR EXT

WIRES ONLY

2-w xmtr

V, ,

?

MEASUREOUTPUTSENSOR MEASURE & SIMULATE

ET E

Max input:

60 VDC/30VAC

Move the field indicator to the uppermost field and enter the Low 1 adjustment point value. Then

enter the correct resistance seen on the Digital Multimeter’s display to Span Reference Value

field in the calibrator. Go back to the uppermost field and enter the High 1 adjustment point

value. Then enter the correct resistance seen on the Digital Multimeter’s display to Span Refer-

ence Value field in the calibrator. Repeat Low 1 and High 1 points if necessary.

When a subrange is adjusted, continue with the next one until all subranges are adjusted.

When ready, select either another Quantity and Function/Port combination or save the adjust-

ment result as described in chapter Saving Adjustment Data on page 16.

Note.

Resistance simulation is valid with measurement current

0.2 ... 2 mA (1 ... 250 ohm), 0.05 <Imeas•Rsim < 0.5 V (250 … 4000 ohm).

Ohm/RTD simulation settling time 1 ms.

Calibration and Adjustment Instructions for MC5 Multifunction Calibrator For Main Firmware Version 1.90

Page 13/16

Adjusting the Low Voltage Generation in ET Module (±500 mV)

Quantity: Voltage

Function/Port: ET: Low V. Sensor Sim.

The lowermost measurement value in the low voltage

generation window is the calibrator’s own feedback

measurement of the generated voltage. It is accurate

enough for trimming the generated value. The Digital

Multimeter connected to the loop is optional.

Adjustment point ranges, mV

Low: 0

High: 400 … 500

Move the field indicator to the uppermost field and enter

zero as the low adjustment point. Enter the voltage seen

on the Digital Multimeter’s display to Span Reference

Value field in the calibrator. Then generate a voltage that

is inside the high adjustment point range and enter the

correct value for that point too. Repeat the low and high

adjustments until the voltage generation is accurate

enough.

When ready, select either another Quantity and Func-

tion/Port combination or save the adjustment result as

described in chapter Saving Adjustment Data on page

16.

DMM mV

449.91195

17.10.2002 9:49

Voltage

ET: Low V. Sensor Sim.

mV450.000

Measurement mV

Span Reference Value 449.912

449.912

Field MENU

Calibration

Mode

DMM

Field MENU

MENU

MULTIFUNCTION CALIBRATOR

T/C, Low V 4-w meas

R, RTD

3 & 4-w meas

V, I,+24V Imeas/sink

Low V

HART®

T/C INT. RJ

T/C OR EXT

WIRES ONLY

2-w xmtr

V, ,

?

MEASURE

OUTPUTSENSOR MEASURE & SIMULATE

ET E

Max input:

60 VDC/30VAC

Adjusting the Frequency Generation in ET Module (2.7 mHz … 50 kHz)

Quantity: Frequency

Function/Port: ET: Frequency Gen.

Connect an accurate Digital Multimeter to the calibra-

tor’s terminals highlighted in the adjacent picture.

Adjustment point range, Hz

1000 … 50000

Move the field indicator to the uppermost field and enter

a value inside the adjustment point range. Enter the re-

sistance seen on the Digital Multimeter’s display to Span

Reference Value field in the calibrator.

When ready, select either another Quantity and Func-

tion/Port combination or save the adjustment result as

described in chapter Saving Adjustment Data on page

16.

DMM Hz

45 000.000

17.10.2002 10:32

Frequency

ET: Frequency Gen. pos.square

Hz45000. 0

Amplitude [Vpp] 5.00

Span Reference Value 45000.000

Field MENU

Calibration

Mode

MULTIFUNCTION CALIBRATOR

T/C, Low V 4-w meas

R, RTD

3 & 4-w meas

V, I,+24V Imeas/sink

Low V

HART®

T/C INT. RJ

T/C OR EXT

WIRES ONLY

2-w xmtr

V, ,

?

MEASURE

OUTPUTSENSOR MEASURE & SIMULATE

ET E

Max input:

60 VDC/30VAC

Note.

The default Amplitude is 5 Vpp. Change it to a more suitable level, if needed.

Calibration and Adjustment Instructions for MC5 Multifunction Calibrator For Main Firmware Version 1.90

Page 14/16

Adjusting the Voltage Generation in ET Module (±12 V)

Quantity: Voltage

Function/Port: ET: Voltage Generation

The lowermost measurement value in the voltage gen-

eration window is the calibrator’s own feedback meas-

urement of the generated voltage. It is accurate enough

for trimming the generated value. The Digital Multimeter

connected to the loop is optional.

