Bijur Delimon L18P User manual

Other Bijur Delimon Lubrication System manuals

Bijur Delimon

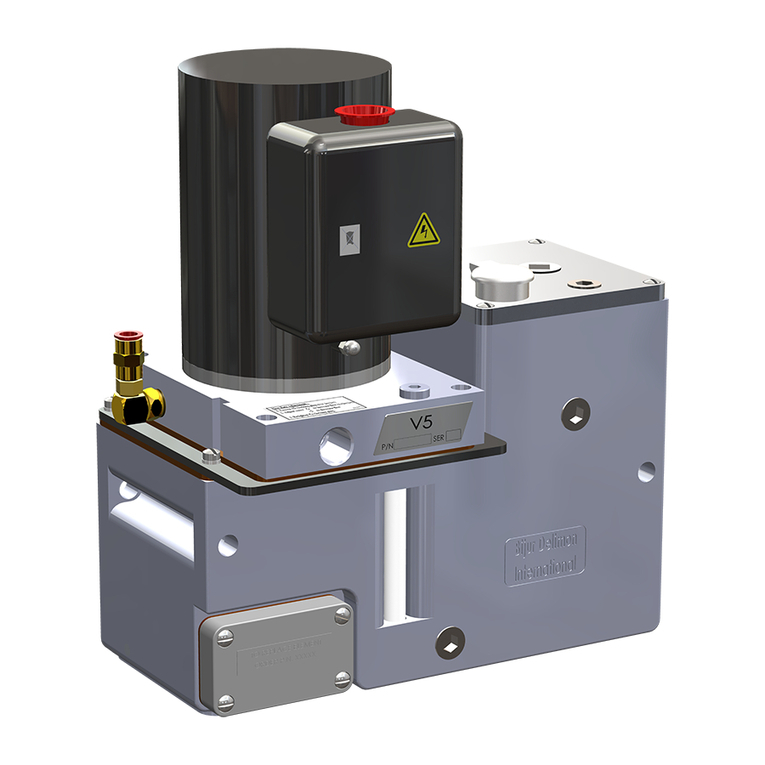

Bijur Delimon V5B User manual

Bijur Delimon

Bijur Delimon SG-A User manual

Bijur Delimon

Bijur Delimon L2P User manual

Bijur Delimon

Bijur Delimon TM-5 User manual

Bijur Delimon

Bijur Delimon M2500G User manual

Bijur Delimon

Bijur Delimon V5B User manual

Bijur Delimon

Bijur Delimon TMD-5 User manual

Bijur Delimon

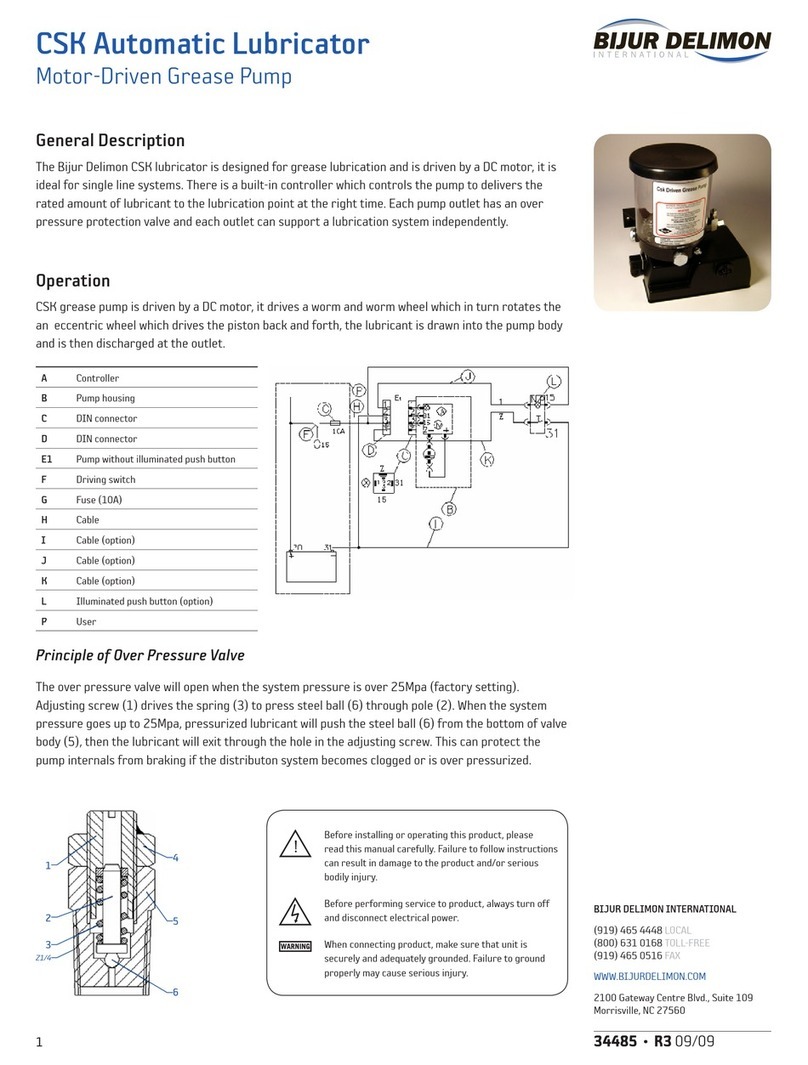

Bijur Delimon CSK User manual

Bijur Delimon

Bijur Delimon V5 60444 Instruction manual

