Beluk BLR-CM 3 phase User manual

Reference Manual

BLR-CM/BLR-CM3phase

Rev. 08

2018-09

Beluk GmbH

Taubenstrasse 1

86956 Schongau

Germany

Tel.: +49/(0)8861/2332-0

Fax: +49/(0)8861/2332-22

E-Mail: [email protected]

Web: http://www.beluk.de

Reference Manual

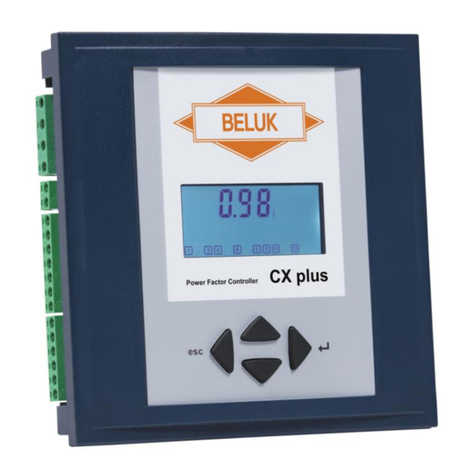

Power Factor Controller

BLR-CM

BLR-CM3phase

Reference Manual

BLR-CM/BLR-CM3phase

Rev. 08

2018-09

2

Revisionlist

Datum

Name

Revision

Kommentar

02.09.08

Le

01

initial document release (SW 2.5.1)

19.09.08

MR

02

Editorial changings

21.07.10

MR

03

SW 2.7.0 incl. datalogger

02.08.10

MR

04

AI for BLR-CM3phase

13.09.10

MR

05

Editorial corrections

20.09.10

Le

06

Add menu items to “Quickstart SETUP”

16.07.18

SO

07

Removement of DQS-Logo

26.09.18

SMi

08

Layout changes, changes in the standard settings

Reference Manual

BLR-CM/BLR-CM3phase

Rev. 08

2018-09

3

Important Notice:

BLR-CM with option –DM includes a rechargeable battery to run the real-time clock. To replace this battery, please send

the relay to Beluk. We will forward this battery to a recycling system.

Important information!

If the sign aside appears besides a text passage in the manual the reader is strongly advised to read the

corresponding information as it is very important for the device usage! It can contain safety advice or other

information for the correct handling of the device. If the information is disregarded, the device may be inop-

erable or even damaged!

!

Reference Manual

BLR-CM/BLR-CM3phase

Rev. 08

2018-09

4

Contents

1Installation and Connection ..........................................................................................................5

1.1 Auxiliary voltage ............................................................................................................................................. 5

1.2 Current measurement..................................................................................................................................... 5

1.3 Voltage measuring .......................................................................................................................................... 6

1.4 Control outputs............................................................................................................................................... 6

1.5 Alarm relay ..................................................................................................................................................... 7

1.6 Digital input .................................................................................................................................................... 7

1.7 Digital output .................................................................................................................................................. 7

1.8 User Interface ................................................................................................................................................. 8

2MENU BLR-CM...............................................................................................................................9

2.1 MEAS. VALUES ................................................................................................................................................ 9

2.2 HARMONICS...................................................................................................................................................10

2.3 STEPINFO .......................................................................................................................................................10

2.4 Quickstart SETUP............................................................................................................................................11

2.5 SETUP.............................................................................................................................................................14

2.6 MANUAL ........................................................................................................................................................27

2.7 DATALOGGER (option –DM)...........................................................................................................................28

2.8 DEVICE INFO...................................................................................................................................................29

3Wiring diagrams BLR-CM.............................................................................................................30

3.1 BLR-CM06/12R ...............................................................................................................................................30

3.2 BLR-CM06/12T ...............................................................................................................................................31

3.3 BLR-CM12RT...................................................................................................................................................32

3.4 BLR-CM06/12R-3A (BLR-CM3phase)...............................................................................................................33

3.5 BLR-CM06/12T-3A (BLR-CM3phase) ...............................................................................................................34

3.6 BLR-CM12RT-3A (BLR-CM3phase) ..................................................................................................................35

3.7 BLR-CM06/12R-HV .........................................................................................................................................36

3.8 BLR-CM06/12R-3AHV (BLR-CM3phase) ..........................................................................................................36

3.9 BLR-CM I/O ....................................................................................................................................................37

3.10 Synchronizing of datalogger ...........................................................................................................................37

4Standard Setting..........................................................................................................................38

5Trouble shooting .........................................................................................................................40

6Technical Data .............................................................................................................................41

Reference Manual

BLR-CM/BLR-CM3phase

Rev. 08

2018-09

5

1 Installation and Connection

Only qualified staff is allowed to perform the installation. All legal rules have to be observed and technical

standards have to be met. Before connecting the device check that all connecting leads are de-energized and

that current transformers are bypassed.

1) Compare auxiliary-, measurement-, control voltage, frequency and the current path of the device (see

type label) with the data of the electricity network.

2) Assemble the relay in the switch panel with the 2 mounting clips. If the device is not fitting in the

cutout the small plastic bars on the side of the case can be removed with a knife.

3) Connect protective ground to the terminal link of the case.

4) Connect in accordance to the wiring diagram (see chapter "connection"). Pay special attention to the

cross section size of the CT connections! An integrated voltage observation with regard to the auxiliary

voltage in BLR-CM guarantees a safety disconnection of the capacitors in case of undervoltage. It must

be ensured, that auxiliary voltage is taken from the identical phase as control voltage for the contac-

tors, to guarantee that all switching elements are safely switched off in case of under voltage.

