Exhaust Duct Design_R5.doc Page 2 of 16 2016-10-07 (C)

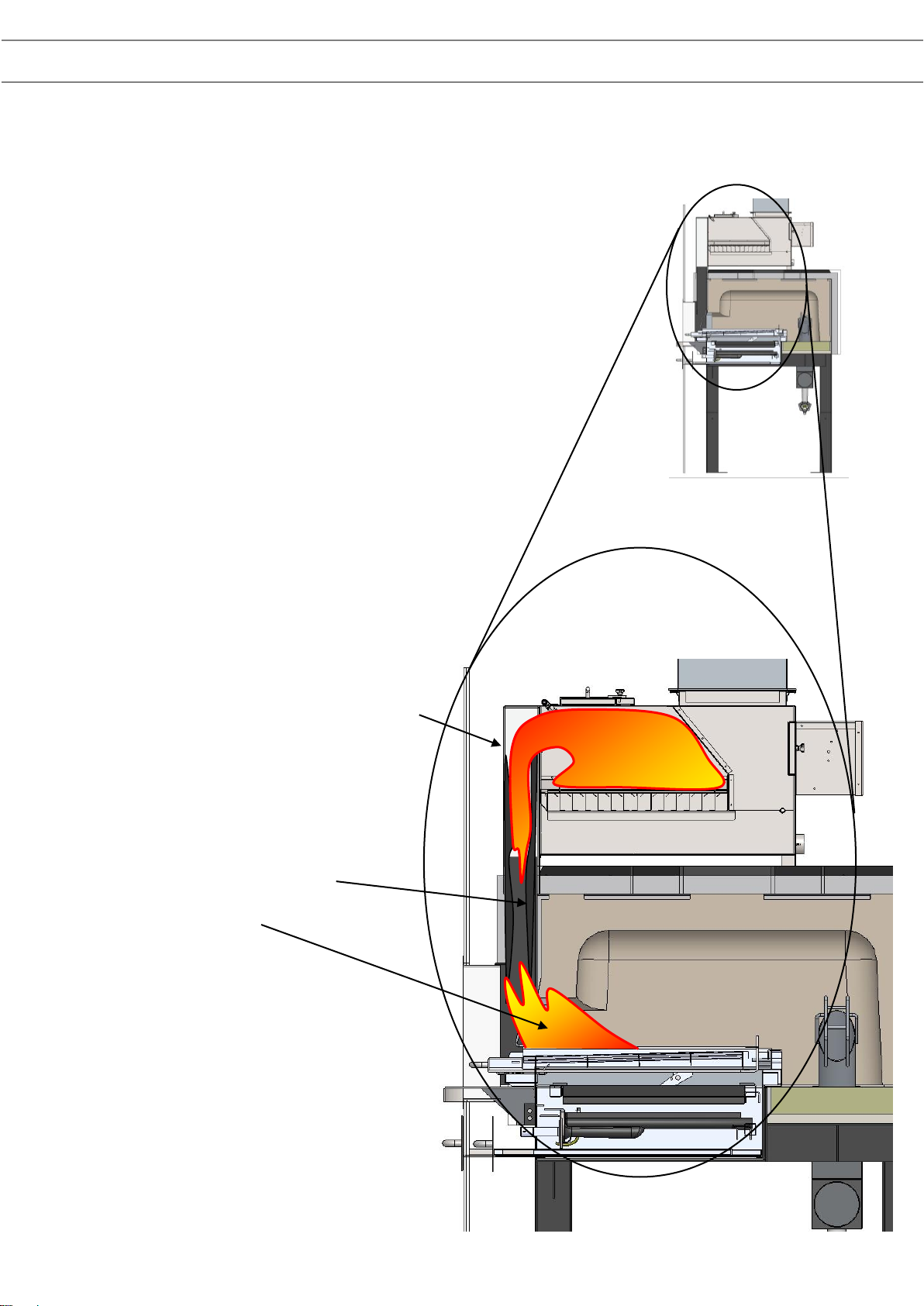

General Information on Flues

Due to the nature of wood fired ovens, the exhaust temperatures can be quite high

and sparks or embers may be present (hence fire danger should be considered.)

To avoid problems there are a number of options to be considered:

It is always important to keep the flue system clean.

