5

7. Placethe cover overthe bodyinthe properposition, as

marked in Step 1 of the Disassembly procedure.

8. Using the four Phillips head screws and lockwashers,

secure the cover to the body. Torque the screws to

50-80inchpounds.

TESTING THE REBUILT LQ-3™AND LQ-4™

FRONT AXLE RATIO VALVE

Test the rebuilt LQ-3™or LQ-4™front axle ratio valve by

performingtheoperationaland leakage testsoutlinedinthe

Service Checks section of this manual.

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID

PERSONAL INJURYOR DEATH:

When working on or around a vehicle, the following

general precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

Always wear safety glasses.

2. Stop the engine and remove ignition key when

working under or around the vehicle. When

working in the engine compartment, the engine

should be shut off and the ignition key should be

removed. Where circumstances require that the

enginebeinoperation,EXTREMECAUTIONshould

be used to prevent personal injury resulting from

contact with moving, rotating, leaking, heated or

electrically charged components.

3. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended

procedures. Useonly the proper tools and observe

all precautions pertaining to use of those tools.

4. If the work is being performed on the vehicle’s air

brake system, or any auxiliary pressurized air

systems,make certain to drain theairpressurefrom

all reservoirs before beginning ANY work on the

vehicle. If the vehicle is equipped with an AD-IS™

air dryer system or a dryer reservoir module, be

sure to drain the purge reservoir.

5. Following the vehicle manufacturer’s

recommendedprocedures,deactivatetheelectrical

system in a manner that safely removes all

electrical power from the vehicle.

6. Never exceed manufacturer’s recommended

pressures.

7. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove a

component or plug unless you are certain all

system pressure has been depleted.

8. Use only genuine Bendix®replacement parts,

components and kits. Replacement hardware,

tubing, hose, fittings, etc. must be of equivalent

size, type and strength as original equipment and

be designed specifically for such applications and

systems.