5) Remove short circuit links of the current transformer before commissioning!

1.1 Auxiliary voltage

At BLR-CM auxiliary voltage has to be connected separately from measuring voltage. The terminals for auxiliary voltage

are marked with La, Lb and 0.

Terminal 0 has to be connected always. La and Lb are different tapping points of the transformer to allow the usage

with different voltage levels. The detailed connection depends on the device type and can be seen on the sticker at the

rear side of the regulator.

1.2 Current measurement

BLR-CM can be used in combination with x/5Amp current transformer as well as with x/1Amp types. The terminals for

CT connection are marked with K (S1) and L (S2). CT has to be mounted in the way, that K (P1) connected to the feeder

from utility and L (P2) is connected to load.

Current measuring is necessary for calculation of control deviation and capacitors sizes for reactive power regulation as

well as for showing and monitoring different measuring values.

BLR-CM can be used with summation transformer as well. To get proper function, please pay attention to correct po-

larity of all CTs and to the correct setting of CT-factor. The CT-factor for a summation transformer can easily be calcu-

lated by adding the single transformer ratios (e. g. 1000A/5A + 1000A/5A + 1000A/5A = 200 + 200 + 200 = CT-factor

600).

At BLR-CM3phase (option -3A) please take care that the current inputs are connected to the correct phases

in clockwise rotary field.

!

!

Reference Manual

BLR-CM/BLR-CM3phase

Rev. 08

2018-09

6

1.3 Voltage measuring

Terminals Um1 and Um2 are used for voltage measuring. Effective range is 50V to 530V AC and 45Hz to 65Hz. Voltage

measuring is necessary for calculation of control deviation and capacitors sizes for reactive power regulation as well as

for monitoring and protecting capacitors against over- and undervoltage and THD U and for showing different measur-

ing values.

If voltage is out of tolerance (range can be set), all active steps are disconnected and the regulation stops.

Voltage has to be measured as standard either from L1-N or L2-L3. If measuring voltage is taken from L1-N or from L2-

L3, is detected automatically by comparing the value of measuring voltage with the setting of nominal voltage.

It’s also possible to measure voltage from other phases as above. In this case either automatic initialization must run

(2.4.5) or the correct setting for phase-compensation (2.5.3.6) has to be done. Details of the functions can be found in

the referring chapters.

1.4 Control outputs

BLR-CM is available with up to 12 outputs. Depending on the regulator type the outputs can be relay outputs, transistor

outputs or a mix between both types. The indication of the type can be found on the rear sticker either with the type

description or the symbols of the output clamps.

If you have got the regulator type with mixed output steps, please pay attention that the clamp A1 is the

common root for the relay outputs 1 - 6 and clamp A2 is the common root for the transistor outputs 7 - 12!

1.4.1 Relay outputs

The relay outputs of the power factor controller are designed for the direct connection to contactors. The relay outputs

are potential-free with one common root.

Maximum breaking capacity for ohmic load: 250V AC / 5A, 400V AC / 2A, 110V DC / 0,4A, 30V DC / 5A.

Maximum fuse rating: 6A.

1.4.2 Transistor outputs

The transistor outputs of the power factor controller are designed for the direct connection to thyristor switches. These

open-collector outputs have got one common root. To trigger a thyristor switch connect (–) to the root and (+) directly

to the thyristor switch.

Maximum breaking capacity: 8-48V DC / 100mA

!

Reference Manual

BLR-CM/BLR-CM3phase

Rev. 08

2018-09

7

1.5 Alarm relay

BLR-CM is equipped with an alarm relay to signal proper function of the system. The alarm relay has one C/O contact.

The common point is terminal M.

Between the terminals M and MO is the breaking contact. This contact is closed in alarm condition or when BLR-CM is

disconnected from voltage.

Between the terminals M and MS is the closing contact. This is closed in proper condition of the system.

The breaking capacity is 3A / 250V AC.

The circuit diagram is depicted in chapter 3.9!

1.6 Digital input

1.6.1 Digital input for alarm-system

BLR-CM is equipped with a digital input for AC-voltage for alarm-system (50-250V AC, terminals DI1.1 and DI1.2). Digital

input can be active high or active low. The function can be programmed in the menu "SETUP / ALARM / DI INPUT" (2.5.7)

More details for the programming can be found in chapter "ALARM". See circuit diagram in chapter 3.9!

1.6.2 Digital input for data-logger synchronisation (only option –DM)

BLR-CM with option –DM is equipped with a digital input for DC voltage (10-30VDC, terminals DI0.1 and DI0.2). More

details can be found in chapter 2.5.9. The circuit diagram is depicted in chapter 3.10!

1.7 Digital output

BLR-CM is equipped with one digital output (terminals DO1 and DO2). This output is a potential-free closing contact.

The breaking capacity is 5A / 250V AC. The function of this output can be programmed in the menu "SETUP / ALARM"

(chapter 2.5.7). The circuit diagram is depicted in chapter 3.9!

