6

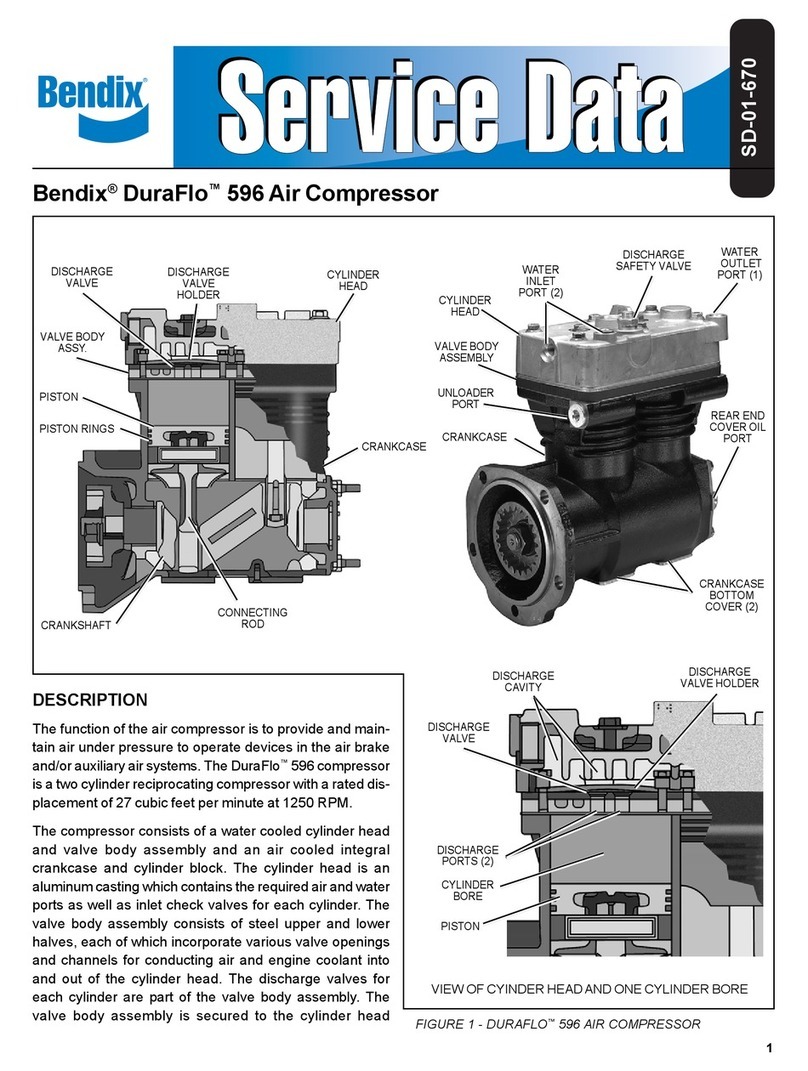

AIR LEAKAGE TESTS

Leakage past the discharge valves can be detected by

removingthedischargeline, applyingshopairback through

the discharge port and listening for escaping air. Also, the

dischargevalves andthe unloader pistonscan bechecked

forleakage bybuilding up the air systemuntil thegovernor

cutsout,thenstoppingthe engine. Withtheenginestopped,

carefully listen for escaping air at the intake. To pin-point

leakage if noted, squirt oil around the unloader pistons. If

there is no noticeable leakage at the unloader pistons, the

dischargevalves maybe leaking.

Ifthe compressordoes notfunctionas describedabove, or

leakageis excessive,it isrecommendedthat itbe returned

to the nearest Bendix authorized distributor for a factory

rebuiltcompressorunder therepairexchange plan.Ifthis is

notpossible, thecompressor canbe repairedwith genuine

Bendix partsinwhich case thefollowinginformation should

provehelpful.

