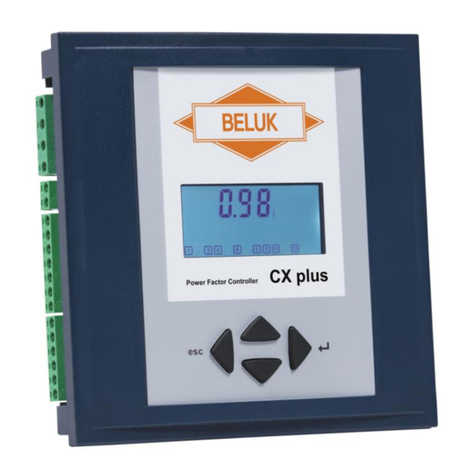

Beluk CX plus User manual

MB_EN_ACXplus-R_BEL_02

Beluk GmbH

Tel.: +49 8861 2332 0

Taubenstrasse 1

Fax: +49 8861 2332 22

86956 Schongau

blr@beluk.de

Germany

http://www.beluk.de

x

CX plus Operating Manual

s

General safety notes

Failure to observe the following instructions can lead to serious

injury or death !

During installation, there is a risk of electric shock. For this reason,

electrical devices may only be installed, operated, serviced and maintained

by qualified personnel. A qualified person is one who has the ability,

experience and knowledge necessary for the construction, installation and

operation of electrical equipment and is trained in the detection and

prevention of potential hazards.

During installation and maintenance, the relevant regulations for

installation of switchgear and for preventing accidents must be observed

and complied with.

Devices with damaged or open housings or terminals may not be

connected to the mains and must be disconnected immediately.

After disconnection of the device, wait for 10 minutes until the capacitors

are discharged before removing doors or covers. After that, check to

ensure that the compensation system has been de- energised.

Beluk GmbH assumes no responsibility or liability for injury to persons or

damage to equipment due to improper installation or installation not for

the intended use carried out by qualified personnel.

New features of the CX plus over the BLR- CX

Modbus: no longer as an external add- on module,

now optionally installed internally.

Alarm memory: enables the storage of the last 10 alarms

New alarms: THD I alarm

I-Low alarm: can be disabled via digital input now:

SETUP/ 500/ 518 → “YES” = I-Low alarm blocked

Control algorithm: in addition to LIFO, AUTOMATIC (best fit) and

PROGRESSIVE, the FIFO algorithm has now also been implemented

Outputs: 6 or 12 stages, separate fan relay (can be used as 7th /13th

stage)

Display: to extend the service life of the backlight, it is turned off

60 seconds after last usage.

Storage Umax and THD Umax

Digital input:

Choice between target cosϕ1 and target cosϕ2, signalisation of an

external alarm or to disable the I-Low alarm

Temperature sensor: NTC now internal.

Installation and commissioning:

1) Before installation, the connection data of the CX plus must be

compared with the data of the supply network and the installation.

2) The working area must be disconnected from voltage and secured

against unauthorised and unintentional restart. The absence of

voltage must be verified with a standardised instrument/ testing

device. The voltage- free system must be grounded and short-

circuited. Adjacent live parts must be covered or placed behind

barriers.

3) The current transformer must be short-circuited! A current

transformer that has NOT been short-circuited generates very high

voltages posing a danger to persons and equipment. The current

transformer can thereby be destroyed.

4) Disconnect and remove the old reactive power controller.

5) Plug the CX plus into the switch panel section and fix it with the two

mounting brackets. (Section 138 x 138 mm)

6) Connect the protective conductor to the PE terminal of the metal

back of the CX plus.

7) Connect the connecting lines as shown in the wiring diagram.

(Current transformer: K [power plant] to S1, L [load] to S2)

8) Remove current transformer jumper.

9) Switch on voltage.

10) With a proper connection and correct connection data, the LCD lights

and the LCD test is active for 1 second.

11) Activation of user-guided initial commissioning “FIrSt SEtUP“ after

confirming “YES“. Afterwards all required parameters are requested

by CX plus. The choice of “NO” requires, that the user implements the

following parameters (12) … 15)) manually.

12) The current transformer factor (Ct) must be entered.

13) The nominal voltage (Un) and the voltage transformer factor (Pt)

must be entered, too.

14) Start the “Automatic initialisation” (AI) or enter the Phaseoffset

(PO) manually.

15) If the „Automatic initialisation” was successfully finished, the

message “AUTO”appears on the LCD.

Control starts after the discharge time lock.

