Beluk BLR-CM Modbus Guide

Technical Documentation

BLR-CM Modbus

Rev. 05

2018-09

Beluk GmbH

Taubenstrasse 1

86956 Schongau

Germany

Tel.: +49/(0)8861/2332-0

Fax: +49/(0)8861/2332-22

E-Mail: [email protected]

Web: http://www.beluk.de

Technical Documentation

BLR-CM Modbus

Technical Documentation

BLR-CM Modbus

Rev. 05

2018-09

2

Document history

Date

Name

Revision

Comment

08.11.06

ATh

01

initial document release

20.03.07

ATh

02

features of new software (V2.1.x)

21.09.07

Le

03

New connector on Modbus hardware

valid from firmware V 2.2.x

18.11.08

Le

04

Inserting additional bus address

24.09.18

SMi

05

Adaption to firmware V 2. 7.x

Layout changes

Technical Documentation

BLR-CM Modbus

Rev. 05

2018-09

3

Content

1OVERVIEW .......................................................................................................................................................... 4

2MODBUS/ RS485................................................................................................................................................. 5

2.1 RS485 (defined in EIA485/ISO8482)................................................................................................................. 5

2.1.1 Connection...................................................................................................................................................... 6

2.1.2 Line termination ............................................................................................................................................. 7

2.1.3 Line biasing ..................................................................................................................................................... 7

2.1.4 Communication indicator ............................................................................................................................... 7

2.2 The Modbus protocol ...................................................................................................................................... 8

2.2.1 Modbus - description...................................................................................................................................... 8

2.2.2 Serial data format ........................................................................................................................................... 8

2.2.3 Serial transmission modes .............................................................................................................................. 9

2.2.4 Function codes................................................................................................................................................ 9

2.2.5 Exception codes ............................................................................................................................................ 10

2.2.6 Master-Slave protocol .................................................................................................................................. 10

3BLR-CM MODBUS...............................................................................................................................................10

3.1 Setup..............................................................................................................................................................10

3.2 Address space ................................................................................................................................................10

3.3 Measurement values......................................................................................................................................11

3.4 Work counters ...............................................................................................................................................12

3.5 Parameter settings .........................................................................................................................................13

3.6 Stage status....................................................................................................................................................17

3.7 Device status..................................................................................................................................................18

3.8 Storage settings .............................................................................................................................................20

4TROUBLE SHOOTING ..........................................................................................................................................21

Technical Documentation

BLR-CM Modbus

Rev. 05

2018-09

4

Important information!

If this sign appears besides a text passage, the reader is strongly advised to read the corresponding information. It

may provide important information about the usage of the device, safety advices or information about the correct

handling of the device. If the information is disregarded, the device may be inoperable or even damaged!

Additional Modbus protocol can be found at www.modbus.org.

The Modbus standards are also available from there.

1Overview

The Modbus communication interface of the reactive power controller CM offers the possibility to read out

measurement values or adjusting settings. This can be done by remote computer systems.

Attention: The BLR-CM can send max. 30 Values per request

The present manual describes the data transmission using the Modbus protocol, which defines methods of data

transport and addressing, but does not generally determined a specific transmission medium (physical transmission

level).

The reactive power controller CM uses the industrial standard RS485 for data transmission. This bus system offers the

possibility to operate several devices at the same bus cable.

A multitude of commercial devices and programmable logic controllers (PLC) are compatible with the Modbus protocol,

which is why a bus system can be set up with little effort.

!

Technical Documentation

BLR-CM Modbus

Rev. 05

2018-09

5

2Modbus/ RS485

The communication protocol Modbus RTU basically includes two levels:

The RS485 industrial standard defines the data transmission medium. Here, the physical data byte transmission

between the bus participants is controlled. This part of the protocol is embedded in higher Modbus levels.

The Modbus application protocol uses the underlying RS485 protocol for data transmission. It defines

commands (“Function Codes”, FC), addresses and data structures.

2.1 RS485 (defined in EIA485/ISO8482)

The communication standard RS485 uses two wires for data transport D(+) and D(-). Signals are transmitted with a

differential voltage level of at least ± 200 mV. Thus, the two logical levels “low” and “high” are possible. Due to its

differential transmission technology, the standard RS485 is particularly resistant to electromagnetic interferences and

wire lengths of more than 1000 meters may be reached.

The reactive power controller CM is compatible with the following transmission rates: 1200; 2400; 4800; 19200; 38400;

57600 and 115200 baud. All parity variations (even, odd and none) are supported.