Bijur Delimon

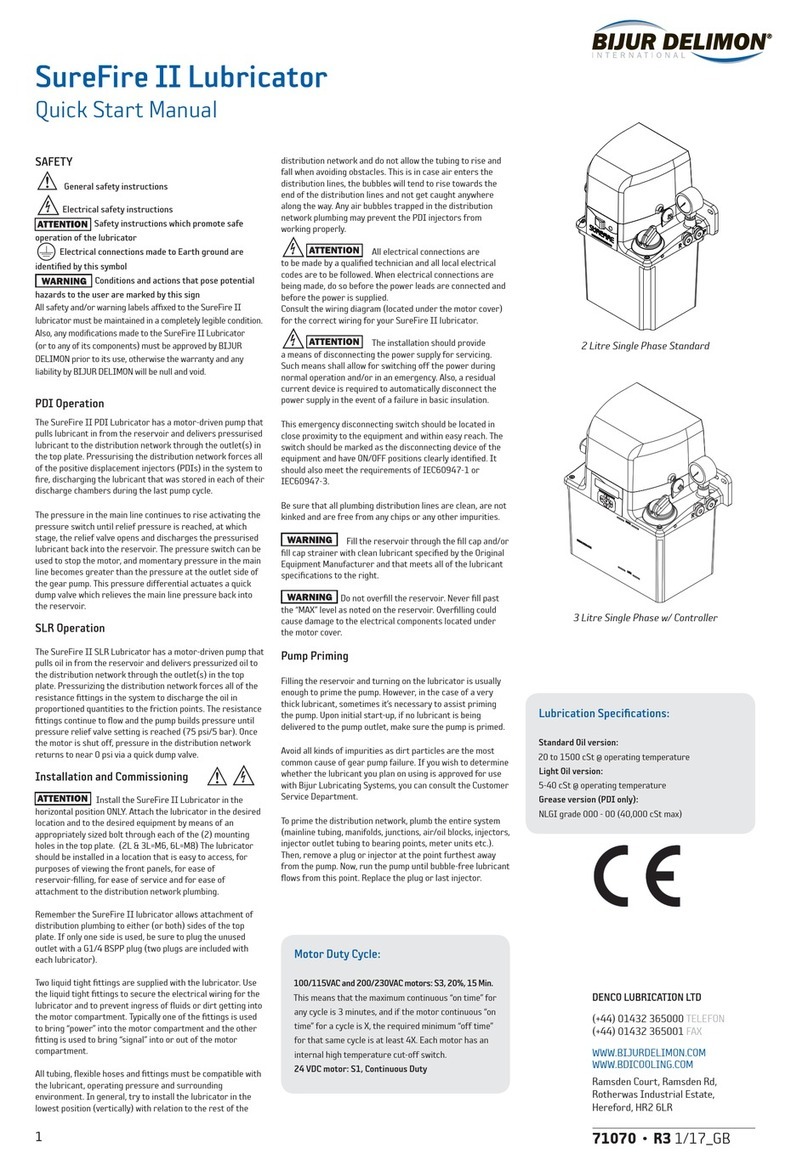

Bijur Delimon SureFire II Instruction manual

Bijur Delimon

Bijur Delimon V3 User manual

Bijur Delimon

Bijur Delimon HAP-P User manual

Bijur Delimon

Bijur Delimon HAP-P User manual

Bijur Delimon

Bijur Delimon Farval CS1000 Manual

Bijur Delimon

Bijur Delimon WS-E User manual

Bijur Delimon

Bijur Delimon SureFire II Instruction manual

Bijur Delimon

Bijur Delimon MultiPort User manual

Bijur Delimon

Bijur Delimon SureFire II Instruction manual

Bijur Delimon

Bijur Delimon V5 User manual

Bijur Delimon

Bijur Delimon V5 User manual