REV. 01

4 / 28

CHAPTER 1 – INTRODUCTION

1.1 INTRODUCTION

Th nk you for purch sing product from the line of tire ch ngers. The m chine h s been

m nuf ctured in ccord nce with the very best qu lity principles. Follow the simple instructions

provided in this m nu l to ensure the correct oper tion nd long life of the m chine. Re d the entire

m nu l thoroughly nd m ke sure you underst nd it.

1.2 TYRE CHANGER IDENTIFICATION DATA

A complete description of the “Tire Ch nger Model” nd the “Seri l number” will m ke it e sier for

our technic l ssist nce to provide service nd will f cilit te delivery of ny required sp re p rts. For

cl rity nd convenience, we h ve inserted the d t of your tire ch nger in the box below. If there is

ny discrep ncy between the d t provided in this m nu l nd th t shown on the pl te fixed to the tire

ch nger, the l tter should be t ken s correct.

1.3 MANUAL KEEPING

For proper use of this m nu l, the following is recommended:

• Keep the m nu l ne r the lift, in n e sily ccessible pl ce.

• Keep the m nu l in n re protected from the d mp.

• Use this m nu l properly without d m ging it.

• Any use of the m chine m de by oper tors who re not f mili r with the instructions nd

procedures cont ined herein sh ll be forbidden.

This m nu l is n integr l p rt of the m nu l: it sh ll be given to the new owner if nd when the

m chine is resold.

