9

5.5 Dummy trailing zero: dZErO

The BA526C digital display can show any number

between -19999 and 19999. If a larger number is

required a trailing dummy zero can be activated

which extends the display range from -19990 to

99990 The last digit is a dummy so the maximum

resolution is 10 digits i.e. the last digit is always 0.

To change the status of the trailing dummy zero

select 'dZErO' from the main menu and press P

which will reveal if the dummy zero is 'On' or 'OFF'.

If the function is set as required, press Eto return

to the main menu, or press the Up or Down button

to change the setting, followed by the Ebutton to

return to the main menu.

After activating the dummy trailing zero, care

should be taken to ensure that the digital display

does not overrrange.

5.6 Position of the decimal point: d.P.

A dummy decimal point can be positioned between

any of the digits, including the dummy trailing

zero, or may be absent. To position the decimal

point select 'd.P.' from the menu and press P.

The decimal point can then be moved or turned off

by pressing the Up or Down push-button, followed

by Eto return to the main menu.

5.7 Bargraph display: bAr

This function enables the 4/20mA input to be

displayed as a column or a single segment on one

or both of the 100 segment bargraphs. When

optional alarms are fitted the right hand bargraph

always displays the alarm setpoints.

To change the bargraph display parameters select

'bAr' from the main menu and press Pwhich will

reveal if the BA526C is programmed to display a

column 'Col' or a single segment 'SEg'. The

setting can be changed by pressing the Up or

Down buttons. Pressing Pagain will show if the

BA526C is programmed to display the input

current on both bargraphs 'dUAL' or on just the left

hand bargraph 'SnGL'. Again pressing the Up or

Down buttons will change the setting. At any point

in the procedure pressing the Ebutton will return

the instrument to the main programme menu.

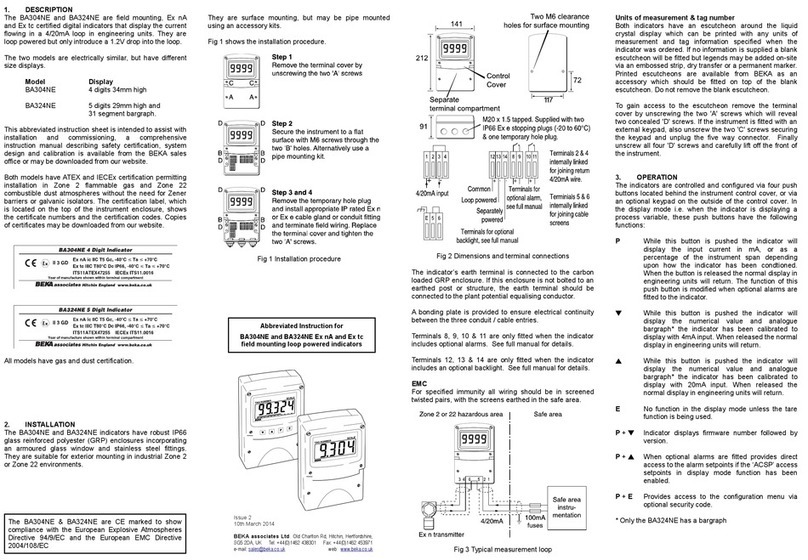

5.8 Calibration using an external

current source: CAL

This function enables the zero and span of the

digital display to be adjusted using an external

calibrated current source. When used with an

accurate traceable current source this is the

preferred method of calibration.

The analogue bargraph is automatically calibrated

when the digital display is calibrated, therefore no

separate adjustments are required. Fig 7 shows

the analogue display resulting from various digital

display calibrations.

To calibrate the indicator select 'CAL' from the

main menu and press P. The indicator will display

'ZErO' which is a request for a 4mA input current.

Adjust the external current calibrator to 4.000mA

and again press Pwhich will reveal the current

zero display. Each digit, except the dummy zero if

activated, of the indicator display can be changed

by pressing the Up or Down buttons. When the first

digit is correct pressing Pwill transfer control to the

next digit. When all the digits have been adjusted,

press Eto enter the new zero. The indicator will

display 'Ent' for a few seconds while the

information is being stored in memory, and will

then return to the 'ZErO' prompt. To adjust the

digital display at 20mA, press the Up button which

will cause the indicator to display 'SPAn'. Adjust

the external current calibrator to 20.000mA and

again press Pwhich will reveal the existing full

scale display. Each digit of the indicator display,

except the dummy zero if activated, can be

changed by pressing the Up or Down buttons.

When the first digit is correct pressing Pwill

transfer control to the next digit. When all the

digits have been adjusted press Eto enter the new

span. The indicator will display 'Ent' for a few

seconds while the information is being stored in

memory, and will then return to the 'SPAn' prompt.

Finally press Eagain to return to the main menu.

This function may also be used when calibrating a

complete loop from primary element to indicator

display e.g. when the indicator is displaying the

output from a level to current converter.