Page3 ©Benewake · All rights reserved · Subject to change without notice · 2021-12-06

TABLE OF CONTENTS

1INTRODUCTION...................................................................................................................................... 4

1.1 FAILURE SCENARIOS ................................................................................................................................. 4

1.2 SYMBOLS AND DOCUMENT CONVENTIONS .................................................................................................... 5

2PRODUCT DESCRIPTION ......................................................................................................................... 6

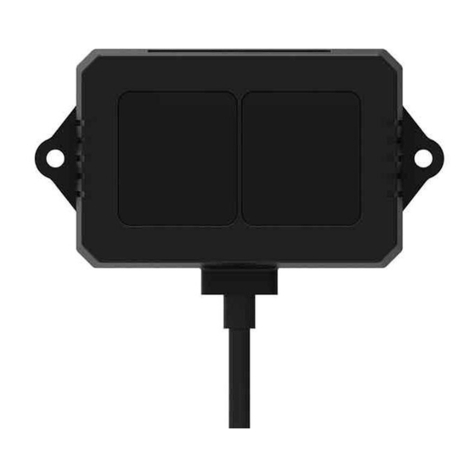

2.1 APPEARANCE OVERVIEW ........................................................................................................................... 6

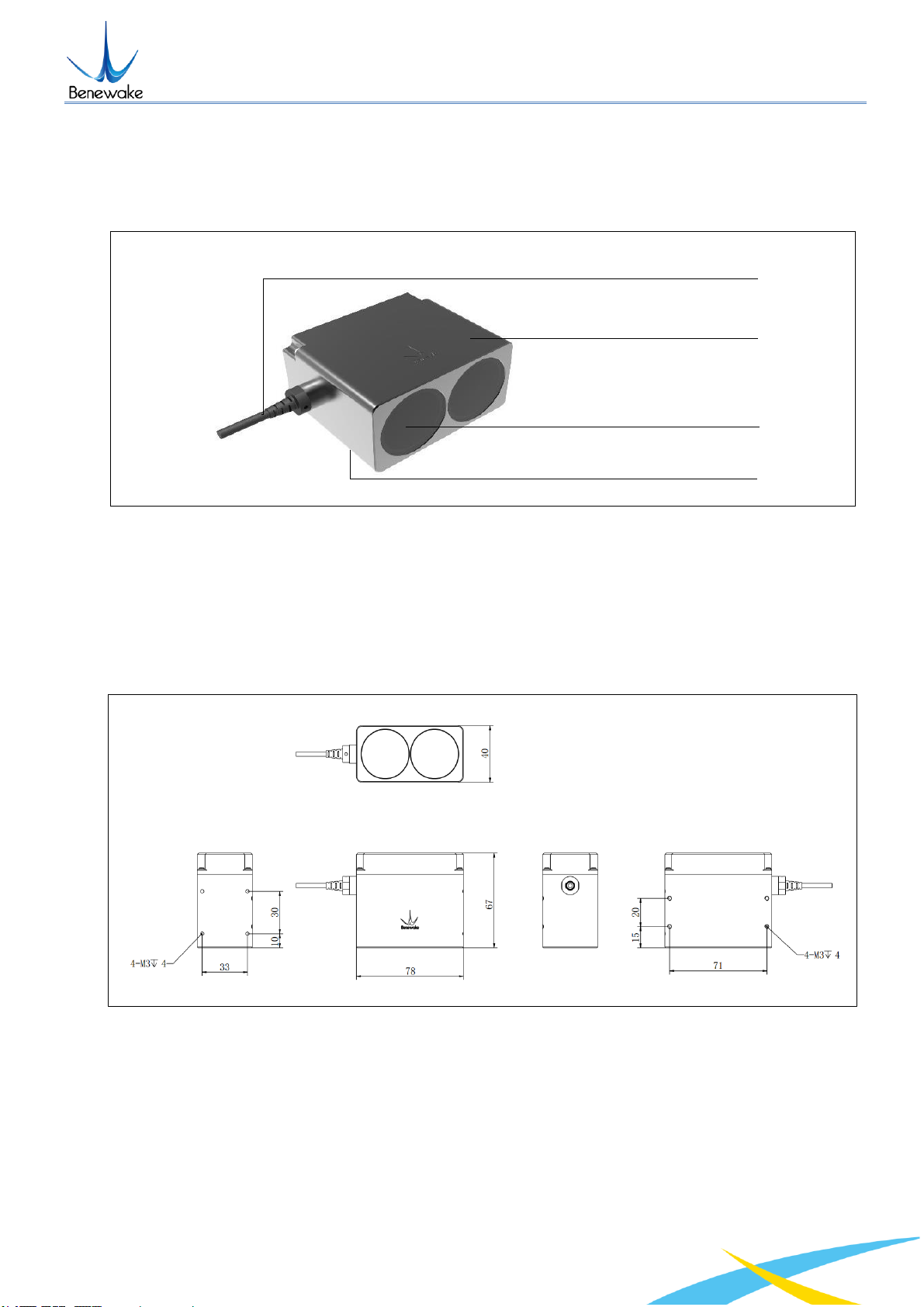

2.2 DIMENSIONAL DRAWING........................................................................................................................... 6

