Beissbarth Start Line MS 201 User manual

Start Line MS 201

de

Originalbetriebsanleitung

Reifenmontiermaschine

en

Original instructions

Tire changer

fr

Notice originale

Machine à monter les pneus

es

Manual original

Máquina para montaje de neumáticos

it

Istruzioni originali

Smontagomme

pt

Manual original

Máquina de montagem de pneus

Reifenmontiergeräte

Tyre Changers

| Start Line MS 201 | 27 en

1 695 108 073 2016-07-27|Bosch Automotive Service Solutions srl

Content English

1. Symbols used 28

1.1 In the documentation 28

1.1.1 Warning notices -

Structure and meaning 28

1.1.2 Symbols in this documentation 28

1.2 On the product 28

1.3 Warning 28

2. User instructions 29

2.1 General provision 29

2.2 Range of application 29

2.3 Safety requirements and notes 30

3. Product description 31

3.1 Intended use 31

3.2 Machine rating plate 31

3.3 Device description 31

4. Transport 32

4.1 Transport and packing 32

4.2 Transport method 32

5. Unpacking 32

5.1 Unpacking 32

5.2 Setting up the MS 201 32

3.4 Scope of delivery 32

6. Initial commissioning 34

6.1 Initial commissioning 34

6.2 Fastening the MS 201 35

6.3 Connecting the MS 201 to power and the

compressed air supply 35

6.4 Checking the pedal functions 35

7. Operation 36

7.1 Safety notice 36

7.2 Check before use 36

7.3 Information about special rims and tires 36

7.4 Unseating the tire bead 37

7.5 Rim location direction 38

7.6 Clamping the rim 39

7.6.1 Clapping the rim from the outside: 39

7.6.2 Clamping the rim from the inside: 39

7.7 Demounting the tire 39

7.7.1 Positioning of the mounting head 40

7.7.2 Lever the top bead over the rim flange 40

7.7.3 Demounting the top bead 41

7.7.4 Demounting the bottom bead (with the

aid of the mounting head) 41

7.7.5 Removing wheels 41

7.8 Mounting the tire 41

7.8.1 Selecting the tire 42

7.8.2 Preparing the tire 42

7.8.3 Positioning of the mounting head 42

7.8.4 Mounting the lower tire bead 42

7.8.5 Mounting the top bead 42

7.9 Procedure for mounting/demounting alloy rims43

8. Inflation 43

8.1 Inflating tubeless tires 44

8.2 Inflating tubed tires 44

9. Maintenance 45

9.1 Warning 45

9.2 Maintenance operations 45

9.2.1 Maintenance unit and bead breaking

cylinder 45

9.2.2 Belt 46

10. Troubleshooting 47

11. Decommissioning 48

11.1 Change of location 48

11.2 Temporary shutdown 48

11.3 Disposal and scrapping 48

11.3.1 Substances hazardous to water 48

11.3.2 MS 201 and accessories 48

12. Technical Parameter 49

12.1 Dimensions for 49

12.2 Range of application 49

12.3 Turntable type 49

12.4 Bead breaker blade 49

12.5 Power 49

12.6 Pneumatic diagram 49

1 695 108 073 2016-07-27| Bosch Automotive Service Solutions srl

28 | Start Line MS 201 | Symbols useden

Danger – Attention electricity !

Risk of injuries, heart failure or death from

electric shock when touching live parts (e.

g. main switch, circuit boards).

¶Work on electrical installations or

equipment is only to be performed by

qualified electricians.

¶Cut the power supply to the MS 201

before opening it.

Direction of wheel rotation

Wheel must turn in direction indicated.

1.3 Warning

Wear safety goggles.

Study the original operating instructions

prior to operation.

Risk of injury from rotating and moving

parts.

1. Symbols used

1.1 In the documentation

1.1.1 Warning notices -

Structure and meaning

Warning notices warn of dangers to the user or

people in the vicinity. Warning notices also indicate

the consequences of the hazard as well as preventive

action. Warning notices have the following structure:

Warning

symbol

KEY WORD – Nature and source of hazard!

Consequences of hazard in the event of

failure to observe action and information

given.

¶Hazard prevention action and information.

The key word indicates the likelihood of occurrence and

the severity of the hazard in the event of non-observance:

Key word Probability of

occurrence

Severity of danger if

instructions not observed

DANGER Immediate impending

danger

Death or severe injury

WARNING Possible impending

danger

Death or severe injury

CAUTION Possible dangerous

situation

Minor injury

1.1.2 Symbols in this documentation

Symbol Designation Explanation

!Attention Warns about possible property damage.

iInformation Practical hints and other

useful information.

1.

2.

Multi-step

operation

Instruction consisting of several steps.

eOne-step

operation

Instruction consisting of one step.

Intermediate

result

An instruction produces a visible

intermediate result.

"Final result There is a visible final result on

completion of the instruction.

1.2 On the product

!Observe all warning notices on products and ensure

they remain legible.

User instructions | Start Line MS 201 | 29 en

1 695 108 073 2016-07-27|Bosch Automotive Service Solutions srl

2. User instructions

2.1 General provision

¶This operating manual is an essential part of the

product. Before operating the device, please read

and heed the warnings and instructions in the

operating manual. It contains important information

on safe operation and maintenance.

¶Leave the operating instructions and warnings in

the operating manual and on the MS 201. Please

keep this operating manual in a safe location for use

at a later date and in its entirety in the event the

device is sold.

¶If the operator reads the operating manual carefully,

the operator can operate the MS 201 correctly and

safely.

¶Please read the operating manual carefully before

connecting the voltage supply and compressed air

supply.

¶Please carefully retain all information and data

supplied and provided.

¶Different tire changers come with different

operating manuals. The operator must check that

the operating manual is the correct one for the

device.

!The MS 201 must be used for the purpose stated

in the operating manual. The manufacturer and its

authorized dealers assume no responsibility for

problems caused by incorrect operation.

!The MS 201 must be operated by technically

capable personnel. The operator must fully

understand the operating manual and have received

professional training. If untrained personnel operate

the MS 201, personal injury and damage to the

tire and rim may result.

!The MS 201 has been designed for use by

personnel with basic mechanical and electrical

skills. For this reason, the description of basic

operations such as how to tighten screws may

not appear in the operating manual. Never allow

inexperienced personnel to operate the MS 201.

If you have any questions in this regard, please

contact your authorized dealer for assistance.

iAll of the figures in the operating manual show

the MS 201 in its original design. The structure

shown may be different from the actual structure of

the machine.

2.2 Range of application

The MS 201 is an electropneumatic tire changer

for passenger cars. Information about the work area

(weight/size) can be found in the Technical Data

section.

Applicable tire types:

RTire standard tire

RReverse tire

RTire without center hole

RRun flat tire (with assist arm)

!Each type of tire has its own specific method of

operation.

!Notice: When demounting / mounting the tire of an

old car (more than 30 years old) / modified car tires

/ tires with a modified rim, accidents may happen.

1 695 108 073 2016-07-27| Bosch Automotive Service Solutions srl

30 | Start Line MS 201 | Symbols useden

2.3 Safety requirements and notes

¶The MS 201 must only be operated by authorized

personnel who have received special training.

¶The manufacturer assumes no liability for any

direct or indirect damage arising from modification

of the MS 201 without the permission of the

manufacturer.

¶The MS 201 machine comes from the factory

with a complete set of instructions and warning

signs. If for some reason these have been damaged

or destroyed, they must be replaced.

¶The MS 201 must be kept away from flammable

and explosive materials.

¶The MS 201 must also be kept out of direct

sunlight and glare.

¶The installation site must be well ventilated.

¶Be sure to use original parts and accessories.

¶The MS 201 must be installed by authorized

personnel in the manner described in the operating

manual.

¶During operation, you should pay attention whether

there is any danger. If a hazard is detected, shut

off the MS 201 immediately and notify the

authorized dealer.

¶When the tire changer running, unauthorized

personnel should be kept away from the machine.

¶The operator must wear protective gear such as

protective gloves, safety goggles and overalls to

prevent accidental injury.

¶The protective conductor must be connected

correctly.

¶When the tire changer is being operated,

unauthorized personnel should be kept away from

the machine.

¶Failure to observe the requirements for operation

or to heed the warnings related to the dangers

specified in the operating manual poses the risk of

injuries to the operators or personnel nearby.

¶The MS 201 must be operated by technically

capable personnel. The operator must have received

special training and understood the requirements in

the operating manual.

¶He or she must also understand related safety

requirements and the requirements for operation.

¶The operator must not operate the MS 201 after

consuming alcoholic beverages.

¶The operator must pay attention to the following:

$All requirements in the operating manual must be

understood.

$The operating principle of the tire changer must

be clear.

$Unauthorized personnel should be kept away

from the MS 201 during operation.

$It is necessary to ensure that installation of the

MS 201 complies with applicable local laws

and regulations.

$It must be ensured that the operators have

received training and have the skill to operate the

MS 201, and they must be monitored.

$Do not detach bolts, nuts or the other

components from the MS 201.

$Do not touch the motor and live parts on the

machine such as connection cables before the

voltage supply has been disconnected.

$Carefully read the operating manual and learn

how to use the MS 201 correctly and safely.

$Keep the operating manual for the future

reference.

¶Do not detach the danger labels, safety warnings

and operation tips on the MS 201.