Reference Manual

BLR-CM/BLR-CM3phase

Rev. 08

2018-09

8

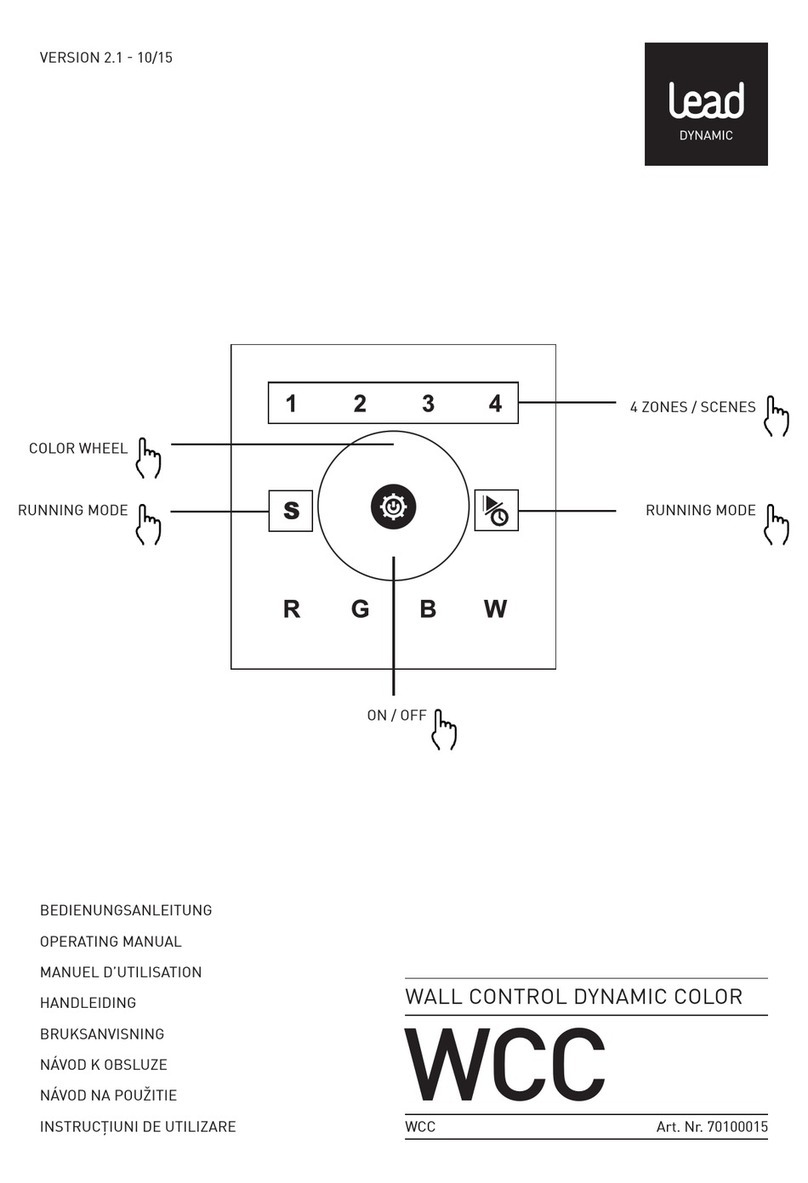

1.8 User Interface

User Interface of BLR-CM is a graphical LCD and a membrane keyboard with 4 soft keys.

LCD is split into 4 areas:

Top area: the two lines of top area are showing information about general status of the relay. The readings

of this area are always available, independent from the menu which is used. The readings of top

area can be adjusted in menu SETUP/DISPLAY.

The “sad face” indicates that there are problems with the level of voltage or current.

The “happy face” indicates that levels of voltage and current are ok.

The “serious face” indicates setting PFC OFF or PFC FREEZE.

Status columns: left and right column are showing the status of the control exits.

Step 1, status: off, type: NORMAL or FAST

Step 2, status: off, type: NORMAL blocked or FIX OFF

Step 3, status: off, type: FAULTY

Step 4, status: on, type: NORMAL or FAST

Step 5, status: on, type: FIX ON

Step 6, status: off, type: OFF, not available or PFC OFF

“NORMAL blocked” can be caused by discharging time (2.5.4.1)

“PFC OFF” can be caused by voltage out of tolerance (2.5.3.7 and 2.5.3.8), by relay is off due to

setting (2.4.6) or due to Alarm system (2.5.7).

Main area: the three lines of main area are for menu navigation and display of information

Softkey area: the soft key area shows the function of the membrane-keyboard. Depending on the opened

menu, the function is different.

1

2!

F

4

5!

Reference Manual

BLR-CM/BLR-CM3phase

Rev. 08

2018-09

9

2 MENU BLR-CM

2.1 MEAS. VALUES

This submenu shows the available measurement values in the main area of LCD. The values can be

chosen by pushing the ▲/ ▼-keys.

Available measuring values:

BLR-CM

BLR-CM3phase (option -3A)

ULL (voltage phase –phase)

ULN (voltage phase –neutral)

THD U(THD voltage)

I(current)

THD I (THD current)

P(total active power)

Q(total reactive power)

S(total apparent power)

F(frequency)

deltaQ (control deviation in kvar)

T(temperature at rear side of the device)

PF (power factor = P/S, kW/kVA)

CP (cos)

OPH (operation hours of pfc-relay)

APF (average power factor)

T-MAX (max. temperature)

WPI / WPE

(counter active work import / export)

WQI / WQC

(counter reactive work inductive / capacitive)

ULL (voltage phase –phase)

ULN (voltage phase –neutral)

THD U(THD voltage)

I1 /I2 / I3 (current)

THD I 1 / THD I 2 / THD I 3 (THD current)

P1 / P2 / P3 (active power for each phase)

Q1 / Q2 /Q3 (reactive power for each phase)

S1 / S2 / S3 (apparent power for each phase)

P (total active power)

Q (total reactive power)