In the RS485 standard, two transmission variations are defined:

2-wire RS485: This type uses two wires for the communication, which is why the same wire pair is used for

both data directions. Therefore, it is necessary to switch between sending and receiving at each device (half-

duplex mode).

4-wire RS485: In this case, a single wire pair is used for each data direction. However, due to the Modbus

protocol, it is also only possible to use the half-duplex mode again. For this reason, it is not possible to increase

the transmission capacity.

The power factor controller CM supports 2-wire RS485 only!

Next to the data lines, a common ground (GND) line must be interconnect all bus participants. It is not allowed to use

the cable shield for this purpose. The shield must be connected to GND, in order to reduce electromagnetic influences.

According to the RS485 standard, up to 32 devices can be connected to a single bus segment. This is done by connecting

all devices in parallel. This concerns the data lines D(+) and D(-) as well as the GND line.

In order to connect more than 32 devices to a bus, a “Repeater” must be used to between the bus-segments.

Technical Documentation

BLR-CM Modbus

Rev. 05

2018-09

6

2.1.1 Connection

There are two Modbus interfaces:

a) 9-pin D-SUB

PIN1 +5V (For data line bias only. It is not allowed to supply external circuits by this pin!)

PIN2 Common ground (GND) for all bus participants.

PIN5 D (B) - Data signal B

PIN9 D (A) - Data signal A

b) 3-pin Connector

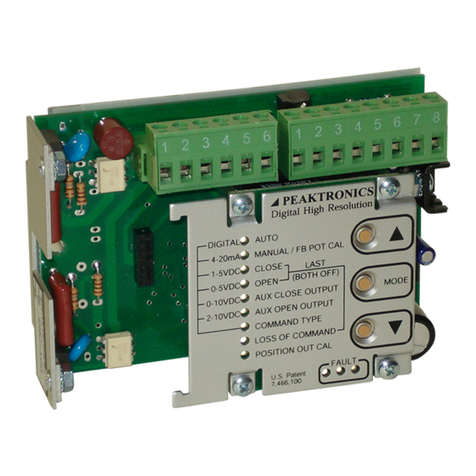

The power factor controller CM uses a 3-pin connector, which is

shown on the right side.

In order to establish a Modbus connection, the data lines + and - and

the common ground (middle pin) must be connected.

Attention: Various vendors uses the assignment A and B. Equating this designation (A = +) and (B = -) does not always

apply. This must be checked for each device.

5

4

3

2

1

9

8

7

6

Technical Documentation

BLR-CM Modbus

Rev. 05

2018-09

7

2.1.2 Line termination

The termination of the bus wire is strictly necessary, in order to prevent interferences and set up a stable connection.

For this reason, both wire ends of the bus must be terminated with a resistor. The value of the resistor must fit to the

cable impedance and is generally selected as 120 Ω. A resistor must be connected at each end of the bus-segment.

Some devices, particularly bus converters, include a termination resistor by default. Therefore, it is necessary to check

the user manuals of all implemented bus devices. If devices, with integrated termination resistor, are connected within

the bus segment, their termination resistors must be switched off. In case it is not possible to switch it off, the respective

devices must be placed at the ends of the bus! Consequently, it is only possible to use two devices with fix termination

resistors!

2.1.3 Line biasing

Without a bias voltage, the logic level in the data wires would be undefined while no data is transmitted. Additionally,

external influences may lead to interferences of the signal level. For this reason, line biasing is required.

This is done by two resistors, which must be in the range of 450 Ω…650 Ω. The first resistor is used as pull-up resistor

and is connected between the data wire + resp. D(+) and +5 V. The second resistor is used as pull-down resistor and is

connected between the data wire –resp. D(-) and 0 V. These resistors are required once per bus segment and their

position within the bus segments is freely selectable. However, it is recommend to select a position in the middle of the

bus wire. Before installing these resistors, it must be checked if the implemented devices already include integrated

bias resistors.

Attention: In case of the BLR-CM, a line bias voltage must be provided externally.

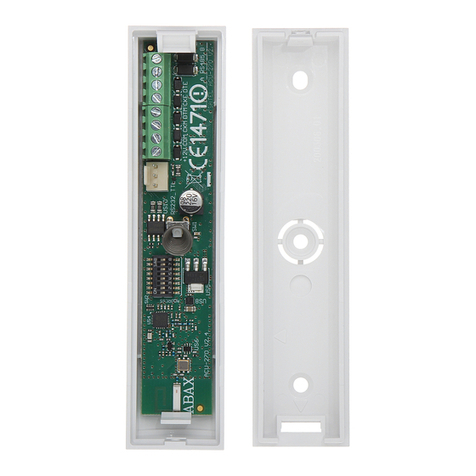

2.1.4 Communication indicator

The yellow LED on the backside of the device indicates an active transmission.

