Table of contents

TX1200 3Version: 1.1

Table of contents

1 Foreword....................................................................................................................................................5

1.1 Notes on the documentation .............................................................................................................5

1.2 Safety instructions.............................................................................................................................6

1.3 Notes on information security............................................................................................................7

2 Introduction ...............................................................................................................................................8

3 Target groups ............................................................................................................................................9

4 MP-Bus.....................................................................................................................................................10

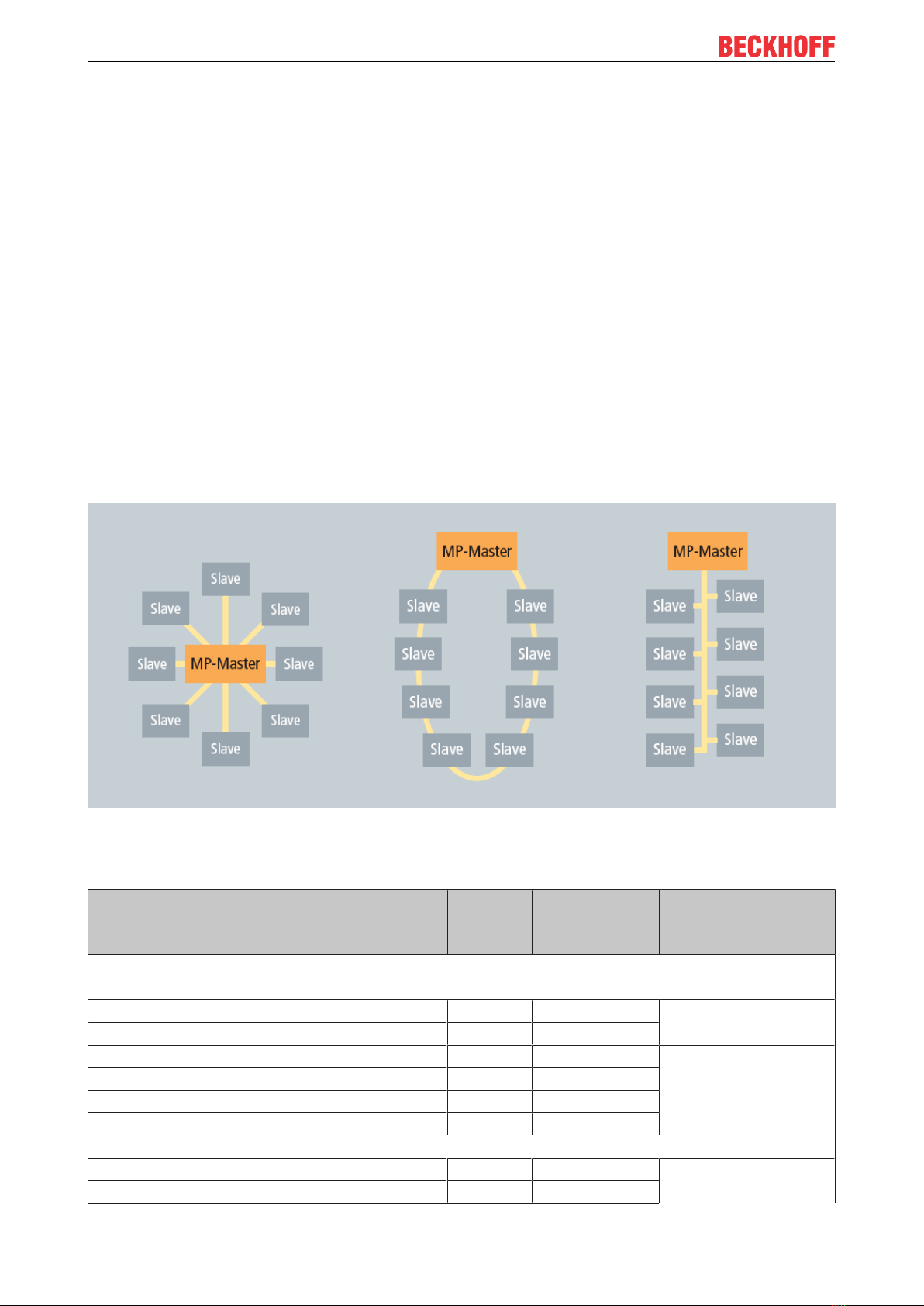

4.1 Topology .........................................................................................................................................10

4.2 Actuator solutions for MP-Bus.........................................................................................................10

5 Integration into TwinCAT........................................................................................................................14

5.1 KL6771 - Linking to the TwinCAT System Manager .......................................................................14

5.2 Integration in TwinCAT (CX9020) ...................................................................................................16

5.3 Integration into TwinCAT (BC9191) ................................................................................................18

6 Programming...........................................................................................................................................22

6.1 General Information ........................................................................................................................24

6.2 Function blocks ...............................................................................................................................24

6.2.1 KL6771............................................................................................................................. 25

6.2.2 MP_Addressing................................................................................................................ 26

6.2.3 MP_CMV.......................................................................................................................... 28

6.2.4 MP_DamperLinearActuator.............................................................................................. 30

6.2.5 MP_EnergyValveV4_Configuration.................................................................................. 31

6.2.6 MP_EnergyValveV4_Process .......................................................................................... 34

6.2.7 MP_EPIV.......................................................................................................................... 36

6.2.8 MP_EPIV_R6 ...................................................................................................................38

6.2.9 MP_EPIV_R6_Parameter ................................................................................................39

6.2.10 MP_EV .............................................................................................................................41

6.2.11 MP_EV_Parameter ..........................................................................................................43

6.2.12 MP_MPX ..........................................................................................................................44

6.2.13 MP_PTH........................................................................................................................... 45

6.2.14 MP_RoomSensor............................................................................................................. 47

6.2.15 MP_RoomSensor_Parameter ..........................................................................................48

6.2.16 MP_Smoker .....................................................................................................................49

6.2.17 MP_TEM_Configuration................................................................................................... 51

6.2.18 MP_TEM_Process ...........................................................................................................52

6.2.19 MP_UST_3....................................................................................................................... 53

6.2.20 MP_VAV........................................................................................................................... 56

6.2.21 MP_VRU_Configuration................................................................................................... 58

6.2.22 MP_VRU_Process ...........................................................................................................59

6.2.23 MP_Window .....................................................................................................................61

6.2.24 MPL_DamperLinearActuator............................................................................................ 62

6.3 Functions.........................................................................................................................................63

6.3.1 NI1000_LuS_TO_INT : INT.............................................................................................. 63

6.3.2 NI1000_TO_INT : INT ...................................................................................................... 64