Generation adjustment point ranges, V

Low: 0

High: 10 …12

Feedback measurement adjustment point ranges, V

1: 2.4 …2.9

2: 4.9 …5.8

3: 10 …12

Move the field indicator to the uppermost field and enter

zero as the low adjustment point. Enter the voltage seen

on the Digital Multimeter’s display to Span Reference

Value field in the calibrator. Then generate a voltage that

is inside the high adjustment point range and enter the

correct value for that point too. Repeat the low and high

adjustments until the voltage generation is accurate

enough.

DMM V

11.000871

17.10.2002 9:53

Voltage

ET: Voltage Generation

V11.000

Measurement V

Span Reference Value 11.001

11.001

Field MENU

Calibration

Mode

MULTIFUNCTION CALIBRATOR

T/C, Low V 4-w meas

R, RTD

3 & 4-w meas

V, I,+24V Imeas/sink

Low V

HART®

T/C INT. RJ

T/C OR EXT

WIRES ONLY

2-w xmtr

V, ,

?

MEASURE

OUTPUTSENSOR MEASURE & SIMULATE

ET E

Max input:

60 VDC/30VAC

The feedback measurement need also be adjusted. To adjust it, move the field indicator to the

uppermost field and enter a value within the first feedback measurement adjustment range. En-

ter the voltage seen on the Digital Multimeter’s display to Span Reference Value field in the cali-

brator. Continue through all the adjustment points.

When ready, select either another Quantity and Function/Port combination or save the adjust-

ment result as described in chapter Saving Adjustment Data on page 16.

Notes.

For feedback measurement adjustment point ranges 1 and 2, only the lowermost value in the voltage generation win-

dow (the feedback measurement value) is changed.

The feedback measurement adjustment point range 3 is both for the voltage generation range and the feedback meas-

urement adjustment. Thus both values are updated.

Calibration and Adjustment Instructions for MC5 Multifunction Calibrator For Main Firmware Version 1.90

Page 15/16

Adjusting the Current Generation in ET Module (±25 mA)

Quantity: Current

Function/Port: ET: Current Generation

Connect an accurate Digital Multimeter to the calibra-

tor’s terminals highlighted in the adjacent picture.

The lowermost measurement value in the current gen-

eration window is the calibrator’s own feedback meas-

urement of the generated current.

Generation adjustment point ranges, mA

Low: 0

High: 20 …25

Feedback measurement adjustment point ranges, mA

1: 4.9 …6

2: 9.9 …12

3: 20 …25

Move the field indicator to the uppermost field and enter

zero as the low adjustment point. Enter the current seen

on the Digital Multimeter’s display to Span Reference

Value field in the calibrator. Then generate a current that

is inside the high adjustment point range and enter the

correct value for that point too. Repeat the low and high

adjustments until the current generation is accurate

enough.

DMM mA

21.999179

Edit Delete OKCancel

17.10.2002 08:59

Current

ET: Current Generation

mA22.000

Measurement mA

Span Reference Value 21.999179_

21.9992

MULTIFUNCTION CALIBRATOR

T/C, Low V 4-w meas

R, RTD

3 & 4-w meas

V, I,+24V Imeas/sink

Low V

HART®

T/C INT. RJ

T/C OR EXT

WIRES ONLY

2-w xmtr

V, ,

?

MEASURE

OUTPUTSENSOR MEASURE & SIMULATE

ET E

Max input:

60 VDC/30VAC

The feedback measurement need also be adjusted. To adjust it, move the field indicator to the

uppermost field and enter a value within the first feedback measurement adjustment range. En-

ter the current seen on the Digital Multimeter’s display to Span Reference Value field in the cali-

brator. Continue through all the adjustment points.

When ready, select either another Quantity and Function/Port combination or save the adjust-

ment result as described in chapter Saving Adjustment Data on page 16.

Notes.

For feedback measurement adjustment point ranges 1 and 2, only the lowermost value in the current generation win-

dow (the feedback measurement value) is changed.

The feedback measurement adjustment point range 3 is both for the current generation range and the feedback meas-

urement adjustment. Thus both values are updated.

