7

For maximum accuracy, the instrument should

be calibrated using an external traceable

current source with a resolution of at least 4µA.

However, when verification is not required, the

instrument may be fitted with an optional

internal calibrator which allows rapid calibration

without the need for external instruments or

disconnec-tion from the 4/20mA input current.

See section 8.2 for details.

6.1 Zero adjustment

Zero is defined as the number displayed by the

indicator with a 4.000mA input current, and may be

adjusted between -1000 and 1000. The zero

potentiometer has two ranges, 0 to 500 and 500 to

1000. Zero polarity is defined by the position of the

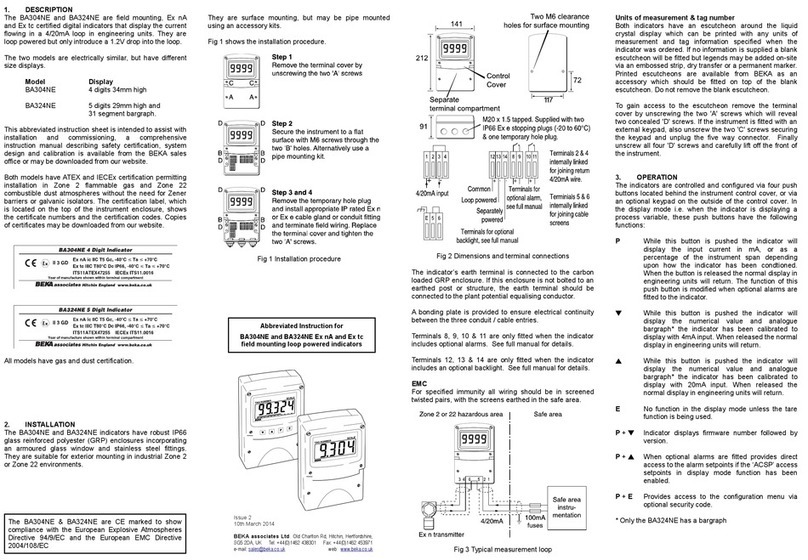

suppression / elevation links which are shown in

Fig 6.

Suppression / elevation links

Position Display with 4mA input

adjustable between

Elevation 0 and 1000

Suppression 0 and -1000

Zero link

Position Display with 4mA input

adjustable between

0 to 500 0 and 500

500 to 1000 500 to 1000

6.2 Span adjustment

Span is defined as the difference between the

number displayed with 4.000mA input, and the

number displayed with 20.000mA input. It is

adjustable between 0 and 1999 in four ranges. Fig

6 shows the position of the span links and the span

potentiometer.

Position of Instrument span

of span links adjustable between

000 to 500 000 and 500

or 500 to 1000 500 and 1000

or 1000 to 1500 1000 and 1500

or 1500 to 1999 1500 and 1999

6.3 Decimal point

A dummy decimal point may be displayed between

any of the four digits. The position or absence of

this decimal point is determined by the position of

the decimal point plug-in link shown in Fig 6.

When calculating the required span and zero

settings the decimal point should be ignored.

6.4 Reverse action

Normally the BA304ND display increases as the

input current increases, but this can be reversed.

Please contact BEKA associates for details.

6.5 Calibration example

The BA304ND is required to display:

25.0 with 4.000mA input

115.0 with 20.000mA input

i.e. A zero of positive 250 (Ignoring decimal point)

A span of 900 (Ignoring decimal point)

A decimal point in position 00.0

The following adjustments are required:

Step 1 The BA304ND is required to display a

positive zero therefore the

suppression / elevation links should be

put in the elevation position.

Step 2 The required zero is 250, therefore the

zero link should be put in the 0 to 500

position.

Step 3 The required span is 900, therefore the

span links should be placed in the 500

to 1000 position.

Step 4 The decimal point is required between

the two least significant digits,

therefore the decimal point link should

be placed in the 00.0 position.

Step 5 With 4.000mA input adjust the zero

potentiometer until the indicator

displays 25.0

Step 6 With 20.000mA input adjust the span

potentiometer until the indicator

displays 115.0

Step 7 Repeat steps 5 and 6 until both

calibration points are correct. The span

and zero controls are almost

independent so it should only be

necessary to repeat each adjustment

twice.

6.6 Over and under-range

If the indicator display range is exceeded, the three

least significant digits will be blanked. Under-range

is indicated by -1 and over-range by 1. If the

display range is not exceeded, the BA304ND will

produce accurate readings outside the 4/20mA

current range. Although not guaranteed, most

BA304ND indicators will operate between 3 and

25mA.