Benelli ZAFFERAN 250 User manual

1

ZAFFERANO

250

Service Manual

2

Contents

Notice.................................................................................................................................................... 4

Preparing documents......................................................................................................................5

General Safety................................................................................................................................5

Inspection /Adjustment.................................................................................................................20

Inspection and maintenance of electrical system ................................................................................40

1. Battery/Charging System............................................................................................................41

1.1 Preparing documents ..............................................................................................................41

1.2 Failure diagnosis .....................................................................................................................42

1.3 Battery .....................................................................................................................................42

1.4 Charging system......................................................................................................................43

1.5 Voltage/current regulator......................................................................................................... 44

1.6 Magneto charging coil .............................................................................................................45

1.7 Magneto disassembly..............................................................................................................45

2. Ignition System............................................................................................................................ 47

2.1 Preparing documents ..............................................................................................................47

2.2 Failure diagnosis .....................................................................................................................48

2.3 Ignition system check..............................................................................................................49

2.4 RELATED PARTS Group........................................................................................................51

2.5Ignition coil................................................................................................................................51

2.6 Trigger......................................................................................................................................52

3.. Startup System...............................................................................................................................54

3.1 Preparing documents ..............................................................................................................54

3.2 Failure diagnosis .....................................................................................................................55

3.3 Startup motor...........................................................................................................................55

3.4 Starter relay.............................................................................................................................56

4.. Bulbs/Switches/Meters................................................................................................................. 58

4.1 Preparing documents ..............................................................................................................58

4.2 Failure diagnosis .....................................................................................................................58

4.3 Replacement of headlamp bulbs.............................................................................................58

4.4 Replacement of front steering lamp bulbs...............................................................................58

4.5 Replacement of tail lamp bulbs...............................................................................................59

4.6 Meter........................................................................................................................................59

4.7 Main switch..............................................................................................................................59

4.8 Horn.........................................................................................................................................60

4.9 Handlebar switch.....................................................................................................................60

Inspection and maintenance of vehicle................................................................................................61

5.. Brake................................................................................................................................................63

5.1 Maintenance instruction...........................................................................................................63

5.2 Failure diagnosis .....................................................................................................................63

5.3 Front disc brake.......................................................................................................................64

5.4 Rear disc brake........................................................................................................................65

6. Body............................................................................................................................................65

7. Front Wheel/Front Suspension...................................................................................................67

7.1 Preparing documents ..............................................................................................................72

7.2 Failure diagnosis .....................................................................................................................72

7.3 Front wheel..............................................................................................................................73

7.4 Steering handle .......................................................................................................................75

7.5 Front fork .................................................................................................................................76

7.6 Radiator/expansion tank assembly.........................................................................................77

8.. Rear Wheel/Rear Suspension....................................................................................................... 80

8.1 Preparing documents ...............................................................................................................80

8.2 Failure diagnosis ......................................................................................................................80

8.3 Rear wheel................................................................................................................................80

8.4 Rear absorber/rear swing arm..................................................................................................82

3

9.. Lubricating System ..........................................................................................................................85

9.1 Preparing documents ................................................................................................................85

9.2 Failure diagnosis........................................................................................................................85

9.3 Oil pump ....................................................................................................................................86

10. Cooling System.................................................................................................................................90

10.1 Preparing Documents..............................................................................................................90

10.2 Failure Diagnosis.....................................................................................................................90

10.3 Water Pump .............................................................................................................................90

11. Cylinder head/valve...........................................................................................................................93

11.1 Preparation documents........................................................................................................... 93

11.2 Failure diagnosis.....................................................................................................................94

11.3 Cylinder head..........................................................................................................................94

12. Cylinder body and piston..............................................................................................................104

12.1 Preparation documents.........................................................................................................104

12.2 Failure diagnosis...................................................................................................................105

12.3 Cylinder body........................................................................................................................105

12.4 Piston....................................................................................................................................106

13. Driving disc/clutch/driven wheel....................................................................................................115

13.1 Preparation documents.........................................................................................................115

13.2 Failure diagnosis...................................................................................................................116

13.3 Left crankcase cover.............................................................................................................116

13.4 Driving disc ............................................................................................................................116

13.5 Clutch/driven wheel ..............................................................................................................119

14. Transmission................................................................................................................................126

14.1 Preparation documents.........................................................................................................126

