3. 1loTransactionI

SE1TION 502-323-400

TOtCH-TONE pulses. It is not necessary to wait

for the end of transmission of data from the test

ca .

3.~ The green (G) lamp shall then light for 3

seconds and go out as the yellow (Y) lamp

lig ts. Three TOUCH-TONE characters are

tra smitted as the (Y) lamp lights. After the (Y)

la plights and the three characters are transmitted,

de~ress the ERASE button and pause to listen for

thd transmission of two more TOUCH-TONE

ch4racters. Next, depress the ATTN button and

he4r two more characters transmitted. (If you do

no~ hear an interrupted tone, the set is working

prdperly.) You may hear a muted 3 second response

to e. The TTTLS will disconnect. Place the

ha dset on-hook. The yellow lamp may be

ex inguished by momentarily going off-hook.

3.1 Gooff-hook, dial the TTTLS using the handset

and then depress END button four times.

As this call is answered by the test line, the fourth

ins ruction lamp will be lighted. (On the standard

fac plate, this lamp is labeled "Follow Special

In tructions.") This tests the lamp and associated

cirluitry. Go on-hook to release test line. Go

off hookmomentarily to reset Transaction telephone

set and extinguish lamp. If no auxiliary manual

en ,ry pad is provided, proceed to 3.25.

A,4XILIARY MANUAL ENTRY PAD (PERSONAL

IDE~TIFICATION NUMBER [PIN])

3.,If the auxiliary manual entry pad is to be

used, it should be installed at this time.

!Imall the D-180687Kit of Parts (Fig. 6), which

in des:

1-5000A-50 dial

1-841934946 mounting plate

1-841935109key(push-to-lock,push-to-unlock)

4-840694194 screws

1-840713366 label

2-D-161488 connectors (provided with kit

of parts manufactured after 1st quarter

of 1976).

1) Remove faceplate by lifting at the midpoints

of the right and left edges. When faceplate

is bowed slightly, the locking tabs at top and

bottom will release.

Note: A 138B-type faceplate (ordered

separately, Table A) will also be required.

(2) Install 841934946mounting plate and 841935109

key (Fig. 7) as follows:

(a) Remove screw holding static arrester

spring (Fig. 7) and slide mounting plate

under the spring. Replace the screw holding

the spring and the associated lead. This

should secure right side of mounting plate.

Note: The static arrester spring is intended

to ground the faceplate and the chrome ring

for electrostatic protection.

(b) Secure left side of mounting plate with

(2) 840694194screws.

(cJ Insert 841935109key with trimmed portion

to right, the LED in the upper right,

and the two indexing or alignment holes over

tabs on the mounting plate to the left.

(d) Secure right side of key using the other

(2) 840694194screws provided.

(3) Install new 138B-type faceplate.

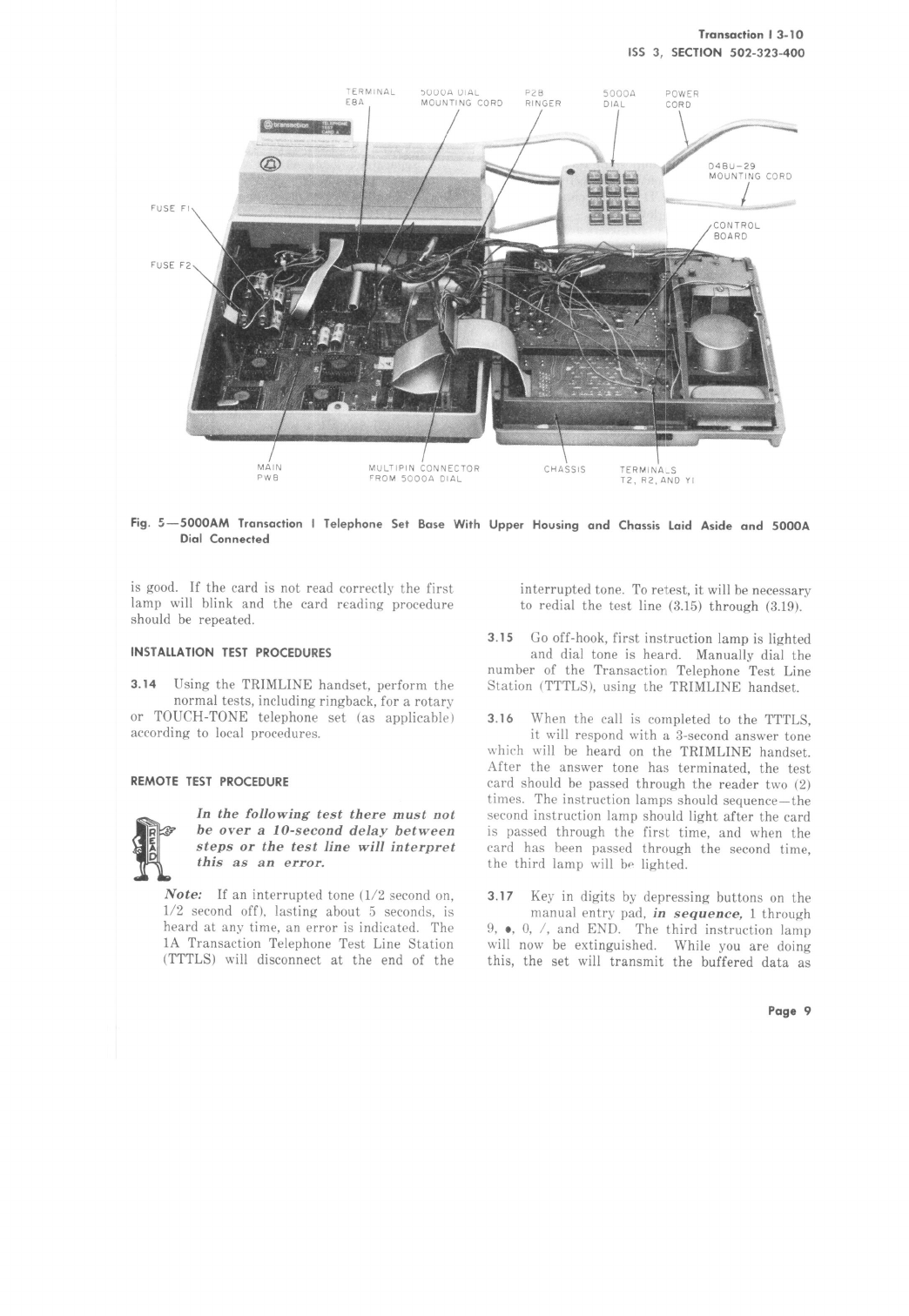

(4) Open the set (3.07); lay the upper housing

and chassis to the right (Fig. 5).

(5) Hold the lower housing up on its side and

feed the mounting cord of the dial through

the cord entrance hole in the base pan. Using

Fig. 5, make connections as follows:

(a) Plug multipin connector of mounting cord

into connector on flex :ribbon cable.

Note: Apolarizing keyin the female connector

assures proper mating of connectors.

(b) Connect 508 plug to 841935109key.

(c) Connect the black (BK) spade-tipped

mounting cord conductor to terminal E8A

on the main PWB.

Note: In early production sets there is no

terminal E8A. In this case, remove the black