¶If there is any damage, please contact the local

authorized dealer promptly.

$During the process of use and maintenance, the

operator should pay attention to the danger of

the high electrical voltage.

$Do not modify the MS 201 or use anything

other than original parts.

$The operators must wear tight overalls, gloves,

safety goggles, and safety shoes, etc.

$When the operator makes operation or

maintenance, it is forbidden to wear loose

clothes, necklace or long hair.

Product description | Start Line MS 201 | 31 en

1 695 108 073 2016-07-27|Bosch Automotive Service Solutions srl

3. Product description

3.1 Intended use

MS 201 is used to demount/ mount the car tire. The

dimension of the rim is 9”-22”. The maximum wheel

diameter is 1050mm, the maximum tire width 13". Any

other use shall be construed as improper use.

!The manufacturer assumes no liability for any

damage arising from operation in a manner not

specified in this operating manual.

3.2 Machine rating plate

Each MS 201 is equipped with an identifying plate

that lists the technical parameters and serial number.

It is prohibited to remove the rating plate from the

MS 201.

iEach MS 201 is equipped with an identifying

plate that lists the technical parameters and serial

number.

Symbol Meaning

V Rated voltage

A Rated current (during operation)

kW Power

Hz Frequency

Ph Phase of the voltage supply

bar Operating pressure from the compressed air

supply

Serial N. Serial number of the MS 201

CE CE marking

iComplete information on the model and serial

number will help our technical personnel provide

you with service and technical support. It will also

make replacement of parts more accurate and

easier. If there is difference between the data in

the operating manual and the data on the rating

plate, that on the rating plate should be considered

correct.

3.3 Device description

!All information about the MS 201 must have

been understood. It must be clear how

$accidents can be avoided.

$the tire changer must be operated.

$the functions and control elements can be used.

!Accidents can be prevented only if every step

required for operation is understood.

!The MS 201 must be installed correctly, operated

correctly and also serviced periodically.