It only flashes, when the device is actually communicating with the bus

master.

The communication indicator LED is available for both connector variants.

Technical Documentation

BLR-CM Modbus

Rev. 05

2018-09

8

2.2 The Modbus protocol

2.2.1 Modbus - description

The Modbus protocol uses the RS485 as an underlying physical layer and implements the data transmission control

mechanisms. Therefore, it is located on layer 2 ("link layer") of the OSI layer model for data exchange systems.

2.2.2 Serial data format

The data is transmitted in fixed frames. The frames are separated by the bus being inactive for at least 3,5 characters.

All data is organized in "protocol data units" (PDUs), which are transmitted over the serial bus system by the underlying

physical protocol layer.

PDU

FC

data

1 byte

n bytes

Illustration 1 : "Protocol Data Unit" - PDU

The PDU consists of two parts:

The "function code" (FC) is a command, which defines how the slave has to respond.

The data block contains information, which correspond to the FC. Its usage depends on the FC, it can either

contain data or register addresses for slave data access.

The PDU defines a single data unit, which has to reach a certain bus device in order to perform an action. The type of

the transfer differs dependent on the physical layer.

To be able to control the transmission, the PDU is extended by two additional blocks. In RS485, the frame is now called

"application data unit" (ADU).

ADU

slave #

FC

data

CRC

1 byte

1 byte

n bytes

2 bytes

Illustration 2 : "Application Data Unit" - ADU

Technical Documentation

BLR-CM Modbus

Rev. 05

2018-09

9

The application data unit, contains two additional blocks of data:

The first field specifies the "slave number", which contains the slave address.

In order to secure the transmission, the las block includes a cyclic redundancy check (CRC) value.

2.2.3 Serial transmission modes

The protocol defines two different encodings for the frames' data contents. The RTU- and ASCII-coding.

Attention: The BLR-CM supports the RTU-mode only!

"Remote Terminal Unit" (RTU)

At this transmission mode, every 8-bit data word contains two 4-bit hexadecimal numbers. They are transmitted as

complete byte to reach a maximum transmission density. With every data word, the following information is

transmitted:

1 Start bit

8 Data bits, "least significant bit" first

1 Parity bit (if set)

1 Stop bit for parity even or odd / 2 if parity is none to compensate missing parity bit

2.2.4 Function codes

As it was mentioned before, the data packet contains "function codes", which specify a command from the bus master

to the bus slave. The slave executes the command (if possible) and answers with the same function code to acknowledge

the command. The valid function code range is specified from 1 to 127, but only a part of it is actually used. Please refer

to the Modbus specifications for detailed Information.

If it is impossible for a slave to execute a command, it replies with an error code (exception code). The function code of

an exception package is the function code itself and the most significant bit is set by the slave to signal the error

condition to the master. Moreover, the content of the data block specify the error in more detail.

The BLR-CM supports the function codes 03hex (read holding register), 04 hex (read input register) and 06hex (write single

register).

Technical Documentation

BLR-CM Modbus

Rev. 05

2018-09

10

2.2.5 Exception codes

If a slave is not able to execute a command, it answers with exception codes. A full list of codes can be found in the

Modbus specification. The corresponding list is not provided at this point, because the master software handles the

most exceptions automatically.

2.2.6 Master-Slave protocol

Since the master-slave protocol is used, only the bus master can initialize a transfer. The "master" starts an exchange

by sending data and the corresponding function code (=command) to the slave. Afterwards the slave executes the

command.

Usually, the unicast-mode is used to communicate within a Modbus system. Here, data packages are send to a

single slave, including its address. The valid address range is between 1 and 247. The slave executes the

command and answers by sending a acknowledge data package back to the master.

In multicast-mode all slaves on the bus are addressed in parallel. They all receive and execute the same

command, but none of them respond. The master initiates a multicast command by using "0" as slave number.

3BLR-CM Modbus

3.1 Setup

If the device supports Modbus, an additional entry is available in the “setup” - menu of the device. In this menu the

following settings can be done:

ADDRESS: This is the device’s slave address (slave ID). The valid range is 1-247.

BAUD RATE: Here, the baud rate can be selected. The valid range is 1200 - 115200 baud.

PARITY: The parity can be selected to be none, even or odd.

While baud rate and parity must be the same for all bus devices, the address must be unique for each device.

3.2 Address space

The data in the BLR-CM is organized and accessed by addresses. Each address accesses one data word. The size of a

data word is always 16 bit.

