Content

GENERAL INFORMATION........................ 4

PRODUCT INFORMATION ....................... 5

Features......................................................5

How do IDVs work?................................................... 5

Compressor model designation ..............6

Nomenclature ............................................................ 6

Technical specifications............................7

Dimensions ..............................................10

VZH052-065G/J/H ...................................................10

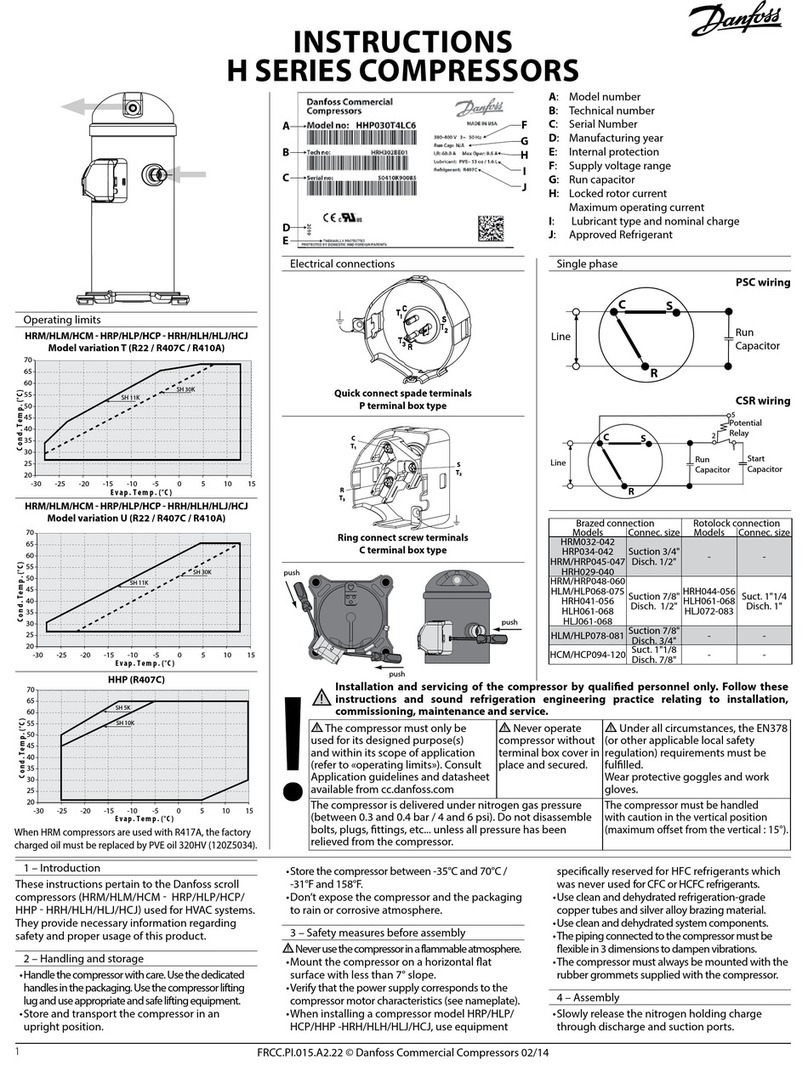

Electrical data, connections and wiring13

Supply voltage.........................................................13

Phase sequence and reverse rotation

protection.................................................................. 15

IP rating.......................................................................16

