General hints:

Part 1: Topic Page:

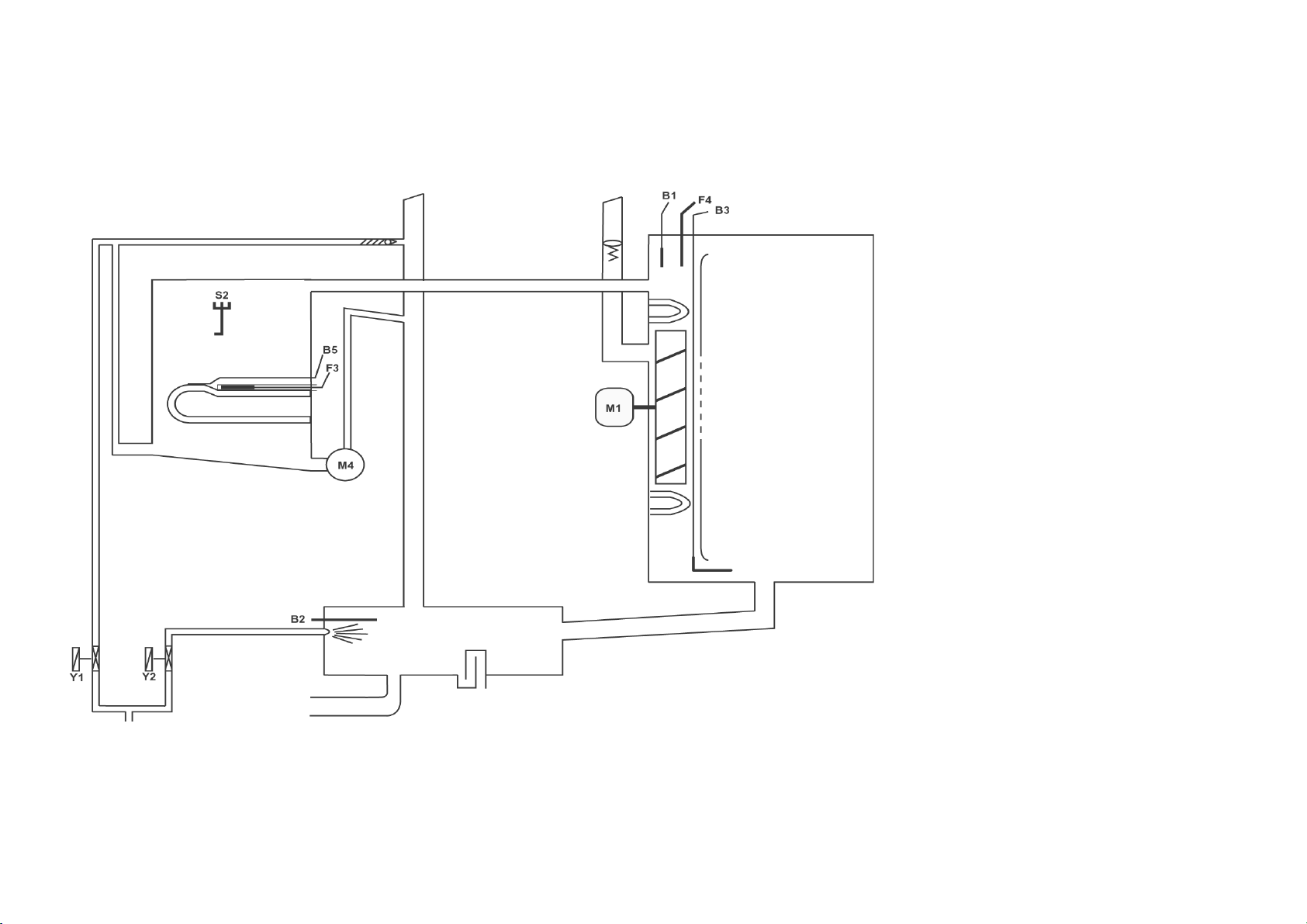

CM technique

1. CM Overlay I - 04

2. CM Principle I - 05

3. CM Water level control I - 06

4. CM Steam control I - 07

5. CM Key code I - 08

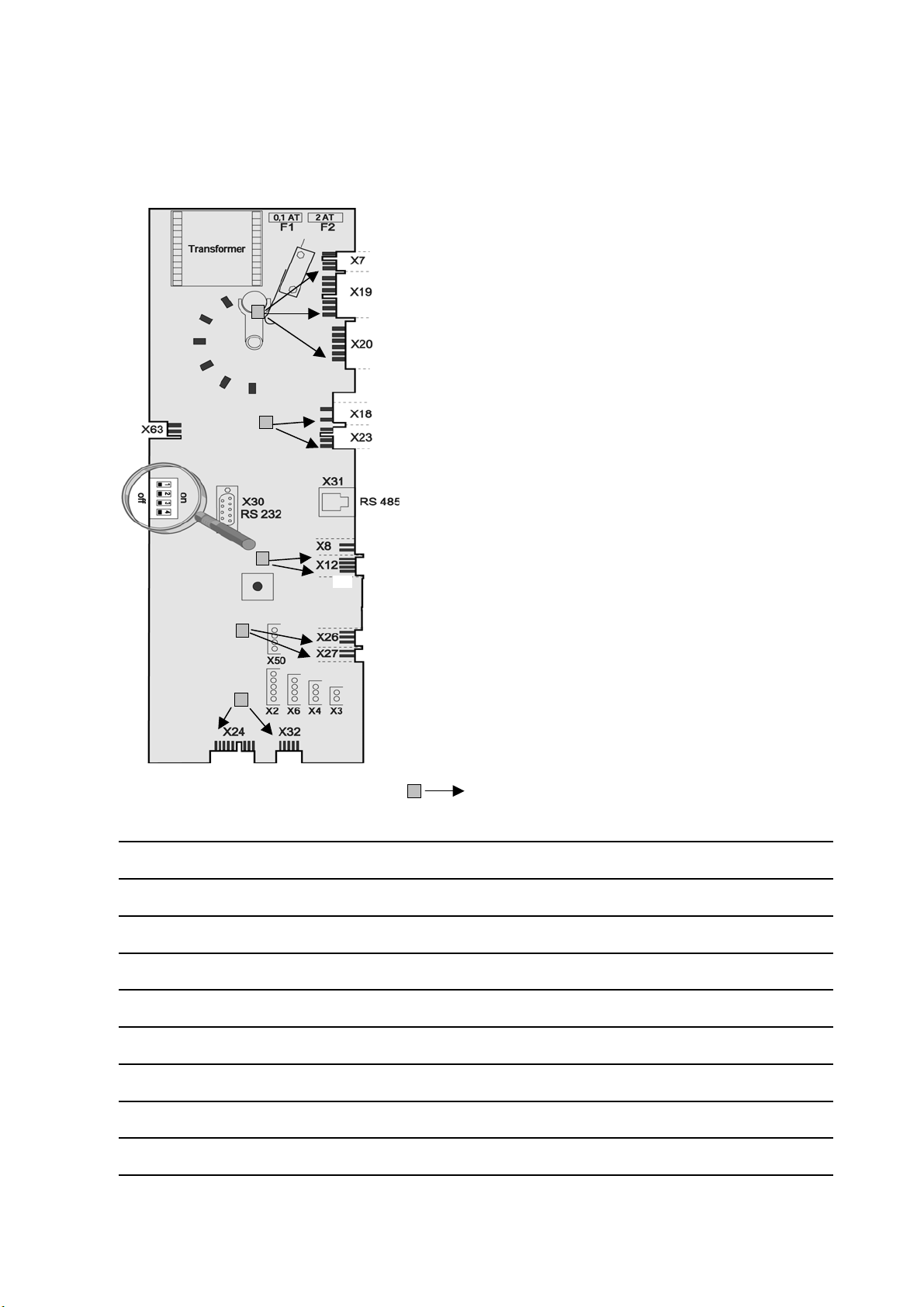

6. CM PCB I - 10

7. CM Sequence of events I - 11

8. CM Service level I - 16

9. CM Diagnostic I - 17

10. CM Running times I - 18

11. CM Basic settings I - 19

12. CM Function test I - 20

13. CM Failure code I - 21

14. CM Gas principle I - 22

15. CM Gas components I - 23

16. CM Change of gas type I - 24

17. CM Table Burner adjustment I - 27

18. CM Setting burner speed I - 28

Training Manual

Diagnostic and troubleshooting

SCC Line from 04-2004

Whenever working on any gas component like:

Gas valve, gas blower and / or changing connected type of gas

a detailed flue gas analysis MUST be done using

adequate CO and CO2measuring equipment!

This shall ONLY be done by trained technicians!

Always check appliance for possible gas leakages!

Isolate the appliance from mains supply

before opening the appliance

When working with chemicals, i.e. aggressive cleaning materials

always wear protective clothing,

goggles, face mask and gloves!

After maintenance / repair the appliance must be checked for electric

safety in accordance with your national, state and local requirements!