When firing the oven with wood, we strongly recommend the use of good,

clean hardwood fuel only.

A build-up of soot and/or creosote in the flue is not good in

any situation. We recommend inspections every three months.

Through these regular inspections you can develop a program

for regular cleaning of your system.

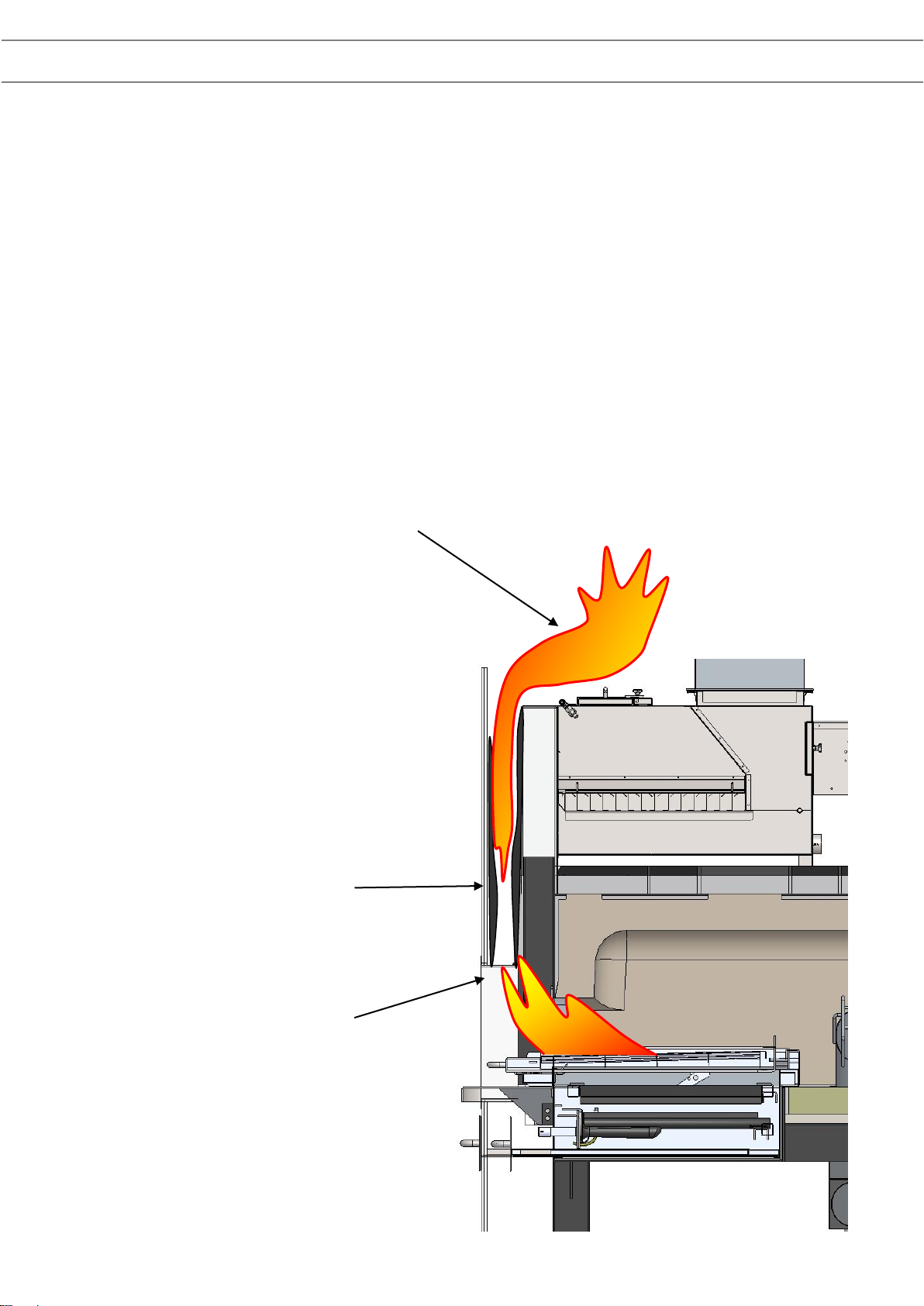

Flue Fires

To reduce the possibility of flue fire we recommend the following steps.

