Bennett H35 Series User manual

Maintenance Manual

High Flow H35 Hydrogen Series

Dual Cabinet Configuration

155211 Rev. B, 12.20.2023

H35 Maintenance Manual i

This manual contains important information for the safe maintenance of this equipment. Read and

understand this manual before applying power. All service personnel should read this manual before

performing service activities.

The material included in this manual is accurate at the date of publication. Failure to follow these

instructions could result in bodily injury, damage to the equipment, or death.

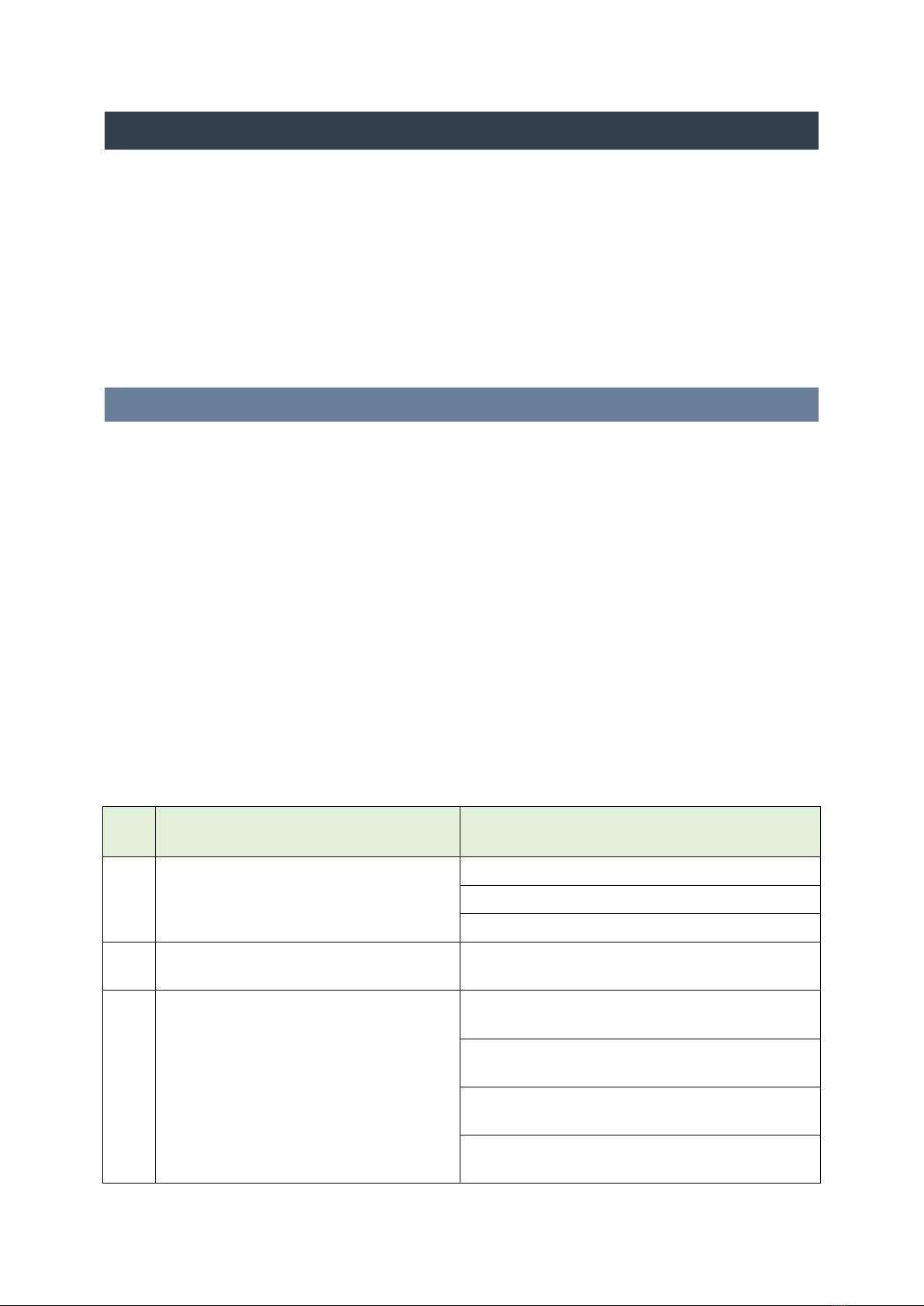

REV LEVEL

DATE

DESCRIPTION

A

11.22.23

Release

B 12.20.23

1. Safety instructions update.

2. Section and figure references repaired.

3. Fuse locations clarified.

4. Improved Meter zero offset procedure

5. Improved Gas Detector section

H35 Maintenance Manual ii

TABLE OF CONTENTS

1SAFETY INSTRUCTIONS ................................1

1.1 SAFETY MESSAGES.................................1

2INTRODUCTIONERROR! BOOKMARK NOT DEFINED.