Motor protection.....................................................16

Approval and certificates .......................17

Low voltage directive 2014/35/EU.................... 17

Internal free volume............................................... 17

SYSTEM DESIGN..................................... 18

Drive installation.....................................18

Direct and indirect exposure of drive to water

18

Condensation...........................................................18

Dust Exposure..........................................................18

Mechanical Mounting ...........................................18

Ambient temperature ...........................................19

EMC installation ..................................... 20

EMC best practices .................................................20

EMC remediation ....................................................20

EMC remediation ....................................................21

Mechanical dimension .........................................21

Unit Architecture.................................... 22

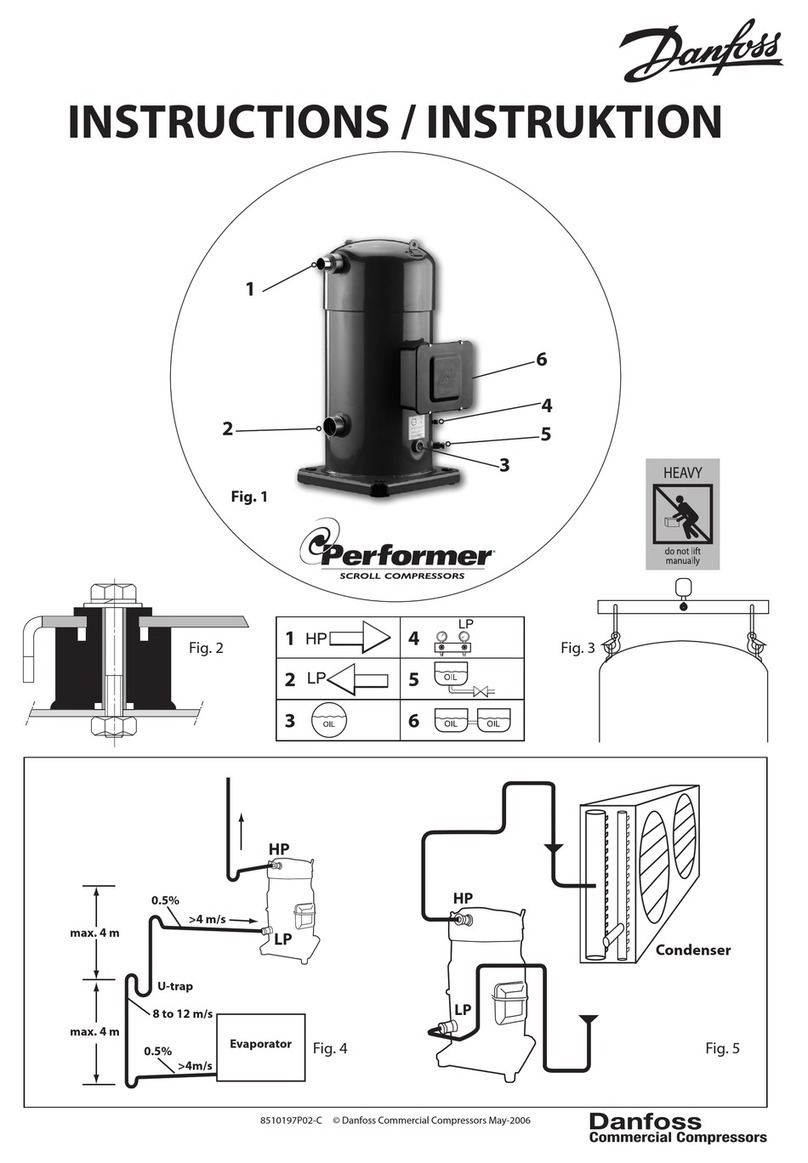

Design piping ......................................... 23

General requirements...........................................23

Design compressor mounting .............. 24

General requirements...........................................24

Single requirements...............................................24

Manage oil in the circuit ........................ 25

Requirement.............................................................25

System evaluation ..................................................25

Test, criteria and solutions...................................25

Manage sound and vibration................ 26

Compressor sound radiation..............................26

Mechanical vibrations...........................................27

Gas pulsation............................................................27

Manage superheat ................................. 28

Requirement.............................................................28

System evaluation ..................................................28

Test, criteria and solutions...................................29

Manage off cycle migration................... 30

Requirement.............................................................30

System evaluation .................................................30