S (total apparent power)

deltaQ1 (control deviation L1 in kvar)

deltaQ2 (control deviation L2 in kvar)

deltaQ3 (control deviation L3 in kvar)

deltaQ (total control deviation in kvar)

CP1 (cosL1)

CP2 (cosL2)

CP3 (cosL3)

PF 1 (power factor 1 = P1/S1, kW/kVA)

PF 2(power factor 2 = P2/S2, kW/kVA)

PF 3(power factor 3 = P3/S3, kW/kVA)

F(frequency)

T(temperature at rear side of the device)

T-MAX (max. temperature)

OPH (operation hours of pfc-relay)

APF (average power factor)

PF (power factor = P/S, kW/kVA)

WPI / WPE (counter active work import / export)

WQI / WQC (counter reactive work inductive / capacitive)

Rotary Field of current path

Reference Manual

BLR-CM/BLR-CM3phase

Rev. 08

2018-09

10

2.2 HARMONICS

The BLR-CM is permanently calculating the harmonics of the voltage and current by using Fourier

transformation. After selecting the submenu these values are displayed separated in even and odd

harmonics of current and voltage in main display area. Every displayed value is related to the fun-

damental wave.

Selection can be done by pushing the ◄►-key.

Scrolling is possible by pushing the ▲/ ▼-keys.

2.3 STEPINFO

Stepinfo shows the information, which is saved in step database. By pushing +-key, the step can be

selected. By pushing ▼-key, the different saved values can be selected. These values are: type of

step, switch cycles, actual capacitor size and derating of capacitor in percent.

2.3.1 STEP TYPE

Different types of steps are possible. With exception of the type FAULTY, the types can be set in SETUP/STEPS (2.5.4.2).

Possible types are:

NORMAL = step is used for normal regulation

FIX-OFF = step is permanently switched-off

OFF = step is permanently switched-off an blend out

FIX-ON = step is permanently switched-in

(step will be switched-off in critical situations like over- and undervoltage, overtemperature or excessive har-

monics)

FAST = step is used for real-time algorithm. More information can be found in chapter 2.5.4.2 and 2.5.5.

FAULTY = the step is detected as defective and is blocked

2.3.1.1 FAULTY STEPS

The detection of faulty steps is only possible, when the automatic step recognition is active (2.5.5.7) and switch cycle is

at least 1 sec. When switch cycle is less 1 sec step recognition is automatic off. A step is “FAULTY”, when BLR-CM cannot

detect any change of reactive power at three switching operations in series of this step.

Faulty steps are signed with "F!" in the status columns. Furthermore the step type "FAULTY" is shown. Defective steps

are blocked for the regulation. Faulty steps can be reset in SETUP/RESET (2.5.10.2), by interruption of supply voltage of

BLR-CM or automatically after 24 hours. Afterwards the step is used again for its regular control function.

Reference Manual

BLR-CM/BLR-CM3phase

Rev. 08

2018-09

11

2.3.2 SWITCH CYCLES

BLR-CM is counting and showing the switching cycles of each step. This value allows the conclusion about the actual

state of the contactors. Switch cycles can be preset separately for each step in SETUP/STEPS (2.5.4.3). Switch cycles of

all steps is also reset, by a reset of complete capacitor database in SETUP/RESET (2.5.10.3).

2.3.3 STEPVALUE

As standard, the STEPVALUES are detected automatically during operation. They are rated to the setting of nominal

voltage. In some special applications, it is required to set the step values manually. This can be done in SETUP/STEPS

(2.5.4.4).

The STEPVALUE is showing the size of the capacitor, which is used for reactive power regulation. The function of this

value can be compared with the c/k value of power-factor control relays of former generations. The STEPVALUE is shown

in kvar. Each step has its own STEPVALUES, at BLR-CM it’s one per step, at BLR-CM3phase there are three step values

per step (one for each phase). Step database is working with two values of capacitor size. The value which is shown in

kvar is the actual value. This is continuously corrected with every switching operation. A second value is saved after the

first ten switch cycles of each step after a reset of step database. This value indicated the original available STEPVALUE.

This value is used to calculate the percentage of actual step value to original step value. This percentage gives very

simple information about derating of the capacitor banks.

When automatic step recognition is not active, the percentage is not shown (2.5.5.7).

2.4 Quickstart SETUP

In this submenu basic settings can be made for the BLR-CM. These settings are necessary for correct function and for

correct display of the measurement values. This menu can be entered without password.

The following parameters can be set in Quickstart menu:

2.4.1 CHANGE LANGUAGE

Standard version of BLR-CM is supporting English, German and French.

2.4.2 NOMINAL VOLTAGE

Function of the setting of nominal voltage is to make a definition about the nominal voltage of the system. The thresh-

old levels for under- and overvoltage are based on this as well as the ratings of the capacitor sizes in step database,

which are used for control and monitoring (2.5.3.7 and 2.5.3.8). The capacitor sizes, which are stored in step database,

are also rated to the nominal voltage.

Independent of connection of the voltage measuring channel, nominal voltage is always the phase-phase

voltage!

!

Reference Manual

BLR-CM/BLR-CM3phase

Rev. 08

2018-09

12

2.4.3 CT FACTOR

The CT FACTOR is the ratio of current transformer. (e. g. 1000/5 = ratio 200). At BLR-CM3phase the CT-Factor is used for

all three current channels.

For current measuring a CT always have to be used!