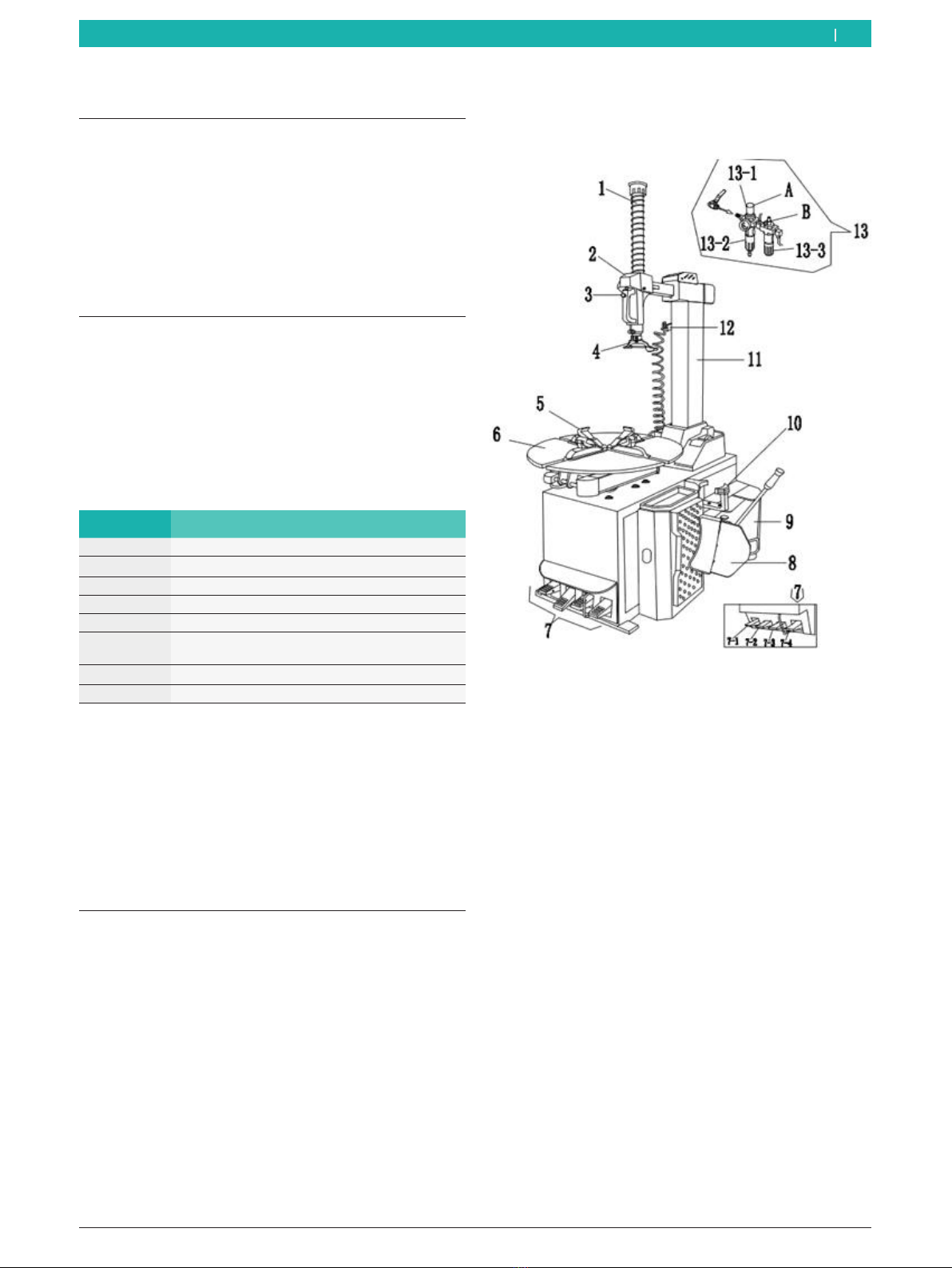

Fig. 1: Product description MS 201

1 Hexagon shaft: for securing the mounting head

2 Cover: dust prevention

3 Mounting arm locking valve: for locking/unlocking the mounting

arm

4 Mounting head: the tool for demounting/mounting the tire

5 Clamp jaw: for clamping the rim

6 Turntable: for placing the wheel

7 Pedal control system

7-1 Mounting arm control pedal: controls pivoting of the mounting

arm

7-2Clamping jaw control pedal: control open/close of the clamping

jaw

7-3Blade control pedal: control the blade movement

7-4Turntable rotation control pedal: control the rotation of the

turntable

8 Bead-breaker blade: for unseating the tire from the rim

9-Blade arm: supports the bead breaker blade

10 Lubricant holder: conveniently positioned for fastening a variety

of lubricant containers

11-Column: support horizontal arm

12-PCL Inflation gun: inflating for the tire

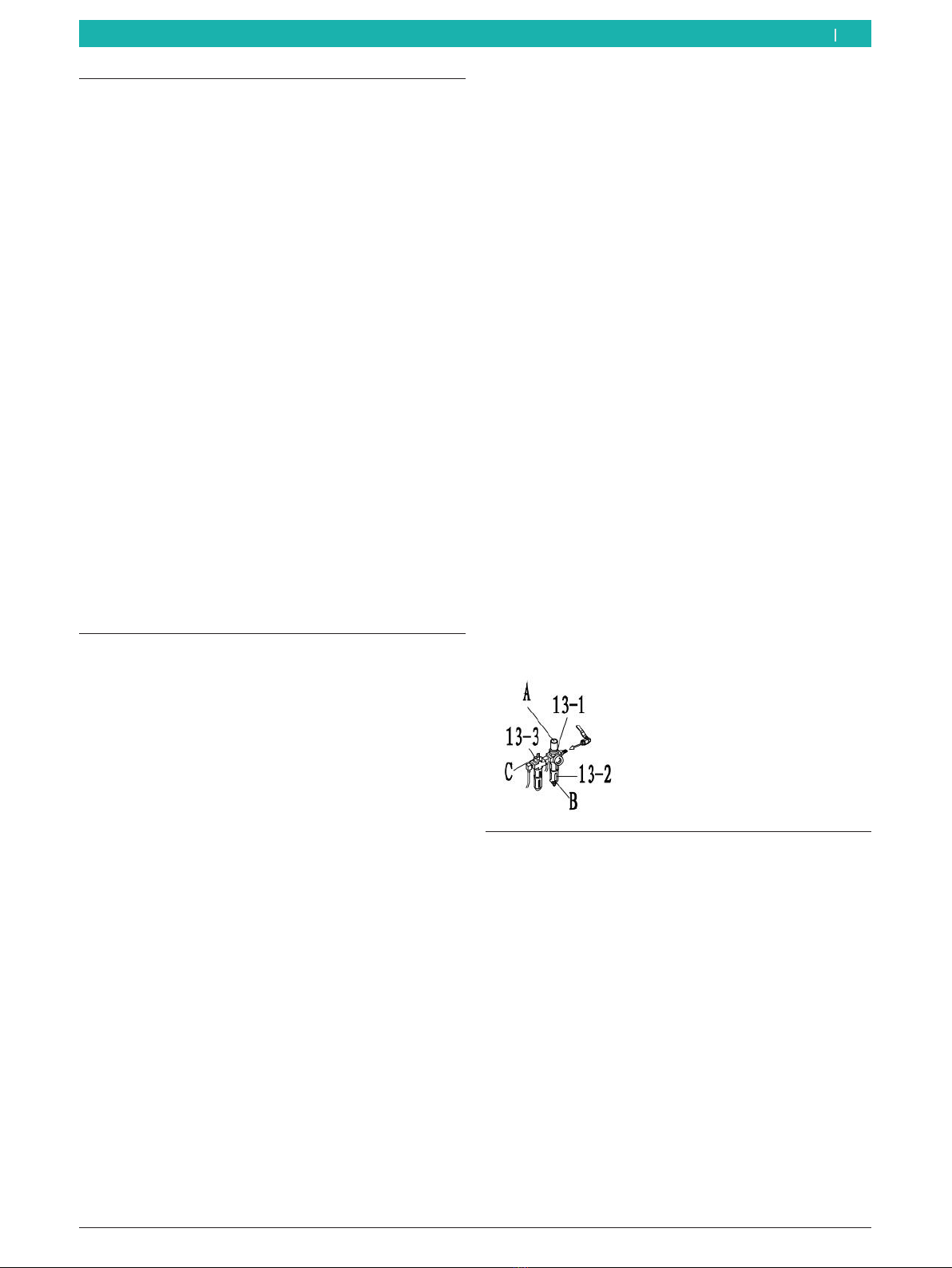

13-Air treatment assembly

13-1 Pressure-limiting valve, for regulating the supply pressure

13-2 Water separator

13-3 Atomized lubricator: provides oil for the air passages

1 695 108 073 2016-07-27| Bosch Automotive Service Solutions srl

32 | Start Line MS 201 | Product descriptionen

4. Transport

4.1 Transport and packing

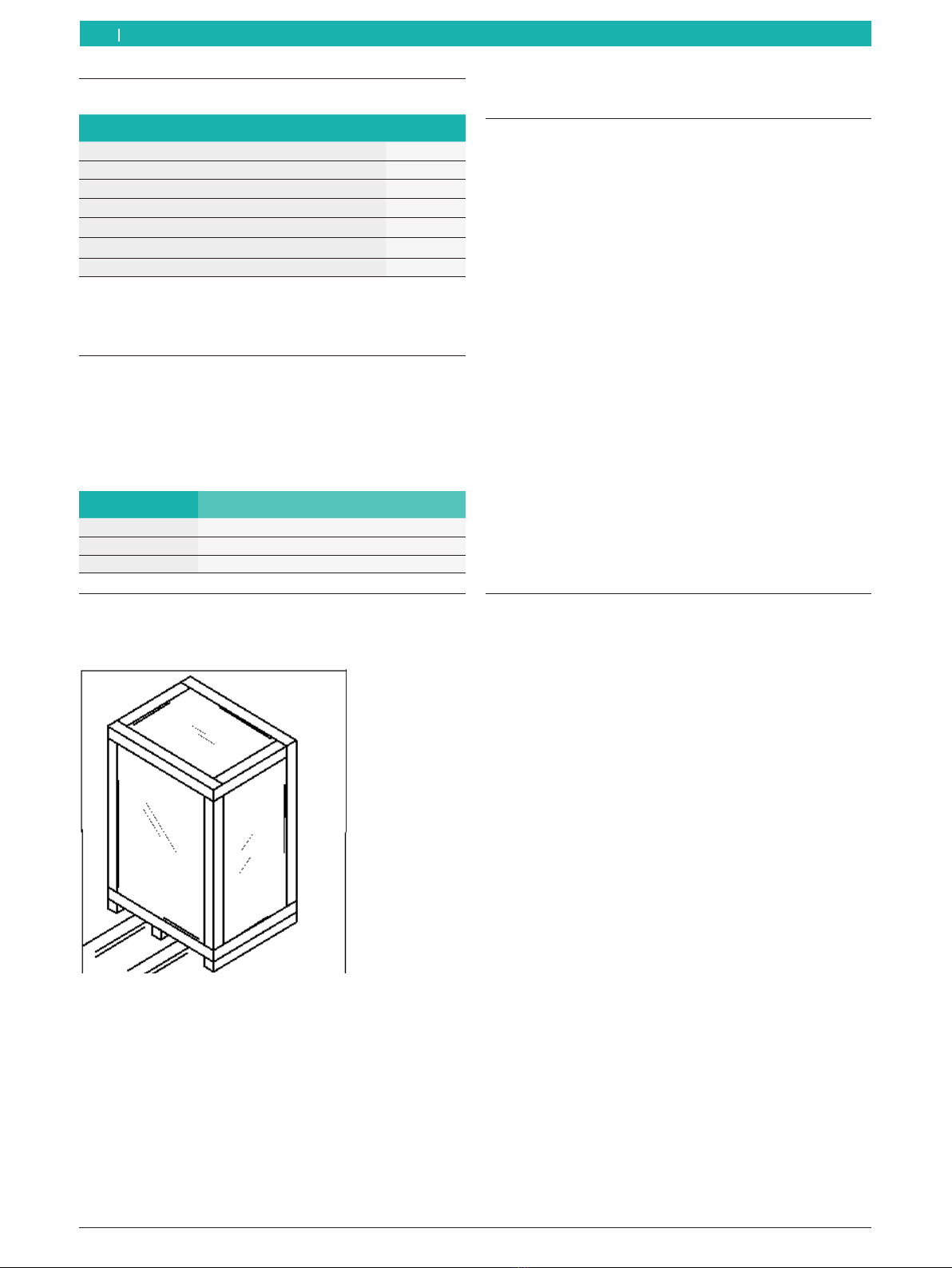

The MS 201 must be placed in the original

packaging for transport. The package should comply

with the following requirements.

The package size requirement:

Dimensions Package size

Width 1150mm

Length 1200mm

Height 1050mm

4.2 Transport method

¶Open the top package, plug the fork of the forklift

from bottom of the original package.

iKeep the original package for the future

transporting.

5. Unpacking

5.1 Unpacking

¶When unpacking, the operator should wear the

proper protective gear such as protective gloves.

¶Check the delivery carefully to make sure that all

parts have been delivered. If there is any mistake,

please contact your authorized dealer at once.

¶The objects in the carton, such as boards, nails,

screws and plastic bags, should be stored in a safe

location.

¶If there are any environmentally harmful or non-

degradable substances, you should treat them in

accordance with local laws and regulations.

!During the process of unpacking, assembly and

transporting, you should follow the following

requirements and handle with care. Otherwise, the

MS 201 could be damaged.

1. Detach the upper cover of the carton and make

sure whether there is any damage or not during

transporting.

2. Find the fastening screws holding the MS 201 on

the pallet.

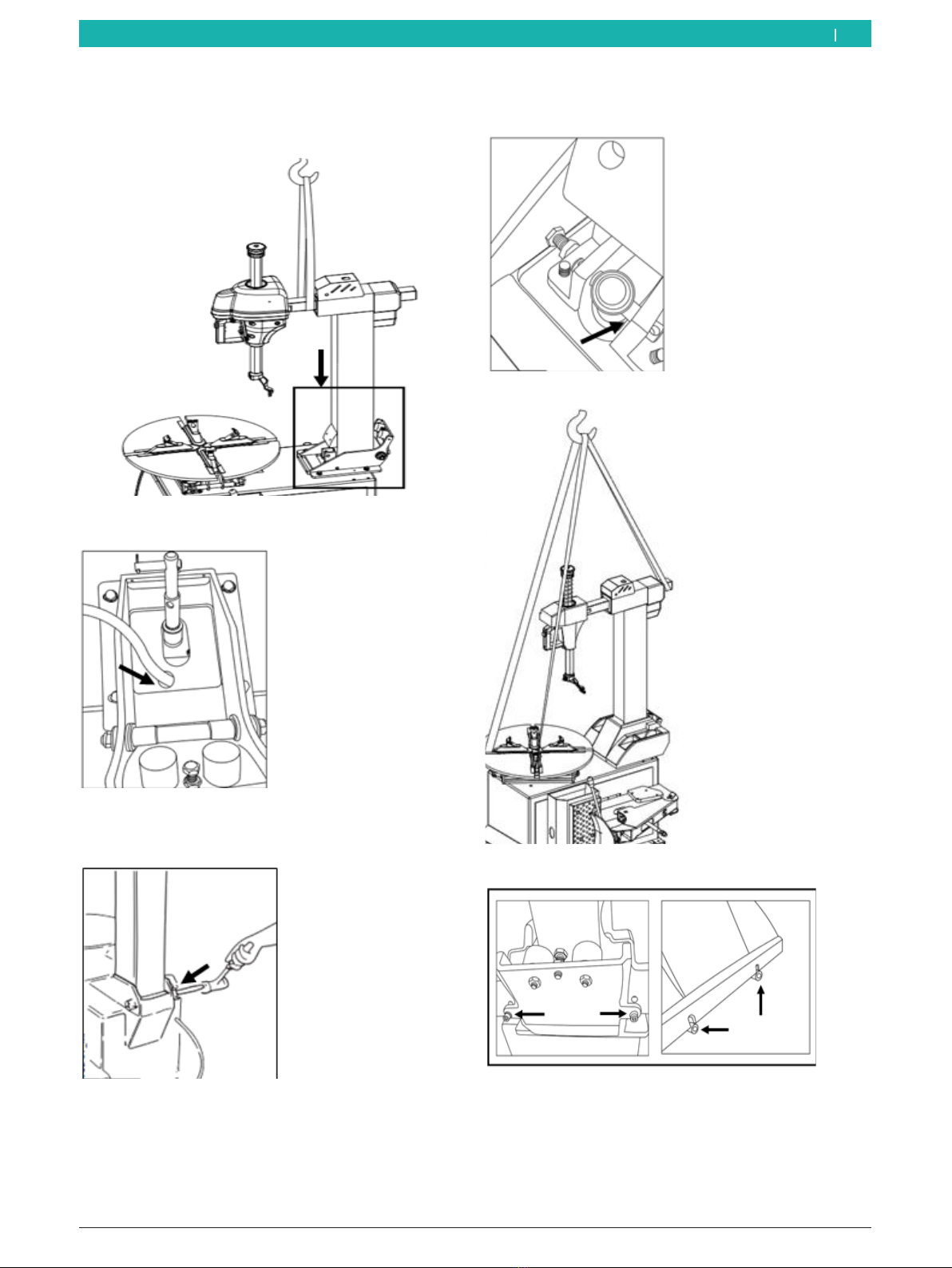

5.2 Setting up the MS 201

!Steps 1 - 11 must be completed on the pallet. Do

not loosen the screw and secure the mounting arm

until installation is complete while the MS 201 is

being moved.

