Beissbarth MS 65 OR RAC S80 User manual

MS 65 OR RAC S80

en

Original instructions

Tyre Changer

zh

使用说明书

拆胎机

1 697 630 500 2013-03-05|Beissbarth GmbH

| MS 65 OR RAC S80 | 3

Contents 4

中文内容 21

1 697 630 500 2013-03-05

| Beissbarth GmbH

4 | MS 65 OR RAC S80 |en

Contents

1. Symbols used 5

1.1 In the documentation 5

1.1.1 Warning notices -

Structure and meaning 5

1.1.2 Symbols in this documentation 5

1.2 On the product 5

2. User information 6

2.1 Important notes 6

2.2 Safety instructions 6

2.3 Electromagnetic compatibility (EMC) 6

3. Product description 6

3.1 Designated use 6

3.2 Requirements 6

3.3 Delivery specification 6

3.4 Special accessories 6

3.5 Description of unit 7

3.6 Description of function 7

4. Initial commissioning 8

4.1 Unpacking 8

4.2 Assembly 8

4.2.1 Cover removal 8

4.2.2 Lifting of the tilting column 8

4.2.3 Column fixing 8

4.2.4 Put in place the vertical rod 9

4.2.5 Mounting of the bead breaking cylinder 9

4.2.6 Machine positioning 9

4.3 Pneumatic connection 11

4.4 Electrical connection 12

4.5 Check rotation direction 12

5. Operating instructions 13

5.1 Moving jaws adjustment 13

5.2 Tire demounting 14

5.2.1 Preparations for demounting 14

5.2.2 Demounting 14

5.3 Tire mounting 15

5.3.1 Mounting preparations 15

5.3.2 Mounting 15

5.4 Inflation 16

5.4.1 Inflation with inflation gun 16

5.5 Functioning anomalies 17

6. Maintenance 18

6.1 Suggested lube 18

6.2 Cleaning and servicing 18

6.2.1 Maintenance intervals 18

6.2.2 Condensate removal 18

6.2.3 Nebulizer oil refill 18

6.2.4 Change oil in the oil nebulizer 18

7. Decommissioning 19

7.1 Place change 19

7.2 Temporary decommissioning 19

7.3 Disposal 19

8. Technical data 19

8.1 MS 65 OR RAC S80 19

8.2 Dimensions and weights 19

8.3 Reach 19

8.3.1 Car wheels 19

8.3.2 Motorcycle wheels 19

9. Glossary 20

1 697 630 500 2013-03-05

|

Beissbarth GmbH

Symbols used | MS 65 OR RAC S80 | 5 en

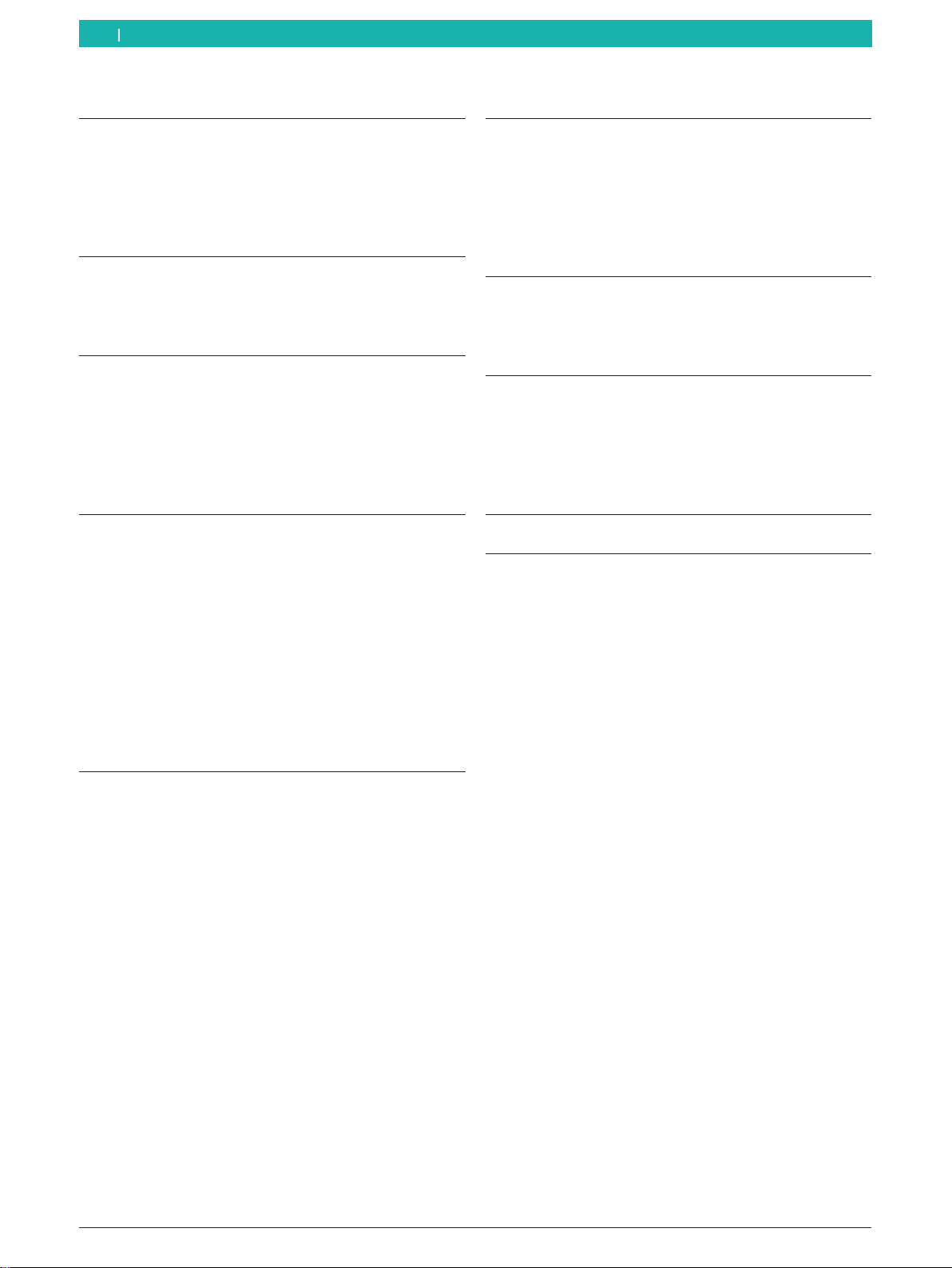

1. Symbols used

1.1 In the documentation

1.1.1 Warning notices - Structure and meaning

Warning notices warn of dangers to the user or people

in the vicinity. Warning notices also indicate the con-

sequences of the hazard as well as preventive action.

Warning notices have the following structure:

KEY WORD – Nature and source of hazard!

Consequences of hazard in the event of

failure to observe action and information

given.

¶Hazard prevention action and information.

The key word indicates the likelihood of occurrence and

the severity of the hazard in the event of non-observance:

Signal

word

Probability of

occurrence

Severity of danger if in-

structions not observed

DANGER Immediate impend-

ing danger

Death or severe injury

WARNING Possible impending

danger

Death or severe injury

CAUTION Possible dangerous

situation

Minor injury

1.1.2 Symbols in this documentation

Sym-

bol

Designation Explanation

!Attention Warns about possible property damage.

iInformation Practical hints and other

useful information.

1.

2.

Multi-step

operation

Instruction consisting of several steps

eOne-step

operation

Instruction consisting of one step.

Intermediate

result

An instruction produces a visible inter-

mediate result.

"Final result There is a visible final result on comple-

tion of the instruction.

Mounting tool

Danger of crushing the fingers between the

mounting tool and the rim.

Mains tension

Danger of electrical shock when touching the

parts of the electrical system.

Bead breaker

Danger of crushing the limbs between the

bead breaker and the tire.

Column tilting

Danger of crushing in the area close to the

tilting column.

1.2 On the product

!Observe all warning notices on products and ensure

they remain legible!

1 697 630 500 2013-03-05

| Beissbarth GmbH

6 | MS 65 OR RAC S80 | User informationen

2. User information

2.1 Important notes

Important information on copyright, liability and warran-

ty provisions, as well as on equipment users and compa-

ny obligations, can be found in the separate manual "Im-

portant notes on and safety instructions for Beissbarth

Tire Equipment". These instructions must be carefully

studied prior to start-up, connection and operation of

the MS 65 OR RAC S80 and must always be heeded.