2.4.4 VT-FACTOR

VT FACTOR is the ratio of the voltage transformer. If the regulator is connected directly to the measurement voltage

without VT the value 1 has to be used

2.4.5 START AI

Automatic initialization is switching all exits. During this test it can get information, which exits are working and it can

correct the connection of the measuring channels for voltage and current by internal settings.

Automatic initialization can be started only when the “happy face” is shown (voltage and current are ok) and when

CONTROL is not set to status OFF or FREEZE manually or by alarm-system. BLR-CM3phase needs at least one 3ph. Ca-

pacitor-bank for AI! If CONTROL setting is FREEZE done by AI, then a restart is possible.

When AI is running, the status line of BLR-CM shows the message: “AI ACTIVE”. The maximum number of switching

operations during AI is 10 per exit (normally between 2 and 5). AI is taking care about the setting of discharge time for

each exit. If there is a very long discharge time necessary, AI will take a certain time.

The following messages from AI are possible:

ALARM: AI OK AI is finished completely. Please check if all used exits are shown with their number in the display

and please check if BLR-CM is working correctly.

ALARM: CHECK CTs (only BLR-CM3phase) (CONTROL setting is: FREEZE) Following reasons are possible: Rotary

field of current measuring is not clockwise or one or two current paths have wrong polarity.

ALARM: STEPS (CONTROL setting is: FREEZE) Capacitors cannot be detected, because they are not controlled

by controller or the rating is smaller as limit. BLR-CM3phase: there is no 3ph. capacitor bank available!

AI ABORTED (CONTROL setting is: FREEZE) AI couldn’t be finished. The reason could be permanent load varia-

tion during AI. Please try it again or do the settings manually.

AUTOMATIC INITIALIZATION is only able to work, when capacitors are used for compensation. If BLR-CM has

to switch reactors for compensation of capacitive load, this feature will cause failures. AI is working at best,

when there are stable load conditions!

!

!

Reference Manual

BLR-CM/BLR-CM3phase

Rev. 08

2018-09

13

2.4.6 CONTROL ON / FREEZE / OFF

ON: Automatic control is running

FREEZE: Automatic control is stopped; status of exit relays is frozen

OFF: Automatic control is stopped; all exit relays are off

2.4.7 cosφ1

This is the setting for target

2.4.8 SWITCH INTERVAL

The switch interval is the time delay between switching steps in regulation.

The switch interval has two different functions:

Protecting the contactors by reducing the number of switching cycles.

Building of the average of the reactive power in the time of the switch interval.

Step recognition is automatically set OFF, when switch interval is off. In regulation mode LIFO, minimum

switching interval is 1 sec longer, as the longest discharging time. In HV-version, the minimum switching time

delay is 8.7 sec.

2.4.9 STEPS

2.4.9.1 STEP TYPE

For every single step its function can be defined separatly. You can select between the following functions:

NORMAL = step is used for normal regulation algorithm

OFF = step is permanently switched of an blend out in step indication

FIX-OFF = step is permanently switched off

FIX-ON = step is permanently switched on (step is supervised and also switched off in critical situations)

The step type "Fast" in only available for BLR-CM with transistor exits. Steps, which are set "Fast" (only

possible for transistor exits) are not available for the normal regulation algorithm. For each "Fast" step a

nominal value has to be set, because the automatic step size detection is disabled in real time algorithm.

FAST = step is used for the real time algorithm. All needed steps to reach the target cosφare switched

simultaneously. There is no delay for switching.

Not used output steps have to be set to "FIX-OFF" or "OFF". So it is ensured, that these steps are not used

for the regulation anymore. No needless alarms are caused! Fix steps are labelled by the permanent symbol

"!" next to the step number! Steps there are set "OFF" are blend out.

!

!

Reference Manual

BLR-CM/BLR-CM3phase

Rev. 08

2018-09

14

2.4.9.2 DISCHARGE TIME

For every single capacitor step an own discharging time can be defined. The discharging time is a blocking time, becom-

ing active after switching off a step. As long as this time is running (display of "!" in the step indication) this step is not

available for the regulation. Discharging time should be adapted to the capacitor discharging unit.

For step exits, which are switching thyristor switches, discharging time can be reduced to the zero.

2.5 SETUP

In this submenu advanced settings can be made for the BLR-CM. These settings are necessary for

application specific adjustments. To enter this submenu, please push the right button for 3 sec. It

is protected by a password (factory setting 2402).

The menu is divided into logical groups. In these groups you can find parameters which are also in Quickstart SETUP.

The following points explain the settings.

2.5.1 CHANGE LANGUAGE

Standard version of BLR-CM is supporting English, German and French.

2.5.2 START AI

See Chapter 2.4.5

2.5.3 MEASUREMENT

2.5.3.1 CT-FACTOR

The CT FACTOR is the ratio of current transformer. (e. g. 1000/5 = ratio 200). At BLR-CM3phase the CT-Factor is used for

all three current channels.

For current measuring a CT always have to be used!

2.5.3.2 VT-FACTOR

VT FACTOR is the ratio of the voltage transformer. If the regulator is connected directly to the measurement voltage

without VT the value 1 has to be used.

2.5.3.3 NOMINAL VOLTAGE

Function of the setting of nominal voltage is to make a definition about the nominal voltage of the system. The threshold

levels for under- and overvoltage are based on this as well as the ratings of the capacitor sizes in step database, which

are used for control and monitoring (2.5.3.7 and 2.5.3.8).

!