The BLR-CM does not differ between the addresses and the function codes. There is one big address space available

and in order to access each address’s data, any valid function code can be used. Nevertheless, the data will only make

sense when interpreted the correct way!

Technical Documentation

BLR-CM Modbus

Rev. 05

2018-09

11

The data can be of the following types:

FLOAT: 32 bit floating-point number, as it is defined in IEEE-754.

UINT16: Unsigned 16 bit integer value.

UINT32, SINT32: Unsigned/signed 32 bit integer value.

Since the data is organized in 16 bit wide words, a set of sequential addresses has to be read in order to get longer data

items. In this case, only the base address is given in the tables. For example, to read a FLOAT value with base address

12, two 16 bit words must be read (addresses 12 and 13). These two values need to be concatenated to form the desired

result of 32 bits. Most SCADA software packages or PLCs can do this automatically.

There exist different types of addresses:

The Modbus address always starts with 0 and can go up to 65535. It can be used with any

function code.

Certain PLCs cannot handle the address 0 and therefore add 1 to the address. So their

addresses system (Modbus address +1) always start with 1.

Some SCADA tools add an offset to determine the function code, which is used to access the

device at the given address. Sometimes, they also add 1 to the Modbus address.

As an example, the address 40001 would be “read Modbus address 0 with function code

03hex”, 30012 would be “read Modbus address 11 with function code 04hex”.

Please refer to the corresponding software’s manual to find the correct addresses.

Attention: The following tables always give the Modbus addresses mentioned first in above list.

3.3 Measurement values

The measured values are available in an interval of 2 data words, starting at address 0. All values can be accessed with

function codes 03hex and 04 hex..

If the current or voltage is too small to calculate valid harmonics, the value at the base address (= the fundamental) is

0.0%. This also indicates, that the higher harmonic current or voltage values are also invalid!

Attention: The values Apparent power sum, Active power sum, Reactive power sum, Lacking reactive power ΔQ and

Power factor (P/S) refere to a symmetrical power system.

!

Technical Documentation

BLR-CM Modbus

Rev. 05

2018-09

12

Address

Value

Words

Type

Unit

0

Frequency

2

FLOAT

Hz

2

Voltage phase –phase

2

FLOAT

V

4

Voltage phase - neutral

2

FLOAT

V

6

Current I1

2

FLOAT

A

18

Apparent power S-sum

2

FLOAT

VA

26

Active power P-sum

2

FLOAT

W

34

Reactive power Q-sum

2

FLOAT

var

42

Lacking reactive power ΔQ

2

FLOAT

var

50

Power factor (P/S)

2

FLOAT

-

58

Total harmonic distortion THD U

2

FLOAT

%

60

Harmonics U 1. order = fundamental wave

2

FLOAT

%

62

Harmonics U 2. order

2

FLOAT

%

64

Harmonics U 3. order

2

FLOAT

%

…

…

…

…

…

122

Harmonics U 32. order

2

FLOAT

%

124

Total harmonic distortion THD I

2

FLOAT

%

130

Harmonics I 1. order = fundamental wave

2

FLOAT

%

132

Harmonics I 2. order

2

FLOAT

%

134

Harmonics I 3. order

2

FLOAT

%

…

…

…

…

…

192

Harmonics I 32. order

2

FLOAT

%

322

Ambient temperature

2

FLOAT

°C

3.4 Work counters

In order to reach an accurate value, work counters/accumulators are arranged in a special way. Each counter consists

of two parts:

1. A FLOAT-type base counter which simply accumulates/integrates the power. If this counter reaches 1000000.0,

the extended counter is increased by one and 1000000.0 is subtracted from the base counter.

2. A LONG-type extended counter, which is used to count portions of MW / Mvar up to (232-1)106.

To get the real work value, the extended counter must be multiplied with 1000000 and afterwards the base counter

value must be added. This keeps the precision of the FLOAT-type base counter in acceptable range, because huge values

can be handled as well.

Technical Documentation

BLR-CM Modbus

Rev. 05

2018-09

13

All values can be accessed with function codes 03hex and 04 hex.

Address

Value

Words

Type

Unit

1792

WQ inductive –extended counter

2

UINT32

MVarh

1794

WQ inductive –base counter

2

FLOAT

Varh

1796

WQ capacitive –extended counter

2

UINT32

MVarh

1798

WQ capacitive –base counter

2

FLOAT

Varh

1800

WP import –extended counter

2

UINT32

MWh

1802

WP import –base counter

2

FLOAT

Wh

1804

WP export –extended counter

2

UINT32

MWh

1806

WP export –base counter

2

FLOAT

Wh

It is possible to read the work counters already summarized since firmware version 2.7.0. These values can be

accessed with function codes 03hex and 04 hex.