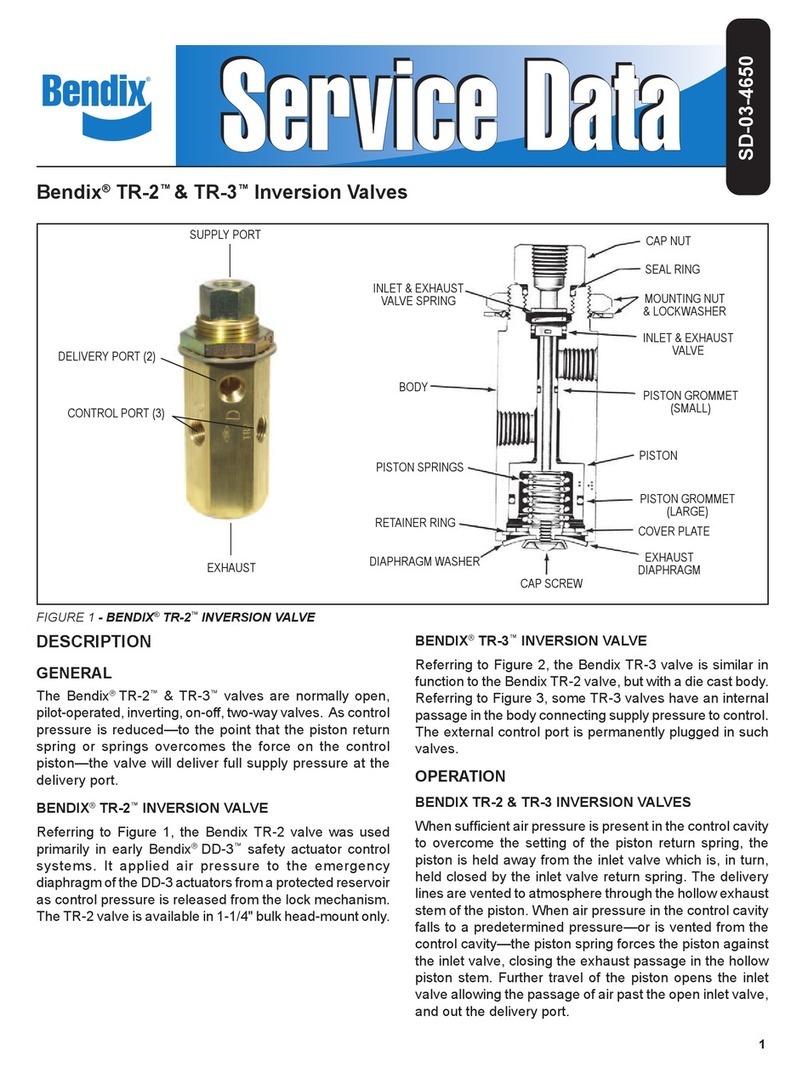

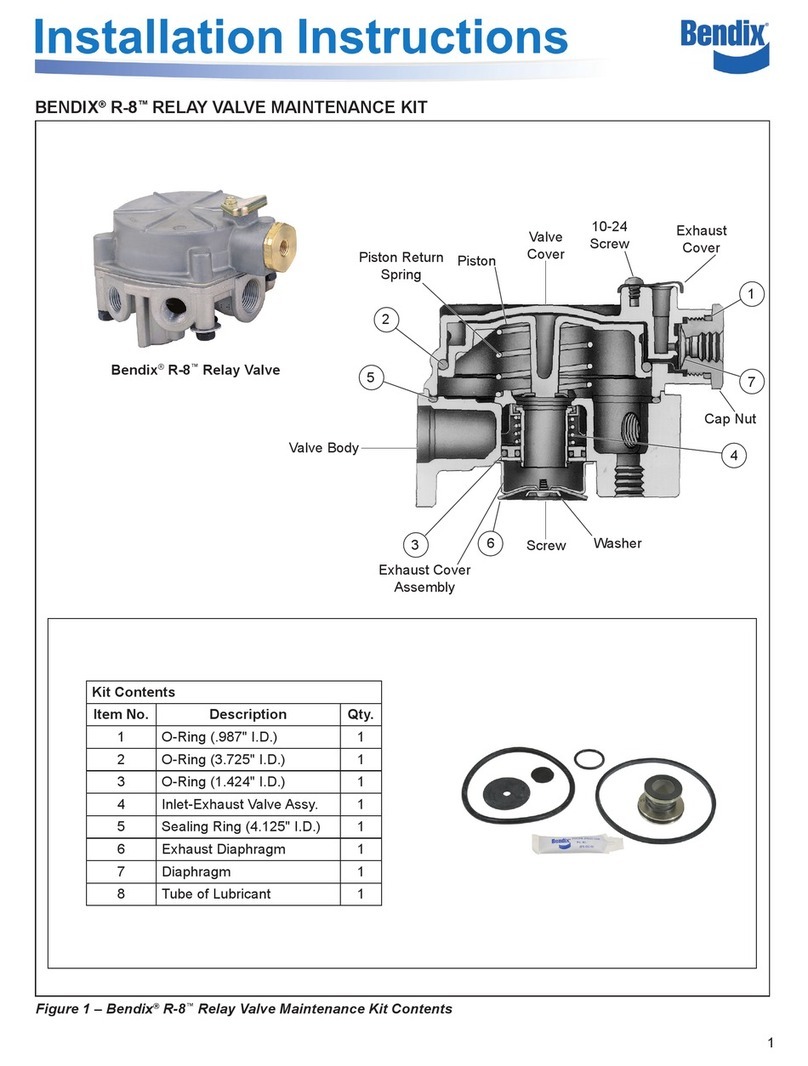

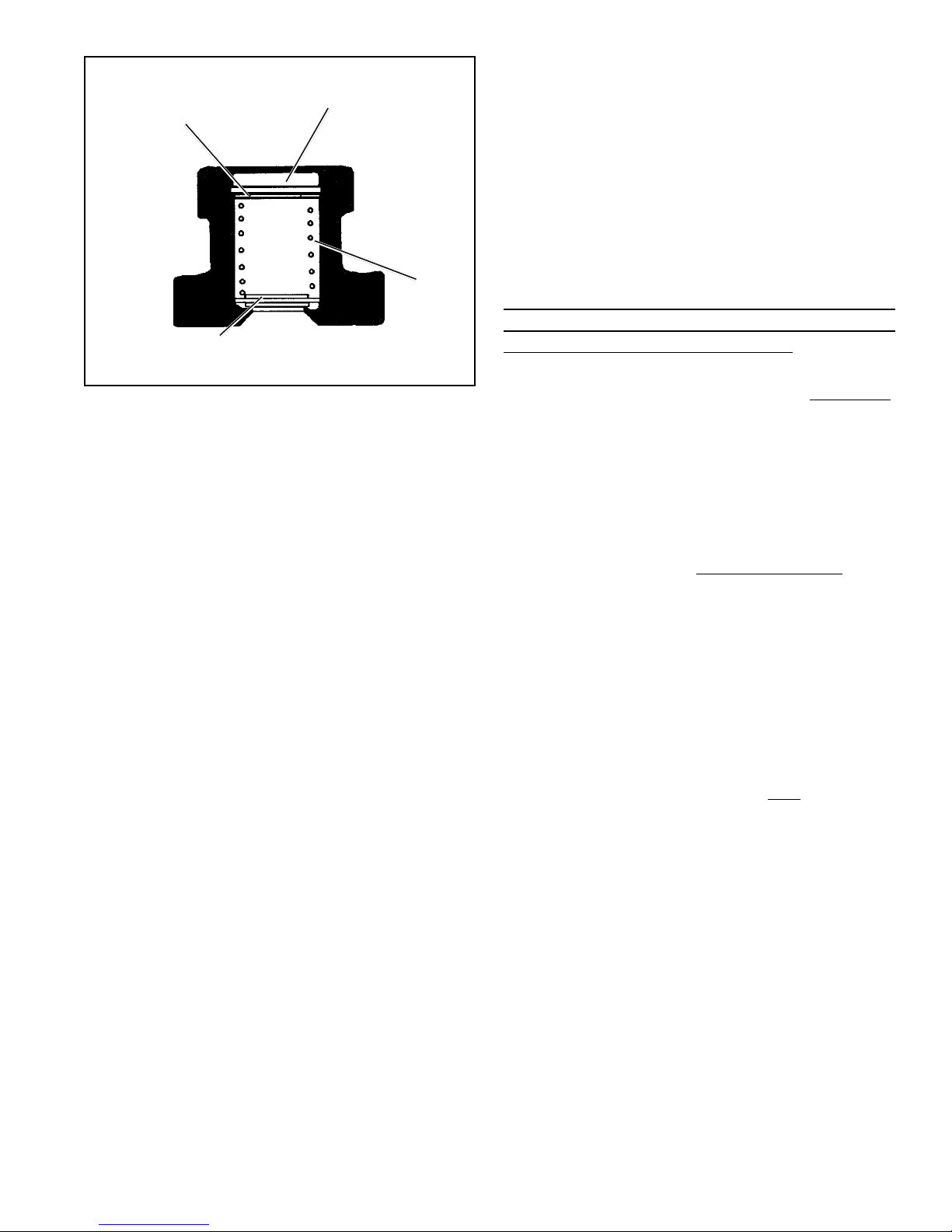

INLET-EXHAUST

VALVE (4)

WASHER

(2)

RETAINING

RING

(1)

INLET

EXHAUST

SPRING (3)

FIGURE 8 - LQ-3™FRONT AXLE RATIO VALVE INNER

PISTON ASSEMBLY

CLEANING AND INSPECTION

1. Wash all metal parts in mineral spirits and dry them.

2. Inspectall parts forexcessive wear ordeterioration.

3. Inspectthe valve seatfor nicksor burrs.

4. Check the spring for cracks or corrosion.

5. Replace all rubber parts and any part not found to be

serviceableduring inspection,usingonlygenuineBendix

replacementparts.

ASSEMBLY

Priortoreassembling the LQfrontaxleratio valve, lubricate

all o-rings, o-ring grooves, piston bores and metal moving

surfaceswithBendix siliconelubricantpiecenumber291126

(DowCorning650-M).

1. (LQ-3™valve — Figure 8) Place the inlet and exhaust

valve (4), valve spring (3), and washer (2) in the inner

piston.Install the retainingring(1) inthepiston, making

certain it is completely seated in its groove.

(LQ-4™valve — Figure 7) Place the inlet and exhaust

valve(10)andspring(9)intheinnerpiston(3).Thespring

must be carefully located under the shoulder in the

innerpiston.

2. Install the large (8) and small (7) diameter o-rings in

theirgrooves on theinner piston.

3. Install the o-ring (6) on the outer piston.

4. Insert the inner piston into the bore of the outer piston.

Note: See Figure 7 for proper inner and outer piston

configurationafterassembly.

5. Place the outer piston spring (5) in the valve body and

thehold-offspring(11) ifused.

6. Install the inner and outer piston assembly in the body

throughthe spring (seeFigure 7).