1. Fasten the hoisting strap (mod. DR 750, 3m and DR

735, 1.5m, factor 6:1).

!Hoisting strap requirement: more than 1 metric ton

and safety factor 6:1.

2. You should use the above method whenever the

MS 201 is moved.

!Do not move the MS 201 unless the MS 201

has been disconnected from the voltage and

compressed air supplies.

3.4 Scope of delivery

Denomination Quantity

MS 201 1

Bead beaker assembly 1

Mounting lever 1

Inflation gun with pressure gauge 1

Bead breaker cover 1

Protection cover claw 1

Mounting tool cover 1

Unpacking | Start Line MS 201 | 33 en

1 695 108 073 2016-07-27|Bosch Automotive Service Solutions srl

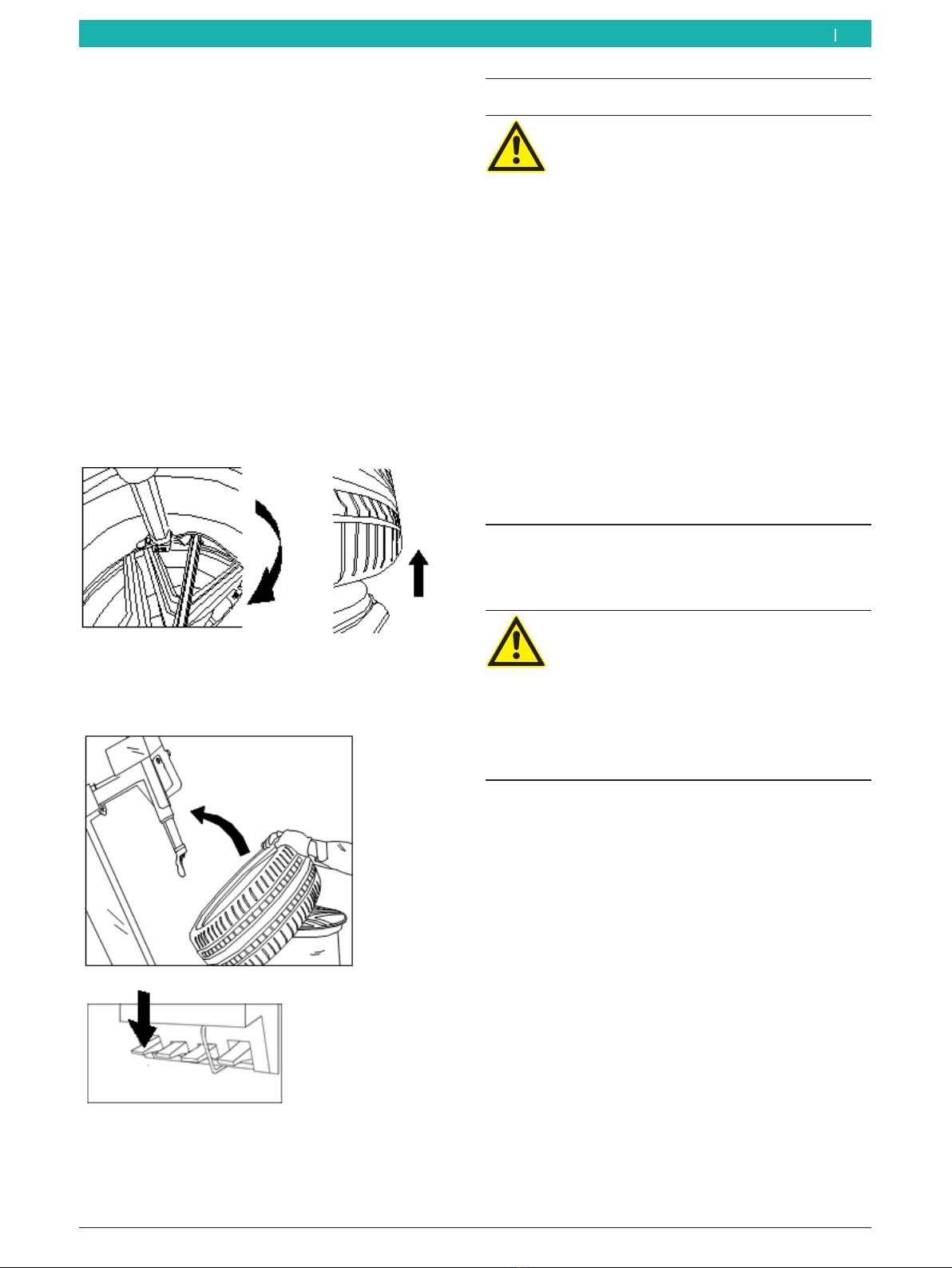

3. Lift the mounting arm onto the MS 201 as shown

in the figure below.

4. Put the air pipe that inside column into the machine

body.

5. Position the MS 201, then drive the fixed axis

insert into the corresponding holes with a hammer

and fasten.

6. Connect the fixed axis insert to the bead breaker

cylinder and mounting column, and then fasten.

7. Before lifting the complete MS 201.

8. Affix the cover then fasten the screw.

1 695 108 073 2016-07-27| Bosch Automotive Service Solutions srl

34 | Start Line MS 201 | Unpackingen

6. Initial commissioning

6.1 Initial commissioning

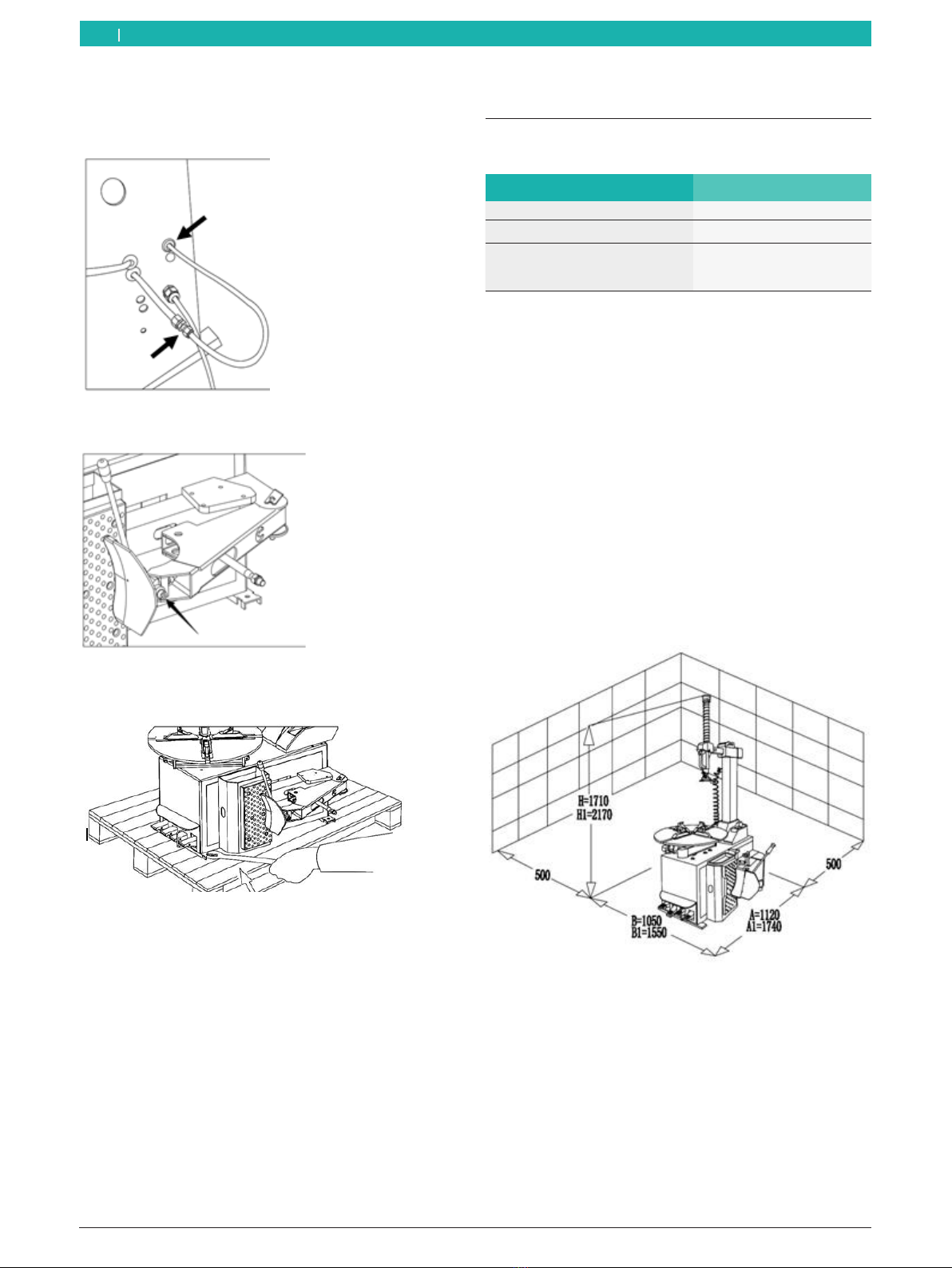

Installation environment requirement:

Initial commissioning Requirement

Temperature 4 - 40ºC

Sea level <1000m

Humidity

at 40°C

at 20°C

50%

90%

1. When selecting the installation location, ensure that

the MS 201 is safe when it is used under normal

operating conditions.