Calibration and Adjustment Instructions for MC5 Multifunction Calibrator For Main Firmware Version 1.90

Page 16/16

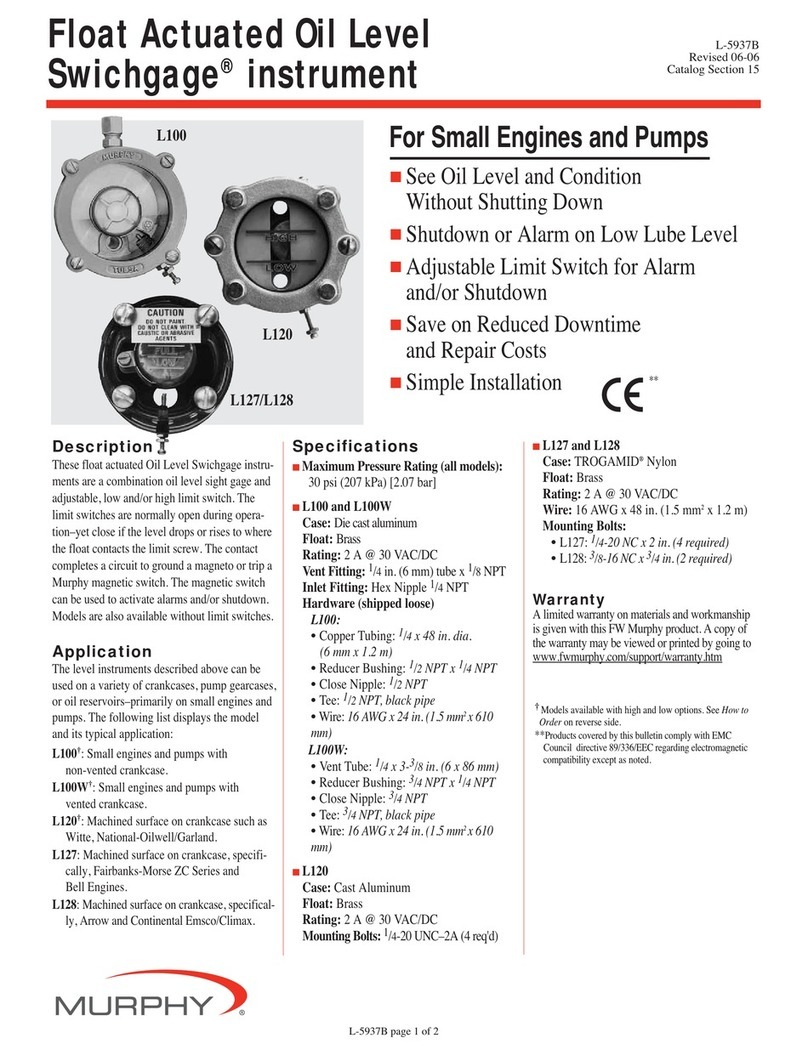

Saving Adjustment Data

The adjustment data has to be saved. Otherwise they

are only valid until the calibrator is shut off.

Open the Save Adjustments window with the following

commands:

D/Menu, C/Others, 2/Maintenance,

2/Calibrator Adjustment and

3/Store Adjustment Data.

Enter the Calibration Laboratory name and edit the cali-

bration period if needed. Move the cursor to a module

name (see picture) and save the data by pressing the

C/Save Data function key.

Note.

The adjustment data can only be saved if it is acceptable (stays within the

limits that the calibrator approves).

Saving adjustment data need not be done individually for each Adjustable

Quantity and Function/Port Combination. When adjustments are saved,

all changed adjustments values are automatically saved.

06.11.2002 17:04

Save

Data Discard

Data

Close

SAVE ADJUSTMENTS

Module name

ET

Cal. Period

365

365

Date 05.11.2002

Calibration Laboratory BEAMEX

E

Setting the Calibration Date When No Adjustment Was Required

If none of the Quantities in a module did need any ad-

justment, here's the procedure for saving the calibration

date and the calibration laboratory name:

Make sure that you start the calibrator with adjustment

mode enabled. For instructions on how to do this, see

chapter Enabling the Adjustment Mode on page 5.

Start the Adjustment Mode by pressing

D/Menu, C/Others, 2/Maintenance,

2/Calibrator Adjustment and 1/Start Adjustment.

Note.

Although no adjustment is needed, the calibration date can only be

entered when Adjustment Mode is started.

05.11.2002 9:50

Update

Date Update

Lab. name

Close

MODULE SETTINGS

Module

P2: INT1C

Cal. Period

365

365

Date 05.11.2002

Calibration Laboratory BEAMEX

P1: INT400mC

P3: B 365

E365

ET 365

RJ 365

Open the window for saving the calibration date and the calibration laboratory name by pressing:

D/Menu, C/Others, 2/Maintenance, 2/Calibrator Adjustment and 4/Module Settings.