3SERVICE, MAINTENANCE PROCEDURES ........4

3.1 PIPING &INSTRUMENTATION ..................4

3.1.1 LOCK-OUT PROCEDURES ...........................4

3.1.2 COMPONENT REMOVAL ...........................4

3.1.3 PIPING CONNECTIONS ..............................4

3.1.4 CHANGING FILTER ELEMENT......................5

3.2 FUELING CONTROL SYSTEM .....................5

3.2.1 LOCK-OUT PROCEDURES ...........................5

3.2.2 PLC PANEL FUSES ...................................5

3.3 819 ELECTRONICS,USER DISPLAYS,

CONTROLS ..........................................6

3.3.1 LOCK-OUT PROCEDURES ...........................6

3.3.2 819 POWER BOARD FUSE LOCATIONS ........6

4TROUBLESHOOTING GUIDE..........................7

4.1 PROGRAMMING AND COMMUNICATION.....7

4.1.1 PROGRAMMABLE LOGIC CONTROLLER (PLC)7

4.1.2 MANAGER’S KEYPAD WON’T ENTER

PROGRAMMING MODE ...........................7

4.1.3 DISPENSER COMMUNICATION ...................8

4.2 POWER AND DISPLAY.............................9

4.2.1 NO POWER ............................................9

4.2.2 THE DISPLAY AMOUNT AND POINT OF SALE

AMOUNT DON’T MATCH .........................9

4.2.3 BLANK DISPLAY .....................................10

4.2.4 DISPLAY SEGMENTS DISTORTED ...............10

4.2.5 DECIMAL PLACE IN WRONG POSITION ......10

4.2.6 NO DISPENSER BACKLIGHT......................10

4.3 HYDROGEN DISPENSING ....................... 11

4.3.1 DISPENSER HAS NO FLOW ...................... 11

4.3.2 SLOW DISPENSING FLOW ....................... 12

4.3.3 INACCURATE PRESSURE READING............. 12

4.3.4 DISPENSER LEAK ................................... 12

4.3.5 VALVE OR VALVES NOT OPENING ............ 12

4.3.6 DISPENSER STOPS PUMPING AFTER SEVERAL

SECONDS ............................................13

4.3.7 THE ELECTRONIC DISPENSER HEAD IS WET 13

5DISPENSER ERROR MESSAGES ...................14

5.1 ERROR CODES.................................... 14

6METER ZERO OFFSET PROCEDURE..............18

6.1 PASSCODES AND MENU SELECTION ......... 18

6.2 ZERO OFFSET CALIBRATION ................... 18

7GAS DETECTORS........................................20

7.1 RESPONSE CHECK AND CALIBRATION ....... 20

7.1.1 10.1 ZEROING AND SPAN CALIBRATION..... 20

8FILL TERMINATION REASON CODES ...........24

9APPENDIX A: MAINTENANCE LOG..............26

9.1 EXTERIOR ......................................... 26

9.2 ELECTRICAL ....................................... 27

9.3 PIPING AND INSTRUMENTATION ............. 28

9.4 OTHER EQUIPMENT............................. 30

9.5 DISPENSER TESTS................................ 31

10 APPENDIX B: FILTER SERVICE MANUAL ......32

Safety Instructions

H35 Maintenance Manual 1

1SAFETY INSTRUCTIONS

Please read and understand the following grouped safety messages that contain safety symbols and

safety words. They are defined as:

RED AND WHITE.IF YOU DO NOT FOLLOW THE INSTRUCTIONS, SEVERE INJURY OR DEATH

WILL OCCUR.

Orange and black. If you do not follow the instructions, severe injury or death can occur.

Yellow and Black. If you do not follow the instructions, damage can occur to the dispenser.

White italic NOTICE over blue. Indicates important information that should be observed.

1.1 SAFETY MESSAGES

1. DANGER: HYDROGEN IS FLAMMABLE. NO SMOKING OR OPEN FLAME

2. DANGER: ALWAYS PLACE A PHYSICAL BARRIER AROUND THE WORK AREA BEFORE

PERFORMING SERVICE OR MAINTENANCE.

3. DANGER: DISCONNECT ALL POWER TO THIS EQUIPMENT DURING INSTALLATION,

SERVICE, OR ANY MAINTENANCE.

4. DANGER: VERIFY PROPER VENTILATION IN THE DISPENSING AREA TO PREVENT

HYDROGEN BUILDUP.

5. DANGER: WEAR APPROPRIATE PERSONAL PROTECTIVE EQUIPMENT (PPE), INCLUDING

SAFETY GLASSES, GLOVES, AND ANTI-STATIC CLOTHING.

6. DANGER: BE FAMILIAR WITH EMERGENCY SHUTDOWN PROCEDURES.

Safety Instructions

H35 Maintenance Manual 2

1. WARNING: To prevent electric shock, keep the electrical parts of the dispenser dry.

2. WARNING: Electronic components are static sensitive. Use proper static precautions

(static straps) before working on the equipment.

3. WARNING: Only technicians who have been trained in operation and programming of

this dispenser should perform programming and maintenance.

1. CAUTION: Do not drill holes in fuel dispensers. Holes can cause failure of the electronic

equipment. The warranty will become void. Use only adhesive backed sign mounting

brackets.

Note: Dealing with hydrogen requires careful attention to safety procedures. If you are not trained

or experienced in handling hydrogen equipment, contact a qualified professional before attempting

any troubleshooting.

introduction

H35 Maintenance Manual 3

2INTRODUCTION

The following table lists the tags that identify each component in the dispenser. Please also refer to

these drawings. Some installations may vary:

•P6883, General Overview, H35 HF Main

Cabinet

•P6801, Piping and Instrumentation Diagram

(P&ID)