2.2 Safety instructions

All the pertinent safety instructions can be found in the

separate manual "Important notes on and safety instruc-

tions for Beissbarth Tire Equipment". These instructions

must be carefully studied prior to start-up, connection

and operation of the MS 65 OR RAC S80 and must al-

ways be heeded.

2.3 Electromagnetic compatibility (EMC)

The MS 65 OR RAC S80 is a class A product as per

2004/108/EG.

3. Product description

3.1 Designated use

MS 65 OR RAC S80 is a modern tire changer for moun-

ting and demounting of car and motorcycle tires.

iMS 65 OR RAC S80 has to be used exclusively for the

specified purpose and only in the functioning scope

shown in these instructions. Any other use different

from that specified has to be considered improper

and therefore not allowed.

iThe manufacturer is not liable for any damage cau-

sed by improper use.

3.2 Requirements

MS 65 OR RAC S80 has to be installed on an even sur-

face made of concrete or similar materials, and has to

be firmly anchored. A pneumatic connection is reque-

sted.

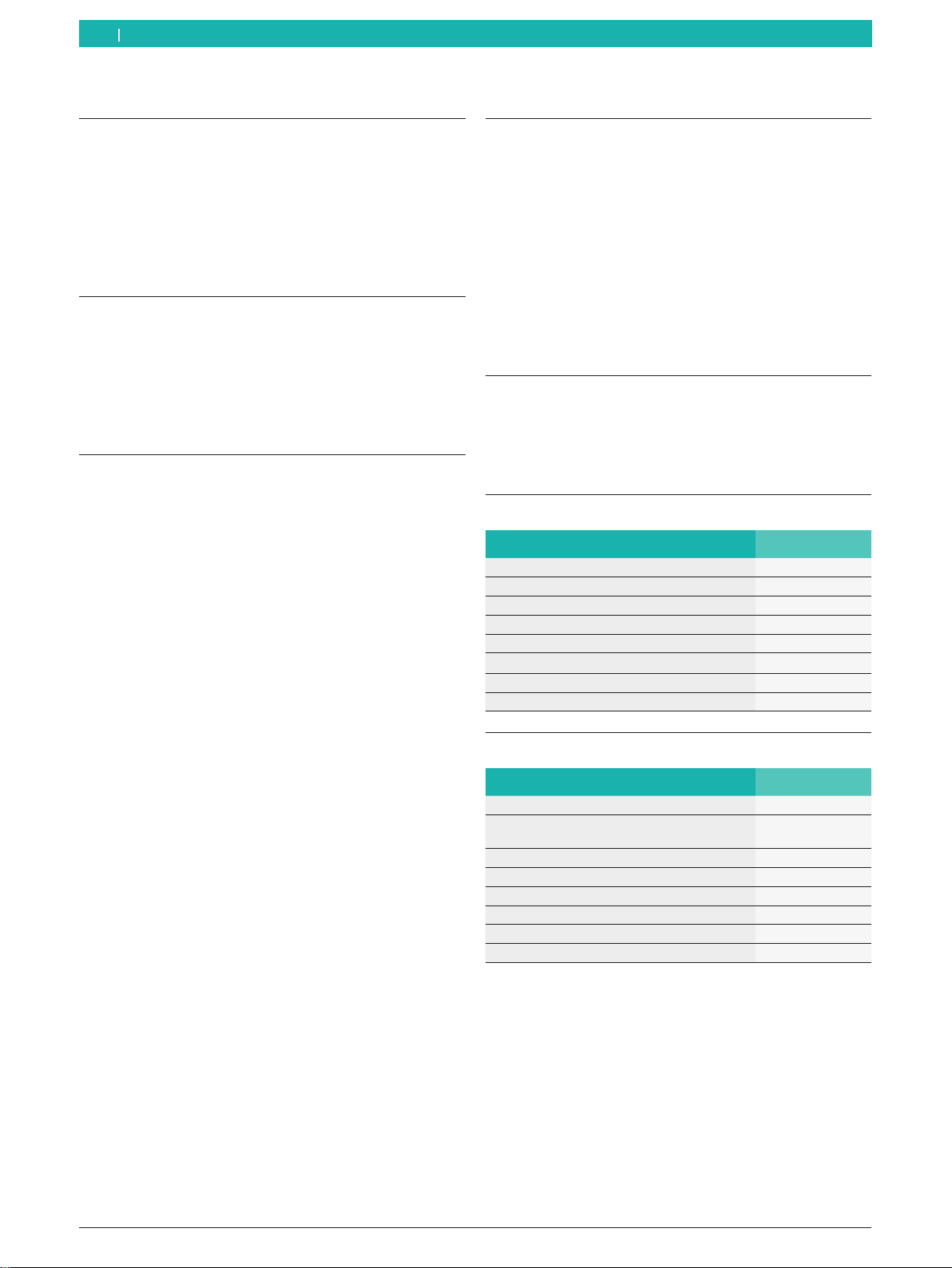

3.3 Delivery specification

Denomination Order code

MS 65 OR RAC S80

Bead lifting lever 1 695 105 190

Brush 1 695 100 123

Inflation gun with manometer 1 697 630 100

Rubber inflation pipe 1 697 630 099

Protection tab 1 695 100 798

Lane protection set for 19" wedge 1 695 104 071

Mounting tool cover 1 695 102 725

3.4 Special accessories

Denomination Order code

8" connections device (4 pieces) 1 695 103 542

Special 17-21" connections device (4 pie-

ces)

1 695 103 543

Motorbike wheel connection device 1 695 103 543

Bead breaker protection 1 695 102 090

Bead locking clamp 1 695 103 302

Lower wedge 1 695 103 261

Upper wedge 1 695 103 216

Tubeless inflation kit 1 695 103 858

1 697 630 500 2013-03-05

|

Beissbarth GmbH

Product description | MS 65 OR RAC S80 | 7 en

3.6 Description of function

Below are reported the main functions of the listed

components of the MS 65 OR RAC S80:

RPedal box, comprehends control pedals of the

equipment (locking flange rotation pedal, bead brea-

king pedal, locking jaws pedal, tilting column pedal).

RBead breaker, for bead breaking of tires from the

rim; it is made of the bead breaking arm pneuma-

tically operated by a double effect cylinder (fitted

with a special device with three positions which, by

letting the blade open more widely, allows also bead

breaking of particularly wide tires), an arm positio-

ning lever, antiabrasive supports for rim support

during bead breaking phases.

RColumn assembly, made of a tilting column with

2 operating positions (which allows demounting

and mounting of tires on rims of remarkable width)

which holds the components needed to demount

(and mount) the tire from the rim: horizontal sliding

arm (with mounting lever), vertical sliding rod (with

locking knob), mounting tool for demounting (and

mounting) the tire from the rim with the help of the

bead lifting lever.

RLocking plate, locking and rotation device (clockwise

and counterclockwise) of the rim, pneumatically

driven by 2 cylinders, made of 4 movable sliders

(adjustable for use also with wheels up to 26'') with

locking jaws for the internal and external locking of

the rim.