14.2 Failure diagnosis...................................................................................................................126

15. Crankcase..................................................................................................................................... 131

15.1 Preparation documents.........................................................................................................131

15.2 Failure diagnosis...................................................................................................................131

Inspection and maintenance of Emission control system...................................................................142

16. Emission control system................................................................................................................137

16.1 Emission control system recognizance................................................................................137

16.2 Regular maintenance notes..................................................................................................138

16.3 Mechanic function of Emission control system.................................................................... 139

16.4 Catalytic transfer system...................................................................................................... 140

Inspection and Maintenance of Electronic Fuel Injection (EFI) System............................................. 142

17. Electronic Fuel Injection System................................................................................................... 143

17.1 Introduction of Electronic Fuel Injection System.................................................................. 143

17.2 Components of Electronic Fuel Injection System................................................................ 144

17.3 Methods for Fault Diagnosis and Maintenance ................................................................... 172

17.4 Common troubleshooting..................................................................................................... 181

Circuit Diagram...................................................................................................................................186

4

NOTICE

This manual was produced by the Benelli Motor Company primarily for use by Benelli dealers and

their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one

manual, so it is assumed that anyone who uses this book to perform maintenance and repairs on

a Benelli scooter has a basic understanding of the mechanical ideas and the procedures of

scooter repair. Repairs attempted by anyone without this knowledge are likely to render the scooter

unsafe and unfit for use.

Benelli Motorcycles USA is continually striving to improve all its models. Modifications and

significant changes in specifications or procedures will be forwarded to all authorized Benelli

dealers and will appear in future editions of this manual where applicable.

NOTE:

Designs and specifications are subject to change without notice.

IMPORTANT INFORMATION

Particularly important information is distinguished in this manual by the following notations.

The Safety Alert Symbol means ATTENTION! BE ALERT! YOUR

SAFETY IS INVOLVED!

FailuretofollowWARNINGinstructionscouldresultin severeinjuryordeath

to thescooteroperator,abystanderor apersoninspectingorrepairingthe

scooter.

CAUTION: CAUTION:indicatesspecialprecautionsthatmustbe takentoavoiddamage

to the scooter.

NOTE: NOTE: provides key information to make procedures easier or clearer.

5

Preparing documents

General safety Maintenance

rules

Specification tableFailure

diagnosis General Safety

Carbon monoxide

Engine must be started up in a well-ventilated place, not in a closed area.

Note

Exhaust gas contains poisonous carbon monoxide, which may cause unconsciousness or even

death of human.

Start the engine in an open place. An exhaust removal system shall be adopted if engine

is started up in a closed area.

Petrol

Ventilation is required for working places. Fire is strictly forbidden in any working place or where

petroleum is stored.

6

IMPORTANT INFORMATION

PREPARATION FOR REMOVAL PROCE-

DURES

1. Remove all dirt, mud, dust and foreign ma-

terial before removal and disassembly.

2. Use proper tools and cleaning equipment.

3. Refer to the “SPECIAL TOOLS” section.

4. When disassembling the machine, always

keep mated parts together. This includes

gears, cylinders, pistons and other parts

that have been “mated” through normal

wear. Mated parts must always be reused

or replaced as an assembly.

5. During machine disassembly, clean all

partsand place themin trays in the order of

disassembly. This will speed up assembly

and allow for the correct installation of all

parts.

6. Keepallparts awayfromanysource of fire.

REPLACEMENT PARTS

1. Use only genuine Benelli parts for all re-

placements. Use oil and grease recom-

mended by Benelli for all lubrication jobs.

Other brands may be similar in function

and appearance, but inferior in quality.

GASKETS, OIL SEALS AND O-RINGS

1. Replace all gaskets, seals and O-rings

when overhauling the engine. All gasket

surfaces, oil seal lips and O-rings must be

cleaned.

2. Properly oil all mating parts and bearings

during reassembly. Apply grease to the oil

seal lips.

7

LOCK WASHERS/PLATES AND COTTER

PINS

1. Replace all lock washers/plates and cotter

OR pinsafterremoval.Bendlocktabsalongthe

boltornutflatsaftertheboltor nuthasbeen

tightened to specification.

BEARINGS AND OIL SEALS

Install bearings and oil seals so that the

manufacturer’s marks or numbers are visible.

