2

If,inthe case ofanemergencyorfor some other reasonthe

driver wishes an application of the trailer brakes, he pulls

thePP-3™valve controlbuttonout.Emergencyline pressure

will exhaust out the PP-3™valve exhaust port causing an

application of the trailer brakes.Also, theTP-3™inlet valve

seatsandcloses the serviceline.ThePP-3™valvebutton is

pulledoutandleftoutduringbob-tailedoperationofthetractor.

In normal use the button is pulled out before uncoupling

fromthe trailer and pushed inaftercouplingto the trailer.

Shoulda condition occurresultinginair loss fromthetractor

or trailer system through leakage and the driver fails to

manually pull out the PP-3™valve button, the PP-3™valve

will automatically close at approximately 40 psi and seal

the tractor air lines. The driver cannot, in this condition,

overcomethe emergencyapplicationofthe trailerbrakesby

holding the PP-3™valve button in. If the driver should hold

thebuttonin as emergency line pressure bleeds downfrom

the 40 psi range to approximately 30 psi, the tripper piston

will move and open the tripper exhaust in the PP-3™valve.

Emergencylineairwillexhaustthroughthetripper exhaust

andholdthetrailer brakes applied.

PREVENTIVE MAINTENANCE

Important: Review the Bendix Warranty Policy before

performinganyintrusivemaintenanceprocedures.Awarranty

maybevoided if intrusive maintenance is performedduring

thewarrantyperiod.

No two vehicles operate under identical conditions, as a

result, maintenance intervals may vary. Experience is a

valuableguide in determiningthebestmaintenance interval

forairbrakesystemcomponents.Ata minimum, the PP-3™

valveshouldbeinspectedevery12monthsor3600operating

hours,whichever comes first, for properoperation. Should

the PP-3™valve not meet the elements of the operational

testsnotedinthisdocument,furtherinvestigationandservice

ofthevalve may be required.

OPERATING AND LEAKAGE CHECKS

To make the following operating and leakage checks, an

accurate test gauge installed in a spare hose coupling is

required. The vehicle dash gauge should be checked for

accuracyagainstthe test gaugepriortomaking these tests.

1. Block and/or hold the vehicle by ameansother than air

brakesduringthese tests.

2. Drain vehicle reservoir supply, then close drain cocks.

3. Connect assembled hose coupling and test gauge in

tractoremergency hosecoupling.Startengine andbuild

up system pressure.

4. As reservoir pressure builds up there should be no

pressurereading on testgauge.Whensystempressure

reaches the 30 to 40 psi range on dash gauge make

and hold a foot or hand valve application and observe

that no air escapes at the open trailer service hose

coupling.

5. When system pressure reaches approximately 60 psi,

the PP-3™valve button should be pushed in. System

pressure should show at once on the test gauge

connected in the emergency line and the button of the

PP-3™valveshouldremaininwithoutbeingheld.

6. Buildsystempressure uptoapproximately100 psi,then

stop engine. With engine stopped, wait momentarily,

then notice that dash gauge and test gauge pressure

readingequal.While still in this position, make a footor

handvalveapplicationandobservethat air is delivered

outtheopentrailerservicecoupling.

7. With PP-3™valve button still in, check for leakage at

PP-3™valveexhaust andtripperexhaust ports.Leakage

should not exceed a 1" bubble in 5 seconds at either

point.

8. WithPP-3™valvebutton still in, check for leakageatthe

TP-3™valveexhaustandopenservicecoupling.Leakage

should not be more than a 1" bubble in 5 seconds at

eitherpoint.

9. Pull the PP-3™valve button out: pressure on the test

gauge connected in the emergency line should drop to

zero.Makeandholdahandvalveapplicationandobserve

thatair delivered at the open service coupling does not

exceed a 1" bubble in 5 seconds. Release foot or hand

valveapplication.