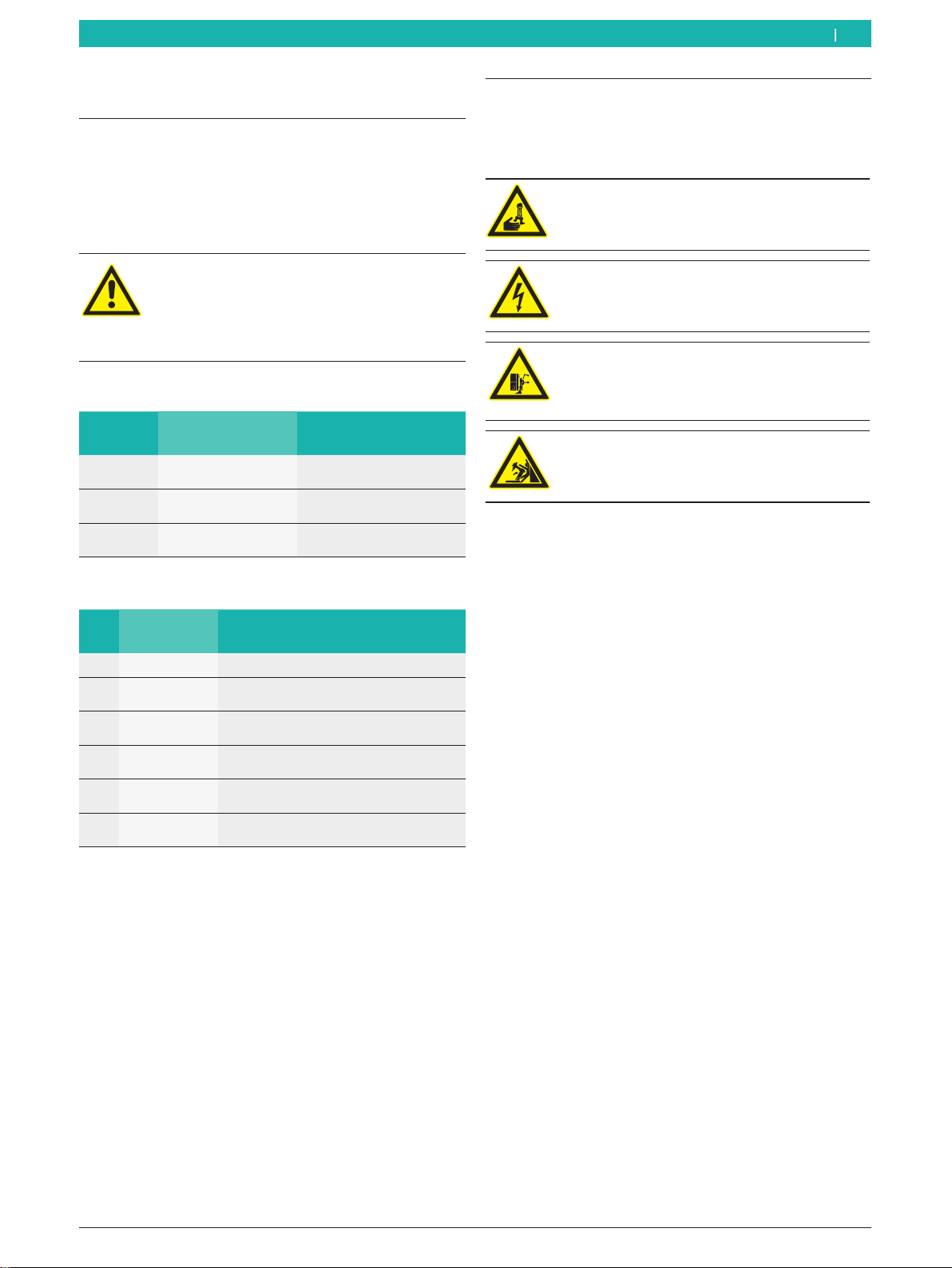

3.5 Description of unit

On the MS 65 OR RAC S80 there are rotating

and moving parts that could injure fingers

and arms.

2

4

3

1

5

7

8

13

12

14

15

18

17

16

6

20

9

10

21

19

652099-01_Mi

11

22

Fig. 1: MS 65 OR RAC S80

Pos. Name Function

1Locking flange rotation pedal Locking plate rotation:

Rclockwise (press down the pedal)

Rcounter-clockwise (lift the pedal from bottom to top)

2 Bead breaker pedal Bead breaking arm activation.

3 Locking jaw pedal Opening and closing of the locking plate jaws.

4 Tilting column pedal Tilting column activation.

5 Bead breaking arm Bead breaking of the tire from the rim.

6 Bead breaking arm lever Bead breaking arm activation.

7 Bead breaker blade Bead breaking.

8 Antiabrasive supports Tire support for bead breaking operations.

9 Tilting column Sliding arm and mounting tool support .

10 Horizontal sliding arm Horizontal positioning of the mounting tool.

11 Locking lever Tire locking of the horizontal sliding arm.

12 Vertical sliding rod Vertical positioning of the mounting tool.

13 Vertical rod locking lever Tire locking of the vertically sliding rod. Operating on the knob it is possible to achieve a 3 mm

spacing (adjustable) from the edge of the rim.

14 Mounting tool Mounting and demounting of the tire from the rim (with the help of the bead lifting lever).

15 Sliding roller To be inserted in the mounting tool BOX, to avoid any kind of friction between the rim and the mounting

tool during tire mounting and demounting phases. For the alloy rims a special "tab" is arranged.

16 Locking plate Locking and rotation of the rim.

17 Movable lanes Positioning of the locking jaws.

18 Locking jaws Internal or external locking of the rim.

19 Grease cup holding ring Mounting paste containing support.

20 Bead lifting lever Lifting of the tire edge in demounting and mounting phases.

21 Speed switch Passing from the first to the second speed.

22 2 position column switch Operation of the 2 position column (lifting and lowering).

1 697 630 500 2013-03-05

| Beissbarth GmbH

8 | MS 65 OR RAC S80 | Initial commissioningen

4. Initial commissioning

4.1 Unpacking

1. Remove the iron tape and the fixing clamps from the

pallet and the packaging cardboard.

iAfter unpacking check the integrity of

MS 65 OR RAC S80 and check that no components

are visibly damaged. In case of doubt do not proceed

to start-up and contact a qualified technician and/or

your vendor.

2. Take out of the transport crate the standard accesso-

ries and the packaging materials.

iDispose correctly of packaging material, hand it over

to the designated collection points.

4.2 Assembly

4.2.1 Cover removal

1. Unscrew the 4 screws of the side cover and remove

the cover itself.

4.2.2 Lifting of the tilting column

1. Unscrew the fulcrum-pin screw of the column with

the hex key 6 and remove the pin.

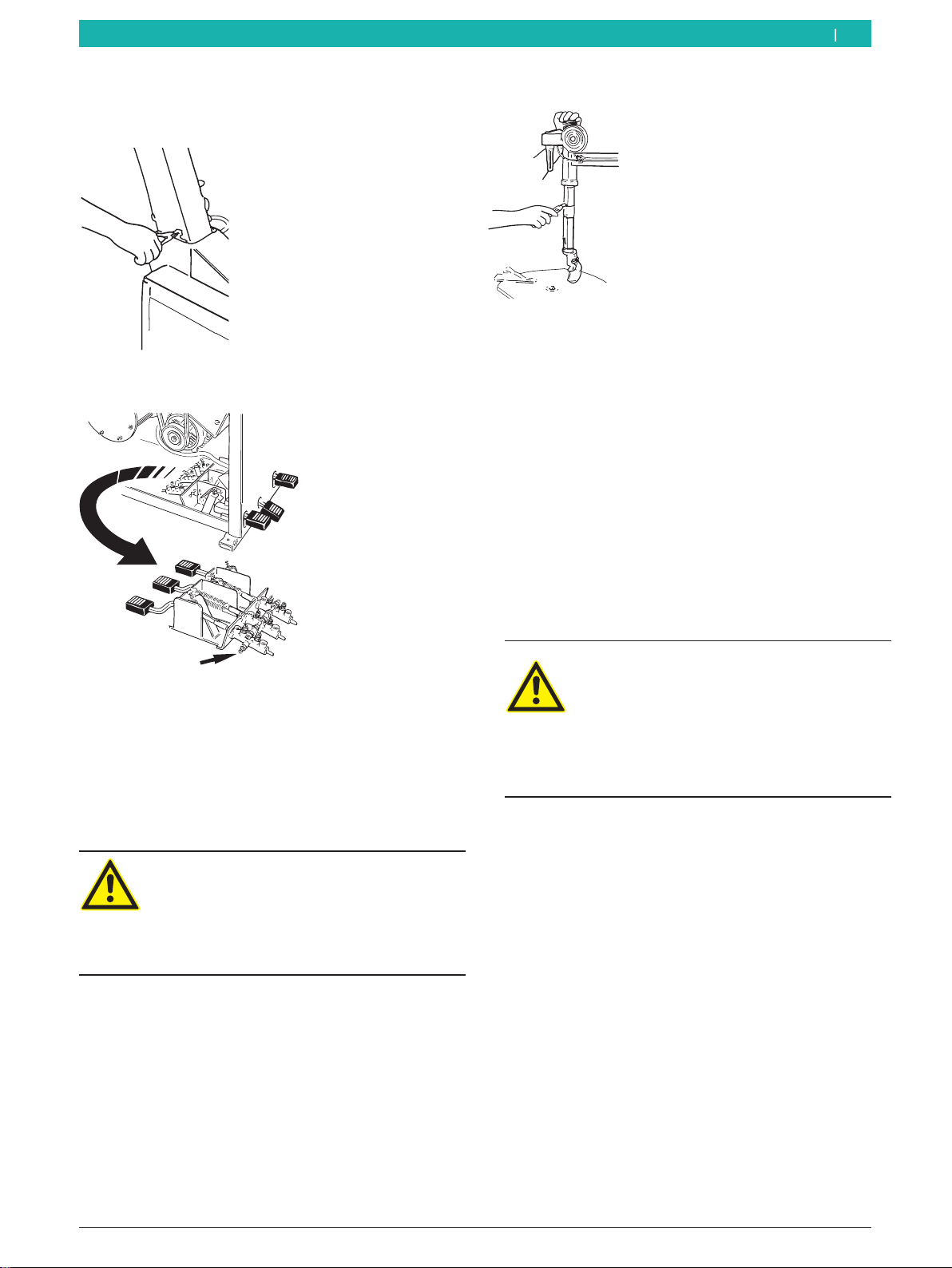

652012-02_Mi

2. Get a 1 Mt lifting sling, DR 50 model (safety factor

6:1); wrap the sling around the tilting column (1),

extend the bead breaking arm and lift the column

with a hoist (2).

