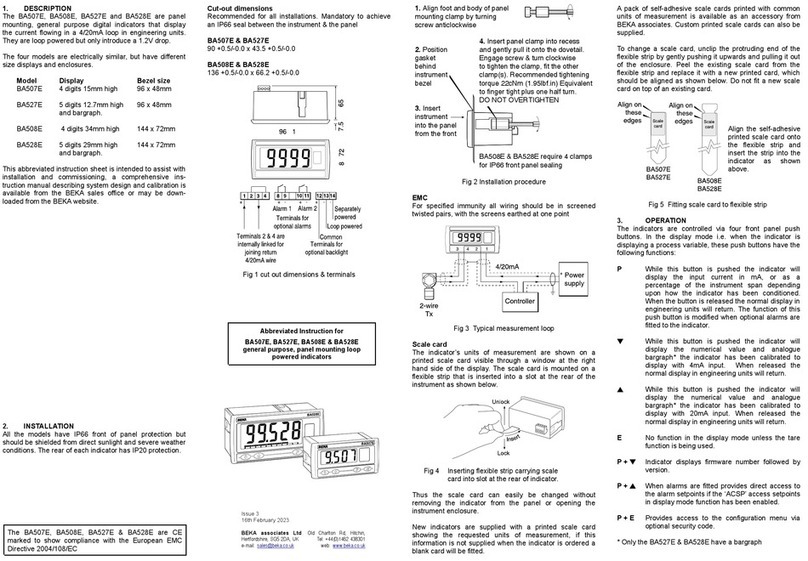

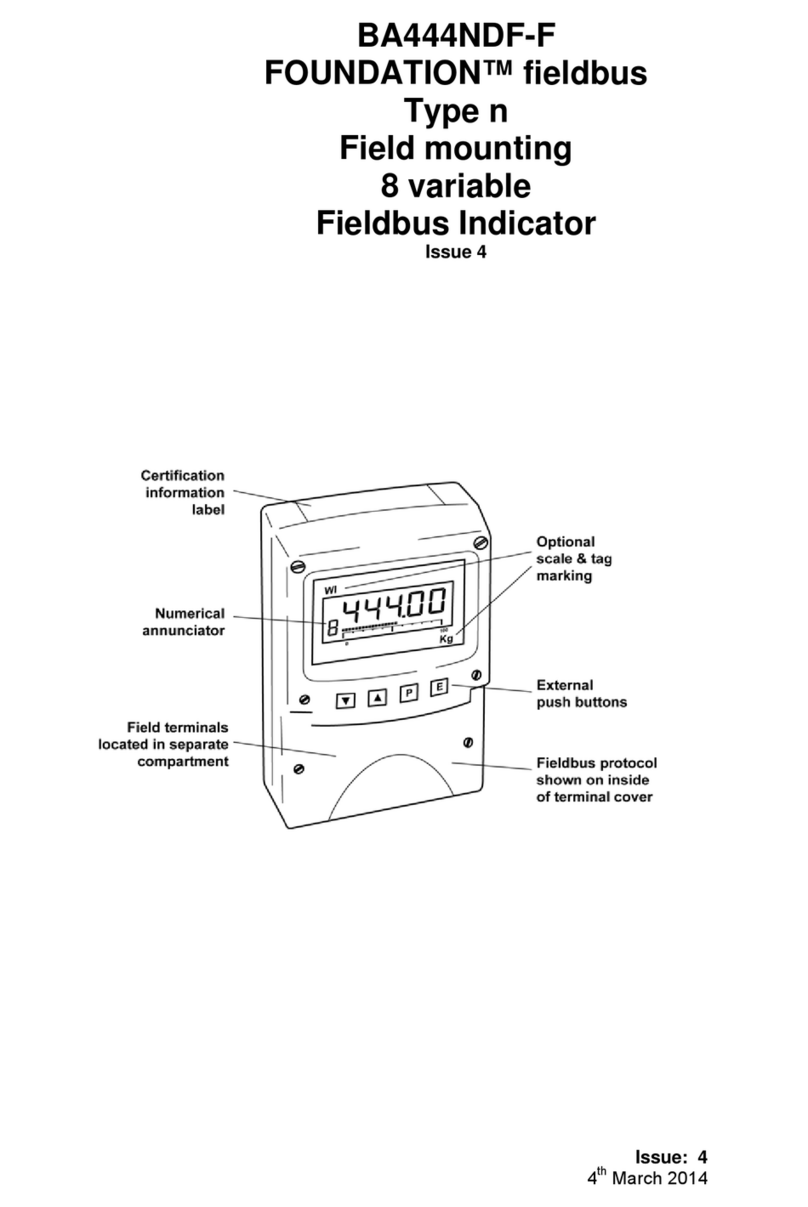

2.1 Controls

The indicators are controlled and calibrated via four

front panel push buttons located below the display.

In the display mode i.e. when the indicator is

displaying a process variable, these push buttons

have the following functions:

PWhile this button is pushed the indicator

will display the input current in mA, or as a

percentage of the instrument span

depending upon how the indicator has

been conditioned. When the button is

released the normal display in engineering

units will return. The function of this push

button is modified when optional alarms

are fitted to the indicator.

▼While this button is pushed the indicator

will display the numerical value and

analogue bargraph* the indicator has been

calibrated to display with a 4mAΦinput.

When released the normal display in

engineering units will return.

▲While this button is pushed the indicator

will display the numerical value and

analogue bargraph* the indicator has been

calibrated to display with a 20mAΦinput.

When released the normal display in

engineering units will return.

ENo function in the display mode unless the

tare function is being used.

P + ▼Firmware number followed by version.

P + ▲Direct access to the alarm setpoints when

optional alarms are fitted to the indicator

and the ‘ACSP’ access setpoints in display

mode function has been enabled.

P + E Access to configuration menu via optional

security code.

Note: * BA327E-SS only

ΦIf the indicator has been calibrated

using the CAL function, calibration

points may not be 4 and 20mA.

3. INTRINSIC SAFETY CERTIFICATION

Both indicators have ATEX and IECEx gas and dust

certification. This section of the instruction manual