Wheninstallingoilseals,applyalightcoatingof

lightweight lithium base grease to the seal lips.

Oilbearingsliberallywheninstalling,ifappropri-

ate.

1 Oil seal

CAUTION:

Do not use compressed air tospin the bearings

dry. This will damage the bearing surfaces.

1 Bearing

CIRCLIPS

1. Check all circlips carefully before reas-

sembly. Always replace piston pin clips af-

ter one use. Replace distorted circlips.

When installing a circlip 1 , make sure that

the sharp-edged corner 2 is positionedop-

posite the thrust 3 it receives. See section-

al view.

4 Shaft

8

CHECKING OF CONNECTIONS

Dealing with stains, rust, moisture, etc. on the

connector.

•

1. Disconnect

2. Connect

3. Dry each terminal with an air blower.

4. Connect and disconnect the connector two

or three times.

5. Pull the leads to check that it will not

come off.

6. Iftheterminalcomesoff,bendupthepin 1

andreinserttheterminalintotheconnector.

7.

•

Connect: Connector

NOTE:

The two connectors “click” together.

8. Check for continuity with a tester.

NOTE:

•

If there is no continuity, clean the terminals.

Be sure to perform the steps 1 to 7 listed

•

above when checking the wire harness.

For a field remedy, use a contact revitalizer

•

available on the market.

Use the tester on the connectors as shown.