652012-03_Mi

1

2

3. Remove the external elastic ring with appropriate

pliers and take off the pin.

652012-04_Mi

4.2.3 Column fixing

1. Align the cylinder rod and the tie rod holes.

652012-05_Mi

2. Insert the air tube in the slot in the machine box.

3. Fix the column to the cylinder tank by inserting

the pin with a hammer and tighten the fulcrum-pin

screw.

652012-07_Mi

1 697 630 500 2013-03-05

|

Beissbarth GmbH

Initial commissioning | MS 65 OR RAC S80 | 9 en

4. Insert again the pin passing through the cylinder

rod and tie rod holes; put back in place the external

elastic ring.

652012-08_Mi

5. Connect the pneumatic lock supply pipe on the

pedal box joint.

652012-10_Mi

1

4.2.4 Put in place the vertical rod

1. Put a hand down on the protection cap (placed on

top of the rod) and press it downwards; with the

other hand remove the steel rod inserted between

the arm and the mounting tool; take off slowly the

hand that was pressing the rod protection cap.

Danger!

The spring could eject violently the rod from

its housing, thus it might be a serious danger

for the operator.

¶Be careful when carrying out this operati-

on.

2. Remove the adhesive tape with a cutter.

652012-09_Mi

4.2.5 Mounting of the bead breaking cylinder

1. Remove the external elastic ring and take off the

hinge rod from its housing in the bead breaking arm.

2. Disconnect the fixing grain of the fixing bush with

hex key, rotate and unblock the fixing bush to

remove pressure from the spring, remove the fixing

pin and remove the adjusting bush from the bead

breaking cylinder rod .

3. Insert the bead breaking arm and centre the joint pin

with the cylinder rod, ensuring that the flat part of

the joint pin is facing the outside.

4. Insert the hinge-pin and put back in place the exter-

nal elastic ring.

5. Place the buffer spring on the provided tab

6. Remount the adjusting bush.

Danger!

Wrong mounting of the bead breaking cylin-

der compromises machine functioning and

can be a serious danger for the operator.

¶During machine installation be sure that

the nut is correctly screwed in the bead

breaking cylinder rod (at least 10 mm).

4.2.6 Machine positioning

1. Put back in place the side door.

2. Loosen the two screws that fix MS 65 OR RAC S80

to the pallet.

1 697 630 500 2013-03-05

| Beissbarth GmbH

10 | MS 65 OR RAC S80 | Initial commissioningen

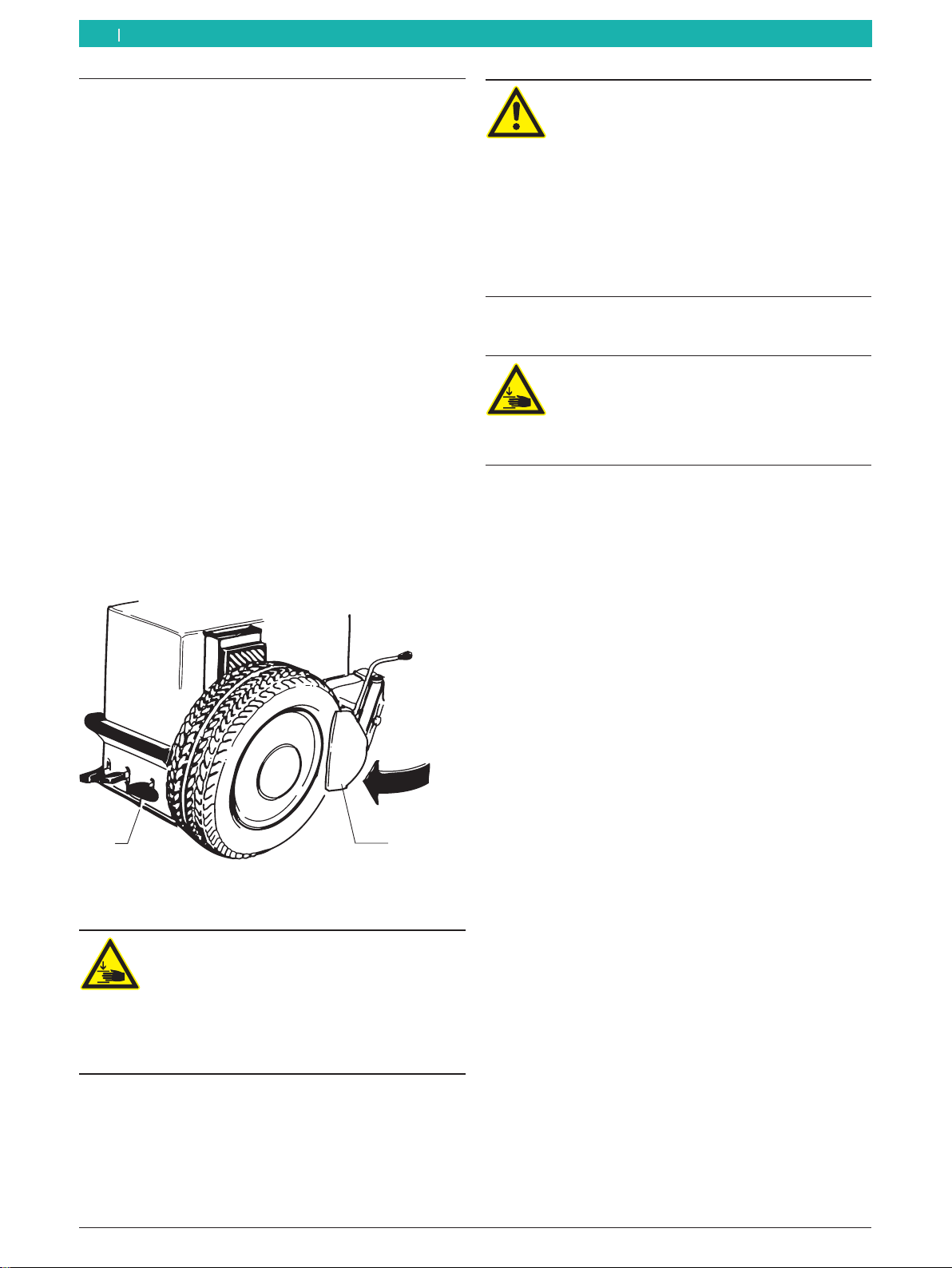

652012-12_Mi

Warning - damage risk!

The lifting belts can crush the flexible supply

pipes of the cylinder or damage the applied

parts of the MS 65 OR RAC S80.

¶Insert the lifting belts carefully.

3. Remove the back protection of the locking lever, as

shown.

4. Insert the appropriate lifting belts (length belt 1: 1

Mt, belt 2: 3 Mt), with sufficient capacity, as shown.

652013-02_Mi

2

1

!

Warning - tilting danger!

The barycentre of the MS 65 OR RAC S80

does not lie in its centre.

¶It is necessary to lift the machine slowly.

5. Lift the MS 65 OR RAC S80 with a lift crane and in-

stall it in the designed area respecting the minimum

distances as shown in the picture.

652016-03_Mi

500 850

1990

950 500

iFor safe and ergonomic use of the

MS 65 OR RAC S80 it is recommended to leave a mi-

nimum of 500 mm space from the surrounding walls.

1 697 630 500 2013-03-05

|

Beissbarth GmbH

Initial commissioning | MS 65 OR RAC S80 | 11 en

Warning - tilting danger!

During tire inflation considerable forces are

exerted.

¶The MS 65 OR RAC S80 has to be fixed in

at least 3 points on the floor (screw holes

see chap. 4.2)..

iIn each screw hole are placed shock absorbers, to

allow a vibration free installation .

6. Put an appropriate lubricator in the mounting paste

holding device.