describes ATEX gas certification. ATEX dust and

IECEx approvals are described in Appendixes 1 and 2.

3.1 ATEX gas certification

Both models have been issued with common

EC-Type Examination Certificate

ITS14ATEX28077X by Notified Body Intertek

Testing and Certification Ltd. This confirms

compliance with harmonised European standards

and has been used to confirm compliance with the

European ATEX Directive for Group II, Category

1G equipment.

The indicators bear the community mark and

subject to local codes of practice may be installed

in any of the European Economic Area (EEA)

member countries. ATEX certificates are also

acceptable for installations in Switzerland.

This section of the instruction manual describes

ATEX installations in explosive gas atmospheres

conforming with EN 60079-14 Electrical

Installations design, selection and erection. When

designing systems for installation outside the UK

the local Code of Practice should be consulted.

3.2 Zones, gas groups and T rating

The indicators have been certified Ex ia IIC T5

Ta = -40ºC to 70ºC. When connected to a suitable

system the indicator may be installed in:

Zone 0 explosive gas air mixture

continuously present.

Zone 1 explosive gas air mixture likely

to occur in normal operation.

Zone 2 explosive gas air mixture not

likely to occur, and if it does

will only exist for a short time.

Be used with gases in groups:

Group A propane

Group B ethylene

Group C hydrogen

In gases that may be used with equipment having

a temperature classification of:

T1 450oC

T2 300oC

T3 200oC

T4 135oC

T5 100oC

At ambient temperatures between -40 and +70oC.

This allows the indicators to be installed in all gas

Zones and to be used with most common industrial

gases.

4