9

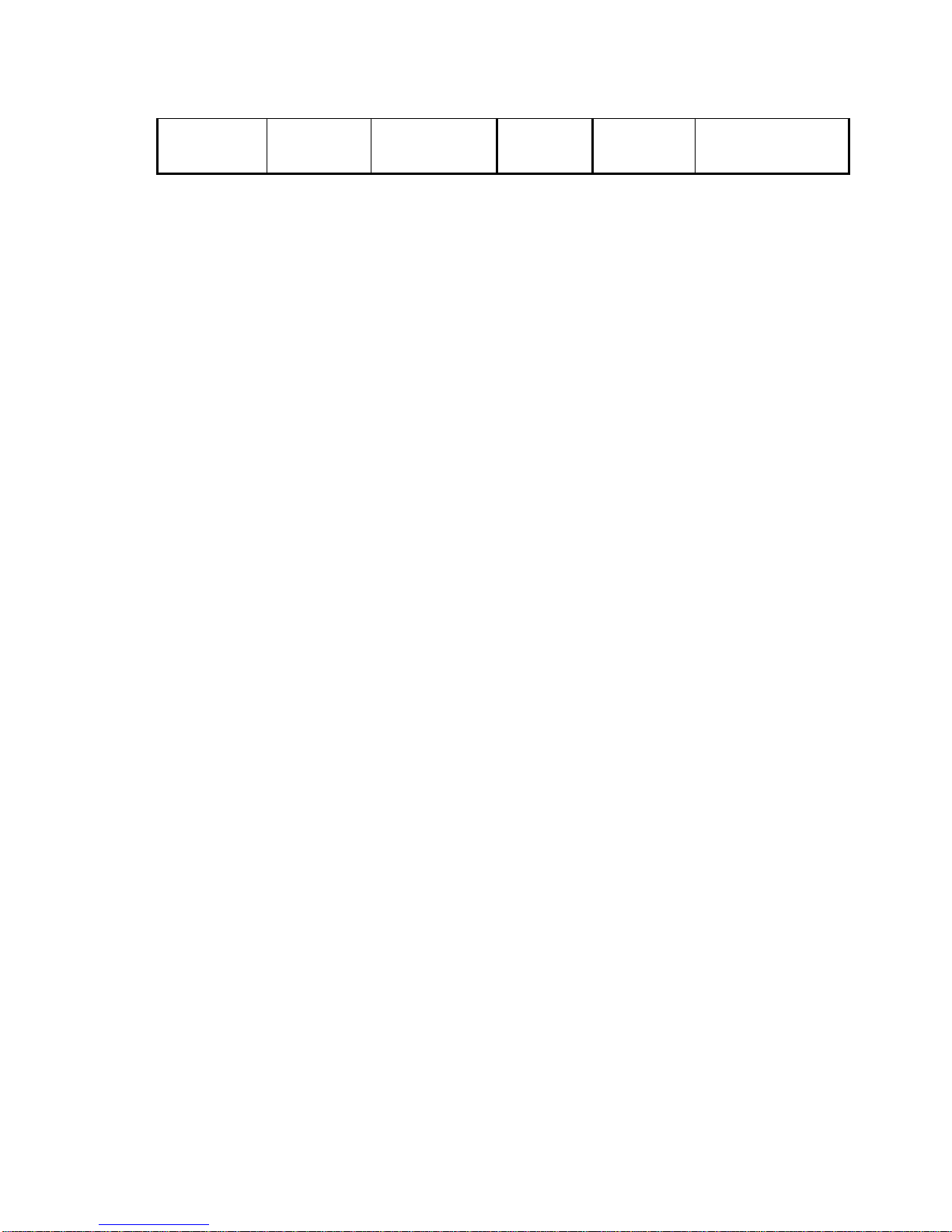

METRIC TO IMP

Known

Multiplier

Result

Torque

mkg

cm.kg

7.233

86.794

0.0723

0.8679

ft

•

lb

ft

•

lb

Weight

kg

g

2.205

0.03527

lb

oz

Distance

km/hr

0.6214

mph

km

0.6214

mi

m

m

3.281

1.094

ft

yd

cm

0.3937

in

mm

0.03937

in

Volume/

cc (cm3)

cc (cm3)

0.03527

0.06102

oz

•

(IMPliq.)

Capacity

lit (liter)

0.8799

qt (IMP liq.)

lit (liter)

0.2199

gal (IMP liq.)

Miscella-

neous

kg/mm

2

Centigrade

55.997

14.2

°

234

lb/in 2

Fahrenheit ( F)

HOW TO USE THE CONVERSION TABLE

All specification data in this manual are listed in SI and METRIC UNITS.

Use this table to convert METRIC unit data to IMPERIAL unit data.

Ex.METRIC MULTIPLIER IMP

**mm ×0.03937 = ** in

2 mm ×0.03937 = 0.08 in

CONVERSION TABLE

••

kg/cm psi (lb/in )

°

10

SPECIAL TOOLS

The following special tools are necessary for complete and accurate tune-up and assembly.

Use only the appropriate special tools; this will help prevent damage caused bythe use of inappropri-

ate tools or improvised techniques.

When placing an order, refer to the list provided below to avoid any mistakes.

Illustration

Tool name

Tool Usage

Weight

Rocker arm shaft puller bolt

These tools are used when removing

or installing the rocker arm shafts.

Rotor holding tool

This tool is used to remove the

flywheel magneto.

Ringnut wrench

This tool is used to loosen and tighten

the exhaust and steering ringnut.

Valve adjusting

tool

This tool is necessary for adjusting

valve clearance.

Fuel level gauge

This gauge is used to measure the fuel

level in the float chamber.

Radiator cap tester

Adaptor

These tools are used for checking the

cooling system.

T-handle

Damper rod holder

These tool are used for holding the

damper rod holder when removing or

installing the damper rod holder.

Clutch spring compressor

Clutch spring holder arm

These tools are used for removing the

nut with holding the compression spring.

Locknut wrench

This tool is used when removing or

installing the secondary sheave nut.

11

Illustration

Tool name

Tool Usage

Flywheel puller

This tool is used for removing the

rotor.

Fork seal driver weight

Fork seal driver attachment (ø33)

This tool is used when installing the

fork seal.

Oil seal guide

This tool is used for protecting the oil

seal lip when installing the secondary

sliding sheave.

Ring nut wrench

This tool is used to loosen and tighten

the steering ring nut.

Sheave holder

This tool is used for holding the

secondary sheave.

Cylinder cup installer set

This tool is used for installing the

cylinder cup to the master cylinder

piston.

Thickness gauge

This tool is used to measure the valve

clearance.

Compression gauge

These tools are used to measure the

engine compression.

Pocket tester

These instruments are invaluable for

checking the electrical system.

Engine tachometer

This tool is needed for detecting

engine rpm.

12

Tool name

Tool Usage

Illustration

Timing light

This tool is needed for detecting

ignition timing.

Valve lapper

This tool is used for removing and

installing the lifter and for lapping the

valve.

Valve spring compressor

Attachment

These tools are used when removing

or installing the valve and the valve

spring.

Middle shaft bearing driver

Mechanical seal installer

These tools are used for installing

mechanical seal.