•P6921, General Overview, H35 HF Auxiliary

Cabinet

•Wire Diagram: P7148 or P7419

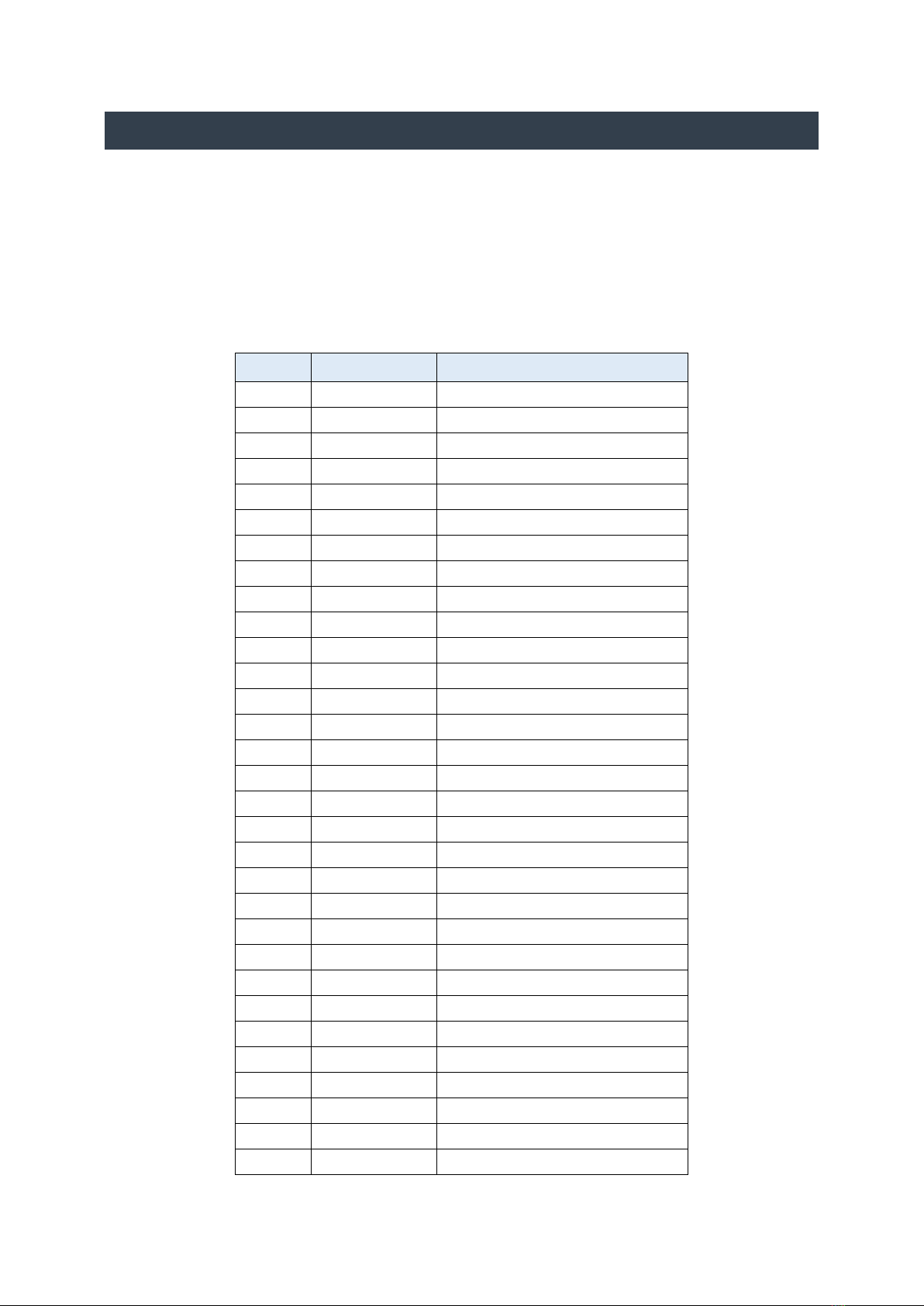

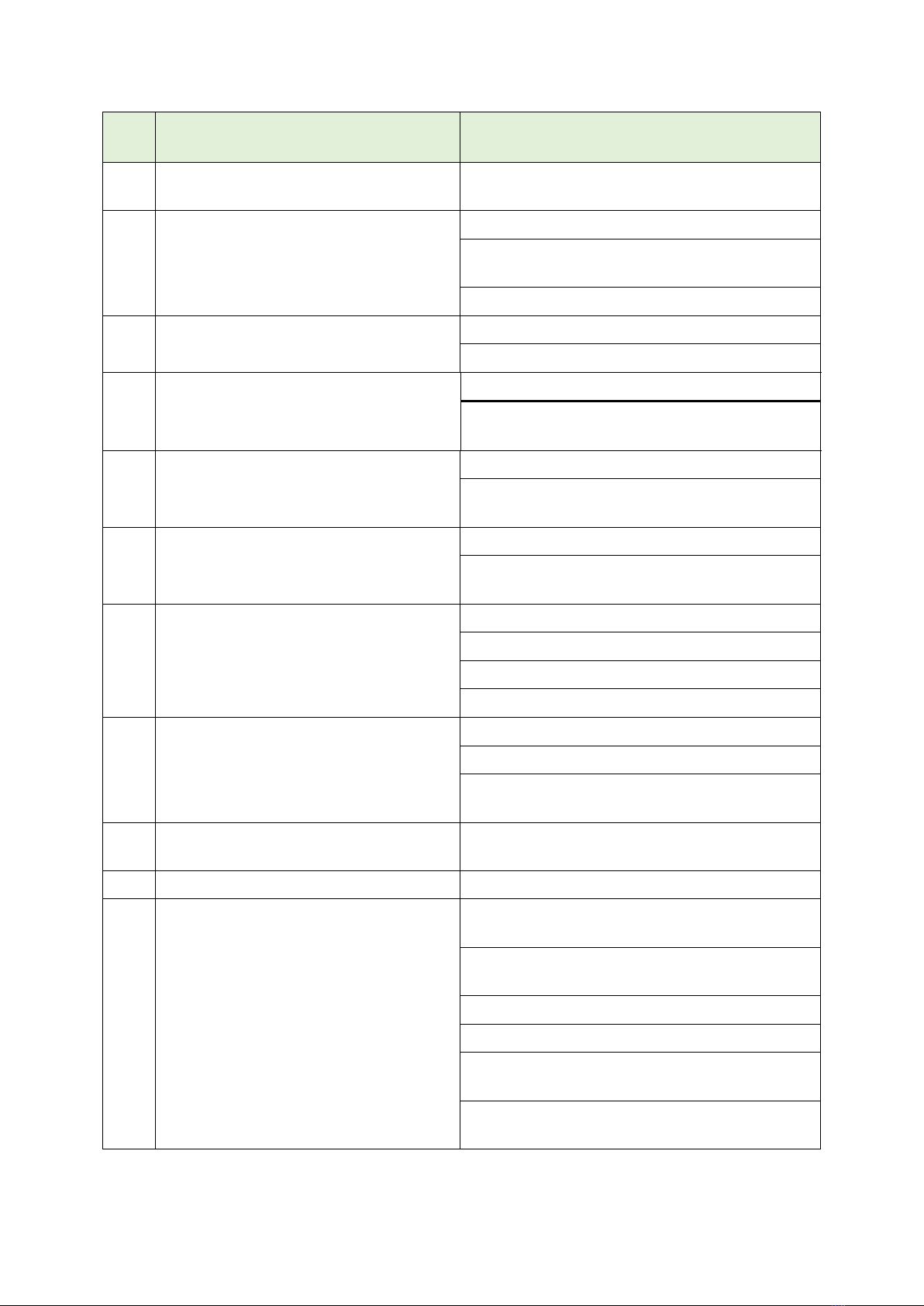

ITEM

TAG

DESCRIPTION

2

TE-100

Thermocouple

3

TE-101

Thermocouple

4

CG-100

Combustible Gas Detector

5

RO-100

Restrictive Orifice

6

SV-104 SV-103

Solenoid Valve

7

HV-100

Hand Valve

8

F-100

Filter

9

FCV-100

Flow Control Valve

10

HV-102

Hand Valve

11

SV-102

Solenoid Valve

12

HE-100

Heat Exchanger

13

RO-102

Restrictive Orifice

14

TT-100

Temperature Transmitter

15

M-100

Meter

16

PT-100

Pressure Transmitter

17

SVFV-100

Solenoid Valve

18

PSV-120

Pressure Safety Valve

19

CV-101

Check Valve

20

AOV-101

Air Operated Valve

21

TT-101

Temperature Transmitter

22

PT-101

Pressure Transmitter

23

CV-100

Check Valve

24

PCV-100

Pressure Control Valve

25

SV-200

Solenoid Valve

26

PSV-220

Pressure Safety Valve

27

TT-201

Thermocouple

28

PT-201

Pressure Transmitter

29

PT-104

Pressure Transmitter

30

CV-200

Check Valve

31

HV-103

Hand Valve

32

CG-200

Combustible Gas Detector

Service, Maintenance Procedures

H35 Maintenance Manual 4

3SERVICE, MAINTENANCE PROCEDURES

3.1 PIPING & INSTRUMENTATION

3.1.1 LOCK-OUT PROCEDURES

The following procedures must be performed before proceeding with any service or maintenance

work on the piping and instrumentation system.

•Isolate the dispenser from sources of pressure. Close the HV-100 Hydrogen Supply Shutoff

valve.

•Completely vent hydrogen out of the system. The maintenance software tool can be used to

manually toggle valves as required to open all portions of the system to the vent outlet.

•Shut OFF the power switch on the 819 Power Board.

•Shut OFF the breaker to isolate the dispenser from AC power.

•During any maintenance: Lock out the dispenser per the regulations of the site.

3.1.2 COMPONENT REMOVAL

Components are mounted to the dispenser frame and can be taken out of the unit by removing the

threaded fasteners holding them in place.

Note: The system must be fully depressurized before removing any component.

3.1.3 PIPING CONNECTIONS

3.1.3.1 CONE & THREAD (C&T)

The primary connection type on pressurized hydrogen lines is C&T. Tubes are fabricated with

tapered ends (cones) which provide a hard seal against a mating cone in the fitting or component.

The connection is maintained with a threaded connection torqued according to size.

