4

Asthe pistonreaches the top of itsstroke andstarts down,

thedischargevalve springreturnsthe dischargevalveto its

seat. This prevents the compressed air in the discharge

line from returning to the cylinder bore as the intake and

compression cycle is repeated.

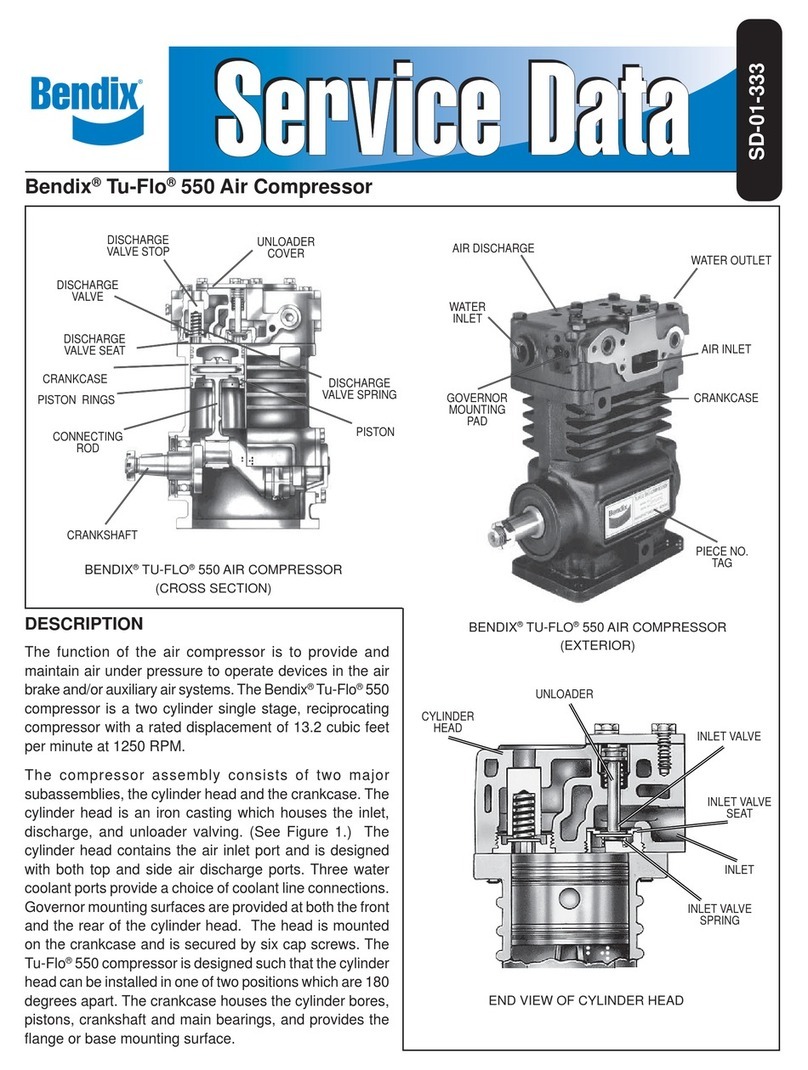

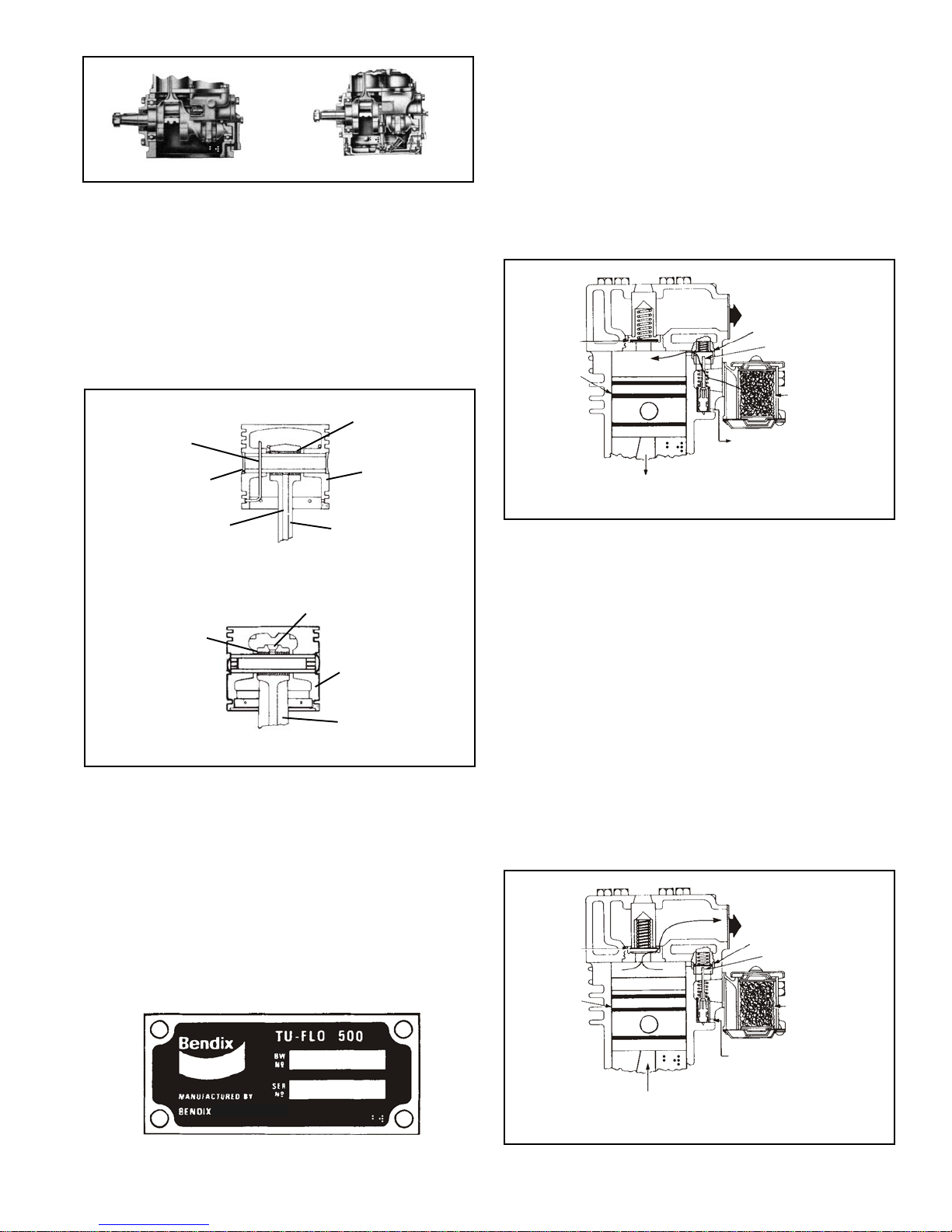

NON-COMPRESSION(Unloaded)

When the air pressure in the reservoir reaches the high

pressuresettingofthegovernor,thegovernoropens,allowing

airto passfrom the reservoirthrough thegovernor andinto

the cavity beneath the unloader pistons. This lifts the

unloaderpistons andplungers. Theplungers moveupand

hold the inlet valves off their seats (Fig. 11).

With the inlet valves held off their seats by the unloader

pistons and plungers, air is merely pumped back and forth

between the two cylinders. When air is used from the

reservoirandthe pressure dropstothe low pressuresetting

of the governor, the governor closes, and in doing so,

exhausts the air from beneath the unloader pistons. The

unloader saddle spring forces the saddle, pistons and

plungers down and the inlet valves return to their seats.

Compressionis thenresumed.

COMPRESSOR & THE AIR BRAKE SYSTEM

GENERAL

The compressor is part of the total air brake system, more

specifically,the chargingportionof theairbrake system.As

acomponent inthe overallsystem its condition,duty cycle,

proper installation and operation will directly affect other

components in the system.