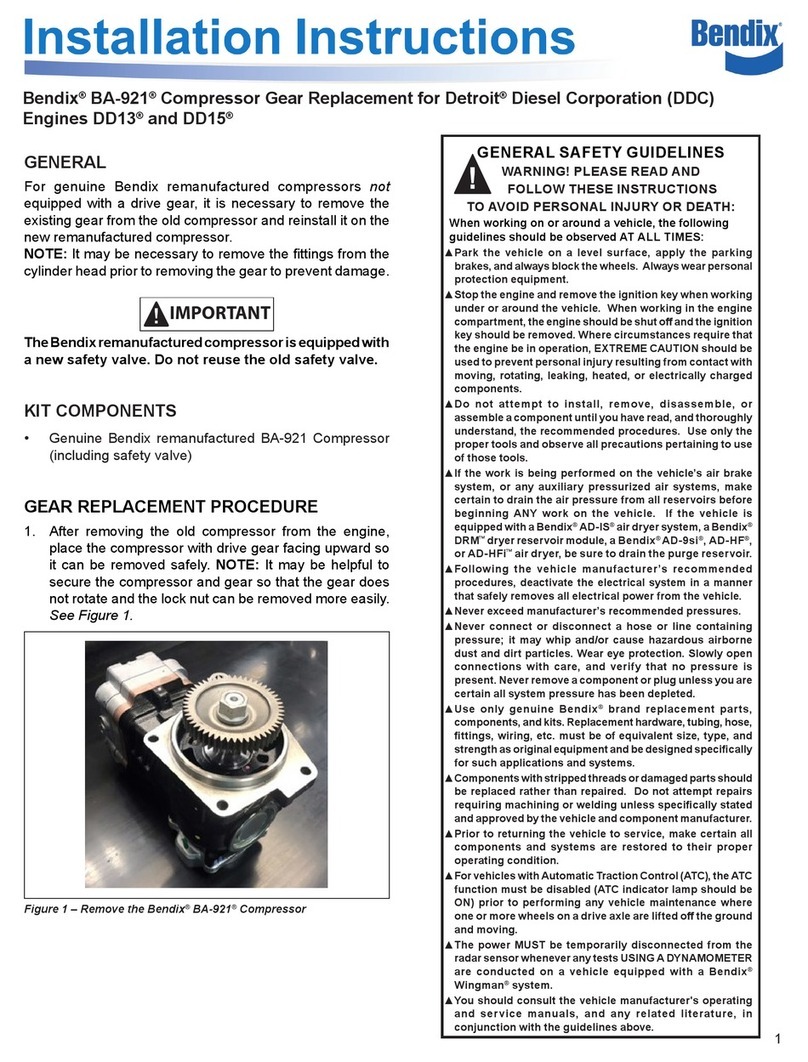

REMOVING AND INSTALLING

REMOVING

Theseinstructionsaregeneralandinsomecases additional

precautionsmust betaken.

Drain air brake system.

Drainenginecoolingsystem,compressorcylinderhead and

block.

Disconnect all air lines, water and oil lines to and from

compressor.

Removecompressor mountingbolts andcompressor from

engine.

Use a gear-puller to remove the gear or pulley from

compressorcrankshaft.

INSTALLATION

Clean oil supply line. Before connecting this line to the

compressor run the engine briefly to be sure oil is flowing

freelythrough thesupply line.

Clean the oil return line or return passages through the

brackets; these passages must be unrestricted so oil can

return to the engine.

Prelubricate compressor cylinder walls, piston rings, and

bearingswithcleanengineoilbeforeassemblingcompressor.

Always use a new mounting gasket and be sure oil hole in

gasket and compressor is properly aligned with oil supply

line.

Inspect pulley or gear and associated parts for wear or

damage.Theymust be aneatfiton compressorcrankshaft.

Replace pulley or gear if worn or damaged.

Installpulleyorgear on compressorcrankshaftmakingsure

it properly contacts the shaft and does not ride the key.

Tighten crankshaftnut to65-70 ft. lbs.andinstallcotter pin.

Besure theaircleaner isclean and properlyinstalled. Ifthe

compressor intake is connected to either the engine air

cleaner or supercharger, these connections must be tight

withno leakage.

Clean or replace any damaged or dirty air or water lines

which may be corroded, before connecting them to the

compressor. Use a new discharge fitting gasket.

Align compressor drive and adjust proper belt tension.

Tighten mounting boltssecurelyand evenly.

After installation run compressor and check for air, oil, or

water leaks at compressor connections. Also, check for

noisy operation.

DISASSEMBLY

GENERAL

Clean compressor exterior of road dirt and grease using a

good cleaning solvent. Before compressor is completely

disassembledthefollowingitemsshouldbemarked toshow

theirrelationship whenthe compressoris assembled:

The cylinder block in relation to crankcase, end covers’

relation to crankcase, position of crankshaft in relation to

crankcase, the cylinder head’s relation to the block.

Aconvenient methodto indicatethe aboverelationships is

to use a metal scribe to mark the parts with numbers or

lines. Do not use a marking method that can be wiped off

or obliterated during rebuilding, such as chalk. Remove all

compressor attachments such as governors, air strainers

or inlet fittings, discharge fittings and pipe plugs.