2. The MS 201 must be connected to the voltage

supply and compressed air suppl; we thus

recommend that the MS 201 be set up close to

these two utilities.

3. Installation position should at least leave the space

in the following figure to secure free movement of

each part of the machine.

4. If the MS 201 is installed outdoors, you should

take measures to protect it from rain and sun. The

MS 201 is not intended to be used outdoors.

5. The work are should enjoy enough light to secure

the operators can observe each details of the

operation.

!Besides the operator, no other personnel should be

in the work area when the machine is running.

9. To connect the air hose, open the side panel of

machine housing, then attach the air hose to the

straight connector.

10.Assemble the bead-breaker blade, then fasten the

screws.

11.Loosen the anchor bolt, push the mounting arm

to the innermost position, and prepare the lifting

device.

Initial commissioning | Start Line MS 201 | 35 en

1 695 108 073 2016-07-27|Bosch Automotive Service Solutions srl

6.2 Fastening the MS 201

!For the procedure when lifting the MS 201,

please see the figure. Lift the MS 201 carefully

(the middle of the MS 201 is not identical with

the center of gravity) and protect the plastic covers

to prevent damaging them.

1. Detach the bolts and nuts fixed on the machine

chassis.

2. Bind the hoist tape (mod. DR 750 of 3m and DR

735 of 1.5m factor 6:1).

3. Lift the MS 201 carefully.

4. Remove the pallet and position the MS 201 at

the preselected location.

!Ensure that the nozzle and air hose on the

MS 201 are not damaged during the hoisting

operation. Be very careful when lifting the

MS 201.

iIf tires will be inflated on the turntable, you must

secure the MS 201 to the floor.

5. Use an M10 bolt (grade 12.9), placed through the

hole in the pallet, to secure the MS 201 to the

floor.

6.3 Connecting the MS 201 to power

and the compressed air supply

!In accordance with the electrical specification, the

voltage supply must be equipped with a fuse and a

properly grounded protective conductor connection

as well as a safety switch.

iIf the MS 201 does not have a plug, the user

should prepare a 16A plug suitable for the operating

voltage of the tire changer and as specified in the

electrical code.

1. Connect the MS 201 to the voltage supply.

RThe voltage deviation should be 0.9 - 1.1 times the

rated voltage range, and the frequency deviation

should be 0.99 - 1.01 times the rated frequency

range. You should take the necessary protective

methods.

ROnly qualified personnel should make the

connection to the voltage supply.

RIf the MS 201 is not being used, please

disconnect the power promptly to ensure that the

MS 201 is not switched on accidently.

RIf the MS 201 will not be used for a long time

and the machine is connected directly to the

electrical cabinet instead of via a plug, the electrical

cabinet should be locked. Only professional

personnel should be able to open the electrical

cabinet in order to ensure that the MS 201 is not

switched on unintentionally.

!The MS 201 must be grounded and the

protective conductor must not be attached to a

heater, plumbing pipe, telephone cable or the like.

2. The compressed air supply must comply with the

requirements for the tire changer. The details of

these requirements are specified in "Technical

parameters" section. The pressure and volumetric

flow of the compressed air supply should meet the

requirements of the MS 201. The pressure must

be between 8and 16bar.

3. Use the special air hose to connect the water

separator, air regulator and lubricator on the side of

the MS 201 (see figure).

4. Please make sure that the oil has been fully filled

reaching the standard oil level. The oil contained

in the lubricator should be SAE 20 oil, or the air

passage will not be lubricated, causing the sealing

kits to be damaged in a short time.

RThe user must mount an air supply shut-off valve and

pressure control valve in front of the MS 201.

6.4 Checking the pedal functions

¶Depress the turntable rotation control pedal 7-4; the

turntable will rotate clockwise.

¶And rise up the turntable rotation control pedal 7-4,

the turntable will rotate counterclockwise.

¶Step down the horizontal arm control pedal 7-1

to the lowest position and the horizontal arm will

swing out.

¶Go on to step down the horizontal arm control pedal

to highest position the horizontal arm will swing

back to the vertical position.

¶Depress the blade control pedal 7-3; the blade

executes its function.

¶Release the blade control pedal 7-3 and the pedal

returns to its original position.

¶Step down the clamping jaw open/close control

pedal 7-2 to the first gear and the clamping jaw will

open.

1 695 108 073 2016-07-27| Bosch Automotive Service Solutions srl

36 | Start Line MS 201 | Initial commissioningen

7. Operation

!The following information must be read, and will be

helpful to the operator to simplify the steps needed

for operation and reduce unnecessary trouble.

7.1 Safety notice

!The MS 201 is intended to be used only to

mount/demount passenger car tires (see the section

"Technical data").

!If an accident happens, shut off the MS 201

immediately.

$Disconnect mains plug.

$Turn off compressed air supply.

7.2 Check before use

1. Before operating the MS 201, always run the

bead breaking cylinder back and forward while

observing the lubricator to make sure it starts

feeding oil to the air passage. After you confirm

that the lubricator works normal, you can guarantee

each part of the air route system under perfect

lubrication.

2. Check the maintenance unit to ensure that the

pressure indicated on the pressure gauge of the

pressure-limiting valve is not less than 8bar.

3. Check whether the power supply connection is

correct.

7.3 Information about special rims and

tires

iSpecial process to be need for some special tires,

which different from the normal demount/ mount

process.

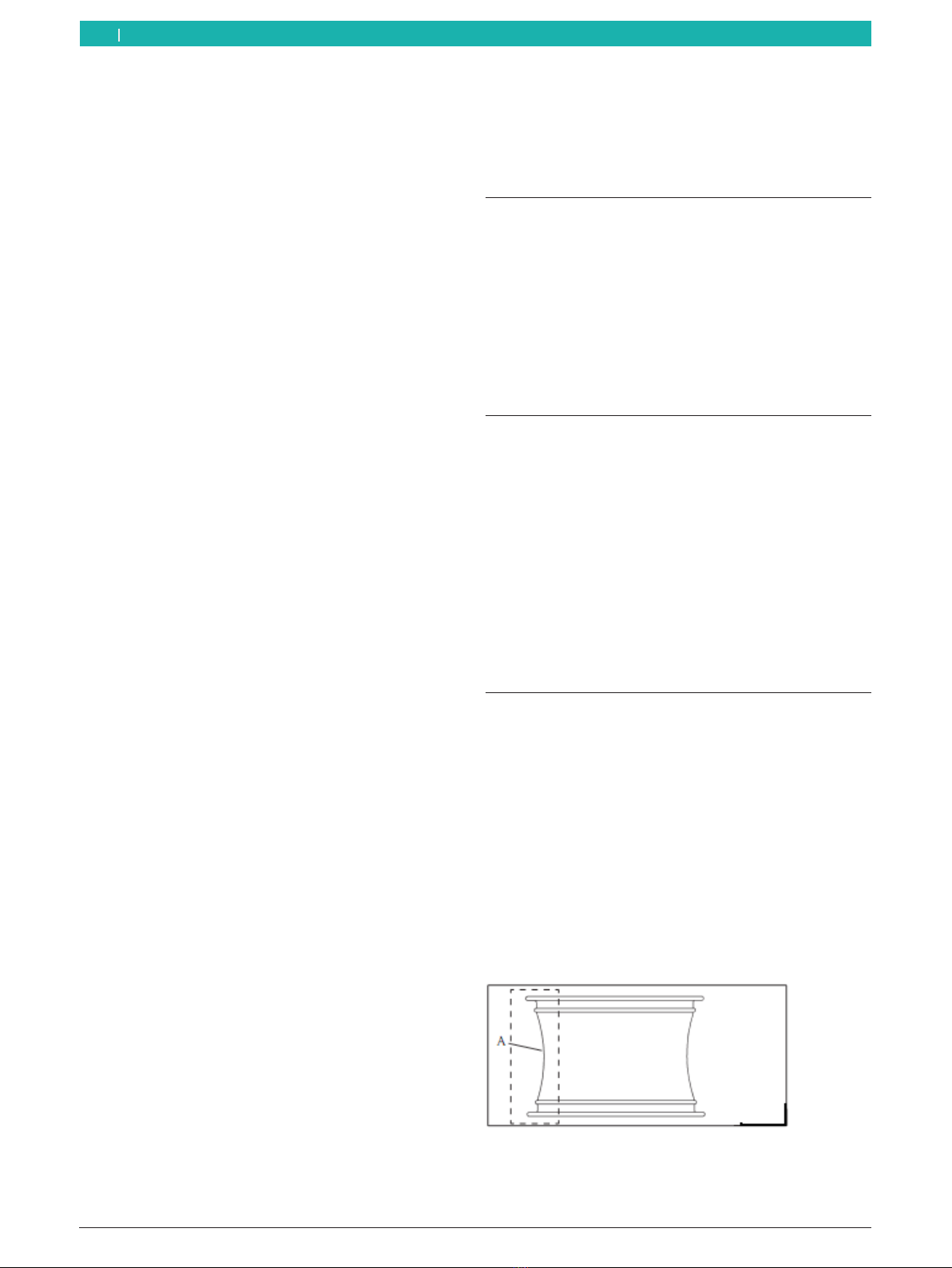

iAs shown in the figure below, some alloy rims have a

very shallow rim channel in the center of the rim. Or

the rim channel has no depression. These rims do

not meet the safety regulations for vehicular traffic

and transportation. In some countries, these types

of rim/wheel are not allowed in the market.