When re-assembling medium pressure connections, apply a thread lubricant approved for use in

hydrogen piping systems. Torque fittings to the specifications listed below.

Fitting Size (Tube OD)

Torque Specification

ft-lbs

Nm

3/8”

30

41

9/16”

55

75

3/4"

75

102

Note: The system must be fully depressurized before removing any component.

Service, Maintenance Procedures

H35 Maintenance Manual 5

3.1.3.2 LOK TUBING & FITTINGS

LOK tubing and fittings connect parts of the system with lower pressure requirements (such as vent

and coolant lines). These connections are a tapered ferrule, permanently attached to the end of a

tube that seals against a mating surface inside the fitting or component.

•Before removal, draw a line across both nuts to mark the tightened position. When re-

installing, ensure they end in the same position.

•LOK Connections do not require the use of thread lube.

3.1.4 CHANGING FILTER ELEMENT

The filter element must be replaced as part of preventative maintenance on the dispenser.

•To change the filter, see the filter service manual in Appendix B.

•Filter housing torque: 30 ft-lbs (40 Nm).

3.2 FUELING CONTROL SYSTEM

3.2.1 LOCK-OUT PROCEDURES

The following procedures must be performed before proceeding with any service or maintenance

work on any electronics.

•Isolate the dispenser from sources of pressure. Close the HV-100 Hydrogen Supply Shutoff

valve.

•Completely vent hydrogen out of the system. The maintenance software tool can be used to

manually toggle valves as required to open all portions of the system to the vent outlet.

•Shut OFF the power switch on the 819 Power Board.

•Shut OFF the breaker to isolate the dispenser from AC power.

•During any maintenance: Lock out the dispenser per the regulations of the site.

3.2.2 PLC PANEL FUSES

For information on the PLC fuse locations and size see the Wire Diagram.

Service, Maintenance Procedures

H35 Maintenance Manual 6

3.3 819 ELECTRONICS, USER DISPLAYS, CONTROLS

3.3.1 LOCK-OUT PROCEDURES

The following procedures must be performed before proceeding with any service or maintenance

work on any electronics.

•Isolate the dispenser from sources of pressure. Close the HV-100 Hydrogen Supply Shutoff

valve.

•Completely vent hydrogen out of the system. The maintenance software tool can be used to

manually toggle valves as required to open all portions of the system to the vent outlet.

•Shut OFF the power switch on the 819 Power Board.

•Shut OFF the breaker to isolate the dispenser from AC power.

•During any maintenance: Lock out the dispenser per the regulations of the site.