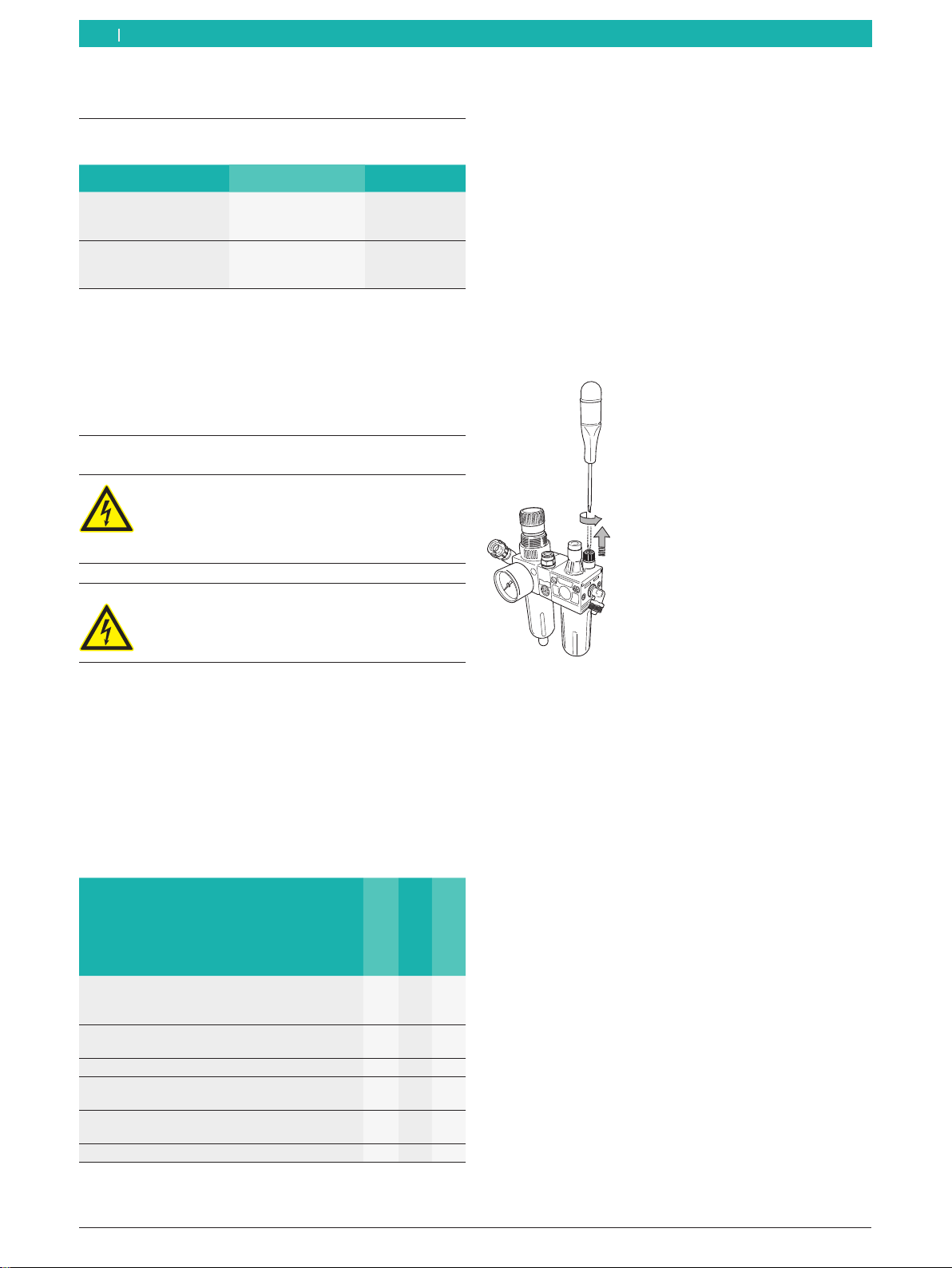

4.3 Pneumatic connection

1. Connect the MS 65 OR RAC S80 to the compressed

air supply unit.

2. In case a bayonet connection is used, approach the

air pipe to the filter unit connection and tighten the

threaded collar.

651003-05 _Rf

3. Adjust to a pressure between 8 and 12 bar.

Pull the red knurled screw (pressure reducing val-

ve) first upwards and then twist it to adjust ope-

rating pressure.

Check pressure on the manometer.

!A 1/4 threaded quick connection is supplied to allow

the pneumatic connection when the operator is not

provided with a bayonet connection.

4. Using a 14 spanner, loosen the rotating joint on the

filter unit.

5. Remove the rotating joint and place the quick con-

nection; finally tighten using the 14 spanner.

!To calibrate the lubricating oil flow, refer to the

Maintenance chapter.

1 697 630 500 2013-03-05

| Beissbarth GmbH

12 | MS 65 OR RAC S80 | Initial commissioningen

4.4 Electrical connection

1. Check the correspondence of the mains tension and

the tension shown on the identification tag.

2. Ask a qualified electrician to mount a connection

plug for single-phase or (depending on the tension

you have ordered ) three-phase current (see the

electrical connections diagram inside the electrical

panel).

iThe costs of arranging a mains protection device for

the plug are borne by the customer.

3. Protect the MS 65 OR RAC S80 according to specific

national rules.

4.5 Check rotation direction

!For a correct functioning of MS 65 OR RAC S80 it is

extremely important that, when the locking flange

pedal shown in Fig. 2 (1) is pressed, the locking

flange (Fig. 2) rotates clockwise.

652012-14_Mi

1

Fig. 2: Check rotation direction.

1 697 630 500 2013-03-05

|

Beissbarth GmbH

Operating instructions | MS 65 OR RAC S80 | 13 en

5. Operating instructions

Warning - tire or rim damage danger!

Excessive pressure can e. g. result in cracks

(on the inside/outside) of the tire. The rim

can be scratched or deformed.

¶Read the Wdk publications available in

German and English! (www.wdk.de: moun-

ting/demounting instructions – criteria

catalogue)

¶Inner temperature of the tire must be at

least 15 °C (only in case of RFT/UHP).

¶Read the Wdk publications available

in German and English! (www.wdk.de:

mounting/demounting instructions – tire

overheating)

¶Adjust pressure to the type of tire.

¶Use the plastic protections on the types of

rim that need it.

!Before demounting or mounting operations it is ex-

tremely important to collect all the rim and tire data.

In this way it will be possible to know in advance the

mounting, the pressure and the required accessori-

es!

iRemove all the balancing weights from the rim.

iIf the semi drop centre of the rim is placed in the

inside part it is necessary to insert a cover to the

locking jaws (see chap. 3.3) on the flanged plate,

because in this case the rim leans on its side during

rotation.

5.1 Moving jaws adjustment

To work on wheels up to 26'', it is possible to adjust the

position of the 4 moving jaws as shown in pic.3.

RFor the adjustment from 20” to 24” it is enough to

press the double pin and move backwards manually

its upper part.

RFor the 26” adjustment, once the 24'' size has been

reached, remove the "R" shaped split pin that locks

the double pin, take off the double pin, put it into

the two rear holes and insert again the "R" shaped

split pin, then make the moving part slide until the

26'' position is reached.

652016-02_Mi

20'' 1

2

3

22''

24''

26''

Fig. 3: Moving jaws adjustment

1 697 630 500 2013-03-05

| Beissbarth GmbH

14 | MS 65 OR RAC S80 | Operating instructionsen

5.2 Tire demounting

iRead the Wdk publications available in German and

English!

(www.wdk.de: mounting/demounting instructions)

5.2.1 Preparations for demounting

!Avoid valve damage!

1. Pull out the valve element from the valve..

The air is discharged completely from the tire.

2. Before starting bead breaking operations adjust the

3 position device according to tire width.

3. Place the wheel on the floor, close to the antiabra-

sive supports of the bead breaker; to put the blade

(1) close to the bead press the bead breaker control

pedal (2). The operation has to be carried out in dif-

ferent points of the wheel (rotating it manually) until

the bead doesn't come off completely.

iLubricate the side of the tire and the rim shoulder

with mounting paste to make the bead breaking

operations easier.

652012-15_Mi

1

2

4. Repeat the operation on the opposite side of the

wheel.

Warning – limb injury danger!

During operation of the bead breaking arm,

be careful in order to avoid that the limbs are

not crushed between the tire and the bead

breaker.

¶Do not insert limbs between the tire and

the bead breaking arm.

Warning – damage risk for RFT or UHP tires!

Cracks in case of operation on cold tire. Tire

explosion in case of high speed.

