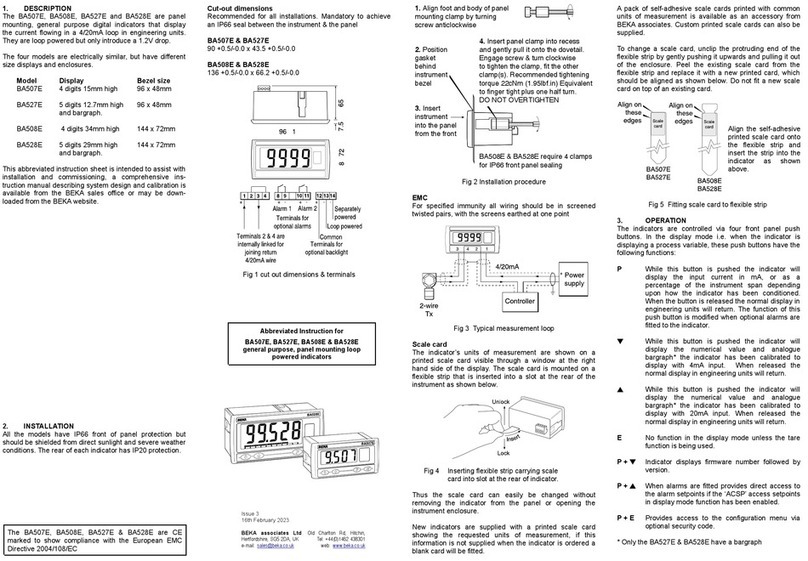

1. DESCRIPTION

The BA427 -SS is a rugged, intrinsically safe, loop

powered panel mounting Set Point Station which

enables the current flowing in a 4/20mA loop to be

manually adjusted via the front panel push buttons,

or an optional external rotary control. The main

application is the adjustment of a plant parameter,

such as a controller set point or an actuator position,

from within a hazardous process area.

Housed in a rugged stainless steel case, the

intrinsically safe BA427 -SS may be safely installed

in an x e, x p, x n or x t panel enclosure without

invalidating the panel enclosure's certification.

To simplify adjustment the Set Point Station

incorporates a 5 digit display and a 31 segment

bargraph which may be calibrated to show the

4/20mA loop current in any linear engineering units.

An optional factory fitted backlight, which may be

loop or separately powered, enables this display to

be read in all lighting conditions.

The BA427 -SS loop current is adjustable between

3 and 22mA but the range may be restricted if only

limited adjustment is required. In addition to the

output being continuously variable, five pre-set

output currents may be configured and subsequently

selected from the front panel push buttons. To

minimise plant disturbance the maximum output rate

of change may be defined.

The BA427 -SS has AT X and UK X intrinsic

safety certification for use in gas and dust hazardous

areas. Both certificates confirm that the front of the

instrument complies with x e, x p and x t ingress

and impact requirements, which in addition to normal

intrinsically safe applications, allows the BA427 -SS

to be installed in an x e, x p or x t panel

enclosure without invalidating the enclosure's

certification.

For international applications the BA427 -SS has

I C x gas and dust certification which is described

in Appendix 2.

2. OPERATION

This instruction manual describes AT X & UK X

system design and installation for use of the

BA427 -SS in a gas hazardous area. Please refer

to Appendix 1 for details of AT X & UK X dust

certification and to Appendix 2 for I C x certification.

Fig 1 shows a simplified block diagram of the

BA427 -SS manual Set Point Station. The 4/20mA

current flowing in the loop may be manually set at

any value between approximately 3 and 22mA using

the front panel & and * push buttons. Initially the

output current changes slowly, but after the button

has been pressed for five seconds the rate of

change accelerates to allow large changes to be

made quickly. The five pre-set outputs, which are

selectable via the instruments front panel push

buttons, allow the operator to quickly select

frequently used plant set points.

To prevent plant disturbance the maximum rate of

output current change initiated by operating the front

panel push buttons, switching between pre-set

outputs or using an optional external encoder may

be defined.

The output resistance of the BA427 -SS is very

high, within the specified operating voltage range,

the loop current will therefore be unaffected by

changes in the supply voltage.

CAUTION

The BA427 -SS output should not be used for

critical safety applications.

Versatile calibration facilities allow the 5 digit internal

display to show the 4/20mA loop current in linear

engineering units. For example, in an application

where the BA427 -SS is being used to adjust the set

point of a speed controller, the internal indicator may

be calibrated to display the required speed in RPM.

For applications in poorly illuminated areas a factory

fitted green backlight is available which may be loop

or separately powered. When loop powered the

backlight produces background illumination enabling

the display to be read at night or in poor lighting

conditions. No additional power supply, intrinsic

safety interface or field wiring are required, but the

Set Point Station voltage drop is increased. When

separately powered, the backlight is brighter but an

additional intrinsic safety interface and field wiring

are required.

Fig 1 Simplified block diagram of BA427 -SS