Address

Value

Words

Type

Unit

2048

WQ inductive

2

REAL

kVarh

2050

WQ capacitive

2

REAL

kVarh

2052

WP import

2

REAL

kWh

2054

WP export

2

REAL

kWh

3.5 Parameter settings

Parameters, which are set by the user, are stored in various data types. The base addresses and the data type can be

found in the table below.

All values can be accessed with function codes 03hex,04 hex and 06hex.

Address

Value

Words

Type

Unit

512

PT ratio x 10

1

UINT16

-

513

CT ratio x 10

1

UINT16

-

514

User parameters 1

1

UINT16

-

515

Phase correction

1

UINT16

°

517

Nominal voltage L - L

2

UINT32

V

519

Limit max. voltage

1

UINT16

%

520

Limit min. voltage

1

UINT16

%

522

Switching time delay x 10

1

UINT16

s

523

Target cos φ 1 (0..100..200 = i0.00..1.00..c0.00)

1

UINT16

-

Technical Documentation

BLR-CM Modbus

Rev. 05

2018-09

14

524

Target cos φ 2 (0...100…200 = i0.00...1.00…c0.00)

1

UINT16

-

525

control sensitivity

1

UINT16

%

526

Tolerance switch cycles balancing

1

UINT16

%

527

Alarm Enable Output Mask 1 (OM1)

1

UINT16

-

528

Alarm action: „Switch Alarm Relay (M)“ (OM1)

1

UINT16

-

529

Alarm action: „Switch DO-Relay (DO)“ (OM1)

1

UINT16

-

530

Alarm action: „Show Display Message (D)“ (OM1)

1

UINT16

-

531

Alarm action: „Target COS-PHI 2 (CP)“ (OM1)

1

UINT16

-

532

Alarm action: „Switch Controll off (O)“ (OM1)

1

UINT16

-

533

Alarm action: „Freeze Control (F)” (OM1)

1

UINT16

-

533

Limit alarm temperature 1 x 10

1

UINT16

°C

534

Limit alarm temperature 2 x 10

1

UINT16

°C

535

Hysteresis temperature x 10

1

UINT16

°C

536

Limit alarm THD U x 10

1

UINT16

%

537

Limit alarm THD I x 10

1

UINT16

%

539

Limit warning step size

1

UINT16

%

540

Limit warning switch cycles

2

UINT32

-

542

Limit alarm active power P

2

UINT32

W

544

Limit alarm reactive power Q

2

UINT32

var

546

pf alarm min (0...100...200 = i0.00...1.00...c0.00)

1

UINT16

-

547

pf alarm max (0...100...200 = i0.00...1.00...c0.00)

1

UINT16

-

548

pf alarm delay time

1

UINT16

s

555

Switching time delay Step exchange x 10

1

UINT16

s

556

Delay time fast control

1

UIN16

per

557

Max. step size (fast control)

1

UINT16

var

559

Mean Q. (fast control)

1

UINT16

Var

560

Datalogger storage interval (0…720)

(Only available with option –DM)

1

UINT16

Min

561

Fast Control Output Mask 1 (OM1)

(Only available with option 1PH: -06T, -12T, -12RT)

Note: Just the THD-U Bit is allowed

1

UINT16

-

562

Alarm frequency: lower limit

(450…(MaxValue-10) = 45,0Hz…(MaxValue-0,1Hz))

1

UINT16

Hz

563

Alarm frequency: upper limit

((MinValue+10)…650 = (MinValue+0,1Hz)...65,0Hz)

1

UINT16

Hz

564

Alarm Enable Output Mask 2 (OM2)

1

UINT16

-

565

Alarm action: „Switch Alarm Relay (M)“ (OM2)

1

UINT16

-

566

Alarm action: „Switch DO-Relay (DO)“ (OM2)

1

UINT16

-

Technical Documentation

BLR-CM Modbus

Rev. 05

2018-09

15

567

Alarm action: „Show Display Message (D)“ (OM2)

1

UINT16

-

568

Alarm action: „Target COS-PHI 2 (CP)“ (OM2)

1

UINT16

-

569

Alarm action: „Switch Controll off (O)“ (OM2)

1

UINT16

-

570

Alarm action: „Freeze Control (F)” (OM2)

1

UINT16

-

571

Language Setting

SW 02.07.xx:

Bit 0 =English, Bit 1 = German, Bit 2 = French

SW 02.08.xx:

Bit 0 =English, Bit 1 = Spanish, Bit 2 = Portuguese

1

UINT16

-

572

Asymmetry factor

1

SINT16

-

573

User parameters 2

1

UINT16

-

574

Q-Offset (-32000…32000 = -3200,0kvar…3200,0kvar)

1

SINT16

kvar

575

Temperature Offset (-100…100 = -10°C…10°C)

1

SINT16

°C

The addresses 514 (User parameters 1), 527 –533 (Alarm Output Mask 1), 561 (Alarm Output Mask 1), 564 –470 (Alarm

Output Mask 2) und 573 (User parameters 2) are coded binary. The assignment of the single bits is depicted in the

following tables.