Update the calibration date and the calibration laboratory name for all modules that were cali-

brated but did not need any adjustment.

Hint.

The Date cannot be edited. It is taken from the calibrator’s internal clock.

To change the system date before setting the calibration press A/Close, A/çBack and then 1/Time/Date (starting

from the Module Settings Window). Then update the calibration date in the Module Settings Window and return to set

the time and date back to “real time”.

Ending Adjustment Mode

To return to normal use of the calibrator press:

D/Menu, C/Others, 3/Calibrator Adjustment and 1/End Adjustments.

Then the calibrator prompts you to shut off the calibrator.

Table of contents

Other BEAMEX Test Equipment manuals

BEAMEX

BEAMEX MC6-WS User manual

BEAMEX

BEAMEX CENTRICAL User manual

BEAMEX

BEAMEX MC6 User manual

BEAMEX

BEAMEX FB150 User manual

BEAMEX

BEAMEX MC4 User manual

BEAMEX

BEAMEX MCS100 User manual

BEAMEX

BEAMEX MC6-Ex User manual

BEAMEX

BEAMEX TC305 User manual

BEAMEX

BEAMEX MC5-IS User manual

BEAMEX

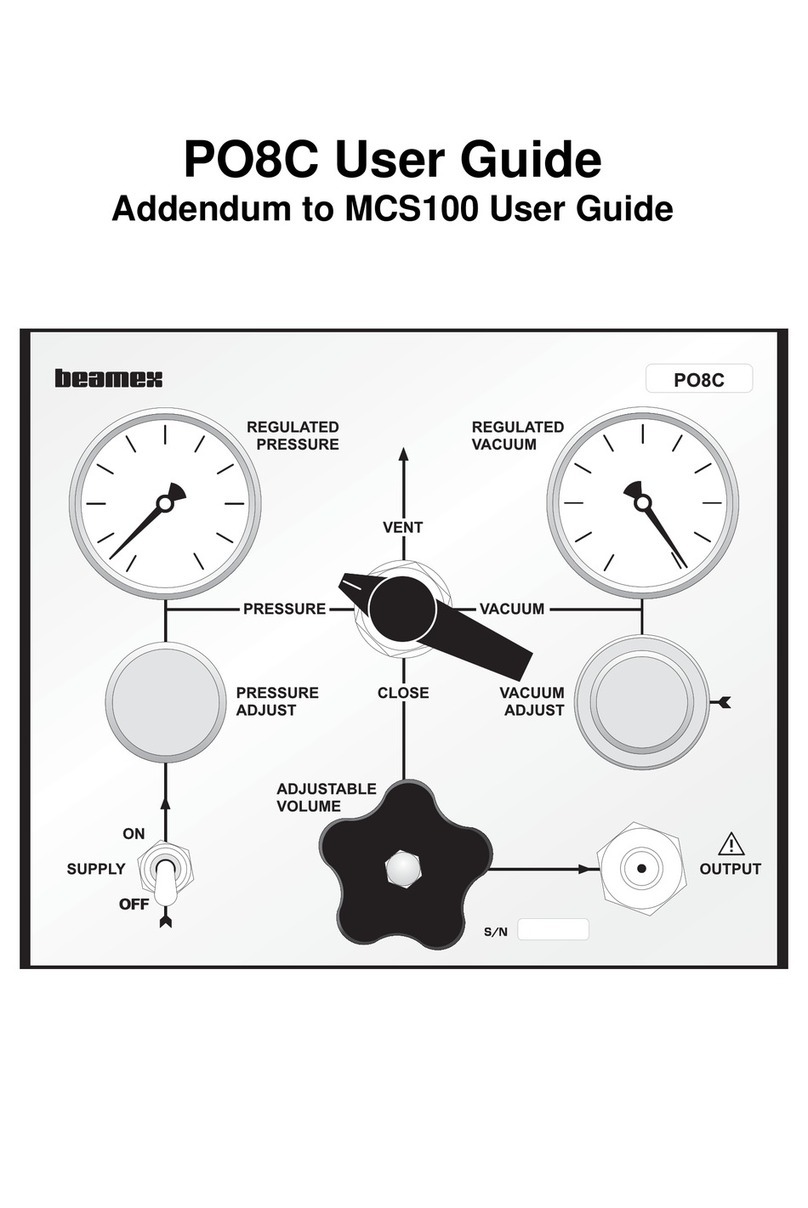

BEAMEX PO8C User manual