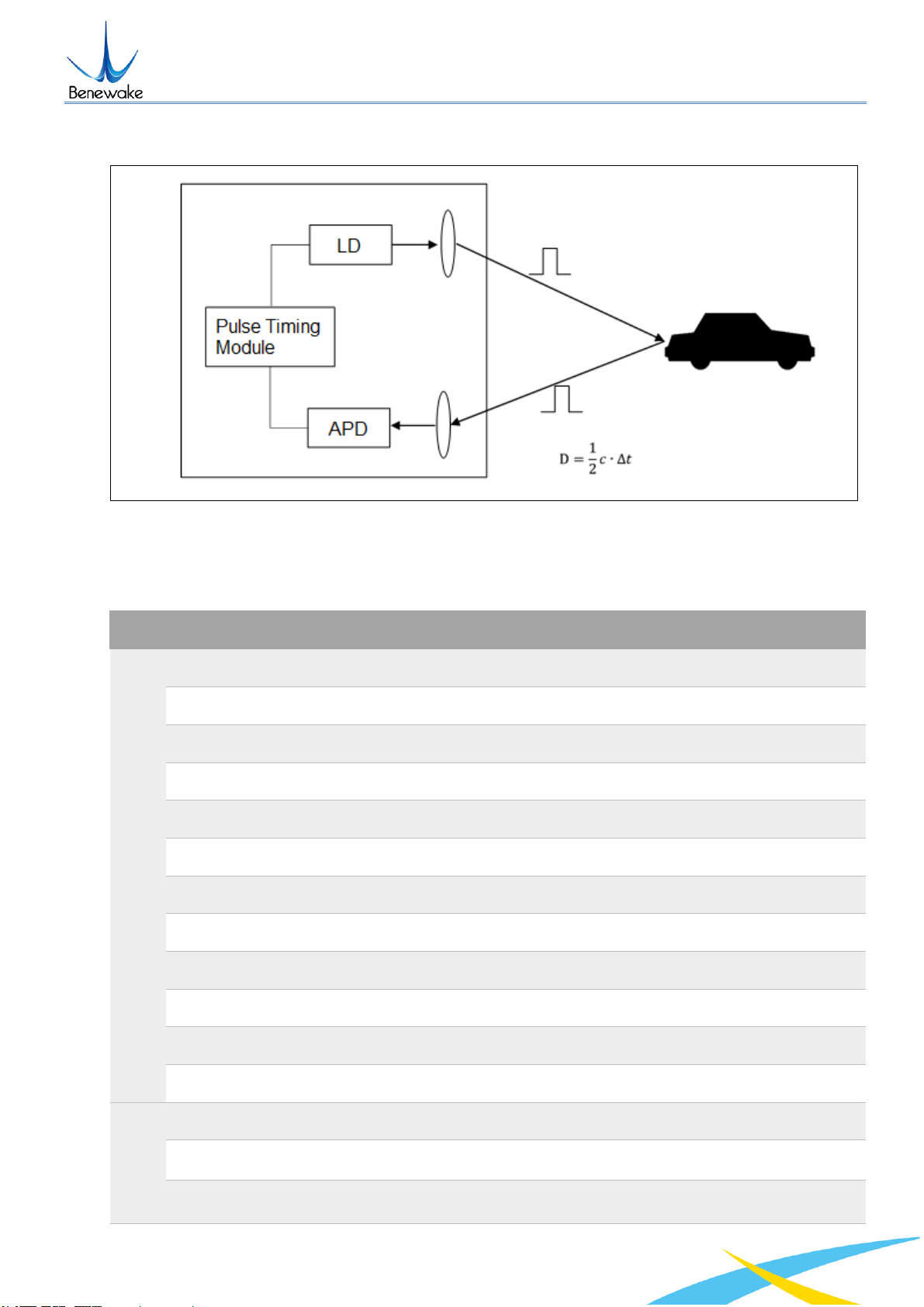

2.3 MEASURING PRINCIPLE ............................................................................................................................. 6

2.4 TECHNICAL SPECIFICATION ......................................................................................................................... 7