User parameters 1

Bit 15

Bit 0

Bit 0

Synchronization Frequency

00 = Automatic

01 = Fix 50 Hz

10 = Fix 60 Hz

Bit 1

Synchronization Frequency

Bit 2

Measurement connection

1 = LL

0 = LN

Bit 3

Stage recognition

1 = Off

0 = On

Bit 4

Switch cycle distribution

1 = Yes

0 = No

Bit 5

Start AI count down (90 s after each restart)

1 = Yes

0 = No

Bit 6

1

1 = Yes

0 = No

Bit 7

Stage exchange

1 = Yes

0 = No

Bit 8

Control

00 = Auto

01 = LIFO

10 = Combi-filter

Bit 9

Control

Bit 10

I < Limit; lock stage

1 = Yes

0 = No

Bit 11

Fast control; Sync. Impulse

1 = Yes

0 = No

Bit 12

DO Type

1 = N. closed

0 = N. opened

Bit 13

DI Type

1 = Low-active

0 = High-active

Bit 14

Capacitive overcompensation

1 = Allowed

0 = Permitted

Bit 15

Progressive algorithm (Using „On“Control must be set Auto)

1 = On

0 = Off

Technical Documentation

BLR-CM Modbus

Rev. 05

2018-09

16

User parameters 2

Bit 15

Bit 0

Bit 0

CT Type

1 = X/1A

0 = X/5A

Bit 1

Control

00 = Control ON

01 = Control OFF

10 = Control FREEZE

Bit 2

Control

Bit 3

Reserved

X

X

Bit 4

Start AI

1 = Start

0 = Stop

Bit 5

Status AI

1 = Active

0 = Inactive

Bit 6

Reserved

X

X

Bit 7

Reserved

X

X

Bit 8

Reserved

X

X

Bit 9

Reserved

X

X

Bit 10

Reserved

X

X

Bit 11

Reserved

X

X

Bit 12

Data logger synchronization via DI-data logger

1 = Active

0 = Inactive

Bit 13

Reserved

X

X

Bit 14

Logic of DI-Data logger input

1 = Low-active

0 = High-active

Bit 15

Reserved

X

X

Alarm Output Mask 1 (OM1)

Bit 15

Bit 0

Bit 0

VOLTAGE Alarm (Over- or undervoltage)

1 = Selected

0 = Deselected

Bit 1

I-HIGH Alarm (I secondary > 6A)

1 = Selected

0 = Deselected

Bit 2

I-LOW Alarm

1 = Selected

0 = Deselected

Bit 3

TEMP 1 Alarm

1 = Selected

0 = Deselected

Bit 4

TEMP 2 Alarm

1 = Selected

0 = Deselected

Bit 5

THD-U Alarm

1 = Selected

0 = Deselected

Bit 6

THD-I Alarm

1 = Selected

0 = Deselected

Bit 7

Stage warning Alarm (OPC, SPL)

1 = Selected

0 = Deselected

Bit 8

Faulty stage Alarm

1 = Selected

0 = Deselected

Bit 9

Digital input (HT/NT)

1 = Selected

0 = Deselected

Bit 10

Reserved

X

X

Bit 11

P-Overload Alarm

1 = Selected

0 = Deselected

Bit 12

Q-Overload Alarm

1 = Selected

0 = Deselected

Bit 13

P-Export Alarm

1 = Selected

0 = Deselected

Bit 14

CONTROL Alarm

1 = Selected

0 = Deselected

Bit 15

COS-PHI Alarm

1 = Selected

0 = Deselected

Technical Documentation

BLR-CM Modbus

Rev. 05

2018-09

17

Alarm Output Mask 2 (OM2)

Bit 15

Bit 0

Bit 0

FREQUENCY Alarm

1 = Selected

0 = Deselected

Bit 1 - 15

Reserved

X

X

3.6 Stage status

Information about every stage are stored in the stage database. The referring information is available in different data

types. The following bit assignment is used in the subsequent registers.

