Beluk BLR-CM Training manual

Commissioning Instructions

Rev. 03

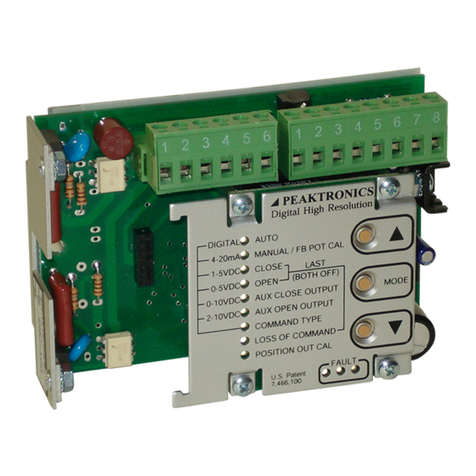

Power Factor regulator BLR-CM

Connection

Only qualified staff is

allowed to perform the

installation. All legal

rules have to be ob-

served and technical

standards have to be

met. Before connecting

the device check that all connecting leads are de-

energized and that current transformers are bypassed.

1) Compare auxiliary-, measurement-, control voltage, fre-

quency and the current path of the device (see type label)

with the data of the electricity network

2) Assemble the relay in the switch panel with the 2 mounting

clips If the device is not fitting in the cutout the small plas-

tic bars on the side of the case can be removed with a

knife

3) Connect protective ground to the terminal link of the case

4) Connect in accordance to the wiring diagram Pay special

attention to the cross section size of the CT connections!

An integrated voltage observation with regard to the auxil-

iary voltage in BLR-CM guarantees a safety disconnection

of the capacitors in case of undervoltage It must be en-

sured, that auxiliary voltage is taken from the identical

phase as control voltage for the contactors, to guarantee

that all switching elements are safely switched off in case of under voltage

5) Remove short circuit links of the current transformer before commissioning!

isplay

User Interface of BLR-CM is a graphical LCD and a membrane keyboard with 4 softkeys

LCD is split into 4 areas:

Top area:

The two lines of top area are showing information about general status of the relay The readings of this

area are always available, independent from the menu which is used The readings of top area can be

parametered in menu SETUP/DISPLAY

The “sad face” indicates that there are problems with the level of voltage or current

The “happy face” indicates that levels of voltage and current are ok

The “serious face” indicates setting PFC OFF or PFC FREEZE

Status columns

:

left and right column are showing the status of the control exits

1 Step 1, status: off, type: NORMAL

2! Step 2, status: off, type: NORMAL blocked or FIX OFF

F Step 3, status: off, type: FAULTY

4 Step 4, status: on, type: NORMAL

5! Step 5, status: on, type: FIX ON

Step 6, status: off, type: OFF, not available or PFC OFF

“NORMAL blocked” can be caused by discharging time

“PFC OFF” can be caused by voltage out of tolerance, by relay is off due to setting or due to Alarm system

Main area: the three lines of main area are for menu navigation and display of information

Softkey area: the soft key area shows the function of the membrane-keyboard Depending on the opened menu, the function

is different

BLR-CM

K1

L1

L2

L3

N

PE

Einspeisung

Supply

Last

Load

K1

BLR-CM

K1

K1

L1

L2

L3

N

PE

Einspeisung

Supply

Last

Load

Commissioning Instructions

Rev. 03

Power Factor regulator BLR-CM

Page 2 of 4

Attention: The present manual is for the first commissioning. For further explanations and more possible settings, please

check the reference manual.

For ease of use and adjustment the BLR-CM user interface consists of a combination of graphical LCD display and 4 soft-press-keys

The following flow chart shows step by step how to commission the BLR-CM The steps below should be followed by pressing the high-

lighted soft-press-keys on the BLR-CM

STEPINFO

>

SETUP <

MANUAL

CHANGE LANG

Standard version of BLR-CM is supporting English, German and French

NOM VOLTAGE

ULL 400 V

Function of the setting of nominal voltage is to make a definition about the nominal

voltage of the system The threshold levels for under- and overvoltage are based on this

as well as the ratings of the capacitor sizes in step database, which are used for control

and monitoring The capacitor sizes, which are stored in step database, are also r

ated to

the nominal voltage

Independent of connection of the voltage measuring channel, nominal voltage is

always the phase-phase voltage!

CT FACTOR

0001 0

The CT FACTOR is the ratio of current transformer (e g 1000/5 = ratio 200)

For current measuring a CT always have to be used!

