7

Aconvenientmethod to indicatetheabove relationship isto

use a metal scribe to mark the parts with numbers or lines.

Do not use a marking method that can be wiped off or

obliterated during rebuilding, such as chalk. Remove all

compressor attachments such as governors, air strainers

or inlet fittings, discharge fittings and pipe plugs.

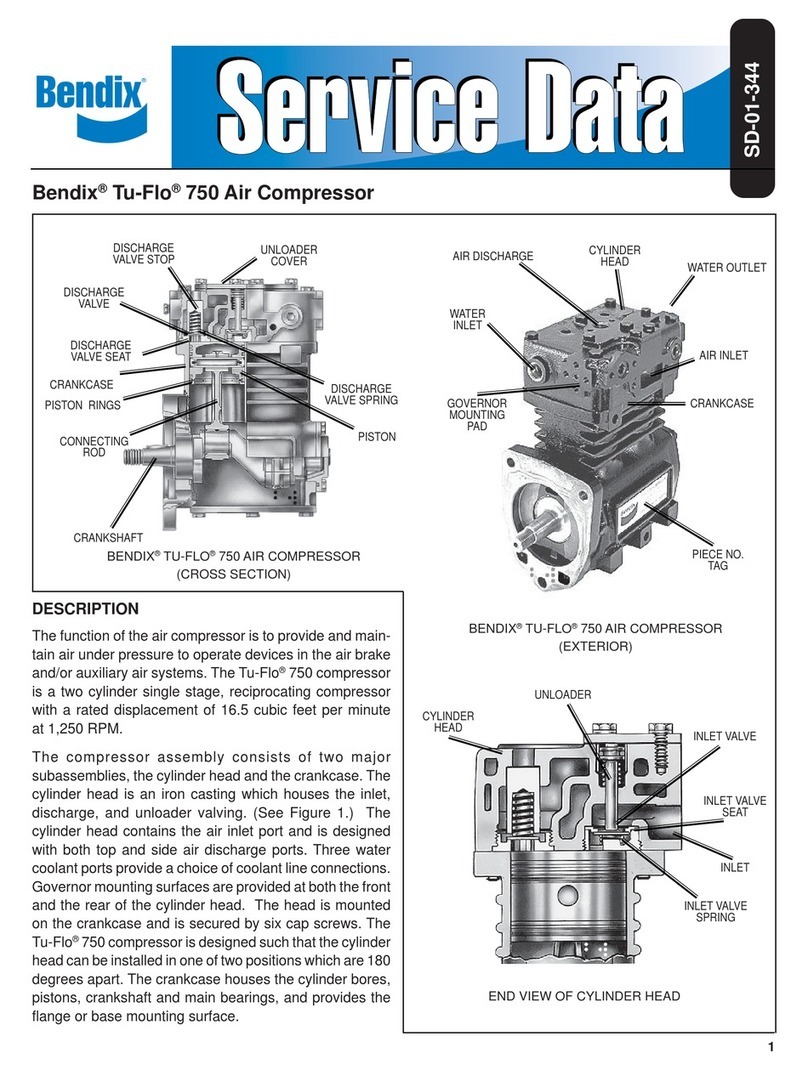

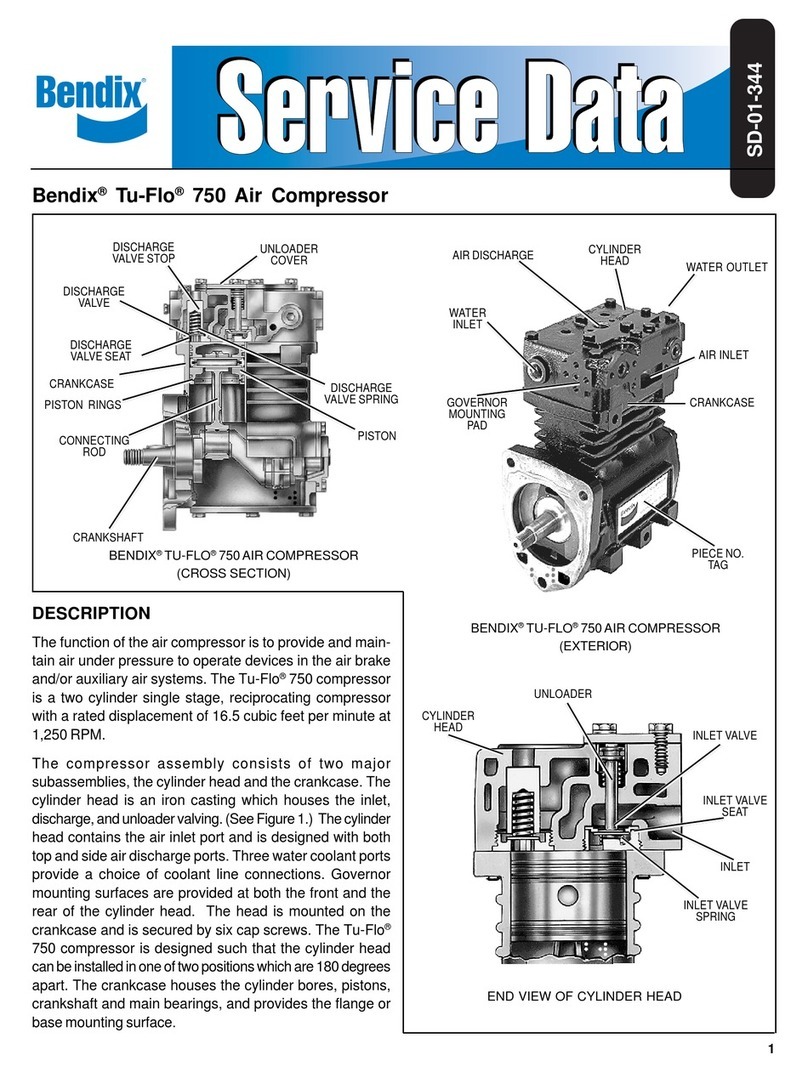

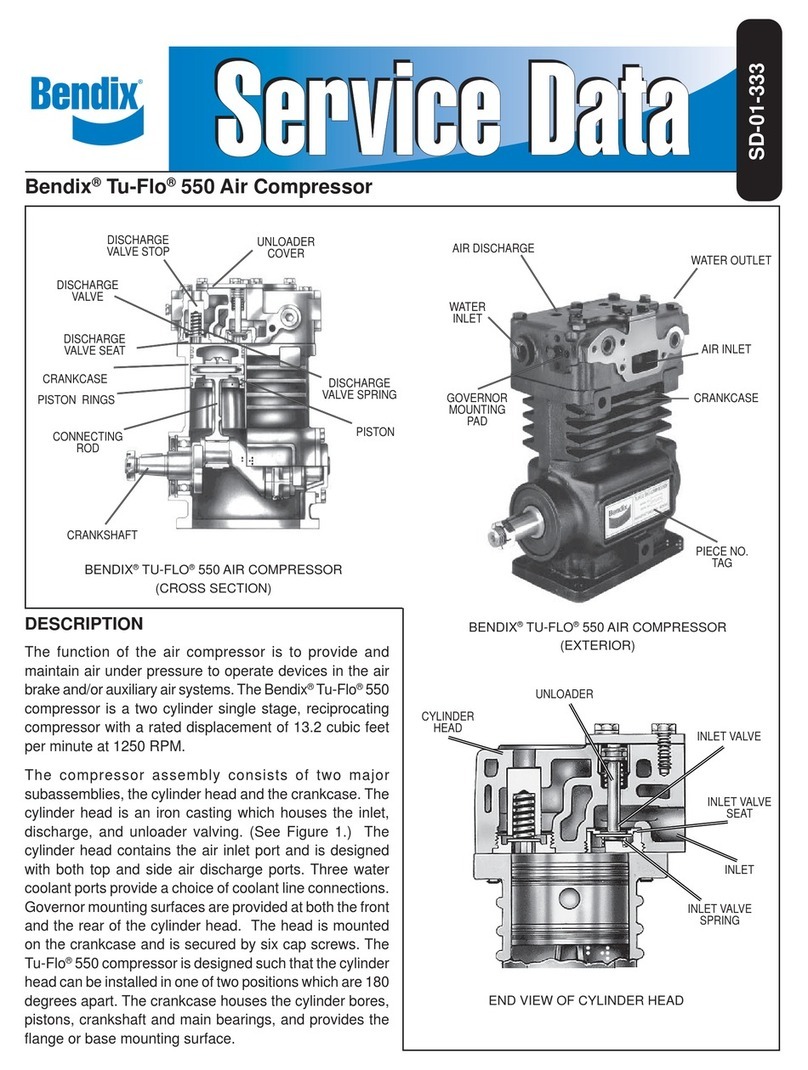

Cylinder Head

Removethe six cylinderhead capscrews andtap the head

withasoft mallettobreak thegasket seal. Removethe inlet

valvespringsfromtheheadandinletvalvesfromtheirguides

in the crankcase. Remove inlet valve guides from around

the inlet valve seats on the crankcase taking care not to

damage seats. Scrape off any gasket material from the

cylinderheadand crankcase.Unscrew the dischargevalve

seats from the head and remove the discharge valves and

springs.Inspectthe discharge valveseats for nicks,cracks,

and excessive wear and replace if necessary.

The discharge valve stops should be inspected for wear

and replaced if excessive peening has occurred. To