Output

Bit 15

Bit 0

S1 –S12

Output of stage 1 to 12

1 = Closed

0 = Open

The base addresses and the data types can be found in the table below. All values can be accessed with function codes

03hex and 04 hex.

Address

Value

Words

Type

Units

768

Fast stage (1 = fast, 0 = normal)

1

UINT16

-

769

Fix stage (1 = fix, 0 = automatic)

1

UINT16

-

770

Fix stage on/off (1 = on, 0 = off)

1

UINT16

-

772

Stage status (1 = defective, 0 = o.k.)

1

UINT16

-

1280

Switching state (1 = on, 0 = off)

1

UINT16

-

In the current firmware version it is possible to switch stages manually via Modbus. In order to switch a stage, the

respective stage must be set to “1” under address 769. After this preparation, the stage can be switched on or off using

the bits in address 770. While switching, the discharge time of the respective stage is considered.

Attention: Switching compensation stages via Modbus must not be done as long as it is not ensured that nobody is

working at the compensation system.

Attention: Performing changes in register 769 result in switching all stages off and according to the respective setting

on again.

Technical Documentation

BLR-CM Modbus

Rev. 05

2018-09

18

All further base addresses and data types can be found in the table below. The values of the step sizes are based on the

nominal voltage.

Adress

Value

Words

Type

Unit

773

Step size L-value step 1

2

SINT32

var

779

Step size L-value step 2

2

SINT32

var

773+(6*(n-1))

Step size L-value step n

2

SINT32

var

...

...

839

Step size L-value step 12

2

SINT32

var

845

Step size F-value step 1

2

SINT32

var

851

Step size F-value step 2

2

SINT32

var

845+((6*(n-1))

Step size F-value step n

2

SINT32

var

...

...

911

Step size F-value step 12

2

SINT32

var

917

Switch cycles step 1

2

SINT32

-

919

Switch cycles step 2

2

SINT32

-

...

...

939

Switch cycles step 12

2

SINT32

-

941

Discharge time step 1 x 10

1

UINT16

s

942

Discharge time step 2 x 10

1

UINT16

s

...

...

952

Discharge time step 12 x 10

1

UINT16

s

3.7 Device status

The following mentioned registers contain information of alarms, messages and the status of the digital outputs. The

assignment of the alarms can be seen in the bit mask below. If the referring bit = 1, the alarm is active.

All these values can be accessed with function codes 03hex and 04 hex.

Address

Value

Words

Type

Unit

1536

Alarm status

1

UINT16

-

Technical Documentation

BLR-CM Modbus

Rev. 05

2018-09

19

Output

Bit 15

Bit 0

Bit 0

Over- or undervoltage

1 = Active

0 = Inactive

Bit 1

Overcurrent

1 = Active

0 = Inactive

Bit 2

No current

1 = Active

0 = Inactive

Bit 3

Temperature 1 too high

1 = Active

0 = Inactive

Bit 4

Temperature 2 too high

1 = Active

0 = Inactive

Bit 5

Alarm voltage harmonics

1 = Active

0 = Inactive

Bit 6

Alarm current harmonics

1 = Active

0 = Inactive

Bit 7

Warning decreased stage capacity

1 = Active

0 = Inactive

Bit 8

Alarm defective stage

1 = Active

0 = Inactive

Bit 9

Alarm signal via digital input

1 = Active

0 = Inactive

Bit 10

System error

1 = Active

0 = Inactive

Bit 11

Absolute active power too high

1 = Active

0 = Inactive

Bit 12

Absolute reactive power too high

1 = Active

0 = Inactive

Bit 13

Export active energy

1 = Active

0 = Inactive

Bit 14

Under- or overcompensation

1 = Active

0 = Inactive

Bit 15

Alarm cosφ is not reached

1 = Active

0 = Inactive

The assignment of the alarm reactions can be seen in the bit mask below. If the referring bit = 1, the output or the

message is active.

Address

Value

Words

Type

Unit

1537

Status messages

1

UINT16

-

Output

Bit 15

Bit 0

Bit 0

Alarm relais

1 = Active

0 = Inactive

Bit 1

Digital output

1 = Active

0 = Inactive

Bit 2

Show display message

1 = Active

0 = Inactive

Bit 3

Target cosφ2

1 = Active

0 = Inactive

Bit 4

Controller stopped, stages off

1 = Active

0 = Inactive

Bit 5

Freeze stages

1 = Active

0 = Inactive

Bit 6 - 15

Reserved

X

X

All settings send by Modbus are considered immediately, but are stored in the working memory only. In

case of a power blackout, these settings will be lost. To store settings durable, they must be written into

the non-volatile memory.