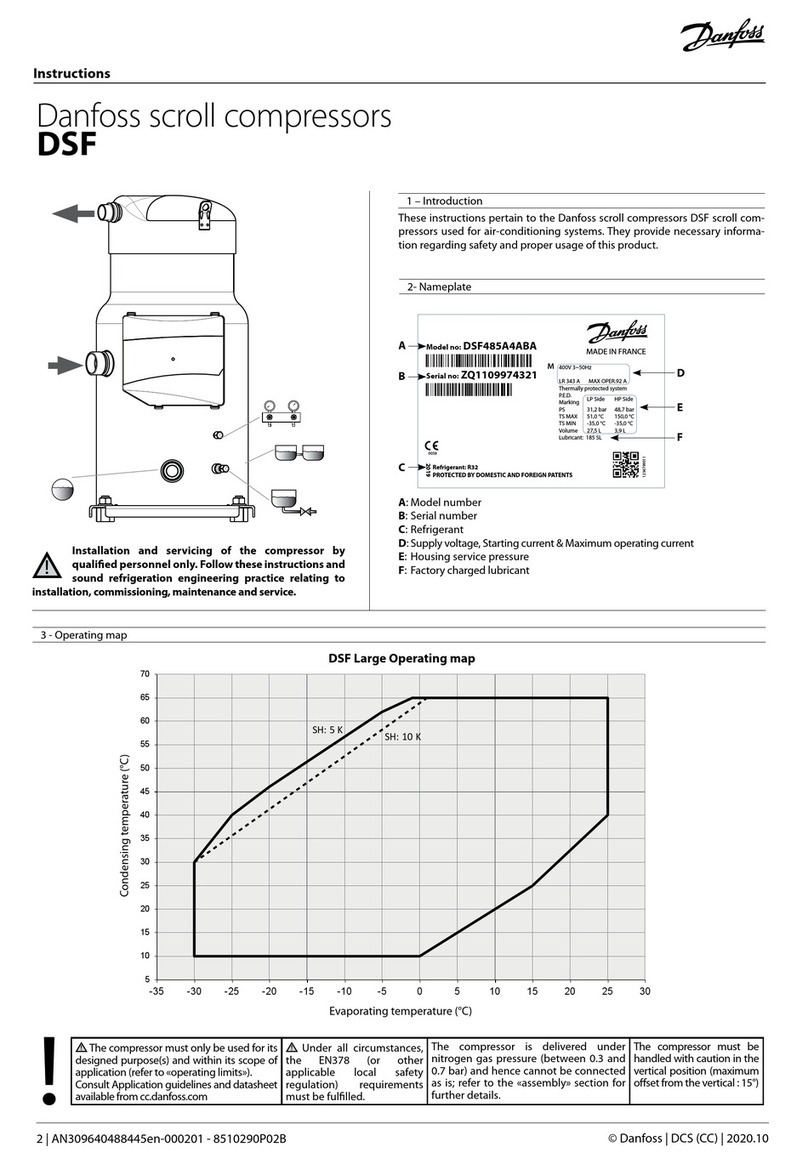

Manage operating envelope................. 32

Requirement.............................................................32

System evaluation ..................................................33

Manage speed limit.................................37

Speed limit requirement......................................37

Start/Stop/Ramp setting......................................37

Control logic ........................................... 38

Safety control logic requirements....................38

Short cycle protection .........................................39

Defrost cycle logic ..................................................39

Pump-down logic recommendations.............39

Oil management logic ..........................................40

Reduce moisture in the system..............41

Requirements........................................................... 41

Solutions.....................................................................41

INTEGRATION INTO SYSTEMS.............. 42

Assembly line procedure....................... 42

Compressor storage...............................................42

Compressor holding charge ...............................42

Handling ....................................................................42

Piping assembly.......................................................43

System pressure test and leak detection .......43

Vacuum evacuation and moisture removal .44

Refrigerant charging..............................................44

Dielectric strength and insulation resistance

tests..............................................................................44

Commissioning....................................... 45

Preliminary check....................................................45

Initial start-up...........................................................45

System monitoring.................................................45

Oil level checking and top-up............................45

Troubleshooting..................................... 46

Dismantal and disposal ......................... 49

ORDERING INFORMATION ................... 50

Packaging ............................................... 50

Ordering codes........................................51

Accessories...............................................52

3AB237586440343en-000601