¶Depress the clamping jaws control pedal 7-2 to the

second position and the clamping jaws immediately

stop.

¶Depress the clamping jaws control pedal 7-2 to the

third position and the clamping jaws close.

¶When the mounting arm is at the innermost position,

it is released and tool head will drop.

¶When the mounting arm is at the middle position, it

is released and the tool head will move up.

¶When the mounting arm is at the outermost

position, the mounting arm and tool head are

locked.

Maintenance unit

¶Pressure-limiting valve 13-1: Pull out the knob on

the top of the pressure-limiting valve A. Clockwise/

counterclockwise turning can adjust the supply

pressure to the MS 201. Press down the knob A

after adjustment.

¶Water separator 13-2: Clockwise/counter clockwise

turning knob B at the lower end of water separator

can deflate the water in the water cup.

¶Lubricator 13-3: Turning the knob at the top end of

the lubricator. Clockwise/counter clockwise turning

can adjust the oil feeding speed of the lubricator.

Note

¶The supply pressure should be in the range of

8-10bar.

¶Regularly vent the water in the water separator.

¶Move the blade cylinder back and forward,

and observe the condition of lubricator. Before

operating, ensure that oil will be fed each day.

Operation | Start Line MS 201 | 37 en

1 695 108 073 2016-07-27|Bosch Automotive Service Solutions srl

!Pay special attention when demounting/mounting

tire that the rim or tire are not damaged.

!In the process of inflating the tire, there is a risk that

the tire may burst.

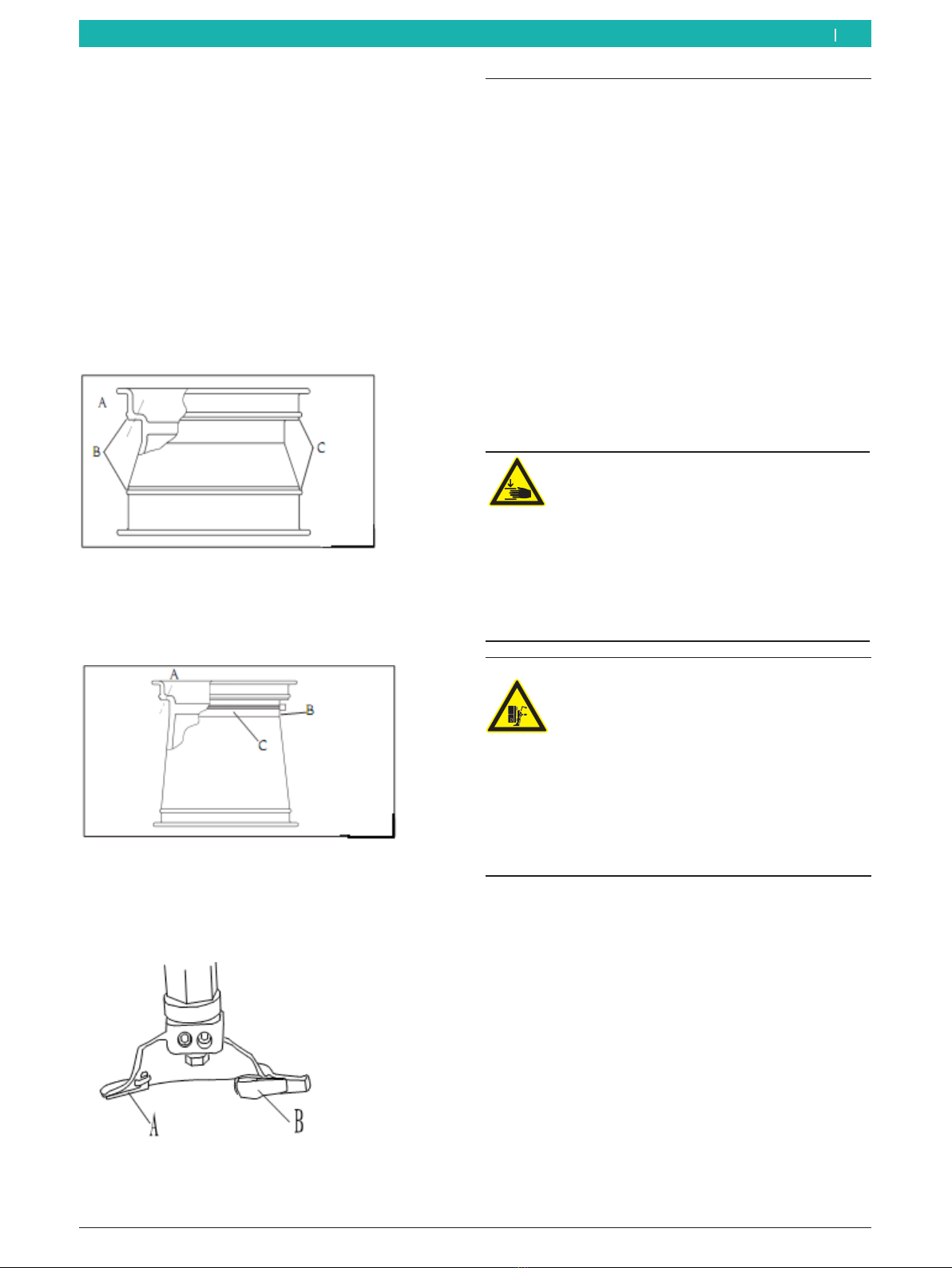

!The cross-section of some rims is that shown in the

figure below. The C position is very deep on these

rims. B is higher than A here. When you break the

bead of this type of tire, you must press the bead,

since it must be lower than the B position. When

mount the tire, the bead opposite to the mounting

head must over B point. At this moment, the bead

can be led into the groove at the middle of the rim.

!Some wheels have the tire pressure inspect system

as figure below. Do not damage the tire pressure

monitoring system when mounting/demounting

tires.

iTo protect the rim, the mounting head plastic cover

should be changed twice a month. If damaged, these

plastic parts should be changed at once.

7.4 Unseating the tire bead

!Not using the grease will seriously damage the tire.

Please use the special grease.

!Remove all balance weights on the rim.

iBefore demounting and re-mounting the tire, check

for signs of wear on all protective plastic parts.

Replace the wheel-guard hoods if necessary.

iAlways establish the rim and tire data prior to

removal/mounting. The method of attachment,

pressure and accessories required can then be

planned in advance.

1. Check whether the tire has been deflated

completely. If not, you should deflate at first.

Warning – Risk of injury from trapping

hands between rim-chuck plate and tire.

As the tire moves, make sure that your hands

do not get caught between the tire and rim-

chuck plate.

¶Before starting, turn the rim-chuck plate to

a position where the rim-chuck claws are

at an angle of 45° to the machine housing.

WARNING – Risk of injury to extremities!

¶Use extreme caution when operating the

bead breaker arm in order to prevent limbs

from being crushed between the tire and

the bead breaker unit.

¶Never reach between the tire and the bead

breaker arm.

¶The clamping jaws on the turntable should

be closed completely.

¶Do not open the clamping jaws while

unseating the tire bead.