Questions during commissioning:

1) No AUTO display → control stopped

Reasons: Manual operation, control is switched off, temperature is

too high, current is less than 15 mA, voltage or THD of voltage are not

permitted

2) U ALARM display → voltage out of tolerance

Check settings for rated voltage (SETUP/ Un) and

voltage transformer (SETUP/ Pt)

3) I Lo ALARM display → no current flow

Possible causes: Connection from the current transformer to

the controller is not correct; current transformer

jumper is not removed; transformation ratio is too large; no current

4) EXPORT display → feeding back of active power

If there is no real feeding back, connect voltage and

check current (phase polarity)

→ section Incorrect connections/ AI –automatic initialisation

5) Incorrect Cos phi → incorrect connection

Connect voltage and check current (phase, polarity)

→ section Incorrect connections/ AI –automatic initialisation

6) Outputs are switched off again immediately

→ section Incorrect connections/ AI –automatic initialisation

7) Frequent switching of the outputs

→output of the capacitors first needs to be detected

Display:

INFO: Stage database

AUTO: Automatic operation

MANUAL: Manual operation

SETUP: Settings menu

ALARM: Alarm memory

EXPORT: Feeding back of active power

NT: 2nd target cosϕis active

ALARM: Flashes if there is an

alarm notification

1st line:

I) cos ϕ/ menu items

II) inductive/ capacitive

2nd line:

I) code of metered and set values

II) metered and set values/ alarm

codes

III) units

Stage display:

Status of the stage (on/ off)

Stage faulty (flashing)

I

II

III

II

I

Operation:

The controller is operated using 4 keys.

Increase values

Select menu items

Exit menus/ Esc

Cursor to the left

Reset alarm (5 sec.)

Opens menus/ Enter

Cursor to the right

Settings

Decrease values

Select menu items

Input parameters:

↑, ↓

→

↑, ↓

→

←

Digit adjust (up/ down)

Move to next position

After the last digit is set, selection of:

- Multiplier k(kilo) or M(Mega)

- Preceding sign i(inductive) or c(capacitive) (flashing of i or c)

Application of values at the end

Abort entry

Main menu:

Select menu items with ↑, ↓, enter the submenu with →

Measurement value display:

(Change with ↑, ↓)

ULL, ULN, I, P, Q, ΔQ, S, THD U, 3.-19. Har. U,

THD I, 3.-19. Har. I, cosϕ, PF, APF, Hz(F), t(°C),

thi (°C), OPh (h), tanϕ, U hi, THD U hi

INFO stage database:

Power and power loss of stages, number of

switching operations, stage type, operating hours.

(→ section INFO stages database)

MANUAL operation:

Intentional switching on and off of

switching outputs.

(→ section MANUAL operation)

SETUP settings menu:

Rated voltage (Un), current transformer (Ct),

voltage transformer (Pt), automatic initialisation

(AI), control on/ off (PFC), target cosϕ1 (CP1),

switching time (St), stage type (Out)

(→ section SETUP settings menu)

ALARM memory:

Memory buffer shows the last 10 alarms. The most

recent alarm is in the first position.

INFO stage database:

Please note: The current status of the outputs is not displayed.

Browse through stages with ↑, ↓and select with →. The selected

stage flashes. ↑, ↓displays the following information:

Current capacitor output

The output relates to Un

Output reduction of the capacitor:

Current output/ nominal output in %

Number of operation cycles

Stage type:

AUTO: Automatically controlled stage

Fon: Fixed stage on

Foff: Fixed stage off

FLty: Stage faulty and disabled

Operation hours:

Shows how many hours the corresponding stage has

already been in operation. Selected stage flashes.

MANUAL operation:

Enter manual operation by pressing → for three seconds.

Browse stages with ↑, ↓. The selected stage is displayed in line 2 as a

number. →switches the stage on or off.

Exit manual operation with ←.

Important information:

-In the menu Manual operation, only stages with stage type AUTO can

be switched. In LIFO mode, FIFO mode and combined filter mode, the

menu Manual operation is disabled. (→Reference Manual)

-The discharge time lock is also active in manual operation.

(Stages are disabled for a certain time after shutdown)

-The voltage must be within the tolerances, otherwise all stages will

shut down. The respective stages can not be switched in Manual

operation.

-THD U-, THD I- and overtemperature- Alarm block the switching of

stages in manual mode.

-After exiting manual mode, there is automatic control starting from

the set status.

SETUP settings menu:

After opening SETUP, submenu 100 appears. → Open menu 100.