VT FACTOR

001 0

VT FACTOR is the ratio of the voltage transformer If the regulator is connected directly

to the measurement voltage without VT the value 1 has to be used

Automatic initialization is switching all exits During this test it can get information,

which exits are working and it can correct the connection of the measuring channels for

voltage and current by internal settings

Automatic initialization can be started only when the “happy face” is shown (voltage

and current are ok) and when CONTROL is not set to status OFF or FREEZE manually or by alarm-system If

CONTROL setting is FREEZE done by AI, then a restart is possible

When AI is running, the status line of BLR-CM shows the message: “AI ACTIVE” The maximum number of

switching operations during AI is 10 per exit (normally between 2 and 5) AI is taking care about the setting of

discharge time for each exit If there is a very long discharge time necessary, AI will take a certain time

The following messages from AI are possible:

ALARM: AI OK

AI is finished completely Please check if all used exits are shown with their number in the display and please

check if BLR-CM is working correctly

ALARM: STEPS (CONTROL setting is: FREEZE)

Capacitors cannot be detected, because they are not controlled by controller or the rating is smaller as limit

AI ABORTE (CONTROL setting is: FREEZE)

AI couldn’t be finished The reason could be permanent load variation during AI Please try it again or do the

settings manually

START AI

CONTROL

ON

ON: Automatic control is running

FREEZE: Automatic control is stopped; status of exit relays is frozen

OFF: Automatic control is stopped; all exit relays are off

COS PHI 1

1 00

This is the setting for target COS PHI1 It will be valid during normal operation

SWITCH INTERVAL

0002 5 S

The switch interval is the time delay between switching steps in regulation

The switch interval has two different functions:

1 Protecting the contactors by reducing the number of switching cycles

2.

Building of the average of the reactive power in th

e time of the switch inte

r

val

Commissioning Instructions

Rev. 03

Power Factor regulator BLR-CM

Page 3 of 4

STEPS

STEP 01

STEP TYPE

NORMAL

+

⊳

Use + to select the

steps and use

⊳ adjust the step

type

STEP TYPE:

Following step types are possible:

NORMAL = step is used for normal regulation

FIX-OFF = step is permanently switched-off

OFF = step is permanently switched-off an blend out

FIX-ON = step is permanently switched-in

(step will be switched-off in critical situations like over- and

under voltage, over temperature or excessive harmonics)

FAST = step is used for real-time algorithm

FAULTY = the step is detected as defective and is blocked

To adjust the dis-

charge time push the

button

STEP 01

DISCHARGE TIME

0075 0 S

Use + to select the

steps and use

to

enter the input window

to adjust the discharge

time

ISCHARGE TIME:

Allows to set the discharge time for each step individually

After completing the steps above, the controller will check the measured voltage and current If all measured values are within the pre-

scribed tolerances, the controller start will start normal operation

If the controller remains in this setup status for more than 5 sec use the flowchart above to check the VT ratio the

nominal voltage and the connection of the voltage measurement

If the controller remains in this setup status, check the connection of the current transformer e g has the short

link been removed and is the respective CT ratio correctly set?

As soon the controller has acquired the measurement voltage and the measurement current it shows the current

cos phi and starts with normal operation

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Menü BLR

-

CM

>

MEAS VALUES

<

HARMONICS

ULL V Voltage Phase-Phase PF1 Power factor

ULN V Voltage Phase-Neutral CP1 Cos phi

THD % Total Harmonic Distortion

Vol

t

age

I A Current OPH Operation hours counter

THD % Total Harmonic Distortion

Cu

r

rent

APF Average power factor

T-MAX °C Highest measured temp

P W active Power WPI WH counter active work import

Q var reactive Power WPE WH counter active work export

S VA apparent power

F HZ frequency WQI varH counter reactive work ind

∆

Q var control deviation WQE varH counter reactive work cap

T °C ambient temperature

Commissioning Instructions

Rev. 03

Power Factor regulator BLR-CM

Page 4 of 4

MEAS: VALUES

>

HARMONICS <

STEPINFO

Harmonics for current and voltage up to 31st order

HARMONICS

>

STEPINFO <

SETUP

Display Step type, switching operations, Step size

Factory setting Adjustable range

STEPINFO

>

SETUP <

MANUAL

CHANGE LANG.

ENGLISCH English, German and French

NOM. VOLTAGE

ULL 400 V 100 – 220kV

CT FACTOR

1 1-6500

VT FACTOR

1 1-350

START AI

NO YES / NO

CONTROL

ON ON / OFF / FREEZE

COS PHI 1

1 00 i 0 60 – c 0,70

SWITCH INTERVAL

10 0 S 0 5 S – 1200 0

STEPS

STEP TYPE

STEPS 1-12 STEP TYPE

NORMAL

NORMAL / FIX-OFF / OFF /

FIX-ON

ISC

HARGE TIME

STEPS 1-12 DISCHARGE

TIME 75 S

0 5 – 1200 S

SETUP

>

MANUAL <

DATALOGGER

To enter in manual mode, please select “MANUAL” and push ► for 3 seconds The automatic control is frozen

and the exits can be switched manually By the means of the + -key the referring step can be selected Chang-

ing the switching state is possible by pushing the ◄►-key

Manual switching is only possible when measurement voltage is in allowed range. Otherwise

over- and undervoltage protection will block this function. After switching off an active step the

discharging time is active. Only after this time is over the step can be switched on manually

again.

