7

5. Following the vehicle manufacturer’s recommended

procedures, deactivate the electrical system in a manner

that safely removes all electrical power from the vehicle.

6. Never exceed manufacturer’s recommended pressures.

7. Never connect or disconnect a hose or line containing

pressure; it may whip. Never remove a component or

plug unless you are certain all system pressure has been

depleted.

8. Use only genuine Bendix®brand replacement parts,

components and kits. Replacement hardware, tubing,

hose, fittings, etc. must be of equivalent size, type

and strength as original equipment and be designed

specifically for such applications and systems.

9. Components with stripped threads or damaged parts

should be replaced rather than repaired. Do not attempt

repairsrequiringmachiningorweldingunlessspecifically

stated and approved by the vehicle and component

manufacturer.

10.Prior to returning the vehicle to service, make certain all

components and systems are restored to their proper

operating condition.

11. For vehicles with Automatic Traction Control (ATC), the

ATCfunctionmust bedisabled(ATC indicator lampshould

beON)priortoperformingany vehiclemaintenancewhere

oneormore wheelsonadrive axle areliftedofftheground

and moving.

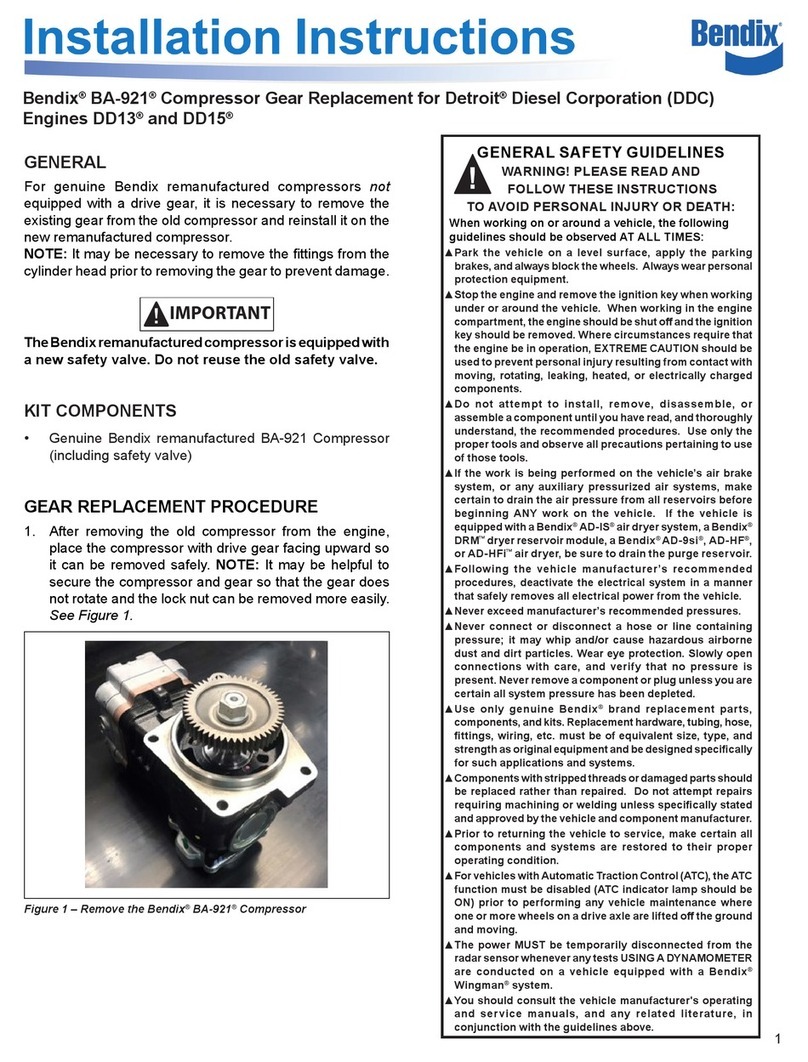

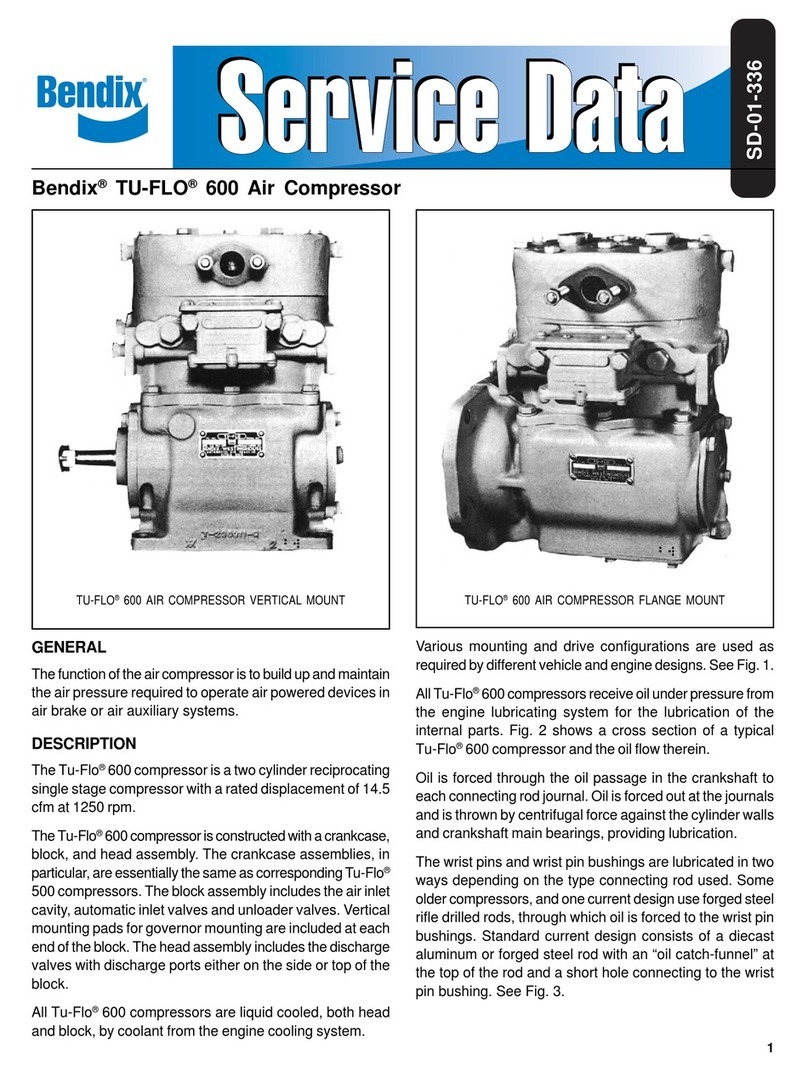

REMOVAL

In many instances it may not be necessary to remove the

compressor from the vehicle when installing the various

maintenance kits and service parts. The maintenance

technician must assess the installation and determine the

correct course of action. These instructions are general

and are intended to be a guide. In some cases additional

preparations and precautions are necessary. In all cases

follow the instructions contained in the vehicle maintenance

manualinlieuof the instructions, precautionsandprocedures

presented in this manual.

1. Block the wheels of the vehicle and drain the air pressure

from all the reservoirs in the system.

2. Drain the engine cooling system and the cylinder head