¶Inner temperature of the tire must be at

least 15 °C.

¶Read the Wdk publications available in Ger-

man and English! (www.wdk.de: mounting/

demounting instructions – tire overheating)

¶Before mounting put the tire in a temperate

room.

5.2.2 Demounting

Warning – hand injury danger!

During locking plate rotation there is a risk of

crush injuries.

¶Do not insert the fingers between the tire

and the rim.

iIn case of remarkable width rims, lift the 2 position

column by means of the dedicated switch.

1. Turn counter-clockwise the locking knob to unlock

the sliding rod.

2. Press the tilting column pedal to tilt the column

backwards.

3. For external locking of the rim press the locking jaws

pedal to prepare the jaws in the open position;

iIn case of internal locking the jaws have to be in the

closed position.

4. Place the wheel on the locking plate

5. Exerting with the hand a pressure on the rim, press

(and release immediately) the locking jaws pedal in

order to lock it.

6. Lubricate with mounting paste the side of the tire till

the edge of the rim.

7. Press (and release immediately) the tilting column

pedal to lower the column.

8. Bring the mounting tool close to the rim until the

roller touches the edge of the rim; by turning clock-

wise the locking knob you achieve automatic hori-

zontal and vertical spacing from the rim and the arm

locking.

9. Insert the bead breaking lever between the mounting

tool and the bead of the rim. To make this operation

easier bring the bead in the part opposite to the

mounting tool inside the semi drop centre of the rim.

iIn case RFT or UPH tires the use of accessories like

clamps, wedge or of the TECNOROLLER SL bead

breaker is suggested.

1 697 630 500 2013-03-05

|

Beissbarth GmbH

Operating instructions | MS 65 OR RAC S80 | 15 en

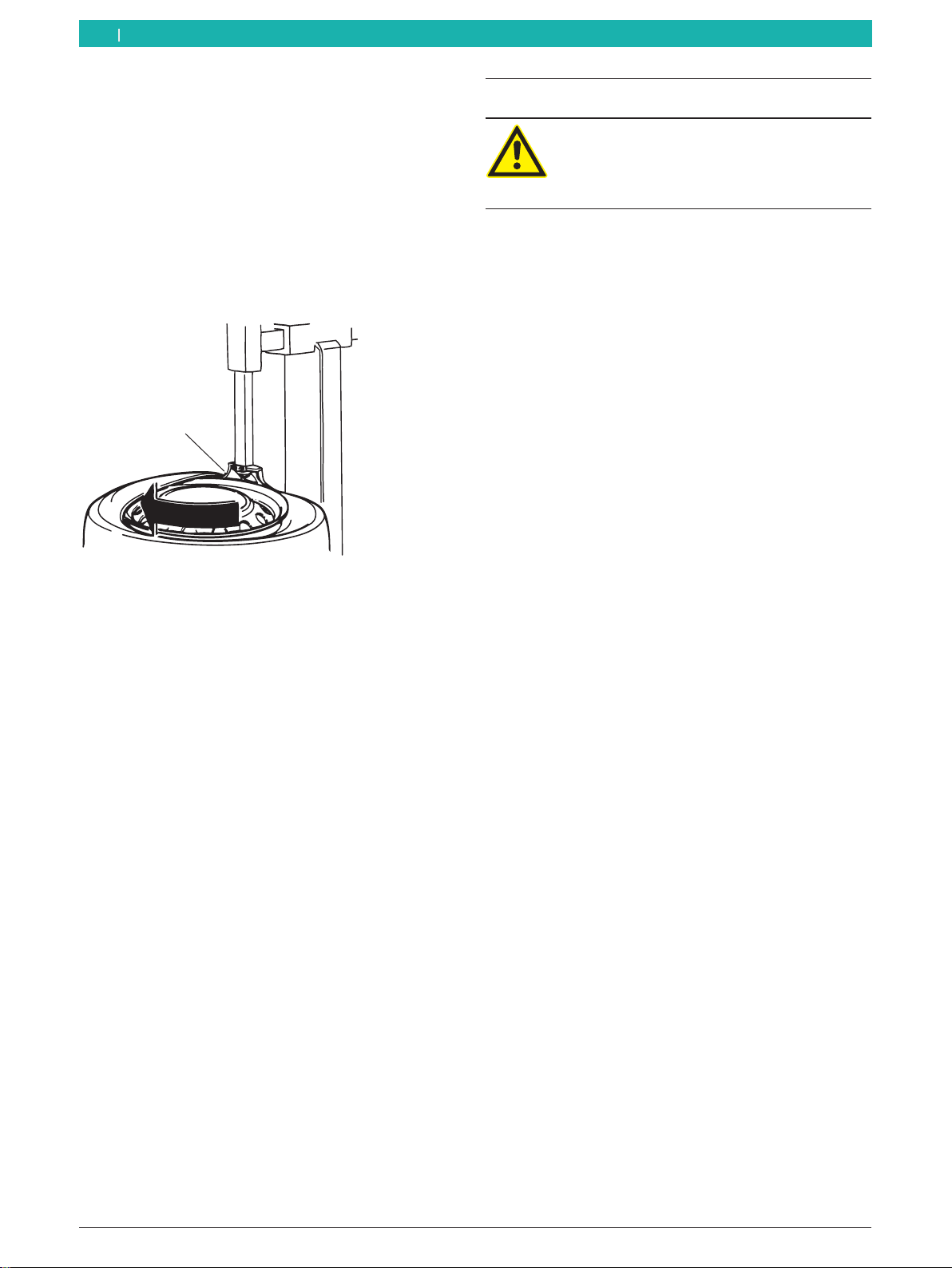

10. With the provided bead breaking lever lift the

edge of the tire and put lay it on the mounting tool

tab (1).

11. Press the rotation pedal to rotate clockwise

the locking plate, until complete ejection of the bead

from the rim.

652012-16_Mi

1

iIn case of tires with tube, press the tilting column

pedal to tilt the column and extract the tube.

12. Repeat the same operations to make the se-

cond bead come out.

13. Press the tilting column pedal to tilt the co-

lumn and remove the tire.

5.3 Tire mounting

Danger of car accidents caused by damaged

rims or tires!

In case of tire or rim damage during moun-

ting dangerous or even lethal situations may

occur during driving.

¶The operator has to be specifically trained.

¶Do not exert excessive forces on the tire or

the rim, adjust the slow rotation speed.

¶Use a sufficient quantity of mounting

paste.

¶In case of anomalies, e.g. suspicious noi-

ses, stop mounting immediately.

¶For mounting of critical rim/tire combina-

tions, read the Wdk publications available

in German and English!(www.wdk.de:

mounting/demounting instructions – crite-

ria catalogue).

5.3.1 Mounting preparations

Warning – damage risk for RFT or UHP tires!

Cracks in case of operation on cold tire. Tire

explosion in case of high speed.

¶Inner temperature of the tire must be at

least 15 °C.

¶Read the Wdk publications available in Ger-

man and English! (www.wdk.de: mounting/

demounting instructions – tire overheating)

¶Before mounting put the tire in a temperate

room.

14. Lubricate with mounting paste the inside of the

rim in correspondence of the edge and of the shoul-

der of the rim and of the semi drop centre.

15. Lubricate the two tire beads with mounting

paste.

16. Lean the tire oblique on the rim.

5.3.2 Mounting

Warning – hand injury danger!

During locking plate rotation there is a risk of

crush injuries.

¶Do not insert the fingers between the tire

and the rim.

iIn case of remarkable width rims, lift the 2 position

column by means of the dedicated switch.

1 697 630 500 2013-03-05

| Beissbarth GmbH

16 | MS 65 OR RAC S80 | Operating instructionsen

1. Rotate the locking plate and bring the valve between

2 o'clock and 4 o'clock position.

2. Press (and release quickly) the the tilting column

pedal to lower the column.

3. Lay the tire bead on the lower left edge of the moun-

ting tool tab.

4. While holding the bead in the semi-drop centre press

the rotation pedal and keep turning the locking plate

until the upper tire bead has passed close to the

mounting tool (1) and it has gone under the edge of

the rim.

652012-17_Mi

1

iBe sure that the bead is inserted in the drop centre

of the rim in order to eliminate bead yields; in order

to make his operation easier, it is suggested, during

rotation of the locking plate, to assist with a bit of

pressure the insertion of the bead in the rim.

iIn case of tires with tube, press the tilting column

pedal to tilt the column backwards; place the rim so

that the valve hole of the tube is positioned at about

90° degrees relatively to the mounting tool position

and, if needed, the tube.