Ignition checker

This instrument is necessary for checking

the ignition system components.

Sealant

This sealant (bond) is used for crankcase

mating surface, etc.

13

Specification (EFI Motorcycle ZAFFERANO)

Moodel

ZAFFERANO

Engine

Engine

type

BJ169MM-5A

Length inches

84.25

Fuel type

91# unleaded

petrol or above

Width inches

31.5

No. of

cylinder

1

Height inches

56.45

ID × stroke

69×66.8

Wheelbase inches

58.75

Total

displacement

249.7ml

Weight lbs.

(Curb weight)

Forward

shaft

165

Startup

Electric

Backshaft

265

CCoooling

Water cooling

Total

430

Lubrication

Force-feed and

splash

Tire

Size

Front wheel

120/70-14

Rear wheel

Air filter

Sponge

140/60-14

Transmission

Device

CClluuttcch

centrifugal

Capacity of

gasoline

tank

2.95 gallons

Performanc

e

Max. speed

75 mph

Transmission

CVT

Grade ability

≥20 degree

Idle speed

-rpm

1400±100rpm/min

Drive

Belt drive

Max. torque

17.3ft.lb /5000rpm

Electric

Device

Battery

capacity/typ

e

12V-6Ah/

dry-charged

Max. Hp

20.8hp /6500 rpm

Magneto

type

QJ(153-2)12V

200W/8500 rpm

Compression

ratio

10.5 : 1

Spark plug

NGK CR8E

Cylinder

pressure

1.25MPa/1500rp

m

Spark plug

gap

0.6-0.7mm

Braking

Diameter

of front

brake disc

(mm)

φ250mm

14

Ignition

spark ignition

DC

capacitance

system

Diameter of

rear brake

disc (mm)

φ250mm

15

A

(Nut)

B

(Bolt)

General torque

specification

•

s

Nm

m kg

10 mm

6 mm

6

0.6

12 mm

8 mm

15

1.5

14 mm

10 mm

30

3.0

17 mm

12 mm

55

5.5

19 mm

14 mm

85

8.5

22 mm

16 mm

130

13.0

GENERAL TORQUE

SPECIFICATIONS

This chart specifies torque for standard fasten-

ers with standard I.S.O. pitch threads. Torque

specifications for special components or as-

sembliesareincludedintheapplicablesections

of this book. To avoid warpage, tighten multi-

fastener assemblies in a crisscross fashion, in

progressive stages, until full torque is reached.

Unless otherwise specified, torque specifica-

tions call for clean, dry threads. Components

should be at room temperature.

A: Distance across flats

B: Outside thread diameter

16

LUBRICATION POINT AND GRADE OF LUBRICANT

ENGINE

Lubrication Point

Symbol

Oil seal lips

O-ring (Except V-belt drive unit)

Cylinder head tightening nut mounting surface

Crankshaft pin outside

Connecting rod big end thrust surface

Rotary filter inner surface

Drive gear inner surface

Cam chain outside sprocket inner surface

Piston pin

Piston outside and ring groove

Camshaft cam profile

Valve stem (IN, EX)

Valve stem end (lN, EX)

Rocker shaft

Valve rocker arm inner surface

Shaft

Shaft (Oil pump assembly)

Gasket (Oil pump assembly)

Holder

Idle gear 1 thrust surfaces

Shaft 1

Idle gear 2 thrust surfaces

Idle gear 2 inner surface

Main axle thrust surfaces

Crankcase mating surfaces

Sealant

Crankcase breather plug

Stator grommet

Sealant

Suction pipe

17

LUBRICATION POINT AND GRADE OF LUBRICANT SPEC

CHASSIS

Lubrication Point

Symbol

Front wheel oil seal lips (left/right)

Swingarm oil seal lips (left/right)

Steering head pipe bearing (upper/lower)

Steering head pipe dust seal lips (upper/lower)

Tube guide (throttle grip) inner surface

Brake cable (brake lever)

