2

S-1130 © 2002 Bendix Commercial Vehicle Systems LLC 2/2002 Printed in U.S.A. All rights reserved.

IMPORTANT! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID

PERSONAL INJURY OR DEATH:

When working on or around a vehicle, the following

general precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

2. Stop the engine when working around the vehicle.

3. If the vehicle is equipped with air brakes, make

certain to drain the air pressure from all reservoirs

before beginning ANY work on the vehicle.

4. Following the vehicle manufacturer’s recom-

mended procedures, deactivate the electrical

system in manner that removes all electrical

power from the vehicle.

5. When working in the engine compartment the

engine should be shut off. Where circumstances

require that the engine be in operation, EXTREME

CAUTION should be used to prevent personal injury

resulting from contact with moving, rotating, leak-

ing, heated, or electrically charged components.

6. Never connect or disconnect a hose or line con-

taining pressure; it may whip. Never remove a

component or plug unless you are certain all

system pressure has been depleted.

7. Never exceed recommended pressures and

always wear safety glasses.

8. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended proce-

dures. Use only the proper tools and observe all

precautions pertaining to use of those tools.

9. Use only genuine Bendix replacement parts,

components, and kits. Replacement hardware,

tubing, hose, fittings, etc. should be of equivalent

size, type, and strength as original equipment and

be designed specifically for such applications and

systems.

10. Components with stripped threads or damaged

parts should be replaced rather than repaired.

Repairs requiring machining or welding should

not be attempted unless specifically approved and

stated by the vehicle or component manufacturer.

11. Prior to returning the vehicle to service, make

certain all components and systems are restored

to their proper operating condition.

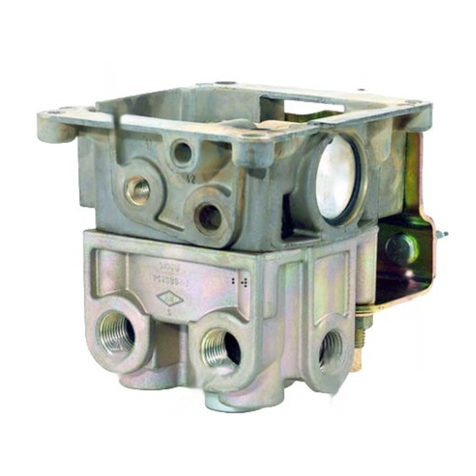

VEHICLEPREPARATION &REMOVAL OFTHE TW-12

NOTE: It may not be necessary in some installations to

remove the TW-12 from the vehicle to service with the Cap

Nut Kit.

1. Apply the parking brake. Identify and disconnect the

supply, exhaust anddelivery lines from theTW-12and

plug the ends of each.

2. Disconnectthe transmission lever linkage fromthe

TW-12cam.

3. Removethevalve from the vehiclebyremovingthe

mountingscrews.

DISASSEMBLY

1. Usinga7/8" wrench remove anddiscard theCapNut(3),

O-ring(4),Inlet ValveStop(2), Inlet ValveSpring(5)and

InletValve(1).

ASSEMBLY

1. Priortoassembly lubricate bores,o-ringand threads

withlubricant BW-663-M (Lubriplate 930-2). Usingthekit

contents install the Inlet Valve(1) into the supply port of

thevalvebody.Placethe Inlet Valve Spring(5)over the

InletValve(1).The Inlet ValveStop (2) is then placed over

theInletValve Spring.

2. PlaceO-ring(4) over the CapNut(3)as shown. With a

7/8"wrench secure the CapNut(3) into the body.Torque

to50-150inch pounds.

INSTALLATION

CAUTION:Do notfillreservoirwithengineon.Duetothe

complexity of the hydraulic park system, extensive bleeding

of the system is required.

1. Reinstallthevalveand cover plate to mounting bracket

onthevehicle.

2. Removeplugsfromthe exhaust, delivery and supply

lines and connect each to its corresponding port.

CAUTION: Whenconnecting the supply linesecure the

CapNutwitha7/8"wrench to prevent overtorquing of

Cap Nut when tightening the supply line fitting.

3. Fillthebrakepumpreservoir.

4. With the vehicle wheels blocked, start the engine and

inspectfor leaks. Release theparking brake. Turn the

engineoff and bleed thechambers until they reacha full

application.Replenishthereservoir.DONOTAPPLY

THEPARKING BRAKE.Starttheengine and runfor15

seconds,turn the engine offandbleed the chambers

until they reach a full application. Replenish the

reservoir.

5. Withtheengine on, cyclethevalve every 20seconds for

10minutes. Release the brakes, turn the engine off,

bleedthe chambers, apply theparkingbrake and

replenishreservoirtofullmark.

TEST

Before placing the vehicle in service, check the system for

correctoperation,possibleleakageandproperlyfilled

reservoirs.