of the compressor. Identify and disconnect all air, water

and oil lines leading to the compressor.

3. Remove as much road dirt and grease from the exterior

of the compressor as possible.

4. Remove the discharge fitting, if applicable, and note their

position on the compressor to aid in reassembly.

5. Remove any supporting bracketing attached to the

compressor and note their positions on the compressor

to aid in reassembly.

6. Remove the 6 mounting bolts that retain the

compressor to the side of the engine block. Note

the position of the 6 mounting bolts. Two of the 6

boltsareshorter andmustbe installedintheiroriginal

locations. Remove thecompressorfromthevehicle.

7. Inspect drive gear and associated drive parts for

visible wear or damage. If the compressor drive

gear is worn or damaged, the compressor must be

replaced. Refertothe Engine Manufacturersservice

manualtoaddress theassociatedenginedrive parts.

8. If the compressor is being replaced stop here and

proceed to “Installing the Compressor” at the end

of the assembly procedure. (Note: Replacement

compressors come with the drive gear pre-

assembled on the compressor.)

PREPARATION FOR DISASSEMBLY

Refer to Figure 8 during the entire disassembly and

assembly procedure.

Place a clean rag over the openings that expose the

gear and crankshaft / connecting rod assembly. No

contamination is permitted in these areas.

Removethebalance of the roaddirtandgreasefrom the

exteriorofthecompressorwith a cleaning solvent. If the

rearendcover (8)isbeing removedfromthecompressor

under repair, mark it along with the two cap screws (7)

in relation to the crankcase. It is also recommended to

mark the relationship of the cylinder head (15), cooling

plate (14), valve plate assembly (13), and crankcase.

Aconvenient method to indicate the above relationships

is to use a metal scribe to mark the parts with numbers

or lines. Do not use marking methods, such as chalk,

that can be wiped off or obliterated during rebuilding.

Prior to disassembly, make certain that the appropriate

kits are available.