Reference Manual

BLR-CM/BLR-CM3phase

Rev. 08

2018-09

15

Independent of connection of the voltage measuring channel, nominal voltage is always the phase-phase

voltage!

2.5.3.4 CONNECTION MEASUREMENT

CONNECTION MEASUREMENT the setting if measuring of voltage is connected between two phases or between phase

and neutral phase. It is normally detected automatically at every start of BLR-CM. This is done by comparing the setting

NOMINAL VOLTAGE and the real measured voltage.

The selection can also be done manually by pushing the ◄► button. The types, "U=L-N" or "U=L-L" are available.

2.5.3.5 SYNCHRONIZATION FREQUENCY

For a high precision of the measurement, the sampling rate has to be synchronized to the frequency of the grid. Caused

by commutation notches of mains voltage it is possible that the automatic synchronizing will not work reliable. This

creates failures in measurement. To avoid these problems, the following settings can be done:

Automatic synchronizing: For best measurement results, when mains voltage is without commutation notches.

FIX-50HZ: For a safe operation at 50Hz grid with bad mains quality.

FIX-60HZ: For a safe operation at 60Hz grid with bad mains quality.

2.5.3.6 PHASE COMPENSATION

The phase compensation enables the user to connect the current- and voltage measurement channels in any way. This

compensation angle complies with the phase angle between connected active current and voltage. The following table

shows the settings for some different connection types. This setting has to be made correct, because otherwise correct

regulation is not possible! If the current transformer is connected inverted, additionally a phase compensation of

180° has to be respected.

Voltage

L1-N

L2-N

L3-N

L1-N

L2-N

L3-N

L1-N

L2-N

L3-N

Current transformer

L1

L2

L3

L2

L3

L1

L3

L1

L2

Connection

U=L-N

U=L-N

U=L-N

U=L-N

U=L-N

U=L-N

U=L-N

U=L-N

U=L-N

Phase-Offset

0°

0°

0°

240°

240°

240°

120°

120°

120°

Voltage

L2-L3

L3-L1

L1-L2

L2-L3

L3-L1

L1-L2

L2-L3

L3-L1

L1-L2

Current transformer

L1

L2

L3

L2

L3

L1

L3

L1

L2

Connection

U=L-L

U=L-L

U=L-L

U=L-L

U=L-L

U=L-L

U=L-L

U=L-L

U=L-L

Phase-Offset

0°+90°

0°+90°

0°+90°

240°+90°

240°+90°

240°+90°

120°+90°

120°+90°

120°+90°

At BLR-CM3phase only the position of the voltage measurement can be compensated, because the regulator calcu-

lates the phase angle for the other phase from phase L1.

2.5.3.7 V-TOLERANZ MIN

The setting has to be done in percent related to the nominal voltage. If the measurement voltage falls below the ad-

justed limit, all active steps are switched off and the regulation stops.

!

Reference Manual

BLR-CM/BLR-CM3phase

Rev. 08

2018-09

16

2.5.3.8 V-TOLERANZ MAX

The setting has to be done in percent related to the nominal voltage. If the measurement voltage exceeds the adjusted

limit, all active steps are switched off and the regulation stops.

2.5.3.9 COUNTDOWN START AI

YES = after starting BLR-CM, a countdown is running. During this countdown it is possible to start AI automatic initiali-

zation by pushing <Enter>.

NO = the countdown is not shown. To start AI, you have to choose Quickstart SETUP.

2.5.3.10 TEMP. OFFSET

The temperature offset allows correction of temperature reading in a range -10°C to +10°C.

2.5.3.11 CT TYPE 1A

This setting changes some internal threshold levels, to optimize the function with 1Amp CTs.

2.5.4 STEPS

Settings concerning the step data base can be found in this submenu. The following settings are possible:

2.5.4.1 DISCHARGE TIME

For every single capacitor step an own discharging time can be defined. The discharging time is a blocking time, becom-

ing active after switching off a step. As long as this time is running (display of "!" in the step indication) this step is not

available for the regulation. Discharging time should be adapted to the capacitor discharging unit.

For step exits, which are switching thyristor switches, discharging time can be reduced to the zero.

2.5.4.2 STEP TYPE

For every single step its function can be defined separately. You can select between the following functions:

NORMAL = step is used for normal regulation algorithm

OFF = step is permanently switched of an blend out in step indication

FIX-OFF = step is permanently switched off

FIX-ON = step is permanently switched on (step is supervised and also switched off in critical situations)

The step type "Fast" in only available for BLR-CM with transistor exits. Steps, which are set "Fast" (only

possible for transistor exits) are not available for the normal regulation algorithm. For each "Fast" step a

nominal value has to be set, because the automatic step size detection is disabled in real time algorithm.

FAST = step is used for the real time

simultaneously. There is no delay for switching.

Reference Manual

BLR-CM/BLR-CM3phase

Rev. 08

2018-09

17

Not used output steps have to be set to "FIX-OFF" or "OFF". So it is ensured, that these steps are not used

for the regulation anymore. No needless alarms are caused! Fix steps are labelled by the permanent symbol

"!" next to the step number! Steps there are set "OFF" are blend out.

2.5.4.3 SWITCH CYCLES

The number of switch cycles can be corrected or reset for each step separately.

2.5.4.4 STEP NOMINAL VALUE

If STEP RECOGNITION is not active, it is required to do this setting, to get proper function of the relay.

STEP RECOGNITION is not active for “Fast” steps or if it is blocked (2.5.5.7) or for switch cycles less 1 sec.

The size of the capacitors can be programmed manually in kvar.