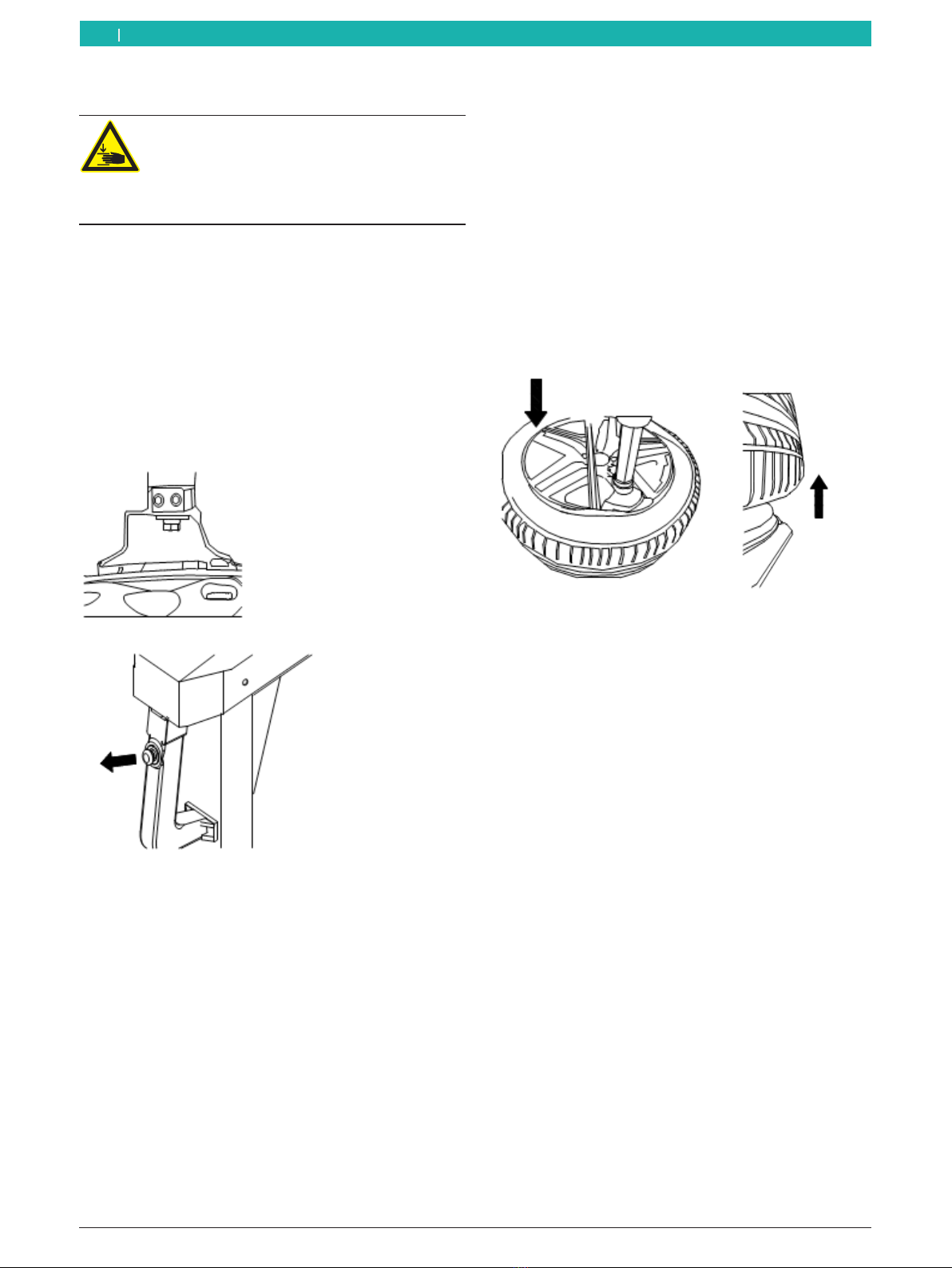

2. Lean the tire against the rubber wheel support.

3. The surface of the blade will stay about 1cm away

from the rim, and the blade should rest on the tire

properly.

!Pay attention to the position of the blade to prevent

it from touching the rim after bead breaking.

1 695 108 073 2016-07-27| Bosch Automotive Service Solutions srl

38 | Start Line MS 201 | Operationen

4. Depress the blade control pedal 7-3 to make the

blade start working.

5. When the bead is broken, release the pedal at once.

6. Rotate the tire until the edge of the tire is detached

from the rim and repeat at the other side.

7. Apply lubricant to the tire.

!Not using the grease will seriously damage the tire.

Please use the special grease.

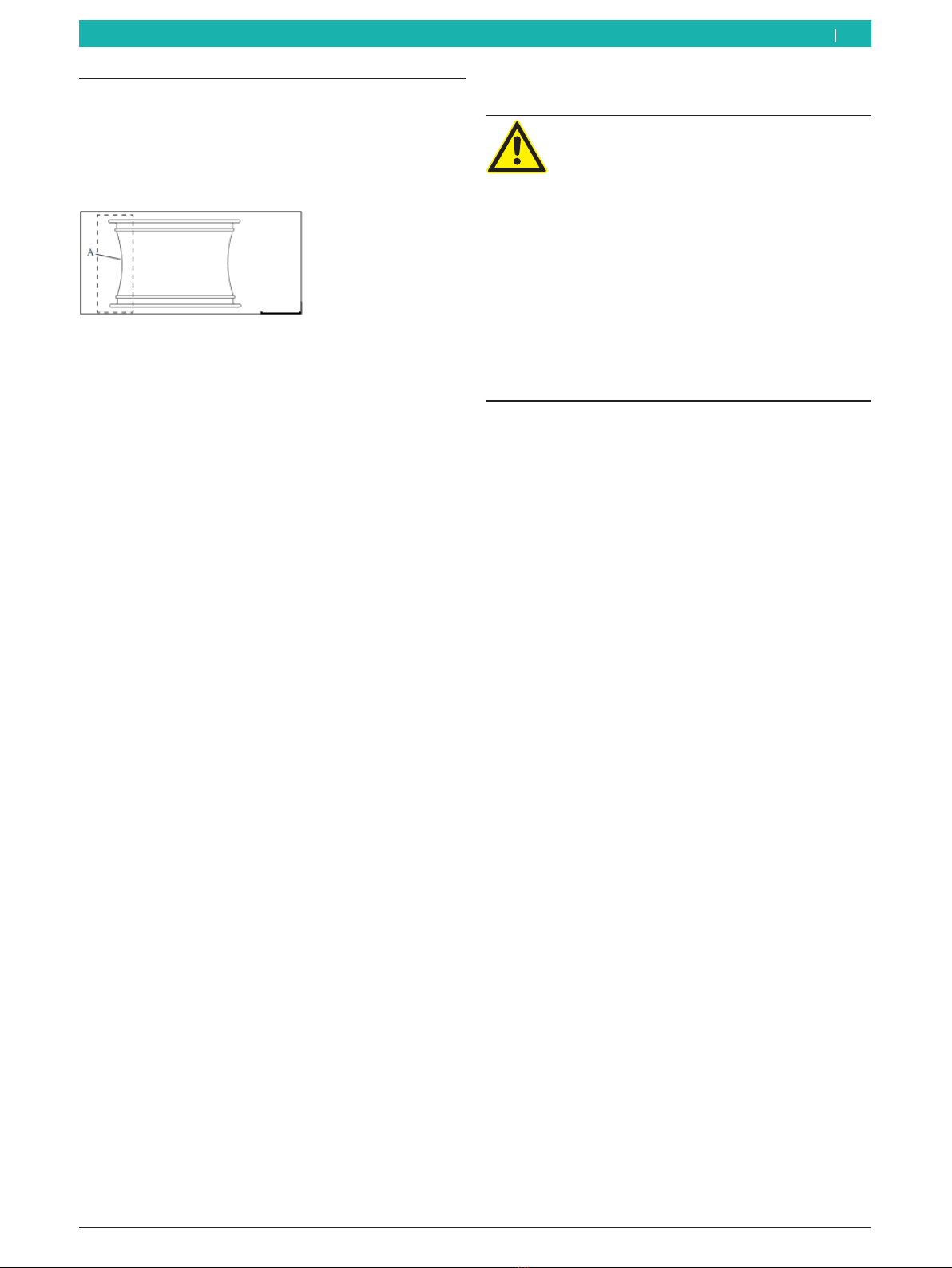

7.5 Rim location direction

How to decide from which side of the wheel to

demount tire?

1. When fix the wheel, the side of standard rim will

upward as figure.

2. Measure three dimension of A, B and C.

3. When fix the rim, the smallest size of C must be

positioned at the top position.

Operation | Start Line MS 201 | 39 en

1 695 108 073 2016-07-27|Bosch Automotive Service Solutions srl

7.6 Clamping the rim

!When the mounting arm swings out, no one is

allowed in the range of its movement.

¶Depress pedal 7-1, swing out the mounting arm and

clean the turntable.

!When clamping the tire, it is absolutely forbidden

to put your hand under the tire. To clamp the tire

correctly, you should position the tire at the very

center of the turntable.

!One operator is enough to position the tire on the

turntable if the weight is less than 25kg.

If the weight is 25kg-50kg, 2 persons will be

needed.

You will need to use the tire lifting device if the

weight exceeds 50kg.

7.6.1 Clapping the rim from the outside:

1. Depress the clamping jaws control pedal 7-2 to open

the clamping jaws.

2. Place the tire on the clamping jaws, while pressing

down the rim.

3. Place the tire on the turntable, and depress the

clamping jaws control pedal 7-2 until the rim is

clamped.

!Make sure the rim is clamped securely.

7.6.2 Clamping the rim from the inside:

1. Close the clamping jaws on the turntable.

2. Place the tire on the turntable, and the press the

pedal until the rim is clamped.

!Make sure the rim is clamped securely.

7.7 Demounting the tire

Warning: Risk of damage to the tire and rim!

Excessive contact pressure may cause

internal or external tearing in the tire. The rim

may become scratched or dented.

¶Follow the mounting and demounting

instructions of Wdk (obtainable in German

and English):

$Criteria catalog.

$Tire overheating.

¶Adjust the pressure to the type of tire.

