800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA / CARIBBEAN

Installation

1.

nspect shippin

packa

e, valve, linka

e, and actuator

or physical dama

e. I

hipping damage has occurred notify appropriate carrier. Do not install

2.

nstall valve with the proper ports as inlets and outlets. Check that inlet and outlet

f 2-way valves are correct. Flow direction arrows must be correct.

.

low out all piping and thoroughly clean before valve installation

4.

lean male pipe threads with wire brush and ra

. If threads have been dama

ed

r exposed to weather, runnin

a tap or die over the threads may strai

hten them.

lean pipes, threads, and valve threads before installation; check for any forei

n

aterial that can become lod

ed in trim components. Strainers should be cleaned

fter initial startup

.

ipe sealing compound should be applied sparingly a

ter cleaning and may not be

pplied to the two lead threads o

a screwed pipe, which are innermost inside the

alve. Sealing compound is to be placed on male threads only. The purpose is to

u

r

cate t

e p

pes w

en t

g

ten

ng.

.

alve must be installed with the stem towards the vertical, not below horizontal.

7.

tart the connection by turnin

the valve or pipe by hand as far as possible. Be

ertain the threads mate by the “feel” of the connection.

8.

se wrenches to ti

hten the valve to the pipe. Do not over ti

hten or strip the

hreads. Two wrenches are necessary to avoid dama

in

the valve.

.

wo-way valve Normally Open or Closed confi

urations must be verified by

xaminin

both the mechanical drawin

s and the valve and actuator.

Warning!

• Valve should not be used for combustible

as applications. Gas leaks and explosions

may result. Do not install in systems, which exceed the ratin

s o

the valve

vo

nsta

at

ons w

ere va

ve may

e expose

to excess

ve mo

sture, corros

ve

umes, vibration, hi

h ambient temperatures, elements, or hi

h tra

c areas with

potential

or mechanical dama

e

Valve assembly location must be within ambient ratings o

actuator. I

temperature is

e

ow -22°

a

eater

s requ

re

.

• The valve assembly will require heat shieldin

, thermal isolation, or coolin

i

combined e

ect o

medium and ambient temperatures – conduction, convection, and

adiation – is above 122°F

or prolon

ed time periods at the actuator.

• Followin

standard procedure, a strainer should be installed be

ore the coil and valve

or in another a

ro

riate

lace in the s

stem.

Visual access must be

rovided. Assembl

must be accessible

or routine schedule

service. Contractor should

rovide unions for removal from line and isolation valves

vo

excess

ve stresses.

ec

an

ca

support must

e prov

e

w

ere re

ucers

ave

been used and the pipin

system may have less structural inte

rity than

ull pipe sizes.

•

ufficient upstream and downstream pipin

runs must be provided to ensure proper

alve ca

acit

and flow res

onse. Five diameters in each direction are recommended

• Life span of valve stems and O-rin

s is dependent on maintainin

non-dama

in

conditions. Poor water treatment or filtration, corrosion, scale, other

articulate can

esult in dama

e to trim components. A water treatment specialist should be consulted.

orma

t

rea

engagement

etween ma

e p

pe t

rea

an

va

ve

o

y s

ou

e

observed. Pipe run that is in too far will damage the valve.

The flan

e allows the actuator to be either parallel or perpendicular to the pipe; there

are four orientations possible

If field installing a spring return actuator, disconnect power and allow actuator to spring

closed. Flip actuator over if necessary to achieve proper rotation direction. DO NOT

U

E THE REVER

IN

WIT

H T

D

THI

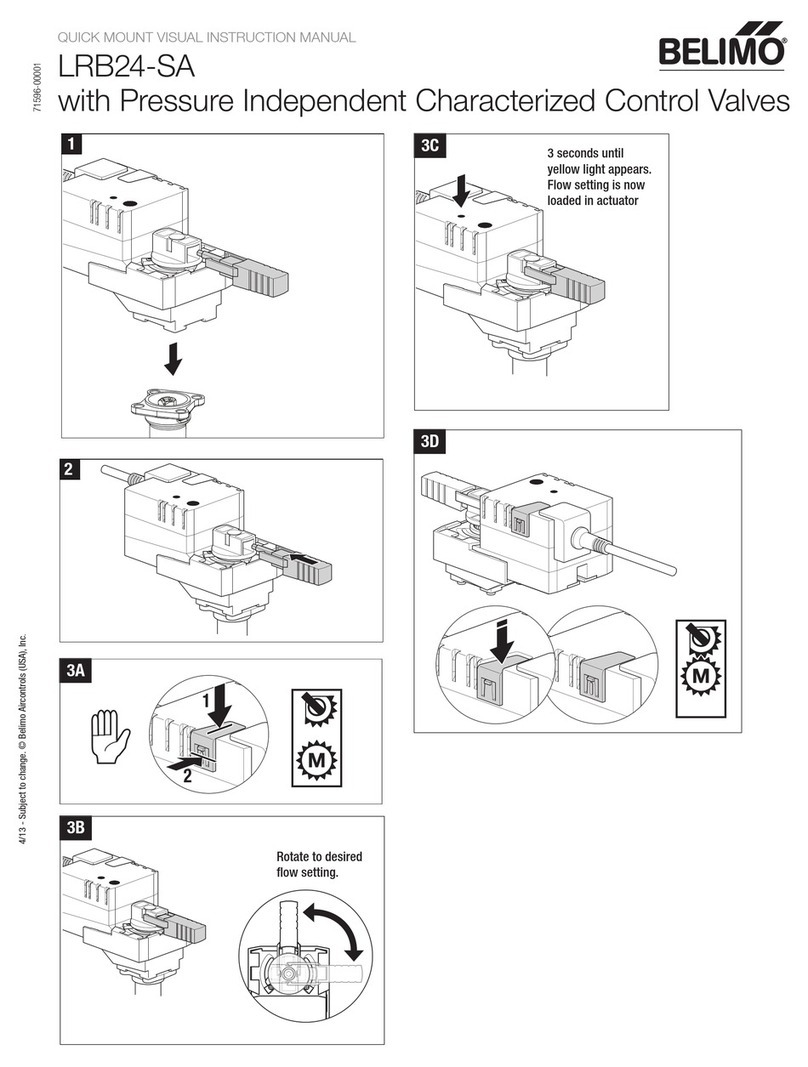

Two-way Valves Mounting

For NORMALLY CLOSED operation:

The ball of the valve must be rotated so that the ball is

L

ED to flow. The actuator

should be mounted with the clamp fully rotated

W (R).

pring return actuators will

show the

W (R) symbol near the clamp and position indicator. Depressing the gear

release to move the clamp rotates non-spring return actuators

For NORMALLY OPEN o

eration:

The ball of the valve must be rotated so that the ball is

PEN to flow. The actuator should

be mounted with the clamp fully rotated

W (L).

pring return actuators will show the

W (L) symbol near the clamp and position indicator. Depressing the gear release to

move the clamp rotates non-spring return actuators. There are marks on the top o

the

valve stem, which indicate the

ort directions

Mounting

e va

ves can

e mounte

n an

os

t

on, exce

t stem

e

ow

or

zonta

Mounting and Installation Instructions

v

Tech.Doc - 04/17 - Subject to change. © Belimo Aircontrols

USA

, Inc