1. Keep the flue system clean. This includes the oven spigot

(prior to the Spray Filter if fitted) and all ductwork. Introduce

regular inspections to develop a program for regular cleaning

of your system.

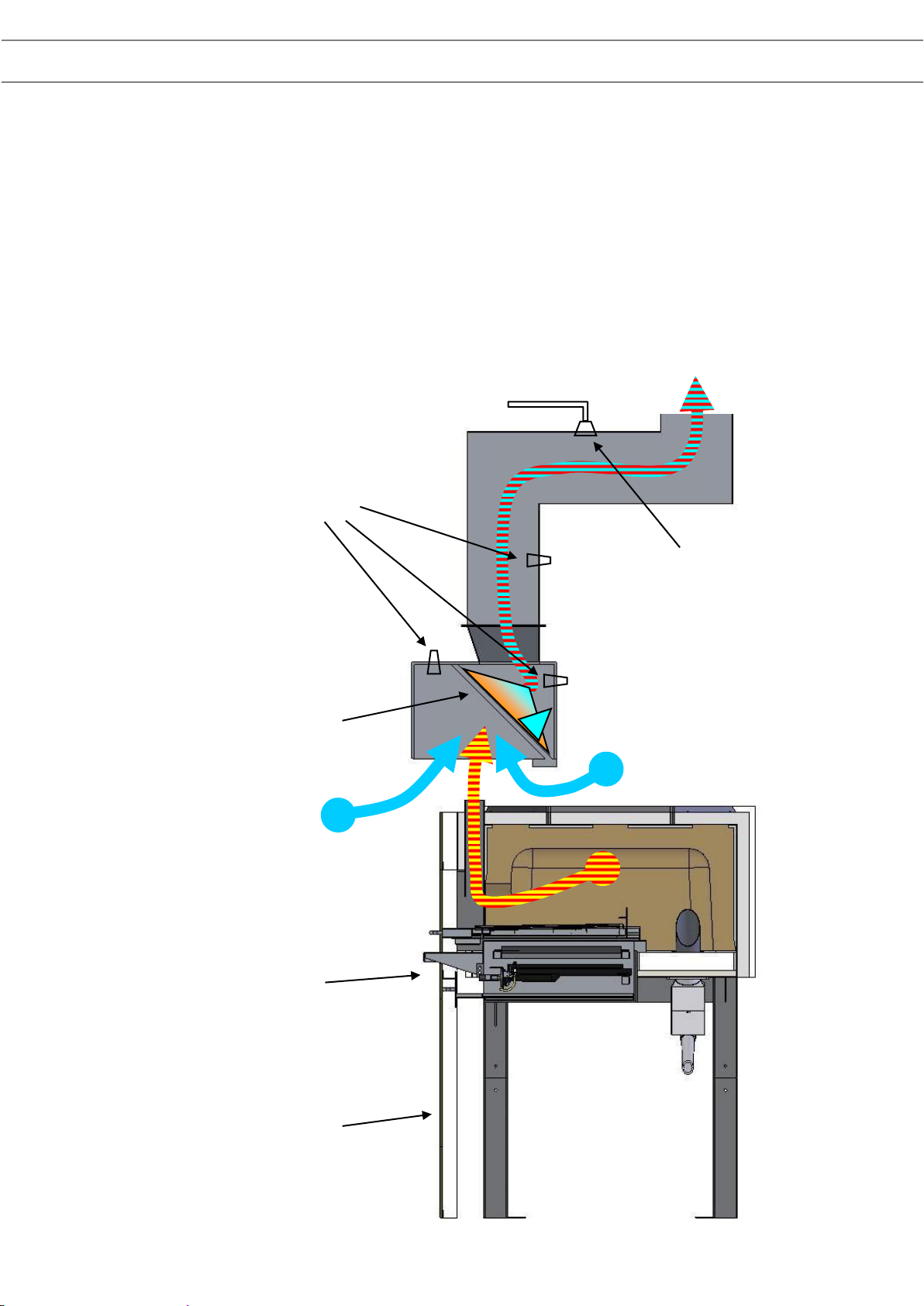

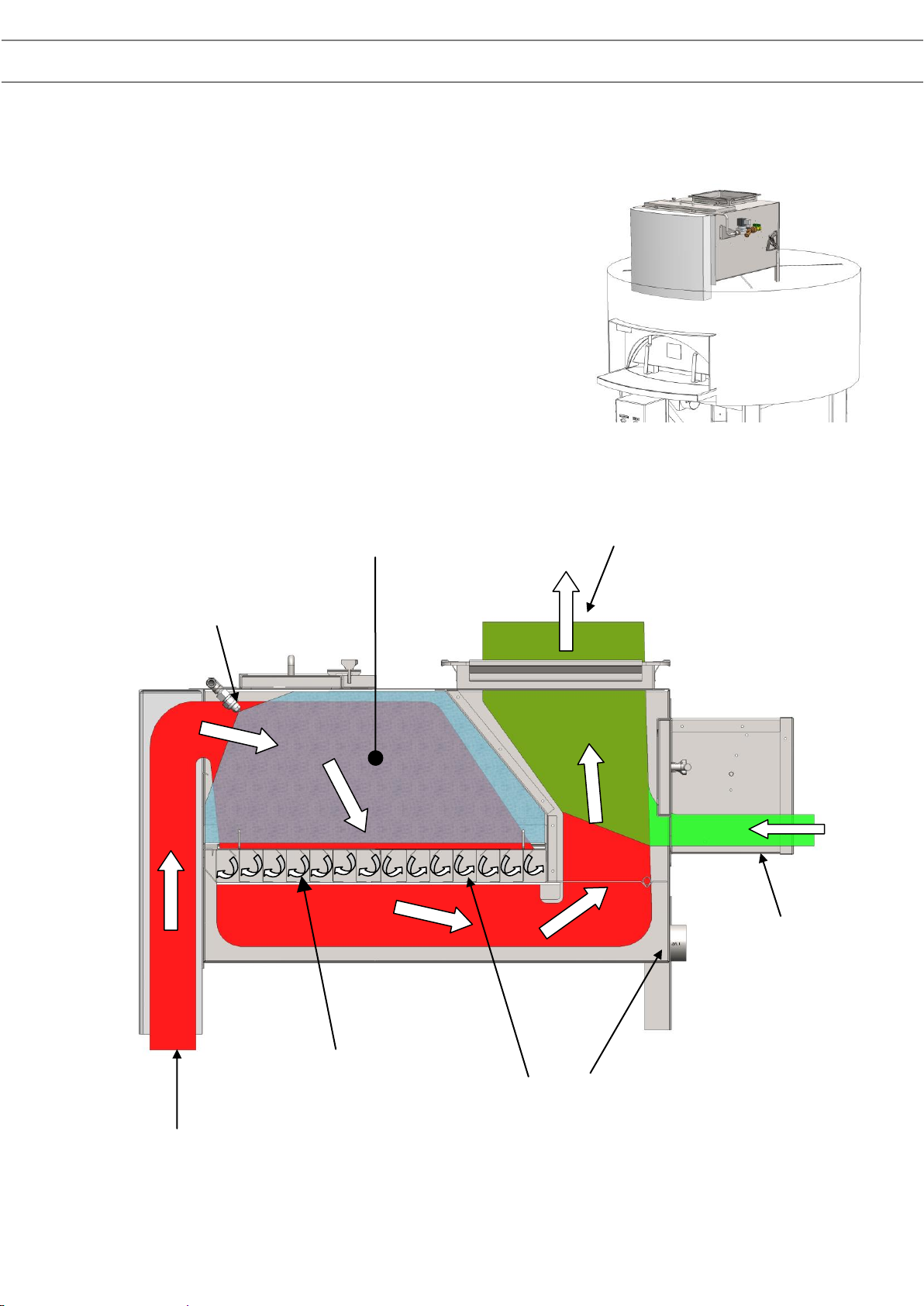

2. For solid fuel ovens it is recommended they be connected to a dedicated

exhaust extraction system.