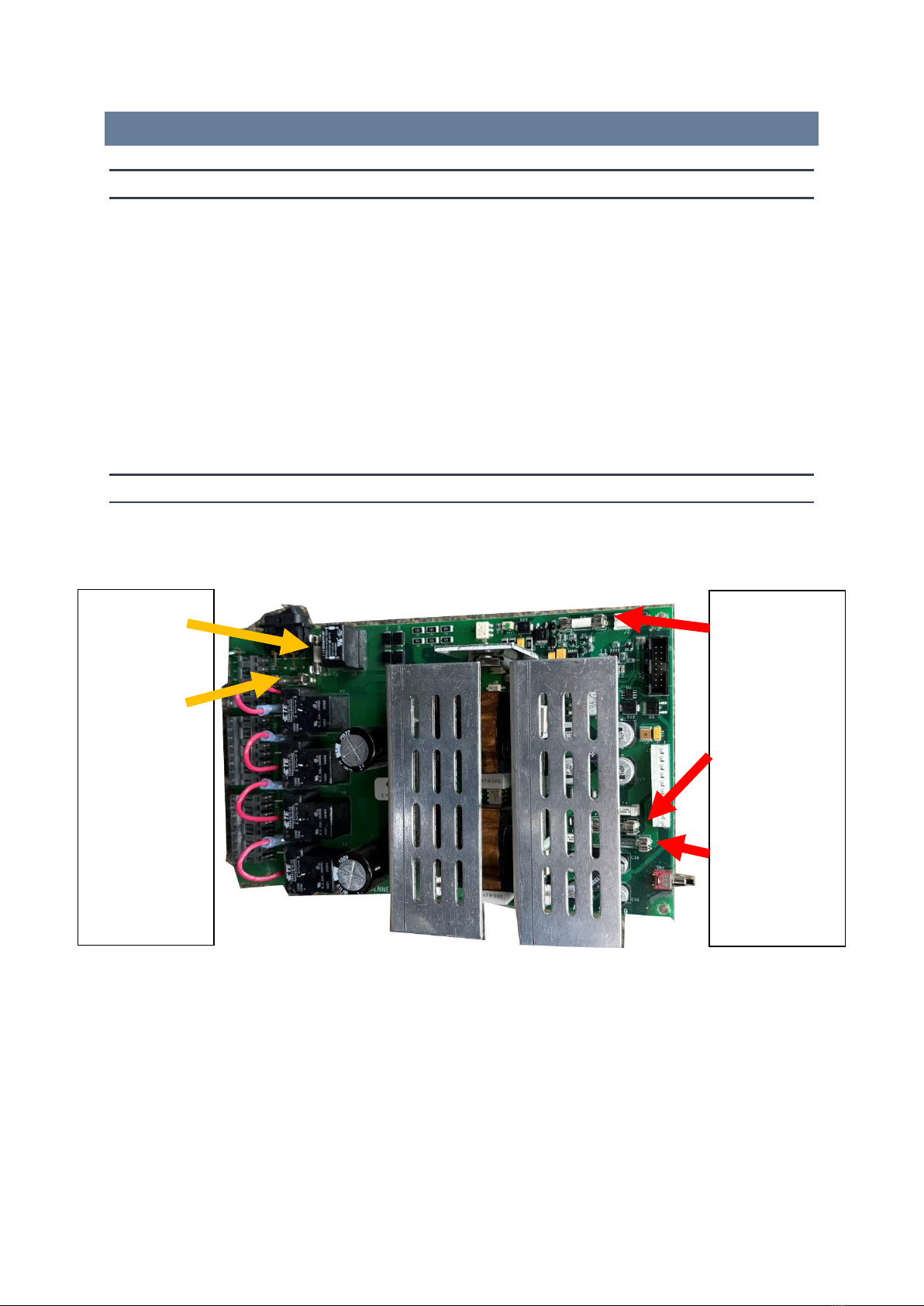

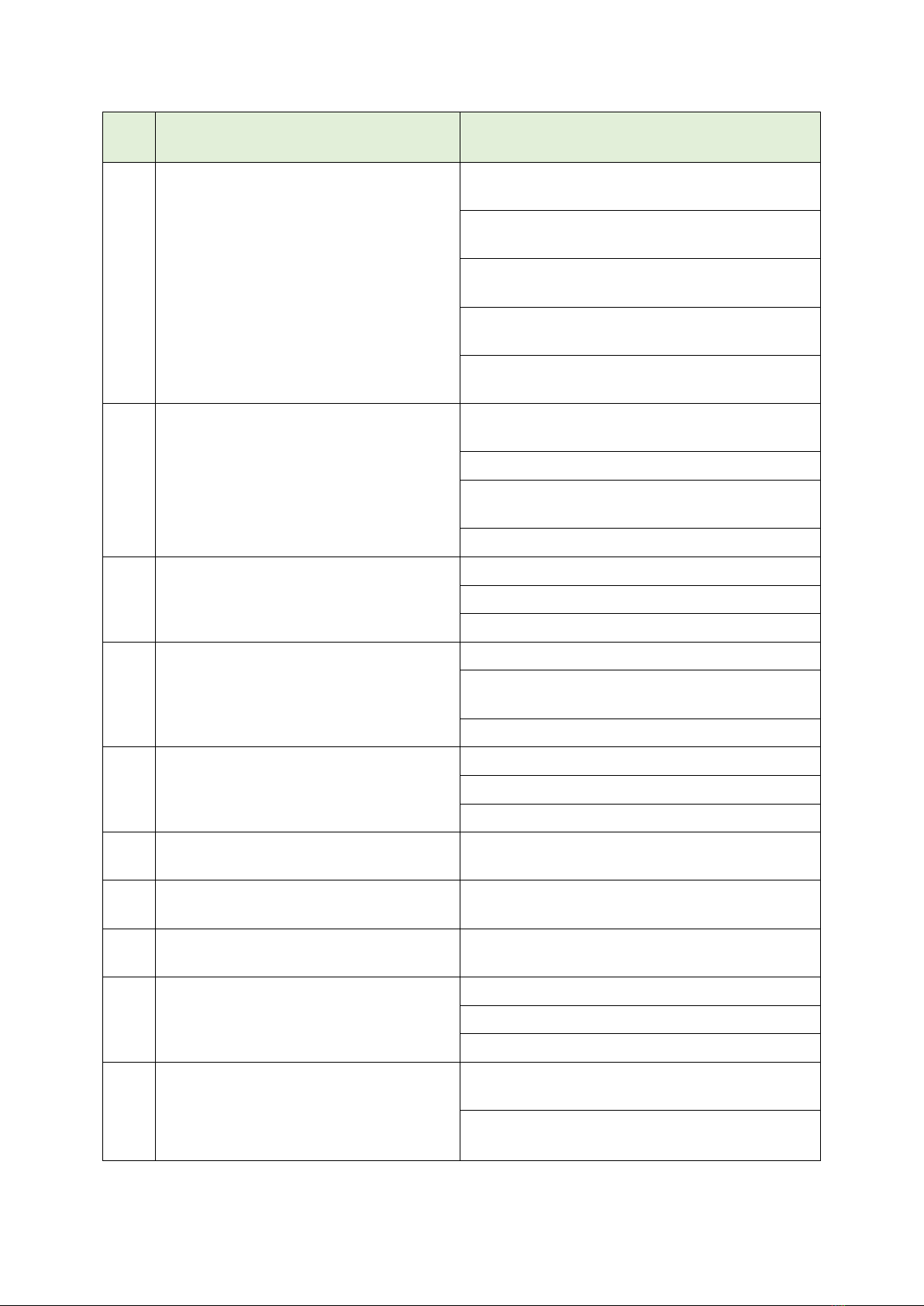

3.3.2 819 POWER BOARD FUSE LOCATIONS

The 819 Power Board has the following fuses:

Figure 3.1. 819 Power Board Fuse Locations.

F2 – Incoming

AC Power

F1 – Motor

Control Circuit

F3 – 12VDC

Backup Battery

Charging Circuit

F5 – 24VDC

Circuit

F7 – 12 VDC

Circuit

Troubleshooting Guide

H35 Maintenance Manual 7

4TROUBLESHOOTING GUIDE

For all electrical troubleshooting please refer to the wiring diagrams.

4.1 PROGRAMMING AND COMMUNICATION

4.1.1 PROGRAMMABLE LOGIC CONTROLLER (PLC)

The PLC, as seen in Figure 3.2, is linked to a remote I/O board

responsible for managing the modules on the rack, depicted in

Figure 3.3.

If the Run state shows a green light, the rack and PLC are

functioning properly.

If red lights are displaying check the following:

•Verify CPU has booted up.

•The PLC monitor shows navigable information, controlled

via the pad beneath it. This helps narrow down the issue.

•Card seated properly – I/O card rack

•Check for damaged card.

•If it is a safety card (yellow) verify plug is on the back side

of the card.

•ET200SP connected to the PLC

•Verify wiring is correct

4.1.2 MANAGER’S KEYPAD WON’T ENTER PROGRAMMING MODE

Problem

Solution

A handle switch has been

activated.

Make sure all the handles are hung up. The system cannot enter

Managers mode if a handle is removed.

Figure 3.2. PLC

Figure 3.3. Remote I/O Card and

Rack.

Troubleshooting Guide

H35 Maintenance Manual 8

4.1.3 DISPENSER COMMUNICATION

Problem

Solution

The dispenser is in Stand Alone

mode.

Program the dispenser in Mode 21 for the correct communication

type. See the Hydrogen Operation Manual.

The handle switch is not

working properly.

Make sure the handle switch is working properly by running

diagnostics mode 5. If not, the handle switch, handle switch cable,

barrier board, or 819 could be the problem. Troubleshoot as needed.

Bad Intrinsically Safe Barrier

Board (ISB) or loose cable.

Check to make sure the handle switch cable is making good contact

with the connector. Replace ISB if necessary, with a known good one.

The 515 box has lost

communication.

Perform a RAM Clear in Mode 49 in the 515 Box. Verify the 515 Box

is ON. Check the cable connections.

Maximum wire length from the

dispenser to the 515 Box.

Make sure that there is no more than 1000 feet between the

dispenser and the 515 box.

Check the Point-of-Sale system

for proper programming.

Is the Point-of-Sale set up for “Handle up Calling”?

Installation Wiring

Verify with the Wiring Diagram.

Ribbon Cable between CPU

Board and Power Board.

Make sure that the connections are snug. Replace cables that are

damaged.