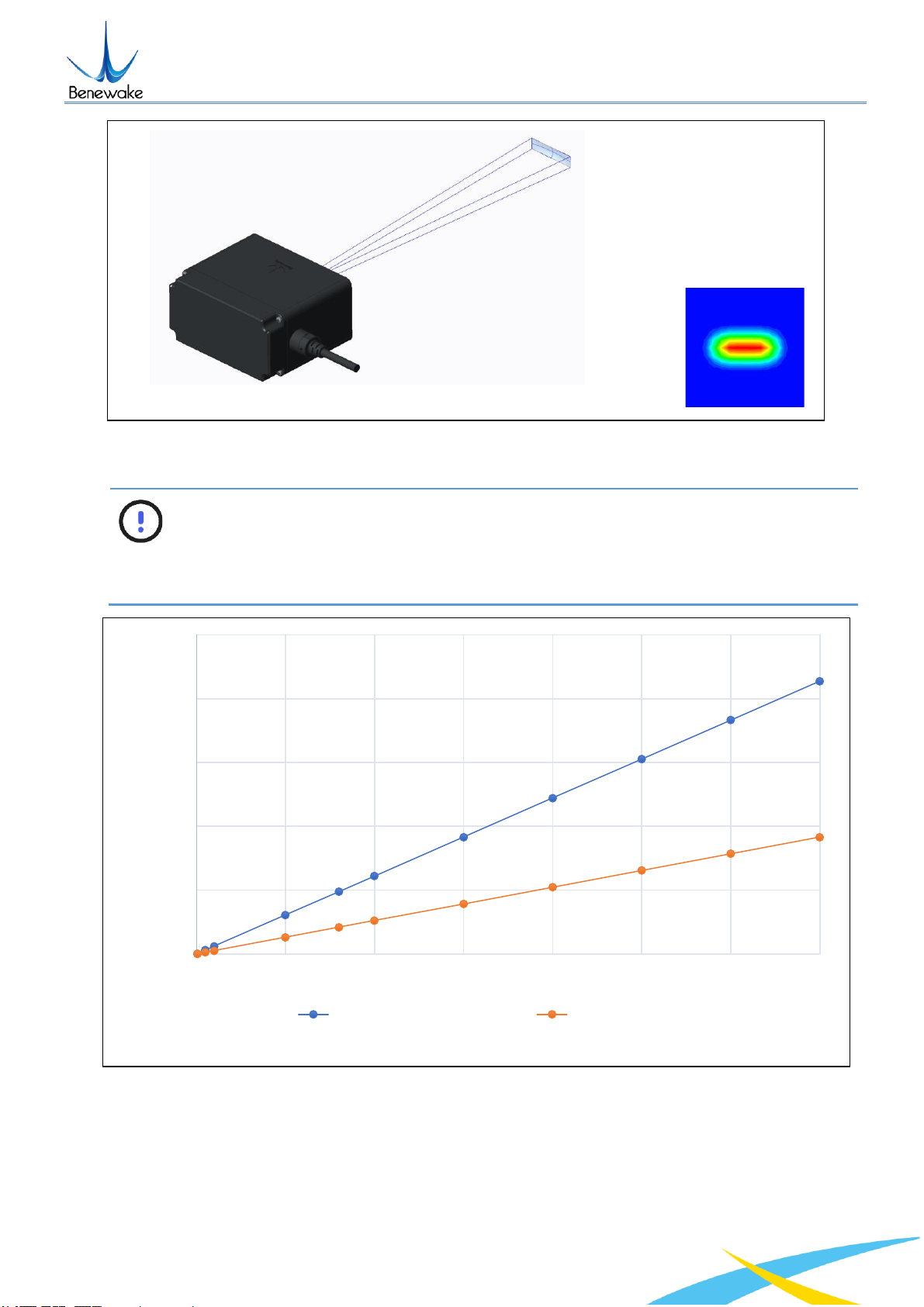

2.5 FOV...................................................................................................................................................... 8

3ELECTRICAL INSTALLATION ................................................................................................................... 10

3.1 PIN AND WIRE COLOR ASSIGNMENT........................................................................................................... 10

3.2 WIRE CROSS-SECTIONS ........................................................................................................................... 10

3.3 WIRING UART INTERFACE....................................................................................................................... 11

3.4 WIRING CAN INTERFACE......................................................................................................................... 11

3.5 CAN BUS ............................................................................................................................................. 11

4PROTOCOLS.......................................................................................................................................... 13

4.1 COMMUNICATION PROTOCOL OF UART..................................................................................................... 13

4.2 USER PROTOCOL: UART ......................................................................................................................... 13

4.3 COMMUNICATION PROTOCOL OF CAN....................................................................................................... 14

4.4 USER PROTOCOL: CAN........................................................................................................................... 14

5CUSTOM CONFIGURATION ................................................................................................................... 14

5.1 PROTOCOL DESCRIPTION ......................................................................................................................... 14

5.2 COMMON COMMANDS........................................................................................................................... 15

5.3 COMMAND EDITING............................................................................................................................... 17

6OPTIONAL ACCESSORIES ...................................................................................................................... 17

6.1 SELF-CLEANING MODULE......................................................................................................................... 17

6.2 AIMING BEAM MODULE .......................................................................................................................... 19

6.3 EXTENSION CORD................................................................................................................................... 20

7QUICK START GUIDE ............................................................................................................................. 21

7.1 CONNECTION AND BASIC TEST .................................................................................................................. 21

7.2 TROUBLESHOOTING GUIDE FOR INITIAL TEST................................................................................................ 22

7.3 WORKING MODE ................................................................................................................................... 23

7.4 INFLUENCES OF OBJECT SURFACES ON THE MEASUREMENT.............................................................................. 23

8TROUBLESHOOTING ............................................................................................................................. 26

ATTACHMENT 1: REFLECTIVITY OF DIFFERENT MATERIALS......................................................................... 28