2

®

General Maintenance

The following periodic preventative maintenance practices are recommended

for all Butterfly Valves.

1. Operate the valve from full open to full closed to assure operability.

2. Check flange bolting, actuator mounts and hangers for

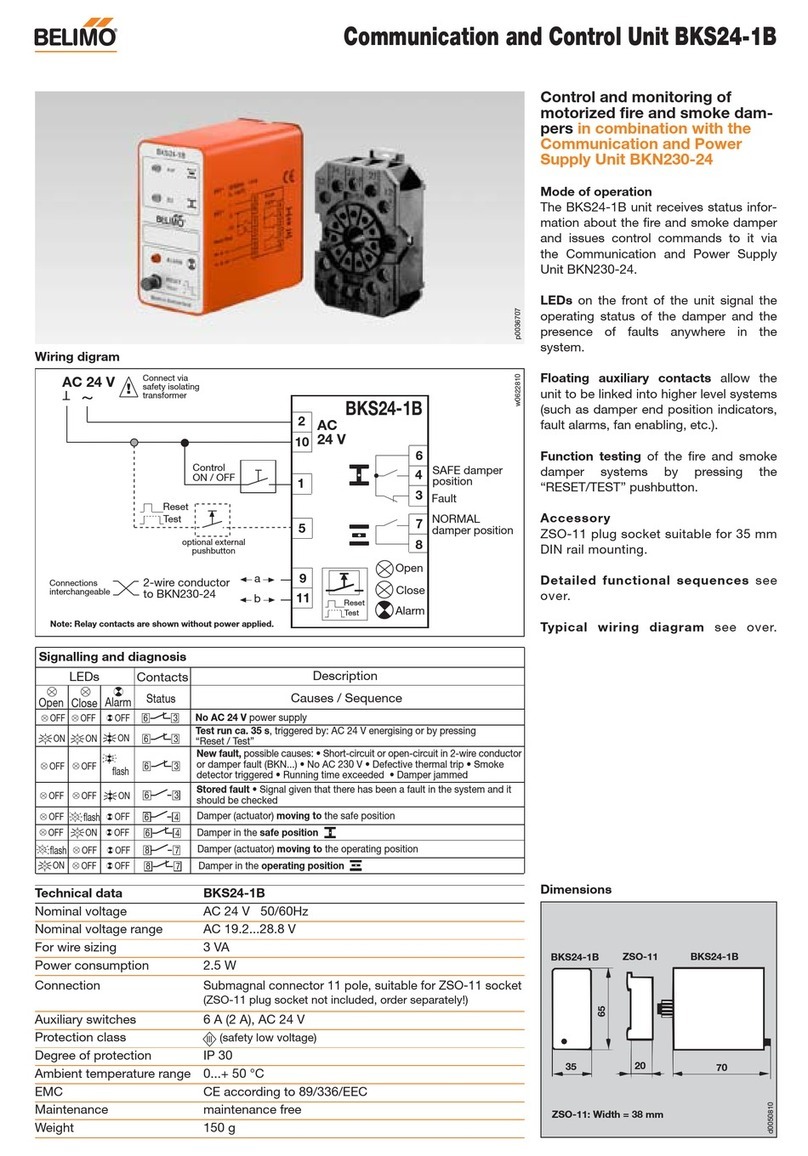

evidence of loosening and correct as needed.

3. Inspect the valve and surrounding area for previous or existing leakage

at flange faces or shaft connections.

4. Check piping and/or wiring to actuators and related

equipment for looseness and correct as needed.

5. If not in use, exercise the butterfly valve (full open and close) at least

once a month.

Safety Precautions

Before removing the valve from the line or loosening any bolts, it is important

to verify the following conditions:

1. Be sure the line is depressurized and drained.

2. Be sure of the pipeline media. Proper care should be taken for

protection against toxic and/or flammable fluids.

3. Never remove the valve without an Operator (Manual or Automatic)

already attached to the valve shaft.

4. Never remove the Operator from the valve while the valve is in the

pipeline under pressure.

5. Always be sure that the disc is cracked approximately 5° off of the

closed position before removing the valve.

Storage of Butterfly Valve Assemblies

• Assemblies must be stored indoors, protected from the elements.

• Materials received on job sites that have long installation lead times

should receive extra protection from construction damage.

• Valve faces must be protected from abrasion, cutting and nicking, as this will

damage the face and may cause flange area leaks.

• Electric actuators cannot be stored in wet, damp or caustic areas.

• Do not store construction material on top of valve assemblies.

L-Series Butterfly Valves

Instruction Manual

Valve Installation Procedure

Position the connecting pipe flanges in the line to insure proper alignment

prior to valve installation. Spread the pipe flanges apart enough to allow the

valve body to be located between the flanges without actually contacting the

flange surfaces. Exercise particular care in handling the valve so as to prevent

possible damage to the disc or seat faces.

Note: Actuator must be mounted at or above pipe center line for all

actuator types.

1. When installing in Victaulic piping systems, use Victaulic 41 series flange

nipples. 741 flanges not recommended without the use of adapter rings.

2. L-Series Butterfly valves are designed to be installed between ANSI

125/150 flat-faced, raised face, slip-on or weld neck flanges.

3. Do NOT use flange gaskets on L-Series Butterfly valves.

4. For Lug style valves:

a. Place the valve between the flanges.

b. Install all bolts between the valve and the mating flanges. Hand tighten

bolts as necessary.

5. Before completing the tightening of any bolts, the valve should be

centered between the flanges and then carefully opened and closed to

insure free, unobstructed disc movement.

6. Using the sequence, tighten the flange bolts evenly to assure uniform

compression. In assembling flange joints, the resilient seating surface

shall be uniformly compressed.

7. If an actuator is to be operated, electricity should be connected to the

unit in accordance with the local electrical codes.

8. Cycle the valve to the fully open position, then back to the fully closed

position, checking the actuator travel stop settings for proper disc

alignment. The valve should be operated to assure that no binding is

taking place. If no power is available, use the manual handwheel.

9. The valve is now ready for operation.

Max Torque for Bolts

Valve Size Bolt Size Max Torque [ft-lbs]

8” 3/4-10” 120

10”-12” 7/8-9” 200

1

3

2

5

6

7

1

4

5

8

9

10 11

12

12/16 - Subject to change. © Belimo Aircontrols (USA), Inc.

71933-00001.B