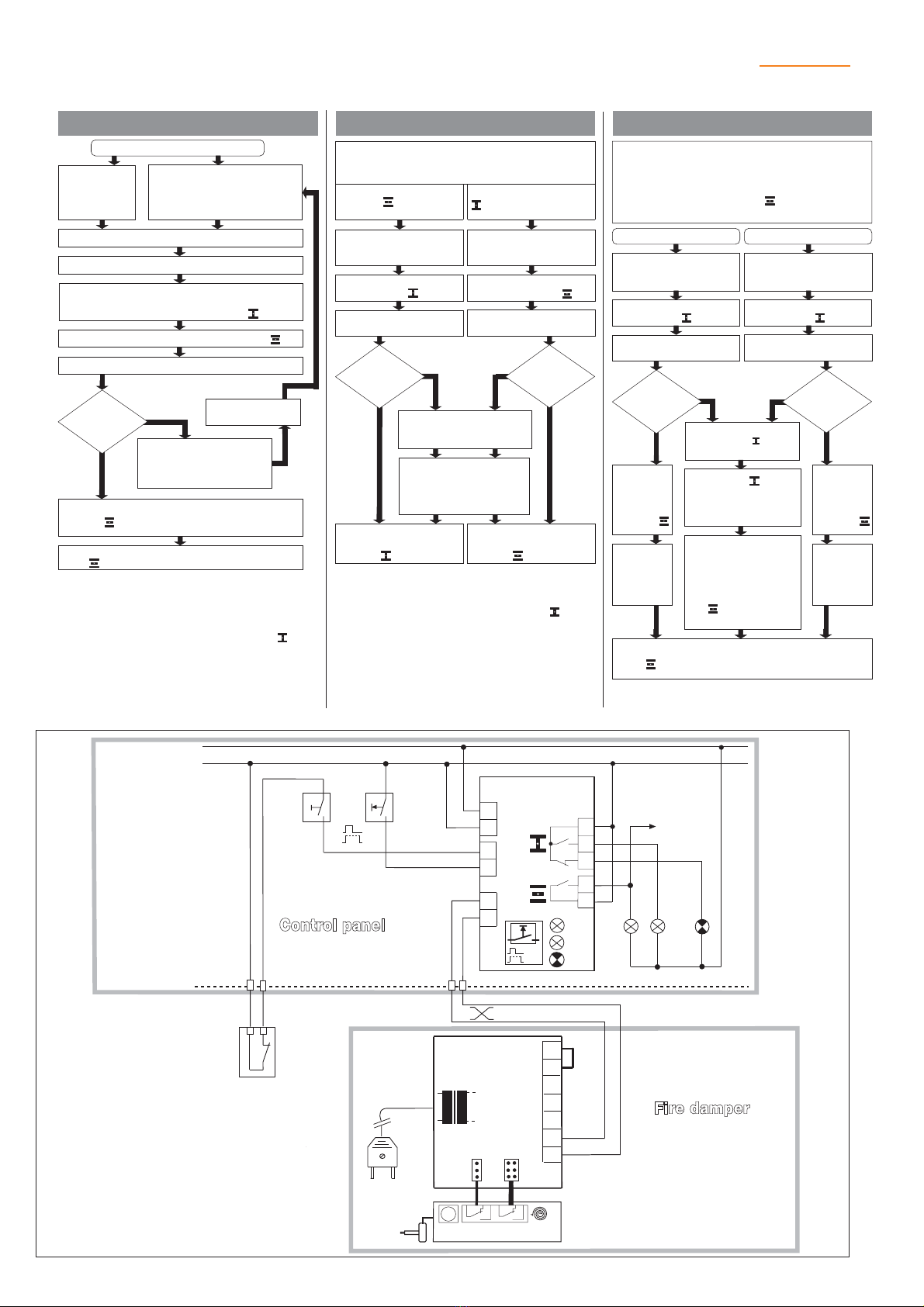

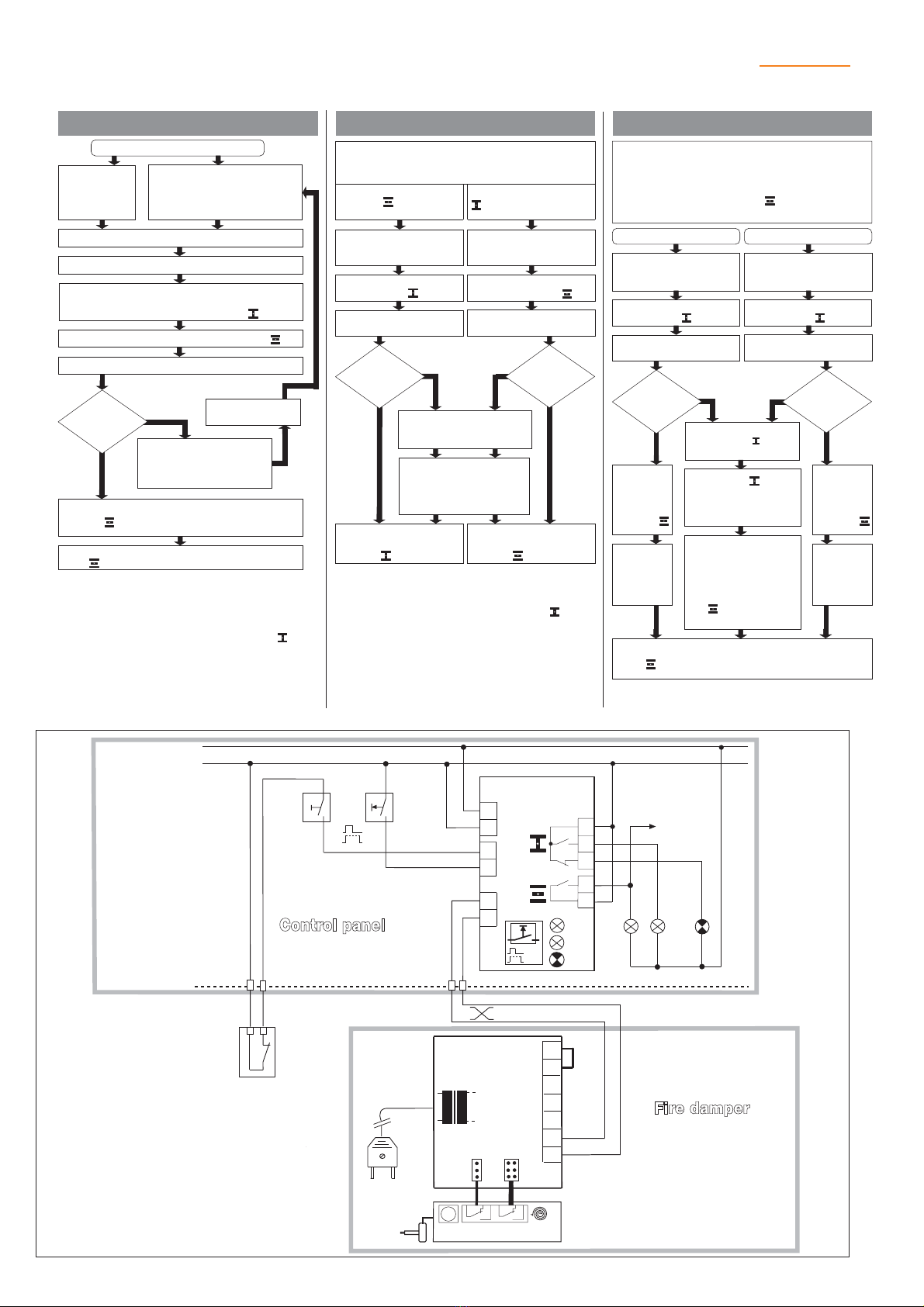

General notes

•The test will be interrupted if a fault occurs during the

test run. The LED “Alarm” flashes to signal a new

fault. The two LED’s “Open” and “Close” are dark

and the damper moves to the safe position .

Contact 6–3 (fault) is closed in this case.

•Anew test run can be started by pressing “Reset/Test”,

by issuing a reset command via terminal 5 or by

interrupting the AC 24 V power supply.

Triggering by:

Energising

of AC 24 V

power supply

Press “Reset/Test” when a new

fault occures ( LED “Alarm”

flashing) or when a fault is stored

(LED “Alarm” steady)

Start – Test sequence

A short unlocking pulse triggers the actuator au-

tomatically if it has been locked manually. So the

damper is moved to the safe position

All LEDs (Open, Close and Alarm) steady

Actuator moving to the operating position

Contact 6–3 (fault) remains closed

When the damper has reached the operating po-

sition , LED “Open” goes steady

All LEDs (Open, Close and Alarm) steady

LED “Alarm” flashes after

a delay and contact 6–3

(fault) is closed

Rectify fault in

system

Damper moves further towards the operating

position . LED “Open” flashes during motion

NO

YES

Actuator

reached switching

position

10°

LED “Close” steady,

i.e. damper in safe

position

LED “Open” steady,

i.e. damper in operating

position

Precondition:

No new faults!

(LED “Alarm” must not be flashing)

Damper in operating

position , LED “Open”

steady

Damper in safe position

, LED “Close” steady

Normal operation

Plant switch

(see Circuit diagram)

at “Control OFF”

Plant switch

(see Circuit diagram)

at “Control ON”

Damper moves to

operating position

Damper moves to

safe position

LED “Close” flashes

during the motion

LED “Open” flashes

during the motion

NO

LED “Alarm” flashes, i.e. a new

fault has occured (contact 6-3

closed)

If the end position is reached

later, LED

“Alarm” changes to

steady and contact 6–3 opens

YES

NO

YES

Actuator

reached switch-

ing position > 80º

within 320 s

Actuator

reached switch-

ing position < 10º

within 35 s

General notes

• If a fault in the system is detected during operation

the damper will move to the safe position imme-

diately. LED “Alarm” starts to flash in order to signal

a new fault and contact 6–3 is closed.