determineif excessivepeening has occurred, measure the

dischargevalvetravel.Dischargevalvetravelmustnotexceed

.057inches.Toremove thedischarge valve stops, support

themachinedsurfaceofthecylinderhead on anarborpress

bedandgently pressthestops fromthe top ofthe head and

outthe bottom.Be sureto allow sufficient clearance for the

stopsbetween the pressbed andthe bottom ofthe cylinder

head. The valve stop bores in the cylinder head must be

inspectedfor excessivescoring.Anewhead body must be

used if scoring is excessive. Discard the inlet valves and

springs,thedischargevalvesandspringsandthe discharge

valveseatsifdefective.

Crankcase Base Plate or Adapter

Remove the cap screws securing the base plate or base

adapter.Tapwithsoftmallettobreak the gasket seal. Scrape

offany gasket materialfromcrankcaseandplateor adapter.

Connecting Rod Assemblies

(Note: Before removing the connecting rods, mark each

connectingrod andits cap. Each connecting rod is

matched to its own cap for proper bearing fit, and

these parts must not be interchanged.)

Straighten the prongs of the connecting rod bolt lock strap

and remove the bolts and bearing caps. Push the piston

withtheconnectingrodsattachedoutthetopofthecylinders

of the crankcase. Replace the bearing caps on their

respective connecting rods. Remove the piston rings from

the pistons. If the pistons are to be removed from the

connecting rods, remove the wrist pin lock wires or teflon

plugs and press the wrist pins from the pistons and

connectingrods.

Ifthe pistonsare removed from the rod,inspect the bronze

wrist pin bushing. Press out and replace the bushing if it is

excessively worn. (See inspection of Parts) Discard the

piston rings and the connecting rod journal bearings.

Discard the wrist pin bushings if they were removed.

Crankcase

Removethe keyor keys from the crankshaftand any burrs

fromthe crankshaftwhere the key or keys were removed.

(Note: ThroughDriveCompressorsmayhaveacrankshaft

key at both ends.)

Removethefourcapscrewssecuring front ordrive-endend

coverorflange adapter.Removethe endcover,takingcare

notto damagethe crankshaft oil seal or front mainbearing,

if any. Remove both of the small seal rings from the

crankcase,and the o-ring from around the frontend cover.

