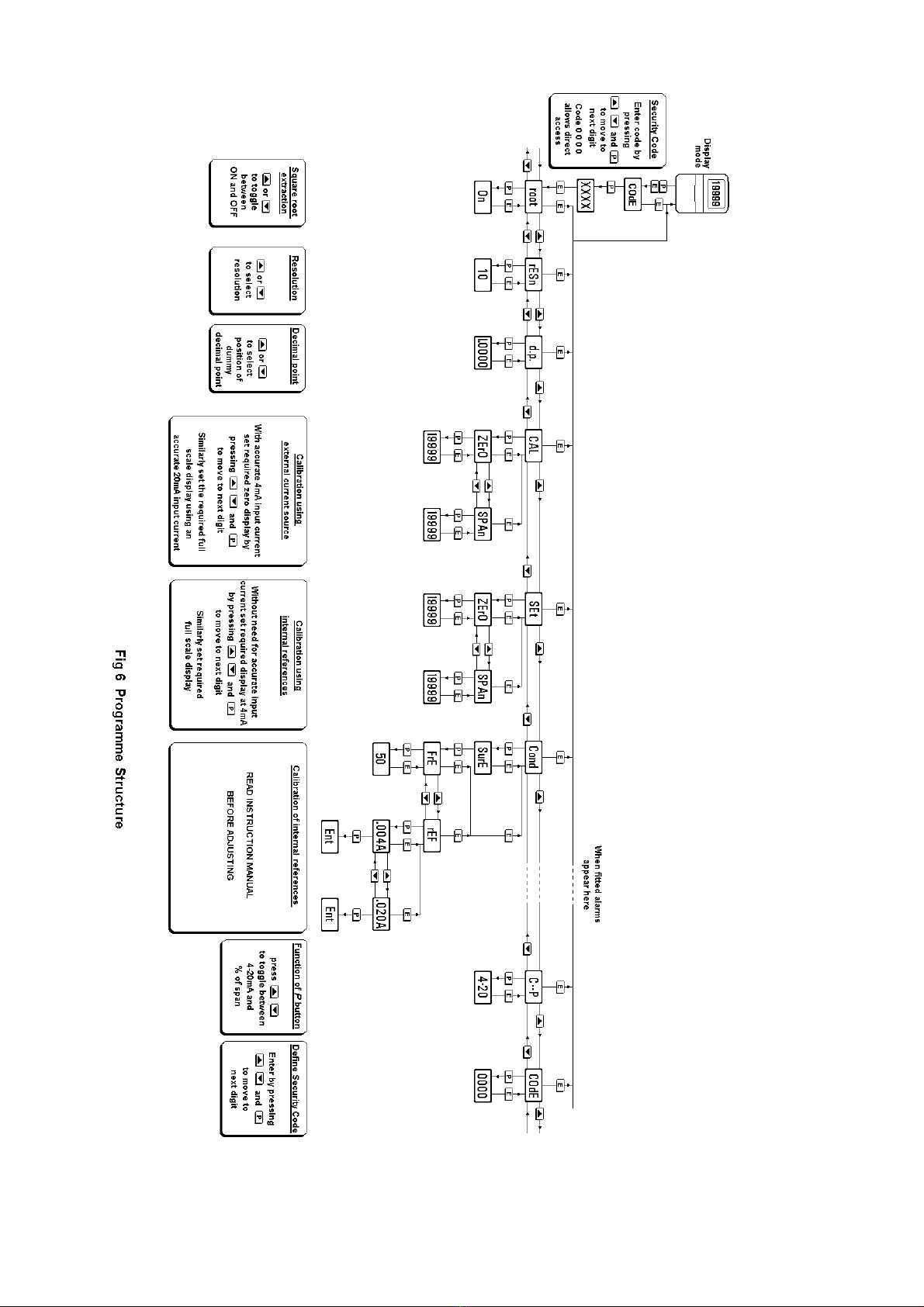

5.2 Root extractor: root

This function is primarily intended for use with

differential flowmeters which have a square law

4/20mA output. To activate the square root

extractor select 'root' from the menu and press P

which will reveal if the function is 'On' or 'OFF'. If

the function is set as required, press Eto return to

the menu, or press the Up or Down button to

change the setting, followed by the E button to

return to the main menu.

For reference, the following table shows the output

current from a non-linearised differential flowmeter.

% of full flow Current output mA

2.5 4.01

10.0 4.16

25.0 5.00

50.0 8.00

75.0 13.00

100.0 20.00

5.3 Resolution: rESn

This function defines the resolution of the least

significant display digit. Decreasing the display

resolution can improve the readability of a noisy

signal. Select 'rESn' from the menu and press P

which will reveal the current display resolution. To

change the resolution press the Up or Down button

to select 1, 2, 5 or 10 digits, followed by the E

button to return to the menu.

5.4 Position of the decimal point: d.P.

A dummy decimal point can be positioned between

any of the digits or may be absent. To position the

decimal point select 'd.P.' from the menu and press

P . The decimal point can then be moved or

turned off by pressing the Up or Down push-button,

followed by Eto return to the menu.

5.5 Calibration of display using an external

current source: CAL

This function enables the zero and span of the

indicator to be adjusted using an external

calibrated current source. When used with an

accurate traceable current source this is the

preferred method of calibration.

To calibrate the indicator select 'CAL' from the

main menu and press P. The indicator will display

'ZErO' which is a request for a 4mA input current.

Adjust the external current calibrator to 4.000mA

and again press P which will reveal the current

zero display. Each digit of the indicator display

can be changed by pressing the Up or Down

buttons. When the first digit is correct,

pressing Pwill transfer control to the next digit.

When all the digits have been adjusted, press Eto

enter the new zero. The indicator will display 'Ent'

for a few seconds while the information is being

stored in memory, and will then return to the 'ZErO'

prompt .

To adjust the display at 20mA, press the Up button

which will cause the indicator to display 'SPAn'.

Adjust the external current calibrator to 20.000mA

and again press P which will reveal the existing

full scale display. Each digit of the indicator

display can be changed by pressing the Up or

Down buttons. When the first digit is correct,

pressing Pwill transfer control to the next digit.

When all the digits have been adjusted press E to

enter the new span. The indicator will display 'Ent'

for a few seconds while the information is being

stored in memory, and will then return to the 'SPAn'

prompt. Finally press Eagain to return to the main

menu.

This function may also be used when calibrating a

complete loop from primary element to indicator

display e.g. when the indicator is displaying the

output from a resistance thermometer transmitter.

5.6 Calibration using internal references: SEt

This function enables the zero and span of the

indicator to be adjusted without the need for an

accurate external current source, or for

disconnection from the 4/20mA loop. The

accuracy of this method depends upon the

accuracy of the internal references which should be

regularly calibrated as described in section 5.7.2

To calibrate the indicator select 'SEt' from the main

menu and press P. The indicator will display

'ZErO'; pressing Pagain will reveal the current

display at 4mA. Each digit of the indicator display

can be changed by pressing the Up or Down

buttons. When the first digit is correct pressing P

will transfer control to the next digit. When the

least significant digit has been adjusted, press Eto

return to the 'ZErO' prompt which completes the

adjustment.

To adjust the display at 20mA, press the Up button

which will cause the indicator to display 'SPAn'.

pressing P again will reveal the indicator display.

Each digit can be changed by pressing the Up or

Down buttons. When the first digit is correct,

pressing Pwill transfer control to the next digit.

When the least significant digit has been adjusted

press E to return to the 'SPAn' prompt followed by

Eto return to the menu.

8