•When the fault has been rectified, the system can be

restarted by pressing “Reset/Test”, by injecting a

reset command via terminal 5 or by interrupting the

AC 24 V power supply.

• No new faults ( LED “Alarm” flashing) and no

stored faults (LED “Alarm” steady)

• Damper in operating position , i.e. LED “Open”

steady

Preconditions:

LED “Close” flashes

during the motion

Local activation

Periodic damper function test

External activation

Press and hold

“Reset/Test”

Activate Reset/Test com-

mand via terminal 5

Damper moves to

safe position

Damper moves to

safe position

LED “Close” flashes

during the motion

NO

Damper continues moving

to safe position and LED

“Close” continues flashing

Safe position reached

after ca. 20 s (spring-

return time) and LED

“Close” steady

YES

NO

YES

“Reset/Test”

command to ter-

minal 5 remains

activated

“Reset/Test”

remains

depressed

If “Reset/Test” is relea-

sed or the Reset/Test

command via terminal

5 is deactivated, the

damper will move back

to the operating posi-

tion

(LED “Open” flashes)

LED“Open”

flashes

during the

motion

Damper

moves

back to

operating

position

LED ”Open” steady signals damper in operating po-

sition

LED“Open”

flashes

during the

motion

Damper

moves

back to

operating

position

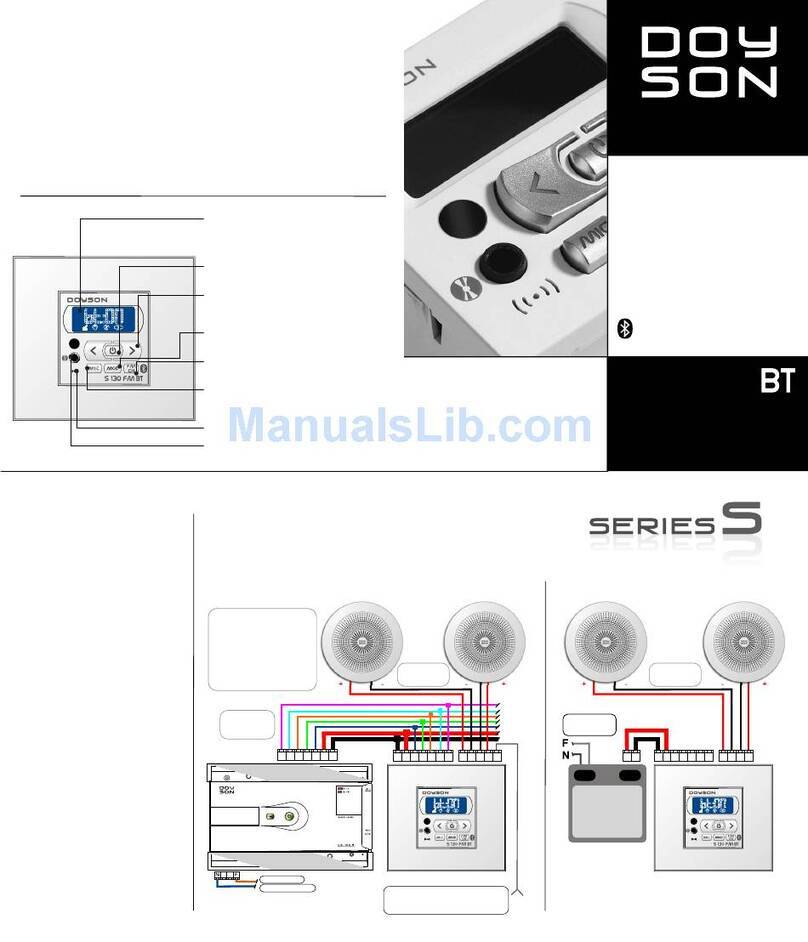

~

2

10

1

5

9

11

Reset

Test

AC

24 V

BKS24-1B

6

4

3

7

8

T

AC 24 V

Control

ON / OFF

Open Close Fault

eventual

fan enabling

Contact

from fire

alarm

system

Connections interchangeable

Open

Close

Alarm

Reset

Test

BKN230-24

Power supply

AC 230 V

1

2

3

4

5

6

7

a

b

BF(G)24-T-ST, BF..24-ST

M

BAE72-S

ENG-93001-93334-08.03-PDF • Subject to technical changes

Functional sequences / Typical wiring diagram

w0624810

BC