5. Repeat the same operations for the insertion of the

second bead.

iIn case of RFT or UPH tires, in order to hold the bead

inside the semi drop centre, the use of accessories

like clamps, wedges or of the TECNOROLLER SL

bead breaker is suggested.

6. Press the tilting column pedal to tilt the column

backwards.

7. Press the locking jaw pedal to release the rim.

5.4 Inflation

Inflation can generate potential danger

situations. The operator has to carry out the

necessary precautions in order to guarantee

operational safety.

!Safety device:

To protect the operator from eventual dangers that

can occur during tire inflating on the locking plate,

the MS 65 OR RAC S80 has been equipped with a

valve that limits operational pressure to 3,5 bar.

5.4.1 Inflation with inflation gun

1. Screw the valve element.

2. Connect the inflation gun to the tire valve.

3. Inflate the tire, by operating on the inflation gun until

reaching nominal pressure.

1 697 630 500 2013-03-05

|

Beissbarth GmbH

Operating instructions | MS 65 OR RAC S80 | 17 en

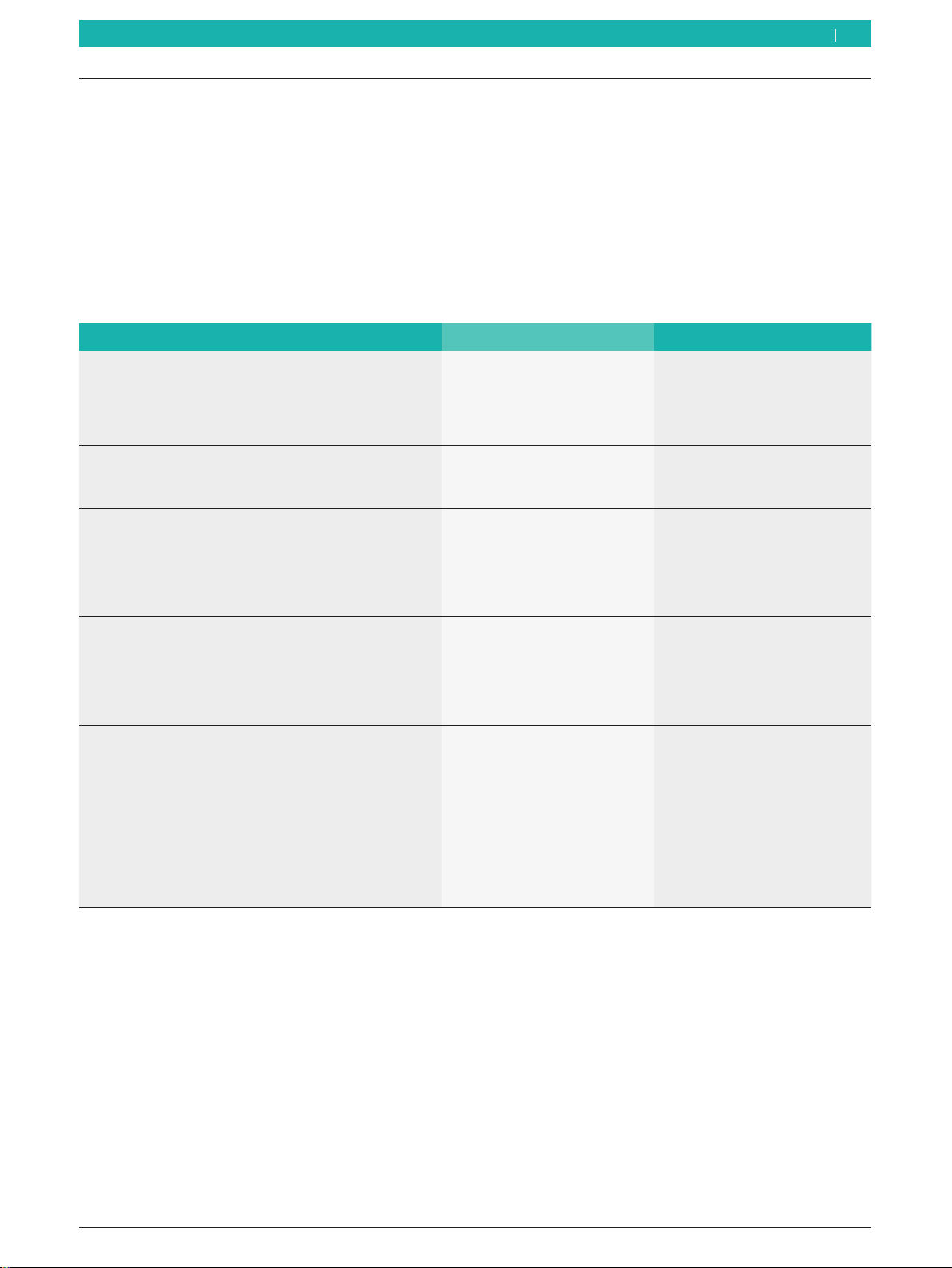

5.5 Functioning anomalies

In the following table all the possible anomalies and their correspondent remedies are listed.

Other supposable functioning anomalies are mainly of technical nature and have to be verified and resolved by

qualified technicians.

In any case contact the assistance service of the authorized vendor of Bosch equipment.

iTo speed up intervention it is important to tell during the phone call the data reported on the identification

plate (tag on the back of the MS 65 OR RAC S80) and the type of malfunction.

!Any intervention on the electrical, hydraulic or pneumatic system, has to be performed exclusively by qualified

technicians which are properly trained.

Anomalies Causes Remedies

The locking plate does not turn in any of the two directions. 1. The network plug is not con-

nected.

2. The network plug is not cor-

rectlyconnected.

3. The tension does not corres-

pond tothe prescribed value.

1. - 2. Check if the network plug

is correctly inserted in the socket

and check connection.

3. Check the tension oftension.

When the locking flange pedal is pressed down, the locking

plate turns clockwise.

1. Phases inversion duringplug

connection.

2. The pedal is pulled up with the

foot.

1. Invert the 2 phases in the net-

work plug (qualifiedelectrician is

required).

2. Press down the pedal.

The locking plate transmits insufficienttorque (low force). 1. Wrong network tension.

2. Wrong phases connection in

the plug.

3. Loosen transmissionbelt.

1. Check the correspondence of

the network tension and the ten-

sion shown on theidentification

plate.

2. Check that the phases in the

plug are correctly connected.

3. Pull the transmission belt.

The locking plate does not lock the rim correctly. 1. The pneumatic sys-

tem is not connected to the

MS 65 OR RAC S80.

2. Insufficient pressure inthe

pneumatic system.

3. The pressure reducing valve is

closed or incorrectly adjusted.

1. Connect the pneumaticsystem.

2. Adjust pneumatic pressure to

the correct value.

3. Open or adjust correctlythe

pressure reducingvalve.

The bead breaker force is not enough for bead breaking. 1. Excessive pressure isexerted.

2. The pneumatic sys-

tem is not connected to the

MS 65 OR RAC S80.

3. Insufficient pressure inthe

pneumatic system.

4. The pressure reducing valve is

closed or wrongly adjusted (valid

for the versions that use this kind

of device).

5. The tire is not completely de-

flated.

1. Exert the right pressure on the

bead breaker.

2. Connect the pneumaticsystem.

3. Adjust pneumatic pressure to

the correct value.

4. Open or adjust correctlythe

pressure reducingvalve.

5. Remove the valve element from

the valve until complete deflation

of the tire.

1 697 630 500 2013-03-05

| Beissbarth GmbH

18 | MS 65 OR RAC S80 | Maintenanceen

6. Maintenance

6.1 Suggested lube

Component Lube Standard

Gearbox ESSO Spartan EP460 ISO 460

DIN 51502-CLP

ISO 34-98-CC

Pneumatic system

(conditioning assem-

bly)

ESSO FEBIS K 32 ISO VG 32

Tab. 1: Lubricants table.

!The manufacturer is not liable for any damage

caused by use of lubes different from those shown in

the table.

6.2 Cleaning and servicing

Before any cleaning or maintenance interven-

tion, disconnect the MS 65 OR RAC S80 by

means of the main switch and disconnect the

network plug.

Before any cleaning or maintenance interven-

tion, disconnect the pneumatic system of the

MS 65 OR RAC S80.

To guarantee full efficiency of the MS 65 OR RAC S80

and to ensure functioning without anomalies it is essen-

tial to clean the machine regularly and carry out perio-

dical maintenance.

Maintenance has to be carried out by the operator

in accordance with the manufacturer's prescriptions

shown here below.