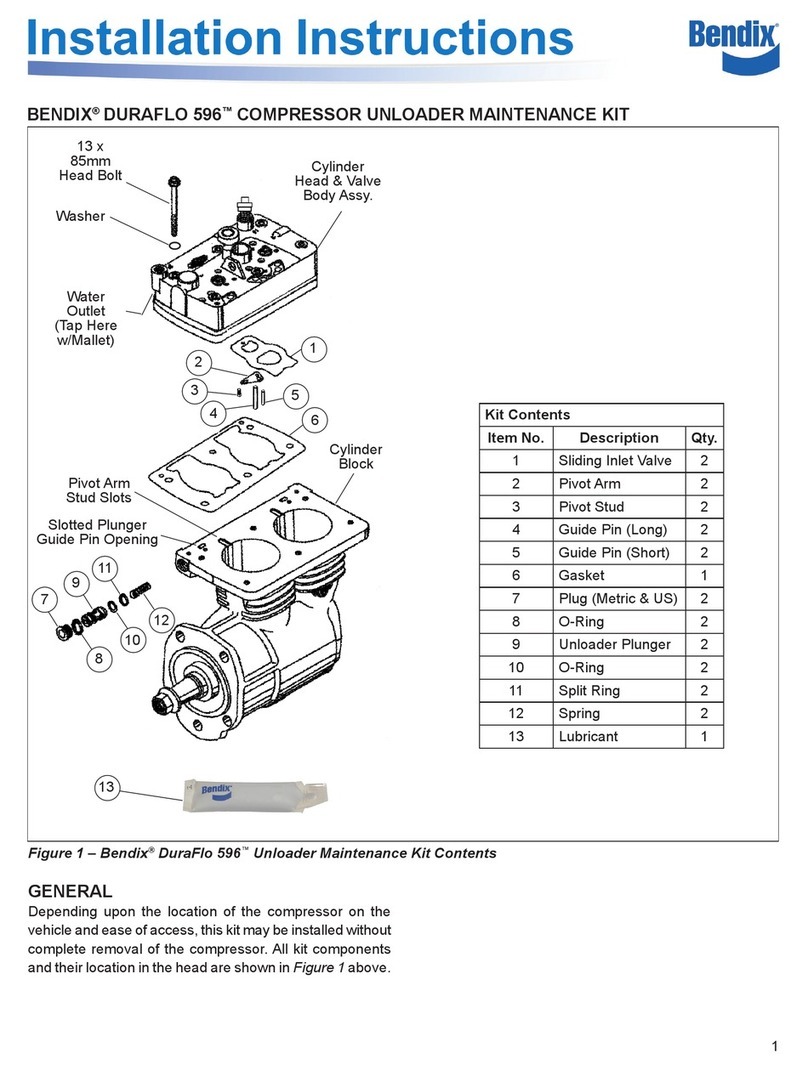

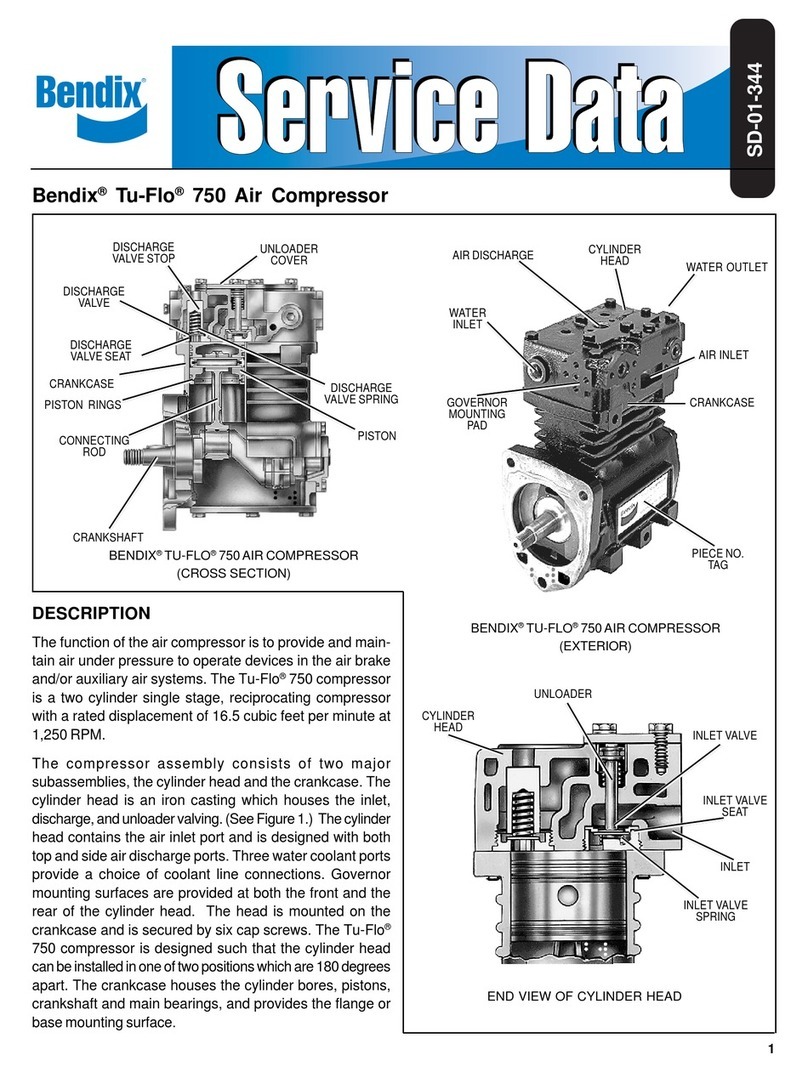

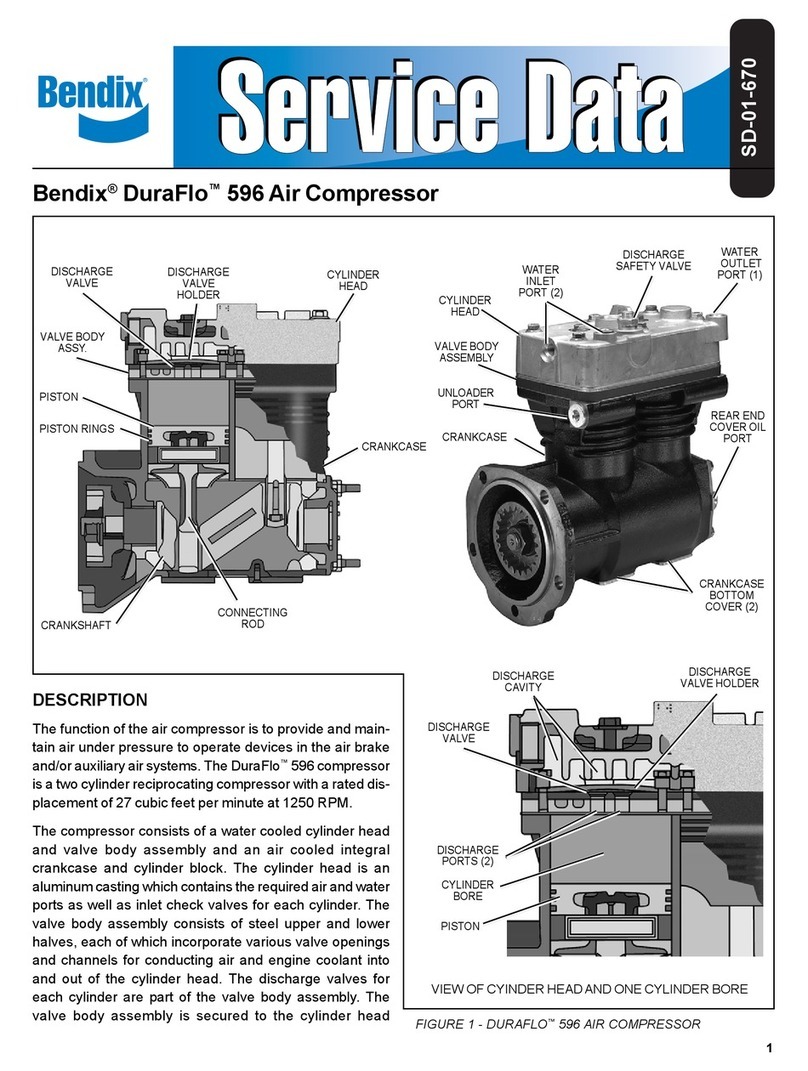

CYLINDER HEAD, COOLING PLATE & VALVE

PLATE ASSEMBLY

1. Remove the washer (3) and discharge safety valve

(2) from the cylinder head (15).

2. Removethefourhexhead bolts (1) from thecylinder

head (15).

3. Gently tap the cylinder head (15), cooling plate (14)

and valve plate assembly (13) with a soft mallet

to break the gasket seal between the valve plate

assembly (13) and the crankcase. Lift the cylinder

head (15) with cooling plate (14) and valve plate

assembly (13) off the crankcase.

4. Remove the metal inlet reed valve/gasket (5).

5. Removethecrankcaseo-ring(12)fromacountersunk

hole on the crankcase (11) deck.