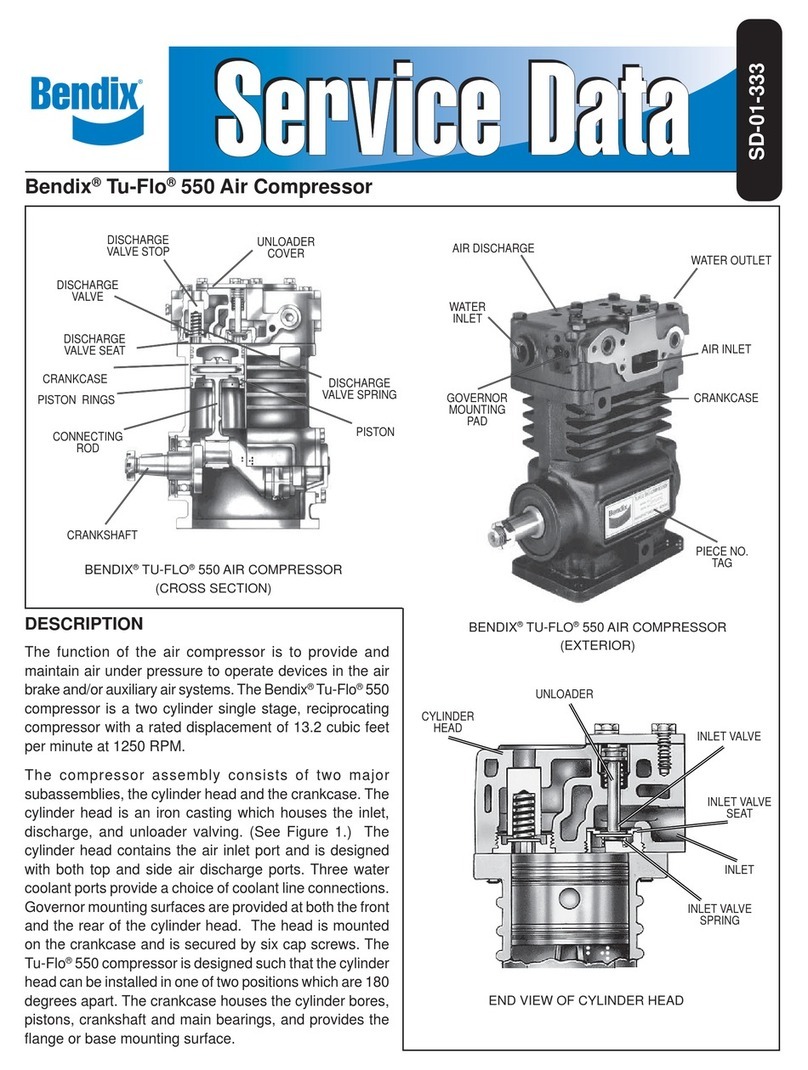

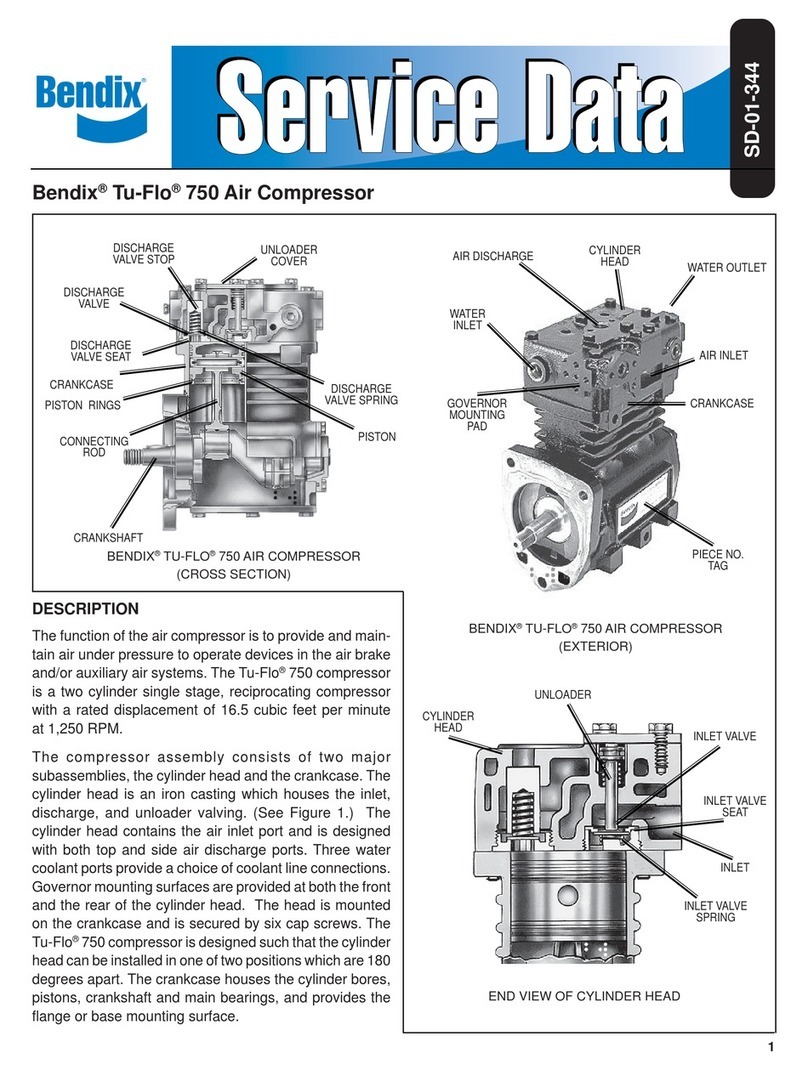

CYLINDER HEAD

Remove the cylinder head cap screws and tap the head

withasoft mallettobreak thegasketseal. Removetheinlet

valvespringsfromtheheadandinletvalvesfromtheirguides

in the block. Remove inlet valve guides from around the

inlet valve seats on the block taking care not to damage

seats. Scrape off any gasket material from the cylinder

head and block. Unscrew the discharge cap nuts from the

headandremovethe dischargevalvesandsprings.Inspect

the discharge valve seats for nicks, cracks, and excessive

wear and remove and replace if necessary.

FIGURE 11 - INLETADAPTER