Troubleshooting Guide

H35 Maintenance Manual 9

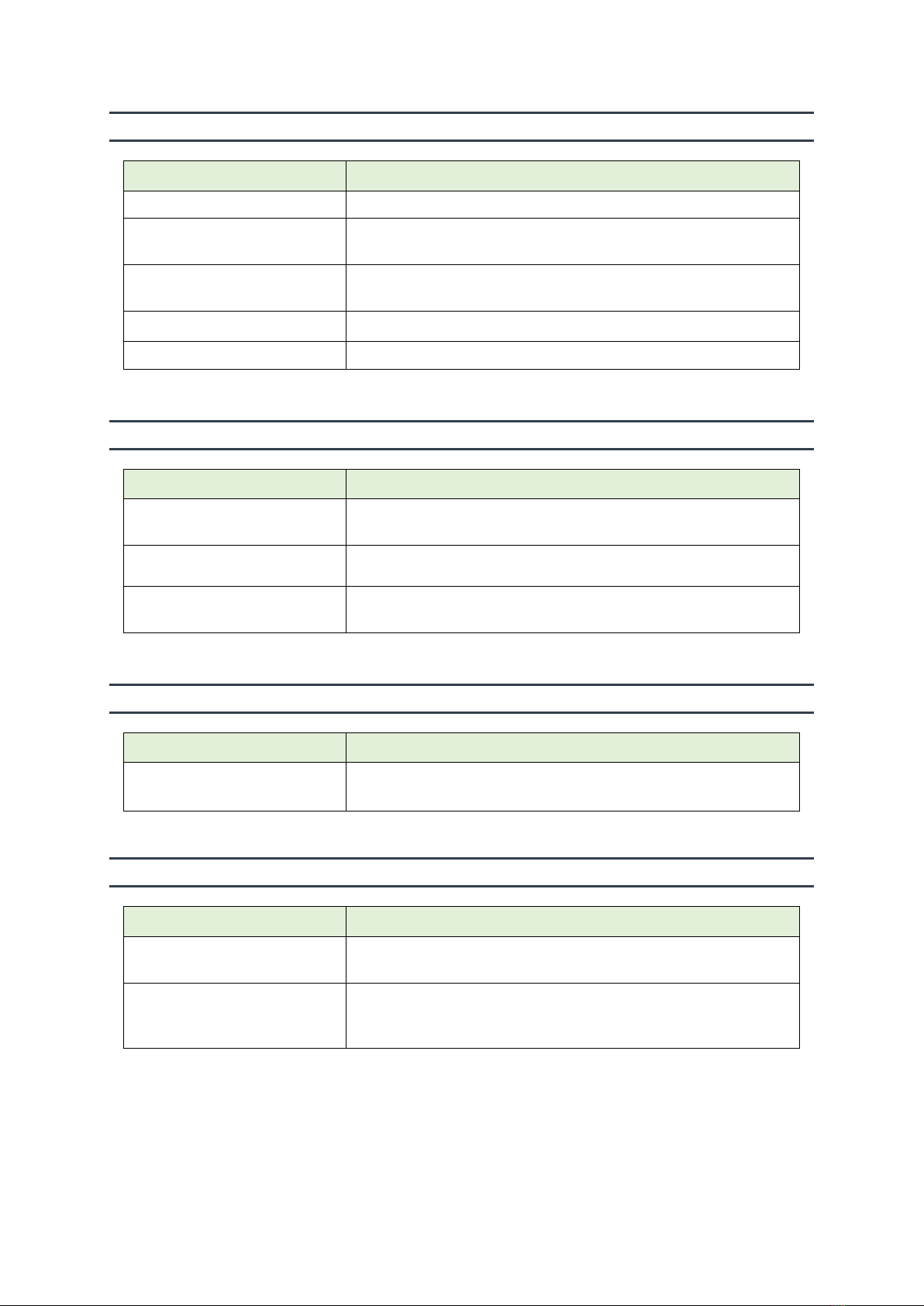

4.2 POWER AND DISPLAY

4.2.1 NO POWER

If the dispenser has no power, follow these steps to diagnose and resolve the issue:

Step

Action

Description

1 Check the Power Switch Confirm that the power switch on the 819 Power Board is in the

ON position.

2

Verify AC Power Supply

Check that the dispenser is receiving AC power.

3 Check Battery Status Verify that the 12V battery in the dispenser is charged. A dead

battery can prevent the dispenser from turning ON.

4 Purge Cabinets (for dispensers

with purge cabinets)

Confirm a positive pressure in the electrical cabinet.

Verify that the purge pressure switch is activated.

Note: It may take up to 4 minutes for the dispenser to power ON

after applying the purge.

5 Gas Detector (for dispensers

with a gas detector)

Verify that the gas detector has power.

Check the gas reading is at 0% LEL.

Note: It may take up to 4 minutes for the dispenser to power on

after applying the purge.

6 Bypass Switch (if safe to use) There is a bypass switch on the timer board for troubleshooting

purposes. Press it to power on the dispenser if it's safe to do so.

4.2.2 THE DISPLAY AMOUNT AND POINT OF SALE AMOUNT DON’T MATCH

Problem

Solution

Incorrect setting for “rounding”

in the dispenser.

Check the dispenser rounding setting. See Menu Code 28: Rounding,

in the Operation Manual.

Troubleshooting Guide

H35 Maintenance Manual 10

4.2.3 BLANK DISPLAY

Problem

Solution

The dispenser is turned OFF.

Check the power switch inside the dispenser. Turn it on.

Blown Fuse Check the system fuse on the Power Board. Refer to the Power

Board section.

The dispenser has been turned

OFF from the main power panel.

Turn on the breaker for this dispenser inside the building.

Bad Display Board

Replace the Display Board with a known good one.

Bad CPU

Replace the CPU with a known good one.

4.2.4 DISPLAY SEGMENTS DISTORTED

Problem

Solution

The display board is broken. Run diagnostics on the display. Do all the segments light up? If not,

replace the Display Board.

Loose cable in the electronics. Check the cables going to the Display Board.

Distorted segments. Plug in the manager’s keypad. Press +/- five times to change the

segments. Stop when the display shows “Enter Side 1”.

4.2.5 DECIMAL PLACE IN WRONG POSITION

Problem

Solution

Programming problem. Check modes 8 and 99

4.2.6 NO DISPENSER BACKLIGHT

Problem

Solution

The dispenser is in power fail. When main power returns to the dispenser the light should come

back on.

The cable came loose from the

Display Board to the Backlight

board.

Check the small power cable for lighting that connects the Display

Board to the Backlight Board.

Troubleshooting Guide

H35 Maintenance Manual 11

4.3 HYDROGEN DISPENSING

4.3.1 DISPENSER HAS NO FLOW

Problem

Solution

Supply Pressure: No Pressure Verify that the hydrogen supply pressure

is within the required range.

No flow, no power. The dispenser is OFF Turn ON the dispenser

Check valve operation

: The valve is not

opening.

Inspect the valves to make sure they are

open and not clogged.

Verify that the valve is opening by measuring

voltage on the 24VDC circuit. Refer to the

CPU board section for guidance.

The dispenser is not authorized.

If connected to a POS, be sure that the POS

is sending authorization. Refer to the Point-

of-Sale reference manual.

Program the

dispenser to be in stand-

alone mode and

test.

The POS did not authorize the dispenser OR

the station has not informed the dispenser

that hydrogen is available.

The CPU is locked up.

Power down the dispenser and bypass the

battery. Power up the dispenser and retry

the operation.

The maximum allocation is set to zero.

Change the allocation setting in

programming to a higher number (e.g., set

to 99).

The nozzle is broken. Replace the damaged nozzle.

The hoses are hung up in the wrong nozzle

boots.

Make sure the hoses are correctly positioned

in their respective nozzle boots.

Hose quality: Hose kinks, damaged. Verify that the hoses are properly connected

and not kinked or damaged.

Bad handle switch. Replace the handle switch if found to be

defective.