↑, ↓ Menu 200 - 600 & 800, with optional Modbus: 200 - 800

(locked with password → Reference Manual)

Un

Ct

Pt

AI

PFC

CP1

St

OUt

Rated voltage (correct setting is very important)

For voltage monitoring and stages database reference.

Current transformer ratio (must be set)

The value is used for calculation and activation of some

measurement values in the measurement menu.

Voltage transformer ratio

Important as the basis for setting Un

Automatic initialisation

→section Incorrect connection/ AI –Automatic initialisation

CONTROL ON/ OFF/ HOLD

Switching on, switching off, freezing the control

Target cosϕ1

Basis for compensation target

Switching time

Defines the speed of the controller

Stage type

Defining stage type: AUTO, Fon, Foff,

Reset faulty stages (FLty)

Incorrect connection/ AI –automatic initialisation:

In case of incorrect connection of the voltage or current path (phase, polarity),

the reactive power controller cannot be operated. Thus, the connection should

be corrected. Since this is not always possible, the CX plus alternatively

provides the following functions:

Automatic initialisation: SETUP/ 100/ AI

The AI switches all outputs on and off several times. This takes a few minutes.

Unused outputs are set to “Foff”.

Stage values are not detected during this process.

After the end of the AI, the function of the controller should be checked.

Requirements for a successful operation of the AI:

-The voltage is within the tolerance

-The current transformer is connected (no simulation)

-Capacitor banks are installed, functional and secured

Possible issues for successful AI:

-Load fluctuations

-Small current signals

Error messages AI/ Abrt:

AI was aborted because no clear result was possible; the control is OFF.

The Phaseoffset can be entered manually as well:

Entering of the correct Phaseoffset SETUP/ 206 → Reference Manual

Stage detection:

During each switching operation, the stage value is determined (except if

this feature is disabled SETUP/ 308 → Reference Manual).

The detected values are updated in the stages database. A loss of capacity

can be determined there.

If a stage does not work in the first three switching operations, it is

automatically assigned to the stage type Foff.

After commissioning, the existing stages have stage type Foff:

Is the current transformer jumper removed?

Is the position of the current transformer correct?

Are all currents and measuring/ operating voltages present?

Faulty stages:

A stage that switches three consecutive times without measurable

success is declared to be faulty. After 24 hours, another test is started.

Stage display: flashes

Status: Flty, stage is disabled

Procedure:

Do individual stage symbols flash during operation mode?

Check fuse, contactor and capacitor output of the corresponding stage.

Acknowledgement in SETUP/ 100/ OUt or restart (interruption of the

measuring/ supply voltage) of the CX plus.

Alarms:

Alarm system settings: SETUP/ 500 → Reference Manual

U

ALARM:

Measuring voltage out of tolerance

I Lo

ALARM:

Measuring current < 5 mA (check I-measuring path)

SETUP/ 500/ 518 → “YES” = I-Low alarm blocked

I Hi

ALARM:

Measuring current > 6 A (transformation ratio of the

built-in current transformer is too small)

PFC

ALARM:

Compensation target unreachable (check system)

HArU

ALARM:

Limit for THD U has been exceeded

HArI

ALARM:

Limit for THD I has been exceeded

StEP/ FLtY

ALARM:

Faulty stages have been detected

SPL/ Nr

ALARM:

Power loss levels below 75 %

Stage number and error code will flash alternately

thi

ALARM:

Overtemperature shutdown of the stages

OPH

ALARM:

Max. operation hours device reached (maintenance)

OPC/ Nr

OPHS/ Nr

ALARM:

Max. operation cycles/ operation hours stages

reached (maintenance)

Stage number and error code will flash alternately

AI/ Abrt

ALARM:

Abort of the automatic initialisation

Re-start the AI when the grid is calmer

or manual setting of the phase offsets

(SETUP/ 206 → Reference Manual)