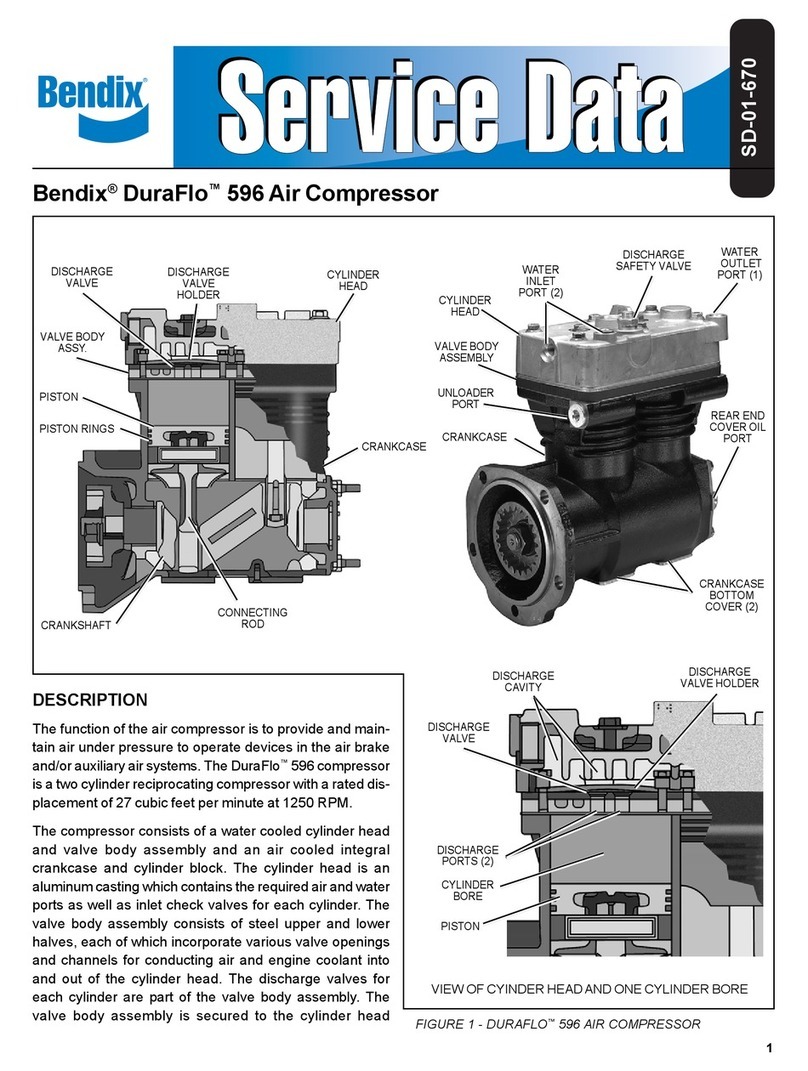

Powered by the vehicle engine, the air compressor builds

theairpressurefortheairbrakesystem.Theair compressor

istypically cooledby theengine coolantsystem, lubricated

by the engine oil supply and has its inlet connected to the

engine induction system.

As the atmospheric air is compressed, all the water vapor

originally in the air is carried along into the air system, as

well as a small amount of the lubricating oil as vapor. If an

air dryer is not used to remove these contaminants prior to

enteringtheairsystem,themajority,butnotall,willcondense

in the reservoirs. The quantity of contaminants that reach

the air system depends on several factors including

installation,maintenanceandcontaminanthandlingdevices

inthesystem.Thesecontaminantsmusteitherbeeliminated

prior to entering the air system or after they enter.

DUTYCYCLE

The duty cycle is the ratio of time the compressor spends

buildingairtothe totalengine running time.Aircompressors

are designed to build air (run "loaded") up to 25% of the

time. Higher duty cycles cause conditions that affect air

brake charging system performance which may require

additional maintenance. Factors that add to the duty cycle

are: air suspension, additional air accessories, use of an

undersizedcompressor,frequentstops, excessiveleakage

from fittings, connections, lines, chambers or valves, etc.

RefertoTableAintheTroubleshootingsectionfor a guideto

variousdutycyclesandtheconsiderationthatmustbe given

tomaintenance ofother components.

COMPRESSORINSTALLATION

While the original compressor installation is usually

completed by the vehicle manufacturer, conditions of

operation and maintenance may require additional

consideration.The following presentsbase guidelines.

DISCHARGELINE

Thedischarge line allowsthe air,water-vapor andoil-vapor

mixture to cool between the compressor and air dryer or

reservoir.The typical sizeof a vehicle'sdischarge line, (see

column2ofTableAintheTroubleshootingsection)assumes

a compressor with a normal (less than 25%) duty cycle,

operating in a temperate climate. See Bendix and/or other

airdryer manufacturer guidelinesas needed.

The discharge line must maintain a constant slope down

fromthe compressorto theair dryerinlet fittingor reservoir

toavoidlowpointswhereicemay formandblocktheflow. If,

instead, ice blockages occur at the air dryer or reservoir

inlet,insulation may beadded here,or if theinlet fittingis a

typical 90 degree fitting, it may be changed to a straight or

45degreefitting.Shorterdischargeline lengths orinsulation

may be required in cold climates.

While not all compressors and charging systems are

equippedwith adischargeline safetyvalvethis component

isrecommended.Thedischargelinesafetyvalve is installed

in the cylinder head or close to the compressor discharge

portand protects againstover pressurizing thecompressor

inthe eventof adischarge line freezeup.

DISCHARGELINE TEMPERATURE

When the temperature of the compressed air that enters

the air dryer is within the normal range, the air dryer can

removemost ofthe chargingsystem oil. If the temperature

ofthe compressed air is abovethe normalrange, oil as oil-

vapor is able to pass through the air dryer and into the air

system. Larger diameter discharge lines and/or longer

dischargeline lengthscan helpreduce thetemperature.

FIGURE 11

DISCHARGE

VALVE

PISTON

STROKE

TO GOVERNOR

INTAKE

STRAINER

UNLOADER

PLUNGER

INLETVALVE

TO RESERVOIR

UNLOADING