Troubleshooting Guide

H35 Maintenance Manual 12

4.3.2 SLOW DISPENSING FLOW

Problem

Solution

Pressure

Verify that the hydrogen supply pressure is within the required range.

Valves

Check that the manual shut off valve at the inlet of the dispenser is fully open.

Power

Confirm that the dispenser's power source is operational.

Hoses

Verify that the hoses are properly connected and not kinked or damaged.

Filter Check the filter located in the lower cabinet for a clog. Clear any debris. See Section 9,

Appendix B of this manual.

4.3.3 INACCURATE PRESSURE READING

Problem

Solution

Calibration Be sure the dispenser is properly calibrated. See the installation manual for calibration

procedures.

External

Interference

Check that there are no strong electromagnetic fields or sources of interference near

the dispenser.

4.3.4 DISPENSER LEAK

Steps

Solution

Is there a dispenser leak?

Evacuate the dispensing area immediately if a leak is detected.

Emergency Shutdown Shut down the dispenser using emergency shutdown on the

dispenser exterior.

Isolate Leak

Isolate the dispenser from the hydrogen supply source.

Ventilation

Provide proper ventilation to disperse leaked hydrogen.

Professional Inspection Contact a hydrogen equipment professional to identify and repair

the leak.

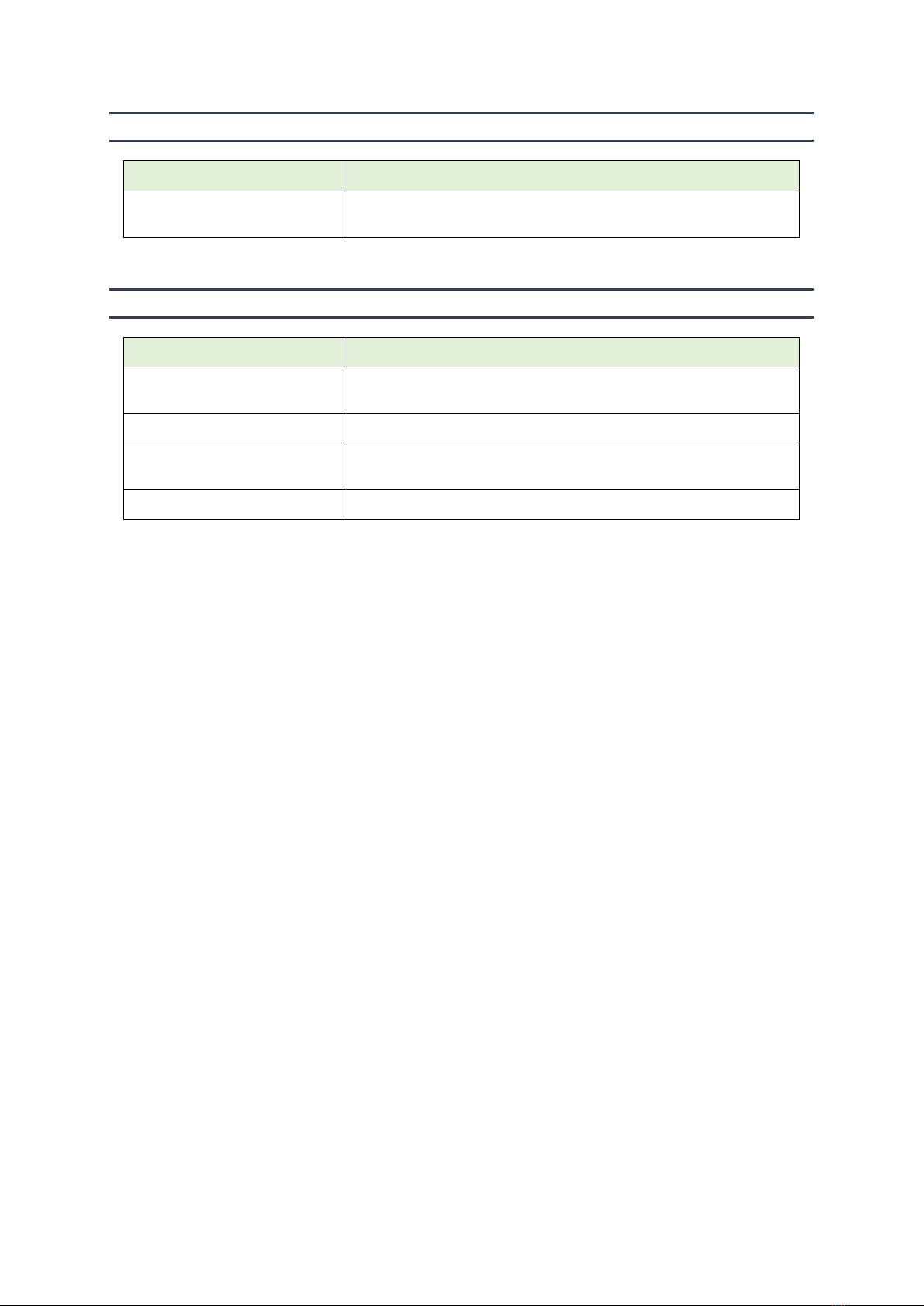

4.3.5 VALVE OR VALVES NOT OPENING

Problem

Solution

Loss of +24VDC.

Troubleshoot the +24vdc signal. Call Technical Support.

Bad Valve.

Replace Valve with a known good one.

Loss of instrument air.

Check breakers in the dispenser. See wire diagram.

Troubleshooting Guide

H35 Maintenance Manual 13

4.3.6 DISPENSER STOPS PUMPING AFTER SEVERAL SECONDS

Problem

Solution

The dispenser stops pumping

after several seconds

See Section 7 Fill Termination Reason Codes.

4.3.7 THE ELECTRONIC DISPENSER HEAD IS WET

Problem

Solution

The door locks are not closed

properly.

Close and lock the doors properly.

Door Lock brackets are bent.

Adjust door lock brackets or replace.

Reuse of gasket when a

component is replaced.

Always replace the gasket when installing a new component.

Unknown water intrusion

Call Bennett Technical Support (800) 423-6638.

Dispenser Error Messages

H35 Maintenance Manual 14

5DISPENSER ERROR MESSAGES

Common solutions to error code messages:

•Power Cycle: Try turning the dispenser OFF and ON again to clear minor errors.

•Reboot Dispenser:Use Mode 49 to reboot the dispenser.

•Clear Memory: Use Mode 58 to wipe the memory including all programming and calibration

values.

•Software Update: Check for software updates that might resolve error messages.

•Raise and Lower the Handle Switch: To clear error codes. Do this twice if initial power up

sends and Emergency Stop Error.

5.1 ERROR CODES

Error codes are displayed when there is a fault condition in the dispenser. In the event of an error, a

message will be displayed on the side of the dispenser where the error occurred.

Any error message will shut down the sale but not disable the dispenser. To clear an error message,

follow these steps

1. Pick up the nozzle from its boot.

2. Raise and then lower the handle switch.

3. The error code is cleared unless this is an initial power up and an Emergency Stop Error has

occurred. If so, repeat this process twice to clear the Emergency Stop Error.