Factory settings

SETUP/ 100

IMPORTANT SETTINGS

open

Un/ rated voltage

400 V

Ct/ current transformer

1

Pt/ voltage transformer

1

AI/ start Ai

NO

PFC/ control

ON

CP1/ target cosϕ1

1

St/ switching time

10 s

Out/ stage type

AUTO

SETUP/ 200

MEASUREMENT

locked

201/ rated voltage

400 V

202/ current transformer

1

203/ voltage transformer

1

204/ tolerance voltage

10 %

205/ voltage LL

NO

206/ phase offset

0

207/ start Ai

NO

208/ synchronisation

AUTO

209/ temperature offset

0°C

SETUP/ 300

CONTROL SETTINGS

locked

301/ sensitivity

60 %

302/ target cosϕ1

1.00

303/ target cosϕ2

i 0.95

304/ EXPORT cosϕ2

NO

305/ switching time

10 s

306/ St stage exchange

2 s

307/ active stage exchange

YES

308/ active stage detection

YES

309/ lock faulty stages

YES

310/ control on/off/hold

ON

311/ control algorithm

1

312/ offset reactive power

0 var

313/ asymmetry factor

1

314/ Qcap stages Off

NO

315/ stage distribution

NO

316/ detect. def. stages

YES

SETUP/ 400

STAGE DATABASE

locked

401/ discharge time lock

75 s

402/ nominal stage value

c 3 var

403/ stage type

AUTO

404/ operation cycles

0

405/ stage operation h

0 h

406/ fan relay as stage 13

NO

Factory settings

SETUP/ 500

ALARM SETTINGS

locked

501/ manual reset

NO

502/ THD U Limit

20 %

503/ THD stages off

NO

504/ delay of harm. alarm

60 s

505/ I= 0 freeze controller

NO

506/ maintenance alarm

NO

507/ operating cycles limit

500 k

508/ limit OPh

65.5 kh

509/ limit OPh stage

65.5 kh

510/ THD I limit

50 %

511/ DI= Hi active

YES

512/ Temp1 limit

30 °C

513/ Temp2 limit

55 °C

514/ control alarm

NO

515/ faulty stages alarm

NO

516/ power loss

NO

517/ alarm illumination

NO

518/ digital input function

CP 2

519/ info lock I-Low

NO

520/ DI-Alarm switch off

stages

NO

521/ I-Low-Alarm

YES

522/ delay I-High-Alarm

10 s

523/ switch off interval

60 s

SETUP/ 600

RESET

locked

601/ factory settings

602/ stages database

603/ operating hours

604/ average power

factor

605/ max. temperature

606/ alarm

607/ firmware info

608/ password change

242

SETUP/ 700

MODBUS SETTINGS

locked

701/ baud rate

19200

702/ parity

EVEN

703/ address

1

SETUP/ 800

Backlight Options

locked

801/ backlight

Commissioning-Mode

NO

802/ delay time

0,25 h

Technical specifications:

Voltage:

90- 550 V, 1 ph., 50/60 Hz, 6 VA

Current:

5 mA- 6 A, 1 ph., <1 VA,

Switching outputs:

Relay, NO contact,

common contact supply: max. 10 A 250 V

AC/ 5 A, 400 V AC/ 1 A

Digital input:

90- 250 V AC

Temperature measurement:

NTC, internal

Signal contact:

Pot.- free relay, normally closed contact,

48 V DC/ 1 A, 250 V AC/ 5 A, 400 V AC/ 1 A

Optional NO/ NC

Fan control:

Pot.- free relay,

48 V DC/ 1 A, 250 V AC/ 5 A, 400 V AC/ 1 A

Interface:

Optional: RS485 Modbus

Ambient temperature:

Operation: -20 °C to 70 °C

Storage: -40 °C to 85 °C

Humidity:

0 %- 95 %, condensing not allowed

Overvoltage category:

300 V LN/ 519 V LL CAT III

or 550 V/ CAT II

Connection:

Screw terminals, pluggable

Housing:

Front: Instrument housing, plastic

Back: Metal

Protection type:

Front: IP41, Back: IP20

Technical specifications:

Weight:

Approx. 0.6 kg

Dimensions:

Housing: 144 x 144 x 58 mm (WxHxD)

Cut-out: 138 (+0.5) x 138 (+0.5) mm

Alarm memory:

Storage of the last 10 alarms

Standards:

IEC 61010- 1

IEC 61000 6- 2

IEC 61000 6- 4: level B

IEC 61326- 1

UL 61010

Conformity:

CE, NRTL(UL), c NRTL (cUL), EAC

Algorithms:

AUTOMATIC (best fit)

LIFO

FIFO

PROGRESSIVE

Combined filter

Max. operating height:

≤ 2000 m

Max. contamination level:

2

Other manuals for CX plus

3

Table of contents

Other Beluk Controllers manuals

Beluk

Beluk BLR-Q(U)06/12R User manual

Beluk

Beluk BLR-CM 3 phase User manual

Beluk

Beluk CX plus User manual

Beluk

Beluk BLR-CM Modbus Guide

Beluk

Beluk CX plus User manual

Beluk

Beluk BLR-CX Installation and operation manual

Beluk

Beluk CX plus User manual

Beluk

Beluk BLR-CX User manual

Beluk

Beluk BLR-CM Training manual

Beluk

Beluk BLR-CX-R User manual