5

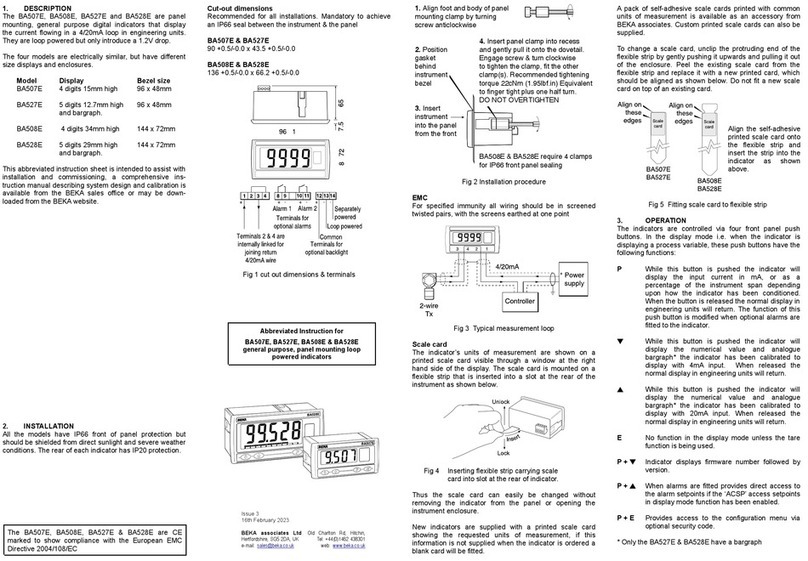

3.3 Pulse input terminals

The BA334D rate totaliser has two alternative

pairs of input terminals enabling the instrument

to count pulses from a wide variety of sources.

Note: Only one pair of input terminals may be

used at one time.

3.3.1 Voltage pulse input

Terminals 3 and 4 are intended for connection

to a voltage pulse source. In Europe, sources

of energy which do not generate more than

1.5V; 100mA and 25mW are, for intrinsic safety

purposes, considered to be simple apparatus

(Clause 5.4 of EN50 020:1994).

Although the BA334D indicator does not itself

comply with the requirements for simple

apparatus, the EC-Type Examination

Certificate specifies that under fault conditions

the voltage, current and power at terminals 3 &

4 will not exceed those specified for simple

apparatus. This allows these input terminals

to be connected to any certified intrinsically

safe apparatus or circuit providing that the

output parameters of the apparatus or circuit

do not exceed: Uo = 28V dc

Io = 100mA dc

Po = 0.7W

The certified intrinsically safe voltage pulse

output of a flowmeter mounted in a hazardous

area, or the output of a certified magnetic pick-

off mounted in a hazardous area may be

directly connected to these terminals providing:

The output parameters of the device do

not exceed the figures shown above.

The device can withstand a 500V rms

insulation test to earth for one minute.

The BA334D EC-Type Examination Certificate

specifies that the maximum equivalent

capacitance and inductance between the two

pulse input terminals 3 and 4 is:

Ci = 20nF

Li = 20µH

To determine the maximum permissible cable

parameters these figures must be subtracted

from the maximum permitted cable parameters

specified for the device connected to terminals

3 and 4.

The BA334D system certificates specify

maximum permitted cable parameters when a

28V 300ΩZener barrier or galvanic isolator is

connected to these terminals.

3.3.2 Contact, 2-wire proximity detector

or open collector input

Terminals 5 and 6 are intended for connection

to a switch contact, a certified open collector

output or a certified intrinsically safe 2-wire

NAMUR proximity detector. The output safety

parameters are:Uo = 10.5V dc

Io = 9.2mA dc

Po = 24mW

and the maximum permitted external

capacitance and inductance is:

Co = 2.0µF

Lo = 248mH

Mechanically operated switch contacts comply

with the requirements for simple apparatus.

Providing the switch and the BA334D are both

located in the same hazardous area, the switch

may be connected directly to terminals 5 & 6.

This also applies to most magnetically

operated reed switches used in turbine

flowmeters.

Similarly, certified intrinsically safe open

collector outputs may be directly connected to

terminals 5 and 6

A certified intrinsically safe 2-wire proximity

detector may also be connected directly to

terminals 5 & 6 providing the input safety

parameters of the detector are less than the

output parameters of terminals 5 & 6. For

guidance the BA334D system certificates

specify some of the intrinsically safe 2-wire

proximity detectors that may be used.

In all cases the device and circuit connected to

terminals 5 & 6 must be capable of

withstanding a 500V rms insulation test to

earth for one minute.

The maximum input safety parameters for

terminals 5 & 6 are:

Ui = 28V dc

Ii = 100mA dc

Pi = 0.7W

and the internal capacitance and inductance is:

Ci = 20nF

Li = 20µH

which allows Zener barriers and galvanic

isolators to be connected to these terminals.

The BA334D system certificates specify the

maximum permitted cable parameters when a

28V 300ΩZener barrier or galvanic isolator is

used to transfer a pulse from the safe area to

the BA334D in a hazardous area.