4. Raise the switch again to continue with the sale.

Use the dispenser diagnostics to determine the problem or to view the error history log refer to the

H35 Operators Manual (Diagnostic Code 2) for more information. Note: Repair the problem that may

have caused the error first and then clear the message.

Error

Code

Error Description Troubleshooting Steps

02 DATA: There is a failure or error with the

RAM

Try to reboot the dispenser.

If needed, move to Power Cycle.

If needed, move to Clear Memory.

03 PRESSR: The pressure at the dispenser is

not at a safe level

Adjust the pressure before continuing.

11 TEMOOR: The ambient temperature is out

of range.

Check temperature readings of thermocouples on

the IS barrier.

Check environmental factors affecting

thermocouples.

Consider the ambient temperature's safety range

for filling.

Verify wiring for thermocouples and barrier is

correct.

Dispenser Error Messages

H35 Maintenance Manual 15

Error

Code

Error Description Troubleshooting Steps

13 HIPRES: The pressure is above the limit of

the dispenser

Lower the pressure before continuing.

14 MtCOMM: Communication issue with the

mass flow meter

Verify the wiring is correct.

Check the meter Modbus settings on the meter

transmitter.

Check the PLC I/O Card for the meter.

15 PLC819: Communication issue between

819 CPU and the PLC

Verify termination resistors are present.

Follow similar steps as Error 14.

16 AMBTEM: The ambient temperature is not

reading.

Verify the thermocouple is not broken.

Verify wiring for thermocouples and barrier is

correct.

17 GASTEM: The hydrogen gas temperature is

not reading.

Verify the thermocouple is not broken.

Verify wiring for thermocouples and barrier is

correct.

18 GASPRS: The hydrogen gas pressure is not

reading.

Verify the pressure sensor is not broken.

Verify correct the wiring and functioning of Analog

Input Card.

19 REGVLV: The flow control valve in the

dispenser is malfunctioning

Open and close the valve.

Verify the valve is opening and closing.

Check the feedback signal.

Verify wiring is correct.

20 FILVLV: The fill valve is malfunctioning

Actuate the valve to verify opening and closing.

Check the circuit breaker if present.

Check the wiring, and verify the valve receives

proper power.

21 HOSTEM: The host temperature is not

reading.

Follow the same steps as Error 17.

22

HOSPRS: The hose pressure is not reading.

Follow the same steps as Error 18.

23 ESTOP: Emergency Stop (ESTOP) issues

An ESTOP error may show up when the dispenser

powers up for the first time.

Check if the ESTOP button on the dispenser is

pressed.

If so, verify the reason for pressing.

Pull the ESTOP button out.

Clear the error following the acknowledgement

procedure.

If the error persists, verify correct wiring for ESTOP

button and control relays.

Dispenser Error Messages

H35 Maintenance Manual 16

Error

Code

Error Description Troubleshooting Steps

24 ACK Needed: Acknowledgment needed for

ESTOP error

Try to clear the error following the

acknowledgement procedure.

Check the wiring of the ESTOP circuit and control

relays.

25 rcGTEM: The gas temperature redundancy

check has failed

Compare the readings of the two thermocouples.

Check wiring and calibrate sensors if needed.

26 rcGPRS: The gas pressure redundancy

check has failed

Compare the readings of the two pressure sensors.

Check wiring and calibrate sensors if needed.

29

GASDET: Gas detector issues.

Indicates that both gas detectors are not

communicating. If A2 is also shown, then

both detectors are in an alarm state.

Verify correct wiring for both gas detectors.

30

GASDT1: Gas detector issues (CG-100)

Verify correct wiring for both gas detectors.

38 GASDT2: Gas detector issues (CG-200)

Verify correct wiring for both gas detectors.

Check the gas detector's voltage.

Verify the addresses match the 819 CPU and the

gas detector.

Verify the baud rate and stop bits on the gas

detector.

For the A2 alarm, check for hydrogen leaks.

Track down the hydrogen leak and repair.

Verify the leak is no longer present.

If no leak is found, check the gas detector reading

with a hydrogen calibration bottle.

If needed calibrate the gas detector.

40,

41

Meter Issues: Potential issue with the

meter

Use diagnostic mode to read the last 10-meter

faults.

Check the meter manual for more details on faults

found.

42 VVOPFA: Vent valve has failed to open

Check the hose pressure reading. If the reading is

above 0.5 MPa the pressure needs to reduce below

0.5 MPa before the error can be cleared.

Toggle the vent valve ON and OFF to check if it will

open and close.

If the valve does not move, verify air pressure and

electrical to the valve is correct.

43

VVCLFA: Vent valve has failed to close

Follow the same steps as Error 42.

Dispenser Error Messages

H35 Maintenance Manual 17

Error

Code

Error Description Troubleshooting Steps

44 FVCLFA: Fill valve failed to close

Verify valve stays closed by monitoring pressure

sensors before and after the fill valve.

When the valve is open those pressure sensors

should be the same.

When the valve is closed the pressure can be

vented down on outlet side of the valve.

The outlet pressure should decrease, and the inlet

pressure should not decrease.

If it does decrease and it is confirmed that the valve

is not energized, then rebuild or replace the valve.

45 FVOPFA: Fill valve failed to open

Verify pressure on the inlet of the fill valve is higher

than the outlet

Open the fill valve

Verify pressure equalizes; if not, check the

energization of the valve

If not, rebuild and replace the valve

46 PLCCOM: Communication loss between

station PLC and dispenser PLC

Verify correct wiring

Verify Modbus parameters

Try a power cycle

47 VIBACT: Vibration switch in the dispenser

is activated

Reset the vibration switch and clear the error

Adjust the setpoint of the vibration switch if

needed

Verify correct wiring

60 POSTAL: General error

Try to reboot the dispenser.

If needed, move to Power Cycle.

If needed, move to Clear Memory.

70 NOECAL: Electronic calibration value issue Verify the calibration value in the 819 CPU is set

properly

71 RANGE: Electronic calibration value is out

of range

Verify the calibration value is set properly

74 UNSEAL: The calibration switch on the 819

CPU is ON

Slide the switch to the OFF position and seal it

closed

99 GENERL: General error

Try to reboot the dispenser.

If needed, move to Power Cycle.

If needed, move to Clear Memory.

nn UNDEFI: Undefined error

Update 819 CPU and PLC to the latest software

version.

Please report to Technical Support (800) 423-

6638.

Other manuals for H35 Series

2

Table of contents

Other Bennett Marine Equipment manuals

Bennett

Bennett BOLT Control BCI8000 User manual

Bennett

Bennett H35 Series User manual

Bennett

Bennett H35 Series User manual

Bennett

Bennett SITE MASTER EMV User manual

Bennett

Bennett LNG Series User manual

Bennett

Bennett HIGH FLOW H35 User manual

Bennett

Bennett BOLT Rocker BRC4000 User manual

Bennett

Bennett 621 User manual