2

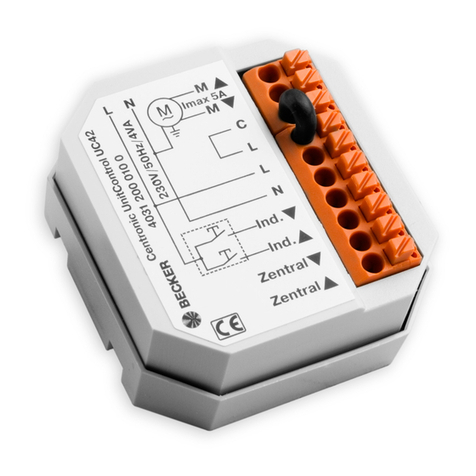

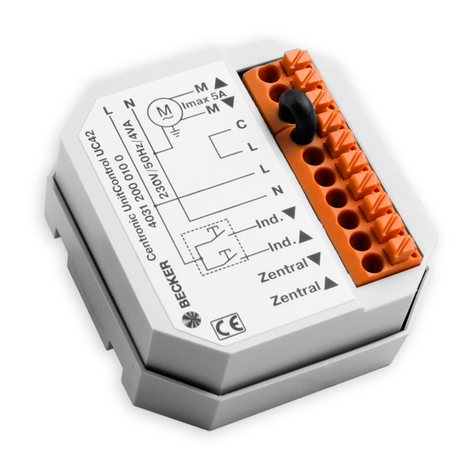

General

Fig. 1 KNX/SMI Actuator REG-3TE16KBT

Up to 16 SMI sun shading drives in up to 16 groups can

be operated centrally using the KNX/SMI Actuator REG-

3TE16KBT.

The drives are operated via the KNX bus system. The

actuator is supplied via the KNX bus. The SMI interface,

however, is operated via a 230VAC auxiliary voltage

source.

The drives are operated directly with 230VAC. A maxi-

mum of 16 motors without fuse protection can be connect-

ed to the SMI interface.

Intended use

The KNX/SMI Actuator REG-3TE16KBT is an electron-

ic device for controlling SMI sun shading systems. The

approval of the manufacturer must be obtained for any use

of the device other than its intended purpose specified in

these instructions.

The actuator is intended for installation in enclosed electri-

cal operating facilities.

Safety instructions

ARNINGW

The electrical installation (assembly)/dis-

mantling must be performed by a certified

electrician in accordance with VDE 0100

or the legal requirements and standards

of the country in which the device is being

installed. The electrician must observe the

installation instructions included with the

electrical devices supplied.

ARNINGW

If it is assumed that hazard-free operation

will not be possible, the device may not

be started or must be deactivated. This

assumption is justified if:

the housing or the connecting lines show signs of

damage,

the device is no longer working.

ARNINGW

It is important to comply with the following

points in the interest of personal safety.

Children may not play with the operating elements of

the control unit or the remote control. Store remote

controls out of reach of children.

Make sure that no persons or objects are in the range

of movement of the driven parts (blinds, external vene-

tian blinds, etc.).

Disconnect the device from the operating voltage if

cleaning or other maintenance work must be per-

formed!

Actuator functions

The software functions of the KNX/SMI actuator are

described in detail in the software manual (article number

40026300110). You can download the software manual

and the product database for the actuator from

www.becker-antriebe.com/downloads or from the ETS

online catalogue.

Installation

The device is intended for installation in a distribution

cabinet. The device is installed by clipping it onto a DIN

rail (TH 35/DIN 60715).

Electrical connection

An on-site overload current protection device (fuse) and a

disconnecting and isolating switch to switch off the entire

unit must be provided.

The unit is electrically connected according to the wiring

diagram on the reverse (Fig. 5). The connection to the

KNX bus system and the drives is made using spring

terminals, the connecting lines are designed as screw

terminals.

Commissioning

After the installation has been completed and the oper-

ating voltages have been applied, the correct connection

can be tested using the manual override operation keypad

under the cover panel (broadcast push button up/down

all drives) (Fig. 3). You will find a detailed description on

the further commissioning in the software manual (article

number 40026300110).

Local operation via App / Bluetooth (LE)

You will find the app for the commissioning or emergency

operation of the actuator in the Apple AppStore and in the

Google Play Store.

Download this to your smartphone.

Once the app is started, the surrounding area is scanned

for actuators. Available actuators are shown and can be

operated. Operation via app has the same priority as man-

ual operation via group objects. The operating behaviour

is as follows:

Brief push of the button = Stop move command

Long push of the button = Up/Down move command

A detailed description of the operation is integrated in the

app and can also be found in the associated software

manual (article number 40026300110). If a motor has

not been allocated to an output, it can be operated only

via SMI broadcast.

The communication between the smartphone and

the KNX devices is established via Bluetooth. This

function can be switched off via the ETS (the func-

tion is always pre-set in the factory to "On").

During parameterisation, change the default pass-

word in accordance with your specifications and

memorise your password in order to prevent ope-

ration by unauthorised persons.