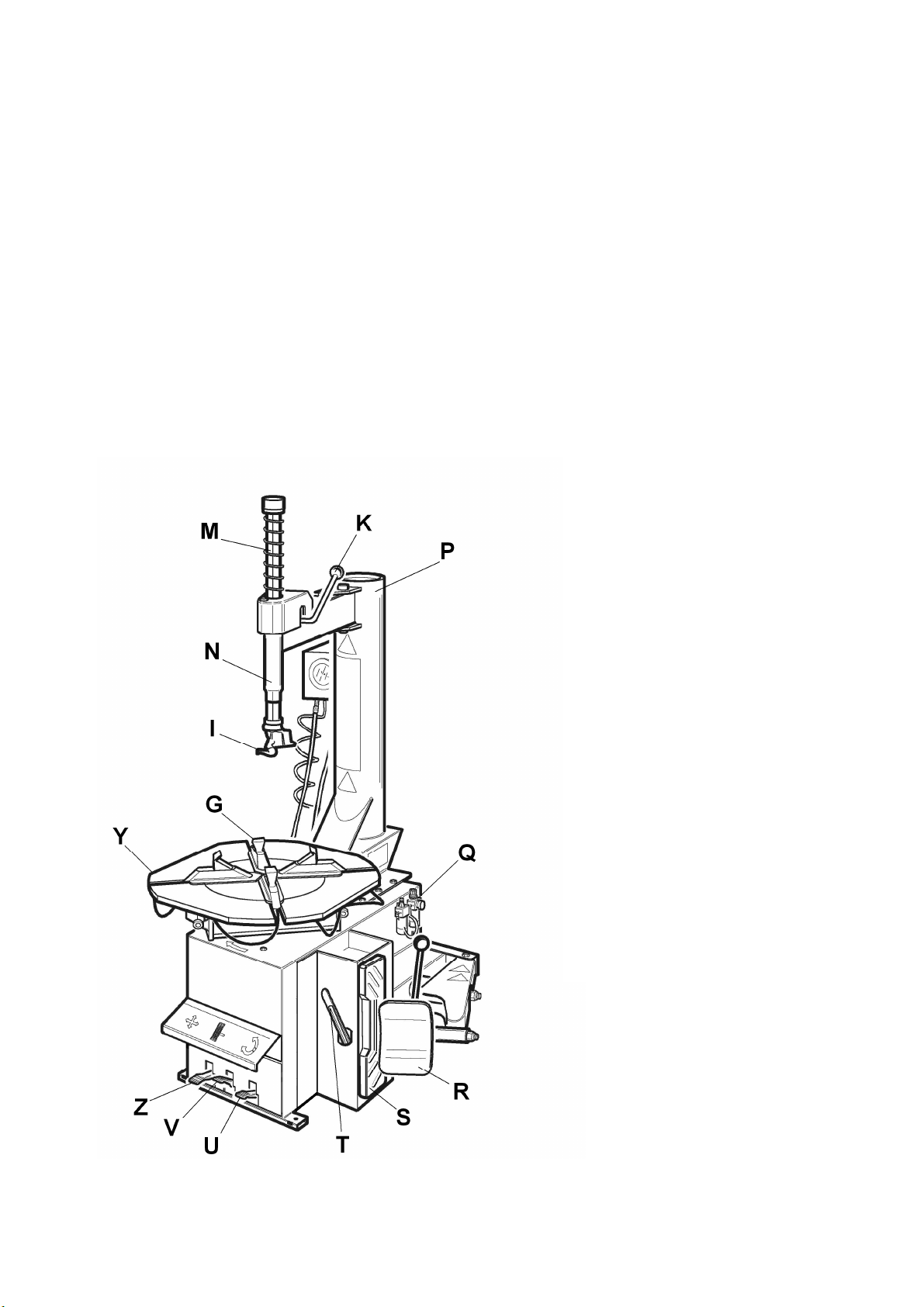

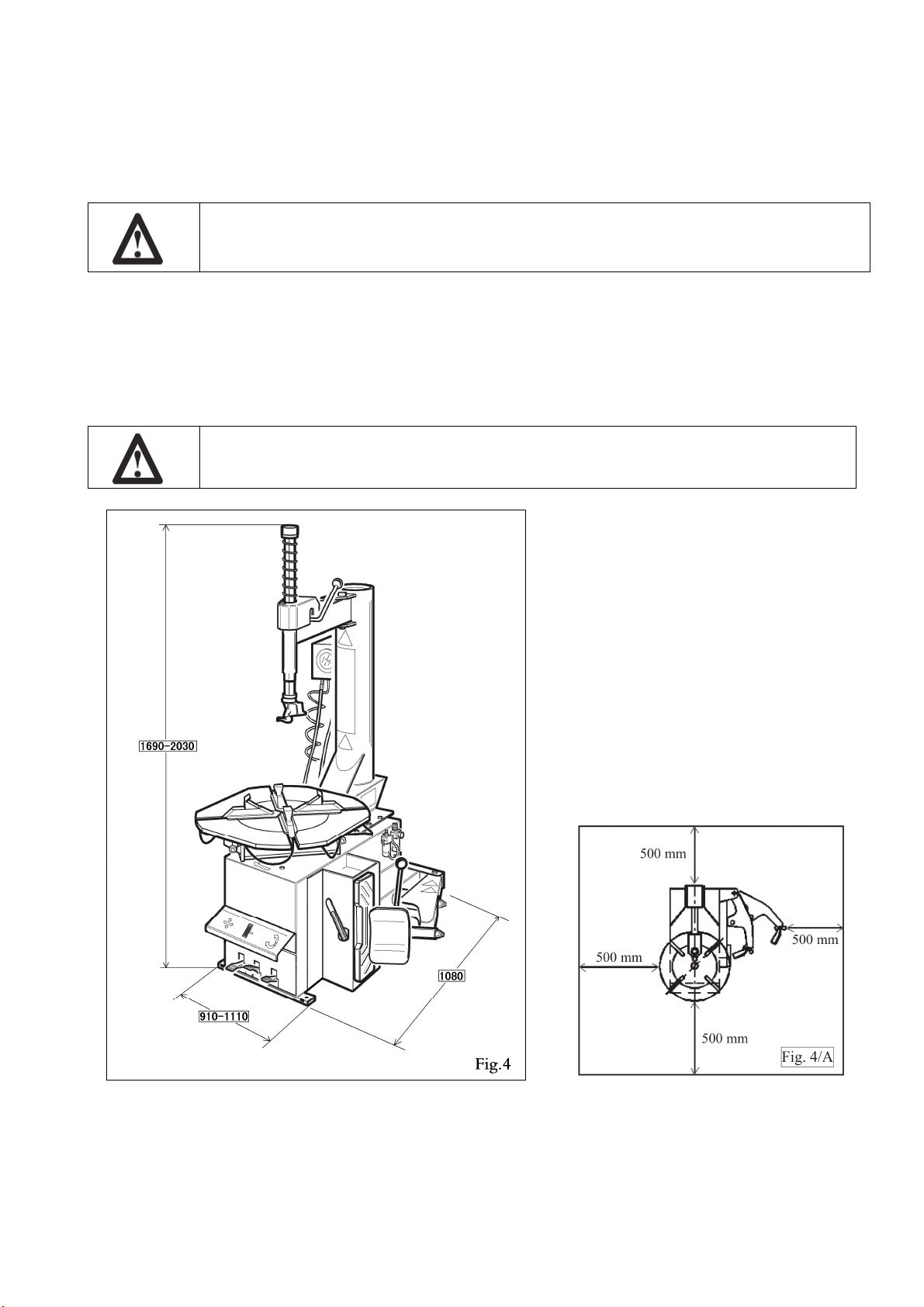

The illust ations have been made out of p ototypes pictu es. It is the efo e

possible that some pa ts o components of standa d p oduction diffe f om those

ep esented in the pictu es.

1.4 GENERAL SAFETY PRECAUTIONS

The ti e change may only be used by specially t ained and autho ized expe t

pe sonnel.

LOGO

Type:

Volt Amp Kw

Ph Hz

Ye r of m nuf cturing:

Air supply: 8-10 b r (116 – 145 PSI)