The programming can be done for each step individually in kvar. So there is no special sequence necessary. A step can

be programmed as a capacitor (c) or as an inductor (i). If you plan to use a mixed mode between capacitors and induc-

tors, please contact Beluk to get more information.

At BLR-CM3phase capacitor size has to be programmed for each phase individually.

A three phase capacitor with 25kvar has to be programmed with 8,3kvar for each phase!

2.5.4.5 STEP RESET

Selecting this point all step sizes can be reset individually.

2.5.5 CONTROL

General explanations for a better understanding:

Target of compensation: BLR-CM is using two parallel working regulation algorithms. The type of steps defines the

algorithm by which each step is controlled.

Normal algorithm is using “NORMAL” steps. The target of regulation of normal algorithm is calculated by target cosφ

and apparent power of fundamental wave. The control deviation is a mean value over the period of SWITCH INTERVAL

(adjustable).

In hybrid compensation panels, the installed dynamic steps are considered in calculation of control deviation to get an

optimum working point for the real time part.

Fast algorithm is using “FAST” steps. The target of regulation of fast algorithm is the real time target reactive power,

which is calculated by apparent power and target cosφ. The operation of Fast algorithm can be tuned by additional

parameters.

At BLR-CM3phase, the fast algorithm is not available. For real time compensation there is used the normal

algorithm with short SWITCH INTERVAL and fix programmed step sizes!

!

!

!

Reference Manual

BLR-CM/BLR-CM3phase

Rev. 08

2018-09

18

Regulation mode normal algorithm: 4 different regulation modes are available at BLR-CM:

1. Auto: The controller is working with the principle of „Best Fit“. Before a switching operation, all capacitor-sizes

in step database are compared with control deviation. The available step which gives the best results will be

switched.

2. LIFO: “Last In, First Out” The controller starts with regulation with step 1 and is switching further exits step-by-

step. Switching-off is done vice versa.

3. Combined Filter: Special algorithm for combined filter banks with two different detuned ratings. The controller

is working like in automatic mode with the principle “Best Fit”. From odd numbered steps, there is at least or

more of the capacitance connected as from even numbered steps.

4. Progressive: Similar to Auto mode. When control deviation is bigger as the biggest available step, the all further

steps are switched in intervals of two seconds. If the setting of switch interval is less two seconds, all further

steps are switched in intervals of one second.

Regulation mode real time algorithm: After measuring one cycle of mains voltage, the control deviation is calculated

and all necessary steps are switched in one operation. The time from end of measuring to generation of the switching

pulse is less 150µsec. Beluk thyristor-switches need from this moment to bring in the capacitors in max 2/3 of a cycle of

mains voltage. This time is needed to to get the next allowed moment for switching operation.

In real time algorithm SWITCH INTERVAL, STEP EXCHANGE and SWITCH CYCLES BALANCING are not working. There are

some separate settings possible. The real time algorithm is always working in “Best Fit” mode.

Sensitivity: (switching threshold) Sensitivity is the switching threshold for switching-on or switching-off the capacitors

in percent (%). The range of the sensitivity can be between 55% and 100% (factory setting is 60%. Due to this, the in

following explanation 60% is used.).

Reference Manual

BLR-CM/BLR-CM3phase

Rev. 08

2018-09

19

Sensitivity is used for two checks:

1. The controller is using sensitivity to check, if a switching operation is necessary or if it’s possible. If the demand

for compensation is bigger as 60% of the smallest for regulation available step, BLR-CM is selecting from step

database, if there are suitable steps to switch.

2. To avoid hunting, the controller is only using steps, which will not overshoot more than 40% (100%-60%) of its

size.

Step exchange: Step exchange is supporting automatic control and combined filter control algorithm to reach an opti-

mum result. If the controller detects that target-pf is not reached it starts searching for a step which gives better results.

If step exchange is active, the controller can replace a switched-in step against a step which matches better, to reach

the target.

Switch cycle balancing: Switch cycle balancing is taking care that steps with similar sizes (tolerance can be programmed

in percent) are used in a way, that they have the same number of switch cycles. At selection of suitable step for next

switching operation, the values of switch cycles, which are saved in step database, are compared. A balanced attrition

of contactors and capacitors is assured by this.

2.5.5.1 CONTROL ON / FREEZE / OFF

ON: Automatic control is running

FREEZE: Automatic control is stopped; status of exit relays is frozen

OFF: Automatic control is stopped; all exit relays are off

2.5.5.2 COS PHI 1

This is the setting for target cosφ1. It will be valid during normal operation.

2.5.5.3 COS PHI 2

This is the setting for target cosφ2. It will be valid when a switch over is caused by the digital input or another program-

mable action.

2.5.5.4 SWITCH INTERVAL

The switch interval is the time delay between switching steps in regulation.

The switch interval has two different functions:

Protecting the contactors by reducing the number of switching cycles.

Building of the average of the reactive power in the time of the switch interval.

Step recognition is automatically set OFF, when switch interval is off. In regulation mode LIFO, minimum

switching interval is 1 sec longer, as the longest discharging time. In HV-version, the minimum switching time

delay is 8.7 sec.

!

Reference Manual

BLR-CM/BLR-CM3phase

Rev. 08

2018-09

20

2.5.5.5 SWITCH INTERVAL STEP EXCHANGE

For step exchange a separate switch interval is used. This is the delay-time between switching-off an active step and

switching-in the next step to get a better power-factor. Step exchange can be set active in menu 2.5.5.10.