Remove the four cap screws securing the rear end cover

and remove the rear end cover taking care not to damage

therearmain bearing,if any.Removeboth of thesmall seal

ringsfromthecrankcaseandtheo-ring from aroundtheend

cover.Ifthe compressorhas ball typemain bearings,press

the crankshaft and ball bearings from the crankcase, then

press the ball bearings from the crankshaft. Remove the

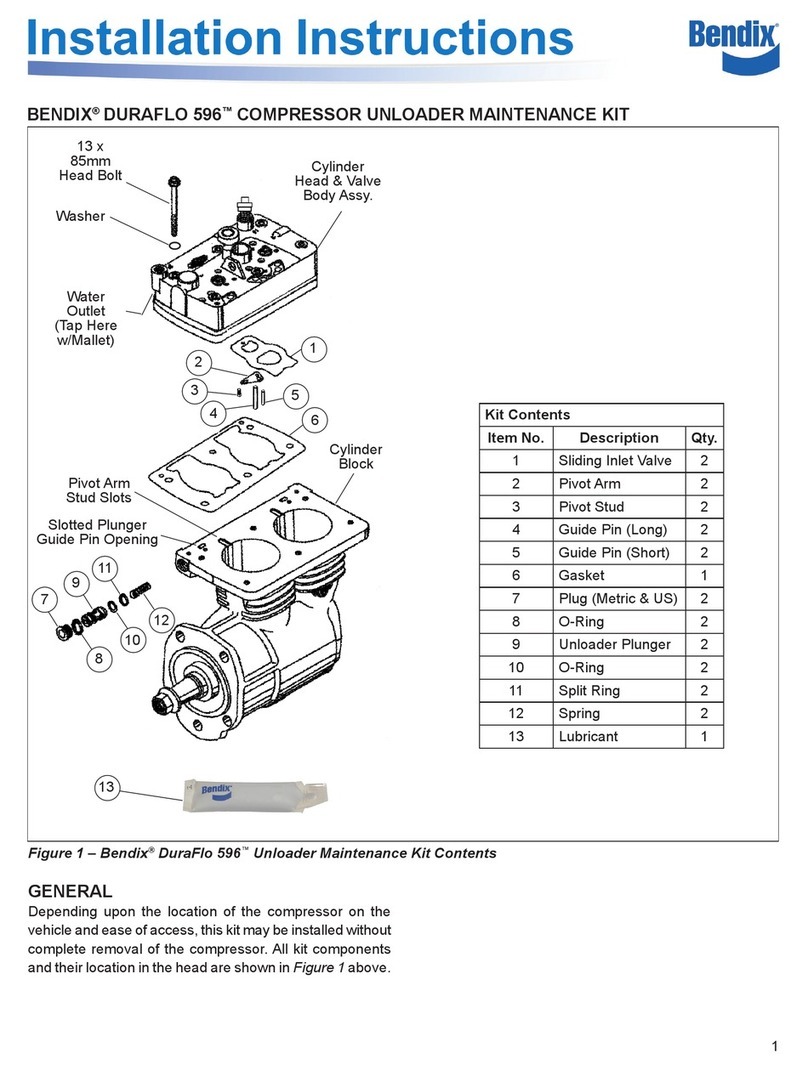

unloader spring, spring saddle, and spring seat from the

inletcavityofthecrankcase,usinglongnosepliers.Remove

theunloaderplungersandguides.Covertheinletcavitywith

ashoprag andapply air pressureto the governormounting

pad unloader port to blow the unloader pistons out of their

bores and into the inlet cavity.

CLEANING OF PARTS

General

All parts should be cleaned in a good commercial grade

solvent and dried prior to inspection.

Cylinder Head

Removeallthe carbondepositsfrom thedischarge cavities

and all the rust and scale from the cooling cavities of the

cylinder head body. Scrape all the foreign matter from the

body surfaces and use shop air pressure to blow the dirt

particles from all the cavities.

Crankcase

Clean the carbon and dirt from the inlet and unloader

passages. Use shop air pressure to blow the carbon and

dirtdeposits from theunloader passages.

Oil Passages

Thoroughly clean all oil passages through the crankshaft,

crankcase, end covers, and base plate or base adapter.

Inspect the passages with a wire to be sure. Blow the

loosenedforeign matterout withair pressure.