NOTE:If thePP-3™valvedoes notfunctionasdescribed

or if leakage is excessive, it is recommended that it be

returnedtothe nearest Bendix authorized distributor for

a factory rebuilt valve. If this is not possible, the valve

shouldbe repaired usinggenuineBendixparts, inwhich

casethefollowing should prove helpful.

REMOVING AND INSTALLING

REMOVING

1. Blockand/orhold the vehicle by a means otherthanair

brakes. Drain air brake system.

2. DisconnectsupplyanddeliverylinesfromPP-3™valve.

3. DriveoutPP-3™valve buttonrollpinand remove button.

RemovePP-3™valve mounting nut,thenPP-3™valve.

INSTALLING

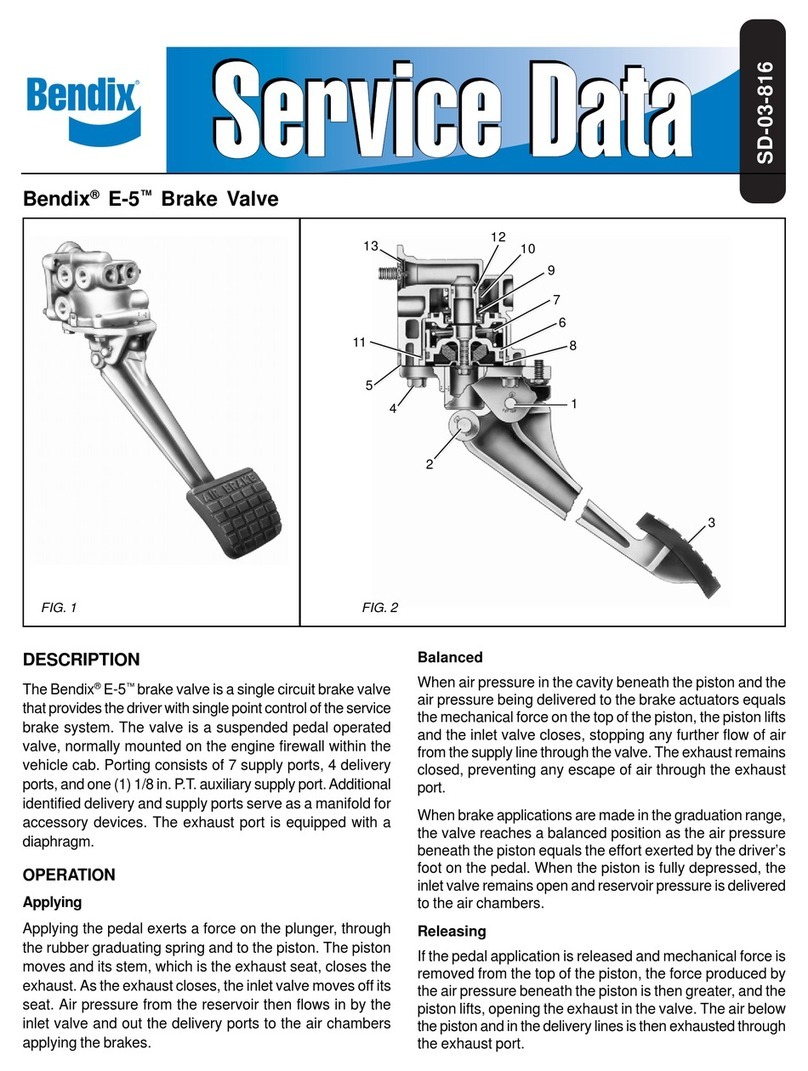

Wheninstallingthe PP-3™valve, refer to Figure2forproper

connectionsalongwithfollowingexplanations:

1. Supplylinefrom tractor reservoir is connectedtosupply

portof PP-3™valve.

2. DeliverylinefromPP-3™valvedeliveryport isconnected

totractoremergencyportofTP-3™valve.

3. PP-3™valve exhaust port and tripper exhaust must be

open.

4. Two(2)portsmarked“Del” onupperPP-3™controlvalve

bodyarepluggedandmustremainplugged.