6.2.1 Maintenance intervals

Maintenance

weekly

monthly

annual

Clean the mechanical moving parts, spray

them with nebulized oil or cherosene and lube

with appropriate grease

x

Remove the condensate from the filter assem-

bly. x

Check oil level in the oil nebulizer. x

Check transmission belt tensioning in order to

avoid its sliding. x

Check the oil level in the gearbox and keep it

always between minimum and maximum level. x

Change oil in the oil nebulizer. x

6.2.2 Condensate removal

1. Turn left the red button placed in the lower part of

the water separator.

2. Remove the accumulated condense by pressing the

same button.

3. Turn back in previous position the red button placed

in the lower part of the water separator.

6.2.3 Nebulizer oil refill

1. Disconnect pneumatic connection.

2. Unscrew the tank cap on the oil nebulizer.

3. Top up oil (see lube table).

652002-15_Mi

6.2.4 Change oil in the oil nebulizer

1. Disconnect pneumatic connection.

2. Unscrew the tank cap on the oil nebulizer.

3. Discharge oil and dispose it (see chap. 7.3).

4. Top up with new oil (see lube table).

1 697 630 500 2013-03-05

|

Beissbarth GmbH

Decommissioning | MS 65 OR RAC S80 | 19 en

7. Decommissioning

7.1 Place change

Procedure:

1. Disconnect electrical connection.

2. Disconnect pneumatic connection.

3. Dismantle the column switch and lean it at the side.

4. Follow what shown for first start up (see chap. 4.2).

5. Fix again the MS 65 OR RAC S80 with its 3 screws

on the pallet (see chap. 4.2).

iIn case of sale or transfer of MS 65 OR RAC S80, all

the documents included in the consignment volume

has to be integrally handed over together with the

equipment.

7.2 Temporary decommissioning

If the MS 65 OR RAC S80 is going to be stopped for a

limited period of time or if the equipment is not being

used for other reasons, always disconnect the network

plug from its socket!

It is suggested to clean accurately the

MS 65 OR RAC S80, also its tools and accessories, and

carry out a protection treatment (e.g. spraying of a thin

oil film).

7.3 Disposal

¶Disconnect the MS 65 OR RAC S80 from the mains

tension and take off the power supply cable.

¶Oil are water pollution risk fluids and have to be

disposed of in accordance with the rules in force.

¶Disassemble the MS 65 OR RAC S80, order the

materials according to the category it belongs to and

dispose of them according to the rules in force.

MS 65 OR RAC S80 complies to the rules of

the European directive 2002/96/CE (directi-

ve on the disposal of electrical and electro-

nic waste).

Electric and electronic devices which are out

of order, together with their cables, accesso-

ries, accumulators and batteries, have to be

disposed of separately from household waste.

¶For disposal of such products, use the

available return and collection systems.

¶The correct disposal of the

MS 65 OR RAC S80 makes it possible to

avoid environmental damage and to put at

no risk the life of people.

8. Technical data

8.1 MS 65 OR RAC S80

Function Specifications

Maximum noise level 75 dB

Bead breaking cylinder force 25000N(2,5t)

Compressed air supply 8 – 12 bar

Power supply tension depending on the cho-

sen tension (see iden-

tification plate)

8.2 Dimensions and weights

Function Specifications

MS 65 OR RAC S80 (H x W x D) 1830 x 1860 x 1110 mm

Net weight 217kg

Gross weight 245kg

8.3 Reach

8.3.1 Car wheels

Function min / max

Tire width 3"– 12"

Maximum tire diameter 1000 mm

Rim diameter (internal locking) 12"– 28"

Rim diameter (external locking) 10"– 26"

8.3.2 Motorcycle wheels

Function min / max

Tire width 3"– 10"

Maximum tire diameter 1000 mm

Rim diameter 15"– 28"

iTo operate on motorbike wheels it is necessary to

install the motorbike wheel connection device, avai-

lable upon request (see chap. 3.4).

1 697 630 500 2013-03-05

| Beissbarth GmbH

20 | MS 65 OR RAC S80 | Glossaryen

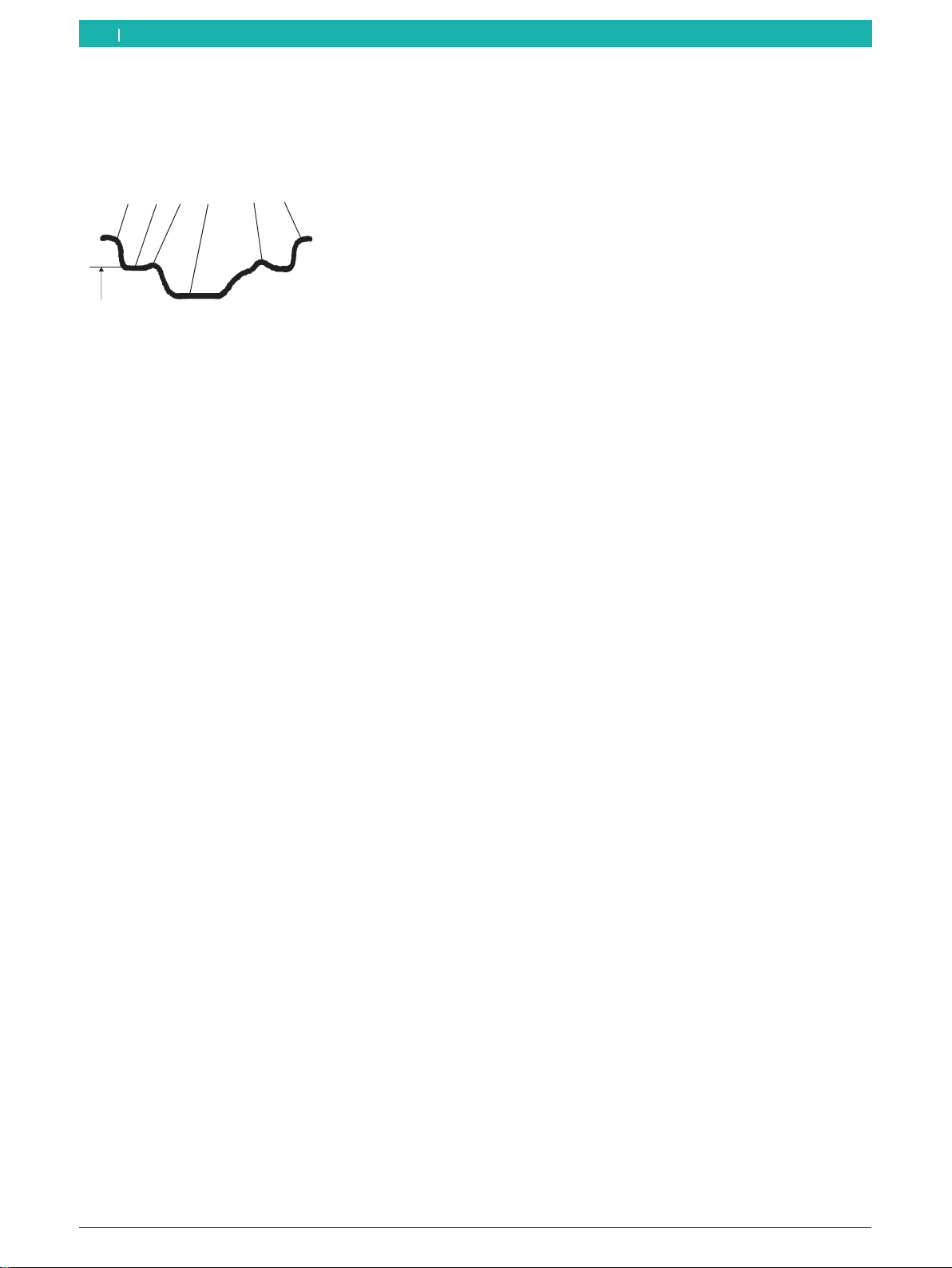

9. Glossary

Rim, structure and names

652001-26_Rf

1

1

3

4

3

2

D

Fig. 4: Rim

1 Rim edge

2 Rim shoulder

3 Hump (lifted edge)

4 Semi drop centre

D Rim diameter

RFT

Run Flat Tyre, tire with emergency functioning features,

normal wheel and spare wheel at the same time.

TCE

Tyre Change Equipment, abbreviation for tire changer.

UHP

UltraHighPerformance tires, name of the brand of a tire

for high speeds.

wdk

German rubber industry association

(registered association).

Table of contents

Other Beissbarth Tyre Changer manuals