!

Technical Documentation

BLR-CM Modbus

Rev. 05

2018-09

20

3.8 Storage settings

Since entered settings are only saved in the RAM, address 4096 can be written with function code 03hex,04 hex or 06hex

to save settings permanently.

Address

Value

Words

Type

Unit

4096

Store parameter data in EPROM

1

UINT16

-

If “29864” is written to the upper address, the previous entered parameters are stored into the EPROM. A successful

writing process is confirmed by a “1” in the same register.

It is not recommended to write data cyclically into the EPROM, since the lifetime of the flash cells is limited!

There are further values in the device’s memory, which are not mentioned in this document. Since they

can contain important device data, the mentioned addresses must be written only.

!

Table of contents

Other Beluk Controllers manuals

Beluk

Beluk CX plus User manual

Beluk

Beluk BLR-CX Installation and operation manual

Beluk

Beluk CX plus User manual

Beluk

Beluk BLR-CM Training manual

Beluk

Beluk BLR-Q(U)06/12R User manual

Beluk

Beluk CX plus User manual

Beluk

Beluk CX plus User manual

Beluk

Beluk BLR-CM 3 phase User manual

Beluk

Beluk BLR-CX-R User manual

Beluk

Beluk BLR-CX User manual

Popular Controllers manuals by other brands

Satel

Satel ACU-270 manual

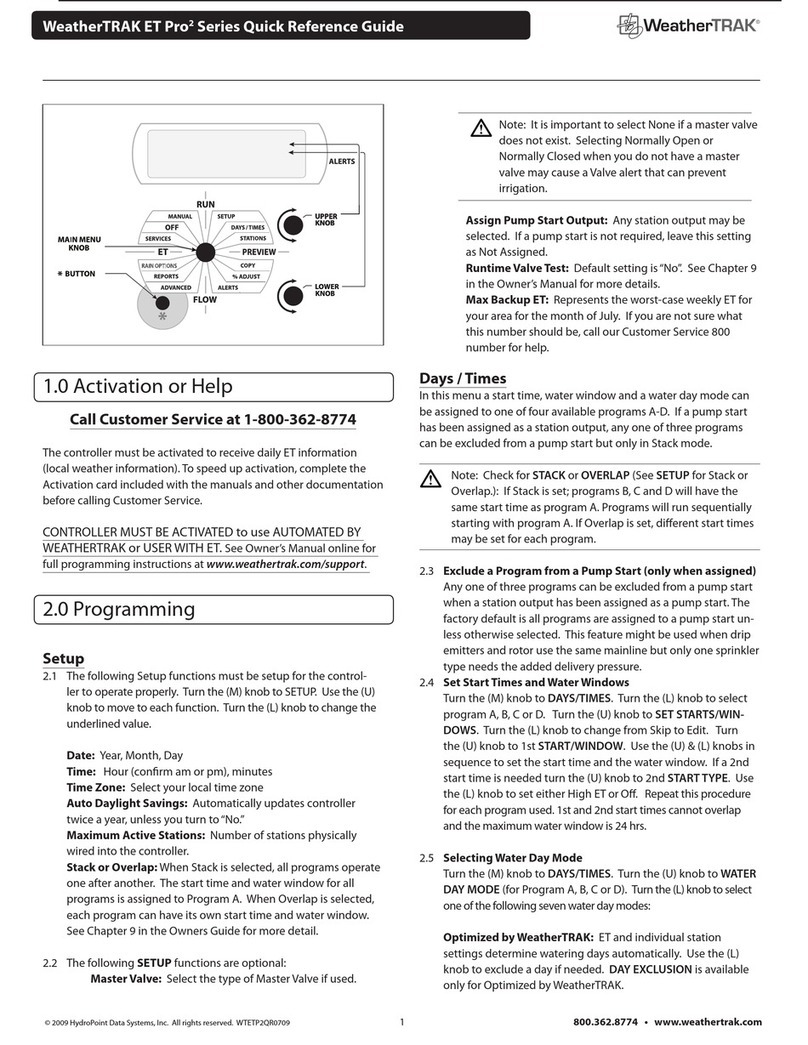

WeatherTRAK

WeatherTRAK ET Pro 2 Series Manual/quick reference guide

WITTUR

WITTUR sematic SDS Rel. 3 instruction manual

amiad

amiad ADI-X IOM Installation, operation & maintenance instructions

usi

usi SmartStep X Series Installation, operation and technical manual

Siemens

Siemens LME7 Series Basic documentation