The menu item “ ATALOGGER” is only visible when the device is equipped with option

–

M.

MANUAL

>

DATALOGGER

<

DEVICE INFO

SETUP HISTORY

In item “SETUP HISTORY” are all changes in the setup of the device stored For

each changed value are the following information’s with time stamp stored:

Name of the setting, e g CT FACTOR and initial value and new adjusted value

For

more detailed information’s, please check the reference book

ALARM HISTORY

In item “ALARM HISTORY” are all alarm events stored For each alarm event are

the following information’s with time stamp stored: Name of alarm e g Temp 1,

adjusted threshold and max value and voltage and current

DATALOGGER

>

DEVICE INFO <

device

type e.g.

BLR-CM

software: z B V 02 07 02

flag: z B MB = Modbus

!

Table of contents

Other Beluk Controllers manuals

Beluk

Beluk CX plus User manual

Beluk

Beluk BLR-CM 3 phase User manual

Beluk

Beluk BLR-CM Modbus Guide

Beluk

Beluk BLR-Q(U)06/12R User manual

Beluk

Beluk CX plus User manual

Beluk

Beluk BLR-CX Installation and operation manual

Beluk

Beluk CX plus User manual

Beluk

Beluk CX plus User manual

Beluk

Beluk BLR-CX-R User manual

Beluk

Beluk BLR-CX User manual

Popular Controllers manuals by other brands

Satel

Satel ACU-270 manual

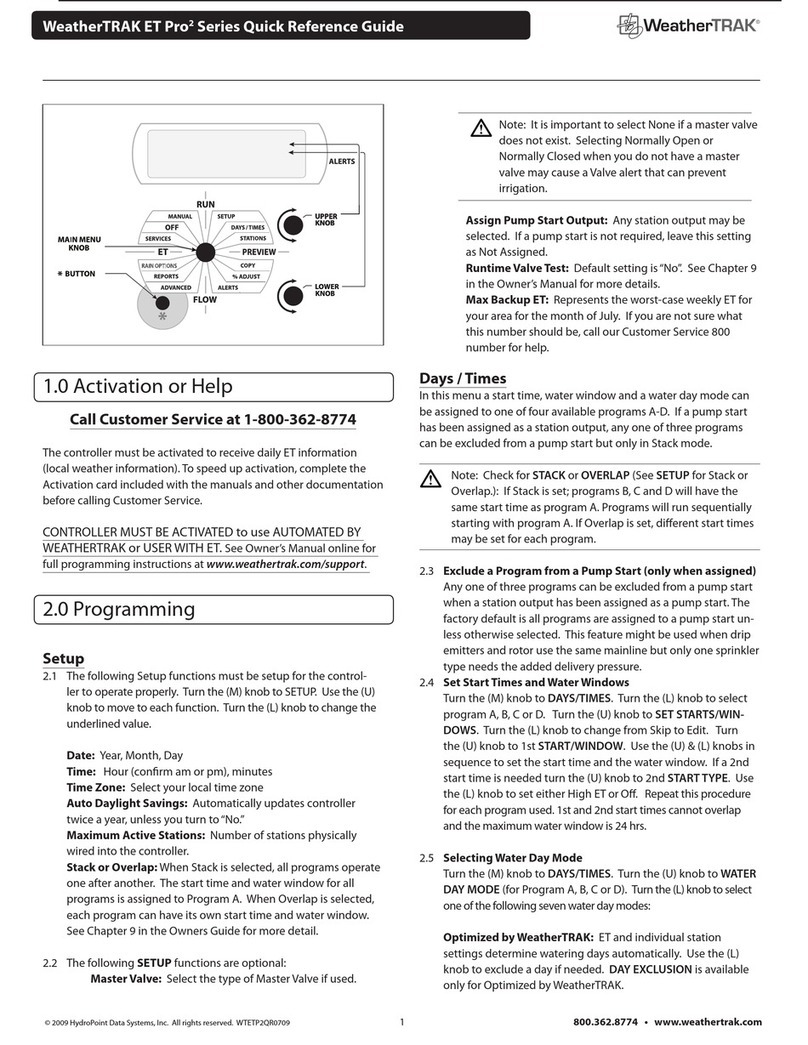

WeatherTRAK

WeatherTRAK ET Pro 2 Series Manual/quick reference guide

WITTUR

WITTUR sematic SDS Rel. 3 instruction manual

amiad

amiad ADI-X IOM Installation, operation & maintenance instructions

usi

usi SmartStep X Series Installation, operation and technical manual

Siemens

Siemens LME7 Series Basic documentation