¶Use the rim guard for easily damaged rims

(e.g. alloy rims).

Additional information on mounting runflat and UHP

tires.

Warning: Risk of damage to runflat and UHP

tires!

Danger of tire rupture (on the inside/outside)

from working at high speed and when the tire

is cold.

¶Tire core temperature at least 15°C.

¶Before demounting the tire, heat it with an

electric tire heater.

1 695 108 073 2016-07-27| Bosch Automotive Service Solutions srl

40 | Start Line MS 201 | Operationen

7.7.1 Positioning of the mounting head

Warning – Risk of hand injuries!

There is a risk of crushing hands when

rotating the rim-chuck plate.

¶Do not reach between the tire and the rim

with your fingers.

1. Press the top bead by hand to leave the space for

positioning the mounting head.

2. Depress the mounting arm control pedal to move the

mounting arm to the work position.

3. Push the button on the mounting arm lock plate to

release the hexagonal shaft.

4. Move the mounting head to the work position. The

plastic part at the nose of the mounting head should

be in contact with the rim.

5. Push the button on the mounting arm lock plate lock

the hexagonal shaft.

7.7.2 Lever the top bead over the rim flange

1. Hold the bead-lifting lever firmly while keeping

space for the mounting head.

iIf the space is not adequate, please refer to the

"Operation tips" section. The tips in the "Operation

tips" section will ensure successful bead breaking.

2. Check that the mounting head has grasped the tire

bead fully.

iIf there is inner tube, please turn the valve 10cm

away to the right and then proceed. This will prevent

damaging the inside of the tire.

Operation | Start Line MS 201 | 41 en

1 695 108 073 2016-07-27|Bosch Automotive Service Solutions srl

7.7.3 Demounting the top bead

1. Depress the pedal 7-4 and rotate the wheel until the

top bead is completely detached from the rim.

2. At the same time, lifting the bottom bead can help

demount the top bead.

3. If the bead slips back into the rim channel during

this process, you can take the measures described

in the "Operation tips" section to demount the top

bead.

7.7.4 Demounting the bottom bead (with the aid of

the mounting head)

1. If the tire has an inner tube, remove it.

2. Use the same process for the lower tire bead until

the tire is demounted successfully.

3. Lever the tire over the upper rim flange with the aid

of the bead-lifting lever.

4. Depress the pedal 7-4, and rotate the wheel until it

is fully detached from the rim.

7.7.5 Removing wheels

1. Swing the mounting arm to the back.

2. Remove the tire.

7.8 Mounting the tire

Risk of accident from damaged rims and

tires!

If the tire or rim is damaged during mounting,

this may lead to dangerous or life-threatening

situations when driving.

¶The tire must bemounted by trained

persons only.

¶Follow the mounting and demounting

instructions of Wdk (obtainable in German

and English):

$Criteria catalog.

$Tire overheating.

¶Do not subject tires and rims toexcessive

force.

¶Set a low speed of rotation when mounting

tires on critical wheels.

¶Use a sufficient amount of lubricant.

¶Stop the fitting process immediately in the

event of any anomalies, such as abnormal

noise.

Additional information on mounting runflat and UHP

tires.

Warning: Risk of damage to runflat and UHP

tires!

Danger of tire rupture (on the inside/outside)

from working at high speed and when the tire

is cold.

¶Tire core temperature at least 15°C.

¶Before demounting the tire, heat it with an

electric tire heater.

iRemove all of the balance weights from the wheel

rim.

1 695 108 073 2016-07-27| Bosch Automotive Service Solutions srl

42 | Start Line MS 201 | Operationen

7.8.1 Selecting the tire

!Before selecting the tire, you should know all

of its technical features, technical parameters,

characteristics and the safety grade of the tire. The

related information is marked on the sidewall of the

tire.

iBefore mounting the tire, please change the valve

insert to an insert for a tubeless tire.

$Confirm whether the tire parameters match the

parameters of the rim. Also make sure that the

rim is not deformed and the center hole is not

damaged. At the same time, ensure that the

surface of the rim has no rust or cracks and that

there are no burrs at the nozzle.

$Confirm that the tire is in perfect condition and

without any damage.

7.8.2 Preparing the tire

1. Lubricate the bead with the special tire grease.

2. Place the tire on the rim at a tilt angle of 45 degrees.

7.8.3 Positioning of the mounting head

¶Depress the pedal pedal 7-1 to move the mounting

head to the initial work position.

iIf the rim has not been changed, the mounting head

will automatically return to the correct working

position.

7.8.4 Mounting the lower tire bead

1. Simultaneously place the bottom bead under the

nose of the mounting head and on the end of the

mounting head.

2. Use your hand to press the tire slightly to guide the

tire into the rim channel.

3. Rotate the turntable clockwise to mount bottom

bead.

7.8.5 Mounting the top bead

Warning – Risk of hand injuries!

Your hand may be crushed if it is between the

rim and the mounting head when the hexagon

shaft returns to its work position.

¶Do not reach between the tire and the rim

with your fingers.

¶Do not place your hand on the tire.

¶Remove all objects that may endanger

operators, e.g. bracelets and loose

clothing, etc.

¶Keep your hands and the other parts of

your body away from the mounting head as

far as possible.

1. Simultaneously place the top bead under the nose of

the mounting head and on the end of the mounting

head.

2. Press the tire bead and guide it into slot in the steel

hook.

!Now, the tire bead cannot slide out of the mounting

head.

iWhen mounting/demounting tires, the tire rotates

clockwise. If the tire jams during the process, please

stop working and rotate the tire counterclockwise to

release the jam.

Operation | Start Line MS 201 | 43 en

1 695 108 073 2016-07-27|Bosch Automotive Service Solutions srl

7.9 Procedure for mounting/demounting

alloy rims

iOn some alloy rims, the rim channel at the middle

of the rim is very shallow or there is no rim channel.

The figure below shows this:

iThe demounting process for the wheel and

demounting the top tire bead differ, since the hook

cannot catch a suitable position. Depending on the

situation, the operator needs to find best position,

i.e. where the resistance for the wheel is the lowest.

8. Inflation

Inflation can lead to hazardous situations.

The user must undertake the necessary

precautions to ensure safety.

¶Wear hearing protection.

¶Wear safety goggles.

¶To protect the user from potential

dangerduring inflation, only inflate the tire

to a maximum 3.5bar while the tire is on

the rim-chuck plate.

¶Avoid any distractions while inflating.

Constantly observe the tire inflation

pressure on the pressure gauge to avoid

over-inflation.

¶When inflating, avoid all distractions.

!During operation, the noise may reach 85dB(A), for

this reason, the operator must wear the appropriate

protective gear.

!The MS 201 is equipped with a pressure-limiting

valve, but if the condition of tire and rim is not good

or the operation is performed incorrect, there is still

the possibility of the tire bursting.

!Do not exceed the maximum pressure specified by

the manufacturer.

During the inflation process, the operator should keep

away from the tire as far as possible.

¶Carefully check if the size of the rim is same to the

size of the tire.

¶Check the wear state of the tire or whether there is

damage or not.

¶During the inflation process, frequently check the

pressure inside the tire.

¶The max. inflation pressure is 3.5bar, do not exceed

manufacturer's recommended pressure under any

circumstances.

¶Keep hands and body away from the tire.

1 695 108 073 2016-07-27| Bosch Automotive Service Solutions srl

44 | Start Line MS 201 | Inflationen

8.1 Inflating tubeless tires

1. Ensure that the rim is held securely on the turntable

and that the mounting head and tire pressing disk

are not in contact with the tire. If possible, they

should be positioned to the farthest point.

2. Install a new valve in the rim.

3. Make sure that the entire tire has been lubricated.

4. Remove the cap from the valve and place the

inflation gun on the top of the insert to inflate the

tire.

5. Interrupt the inflation process occasionally and

check the pressure in the tire until the specified

value is reached. Do not exceed the max. pressure.

The pressure must not be greater than 3.5bar under

any circumstances.

iTubeless tires need a relatively high volumetric flow

of air. If air flow is inadequate, the bead will not

pass over the hump. To increase the air flow, you

can take out the valve insert.

6. Check the connection between the tire bead and

rim.

iThe connection between the tire bead and rim must

be perfect. If there is problem, you must deflate the

tire, unseat the tire bead again and relubricate the

tire bead. Rotate the tire on the rim and then inflate

once again.

7. Screw in the valve insert.

8. Connect the inflation gun and then press the deflate

button to remove the residual air.

9. Attach the valve cap.

8.2 Inflating tubed tires

1. Ensure that the rim is held securely on the turntable

and that the mounting head and tire pressing disk

are not in contact with the tire.

iIf possible, they should be positioned to the farthest

point.

2. Make sure that the entire tire has been lubricated

3. Remove the valve, place the inflation gun head on

the head of the air valve and depress the inflation

pedal to inflate the tire.

4. Push the valve on the tube to release the air

between the tube and tire. Otherwise, the tube will

be damaged.

5. Interrupt the inflation process occasionally and

check the pressure in the tire until the specified

value is reached. Do not exceed the max. pressure.

The pressure must not be greater than 3.5bar under

any circumstances.

6. Screw in the valve insert.

7. Connect the inflation gun and then press the deflate

button to remove the residual air.

8. Attach the valve cap.

Table of contents

Other Beissbarth Tyre Changer manuals