2.5.5.6 ASYM. FACTOR

ASYMMETRY FACTOR of switch interval. The factor is the ratio between switch interval for switching on and switching

off. Switch interval for step exchange is not affected by this setting.

X= 1 = equal

X = +2 to +127: delay switching off = switch interval multiplied by X

X = -2 to -127: delay switching on = switch interval multiplied by X

2.5.5.7 STEP RECOGNITION

Pushing ◄►-key is changing between "ON" and "OFF".

"Step recognition OFF": Capacitor sizes should be programmed manually:

a) When fast-oscillating load influences automatic step size recognition.

b) When recognition of defective steps is not wished

c) When capacitor contactors are switching with a delay of more than 200msec.

"Step recognition ON" Step sizes are detected and corrected automatically during normal operation. “Step recognition

ON” is the factory setting. It allows monitoring of capacitor sizes and gives alarms when they are faulty. Step sizes which

are programmed manually will be overwritten by step recognition.

2.5.5.8 SWITCH CYCLES BALANCING

Pushing ◄►-key is changing between "ON" and "OFF".

Balancing of switch cycles of capacitors with similar sizes produces an equal attrition of the contactors and capacitors.

2.5.5.9 SWITCH CYCLES BALANCING %

Capacitors within this tolerance band are capacitors with similar sizes for switch cycles balancing.

2.5.5.10 STEP EXCHANGE

Pushing ◄►-key is changing between "ON" and "OFF".

the same size, this function makes no sense and in some conditions the relay can start hunting.

2.5.5.11 CONTROL SENSITIVITY

Factory setting is 60%. This value can be set in a range between 55% and 100%.

This manual suits for next models

1

Table of contents

Other Beluk Controllers manuals

Beluk

Beluk CX plus User manual

Beluk

Beluk BLR-CX Installation and operation manual

Beluk

Beluk BLR-CX-R User manual

Beluk

Beluk CX plus User manual

Beluk

Beluk CX plus User manual

Beluk

Beluk BLR-Q(U)06/12R User manual

Beluk

Beluk CX plus User manual

Beluk

Beluk BLR-CM Modbus Guide

Beluk

Beluk BLR-CX User manual

Beluk

Beluk BLR-CM Training manual

Popular Controllers manuals by other brands

Festo

Festo LF-M Series operating instructions

Associated Equipment

Associated Equipment KwikStart Pro Series Operator's manual

Marmitek

Marmitek MT10 BEDROOM X-10 operating instructions

Entity

Entity DomoVoice EN1650 user manual

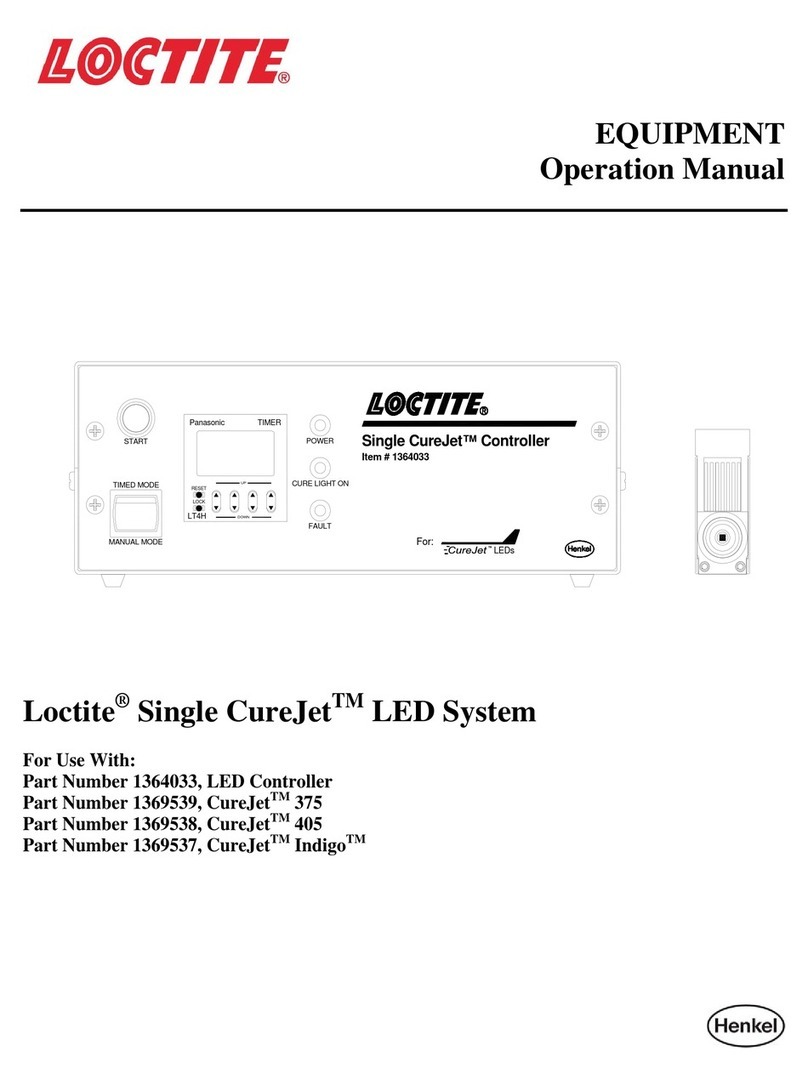

Loctite

Loctite Single CureJet Operation manual

Weathermatic

Weathermatic smartline SL800 owner's manual