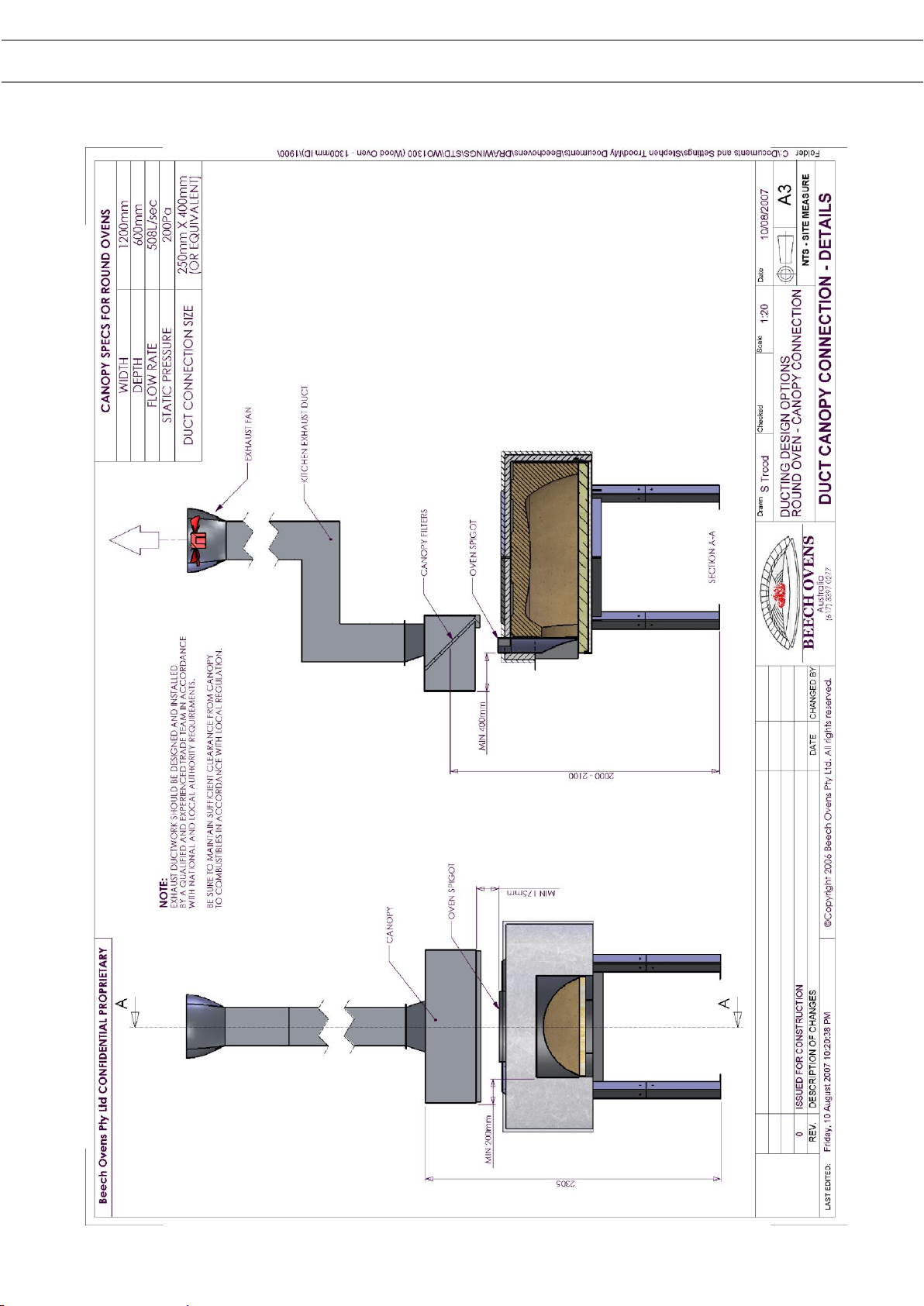

3. To further reduce the risk of fire, a high temperature sprinkler head can be

installed into the duct, connected to a constant/ secure water supply. This can

be included on any flue system. Contact your local fire safety consultant for

more information.

4. Where possible, if connecting to a communal kitchen extraction system,

connect oven to ducting from the dishwasher canopy.

5. For additional safety, use a Beech Oven Spray Filter.

6. Cool air from the ceiling void, restaurant or ideally from outside the building

can be introduced into the Cool Air make-up inlet.

7. Where possible, install the oven under a recommended canopy exhaust

system.