Brake lever and lever holder bolt sliding surface

Sidestand sliding surface

Centerstand sliding surface and mounting bolt

Centerstand stopper pivot shaft

Brake cam pivot shaft and cam surface

18

Periodic Maintenance & Inspection Table

Service cycle and

time Inspection item

Per

600

MI

600

MI

2000

MI

4000

MI

6000

MI

8000

MI

Tools

New

One

mont

h

Three

month

s

Six

months

Nine

months

Twelve

months

*

Air filter

I

C

C

R

C

Ordinary tools

*

Petrol filter

I

I

R

Ordinary tools

*

Fuel filter

C

C

C

Ordinary tools

Replacement of engine

oil

R

Replacement every 2000 MI

Ordinary tools

Tire pressure

I

I

I

I

I

I

Tire pressure

gauge, inflator

Battery inspection

I

I

I

I

I

I

Densimete

r,

multimete

r

Actuation gap

inspection

I

I

I

I

I

I

Ordinary tools

Inspection of steering

handle fastening

I

I

I

Ordinary tools

Absorber working

inspection

I

I

I

Ordinary tools

Screw fastening

inspection

I

I

I

I

I

I

Torque spanner

Oil leakage inspection

for gearbox

I

I

I

I

I

I

Ordinary tools

*

Inspection or

replacement of

spark plug

I

I

R

R

I

Ordinary tools

*

Replacement of

gearbox oil

I

Replacement every 3000 MI

Ordinary tools

Lubrication of each part

L

L

Lubricator

Exhaust pipe

I

I

I

I

I

I

Ordinary tools

*

Ignition timing

I

I

I

I

I

I

Timing lamp

*

Exhaust gas inspection

at idle speed

A

I

A

A

A

A

Tachometer, CO

HC analyzer

*

Throttle inspection

I

I

I

I

I

Ordinary tools

Fuel pipeline inspection

I

I

I

I

I

Ordinary tools

Lighting/metering/electric

devices

I

I

I

I

I

I

Visual multimeter

Main stand bracket

I

I

I

Ordinary tools

Absorber

I

I

I

I

Ordinary tools

*

Torque force of engine

bolts

I

I

I

I

I

Torque spanner

19

AnticipatedInspection

1

Ignition system—obviously continuous ignition abnormality, engine fire or overheating, which

requires inspection and maintenance.

2

Carbon fouling elimination—obviously insufficient horsepower, which requires carbon fouling

removal from cylinder head, piston head and exhaust system.

3

Piston & cylinder—excessive abrasion; replace cylinder if it is blocked.

Please have your motorcycle inspected and adjusted periodically at an authorized Benelli dealership to keep

your vehicle in the best possible condition.

The above table is established under the presupposition of 600 mi/month.

I—Inspection A—Adjustment R—Replacement C—Cleaning L—Lubrication

Note: 1. “*” Regulations on exhaust emission made by the State Environmental Protection Agency

shall be complied with. Maintenance must be carried out in accordance with the instruction

manual supplied by the company. We are not responsible for any loss rising from private adjustment

or maintenance.

2. Increase frequency of washing air filter if your motorcycle runs on sandy/gravel roads or

under heavily polluted environments so as to extend its service life.

3. Motorcycles which often run at high speed or with high mileage shall be maintained more

frequently.

20

Inspection / Adjustment

Preparing information

Periodic Maintenance & Inspection

Table Engine oil/ Oil filter

Fixing steering stem bearing &

handlebar Inspection & adjustment of

throttle cable

Cylinder

pressure Gear

oil

Replacement of gear oil

Drive belt

Free play of the front/rear

brake

Air filter Inspection of brake fluid level

Spark plug Headlamp

Battery Clutch

Ignition timing Front/rear suspension system

Rim/tires Bolt/nut/fasteners

Tire specifications

Preparing Principles

General

Warning!

•Make sure that it is well ventilated before starting the engine. It is forbidden to start it in a

closed area. Exhaust gas, which contains monoxide, may cause unconsciousness or even death.

•Petrol is liable to volatile or explode under certain conditions. Ventilation is required and no fire in

any working places. Fire is strictly forbidden in working areas or where oil is stored.

Table of contents

Other Benelli Scooter manuals

Benelli

Benelli Hornet Manual

Benelli

Benelli ZAFFERANO 250EFI User manual

Benelli

Benelli Pepe Lx User manual

Benelli

Benelli macis User manual

Benelli

Benelli CLASSICA28 User manual

Benelli

Benelli CAFFENERO User manual

Benelli

Benelli Velvet User manual

Benelli

Benelli qattronove x User manual

Benelli

Benelli Pepe User manual