Bespoke Infinity User manual

1

INSTALLATION

MANUAL

Infinity Stairlift

Rail

Carriage

Seat

Huddersfield • England

2

The information contained within this

manual has been designed for use by

Bespoke approved engineers who have

received the appropriate product training

in the following categories,

1. Product installation.

2. Testing and commissioning.

lt is also assumed that the person

using this manual will have the basic

knowledge and skills required in both the

mechanical and electrical aspects to apply

consideration and awareness for the safety

of themselves and others involving their

work.

The contents of this manual are in the

recommended order of placement, which

forms the full installation, and

commissioning

of this standard model.

INTRODUCTION

3

Introduction 2

Contents 3

Rail Preparation and Fixing 4-9

Carriage Preparation and Assembly 10-30

Calibrate and Program the Stairlift 31-35

Troubleshooting 36-39

Wiring Diagrams 40

Certificate of Conformity 41

Demonstration and Handover 42

Installation Tools 43

CONTENTS

4

Remove packaging and protective

wrapping from rail sections.

Position rail sections on staircase as per

Installation Drawing.

Insert the leg stanchions into the relevant

bases and approximately set the height

by tightening the 3 x grub screws on each

base. (Do not tighten too much as these

will need to be adjusted later)

RAIL PREPARATION

266.3

274.7

279.4

279.1

269.9

1147

2108.8

1161.6

265.1

274

269

266.2

267.9

265.4

263

255.7

302

48.9

259.9

269.1

274.1

268.8

261.7

273.5

259.5

265.5

272.2

267.5

275.5

278.9

264.5

14.1

984.7

910.6

1117.4

967.7

719.4

122.3

106.6

125.8

Riser 1

Riser 15

1

2

3

4

5

67

8

9

10

466.7

174.9

180.9

175.3

177.1

170.3

182.8

173.8

176.9

179.1

136.9

170

165.8

166.3

163

172.5

101

100

119.8

2565.6

312.9

499.9

515.6

526.4

442.1

442

442

507.1

489.6

124.2

Base/Stanchion

Number

Type Base

Height

Stanchion

Length

Total Height

1

New

205 ABF

280 312.87

2

New

165 450 499.87

3

New

204 450 515.62

4

New

204 450 526.37

5

New

100 400 442.06

6

New

100 400 442.04

7

New

100 400 442.04

8

New

100 400 442.02

9

New

165 450 507.07

10

New

165 450 489.59

Installation Drawing

RH EXT 180 - Standard Start and

Finish

A3

SHEET 1 OF 3

DWG:

TITLE:

Revision

DATE:

DO NOT SCALE DRAWING

UNLESS OTHERWISE SPECIFIED: DIMENSIONS ARE IN MILLIMETERS (mm)

ASSEMBLY BY:

SAGE ACCOUNT NO.

TYPE:

Model

Handing

Type

Swivel

Seat Type

Footrest

Extra Remotes

Controls

Remote Type

Region

Upholstery Colour

Surveyed By

Dispatch

Bend(s)

Rail Start

Rail Finish

Int' Landing

Int' Charge Point

Foot Covers

Rail Colour

Wall Brackets

Offset Footrest

Rail Length

Rail Sections

Bases to Kit

DRAWING BY:

1

Stairlift Specifications

10

No

7

8324.37

RAL 9010

No

No

N/A

N/A

Standard

Standard

2x90

Courier

Customer

Germany

Red

N/A

Recon

Recon

Recon

Manual

Right

BS 101

New

Standard

Square Ness

& U Bends

Vertical Height

O/B

-5/+15

I/B

-15/+5

Ride Quality

-10/+20

Upper Flights

Lower Flights

-/+2

-20/+20

-10/+20

5

Thread 2-core cable through lower tube of

each section of rail, working from top to

bottom.

Ensure a minimum of 150mm of cable at

each end.

RAIL PREPARATION

6

Assemble rail joints together working from

bottom to top of stairs.

Note: Offer top tubes first.

Apply grease to male part of joint.

Pins should be flush with stair side of rail.

Fit and tighten joint clamps

Using the installation drawing details:

Check top and bottom rail heights over

the corresponding steps.

Check rail angles

Check lower and upper rails are vertically

in line.

Adjust leg heights as required.

Ensure rail to wall measurements match

the Installation drawing.

RAIL FIXING

7

Secure plates to the staircase by the

following method:

Loosen grub screws on leg collar

Fix foot-plate with 3 screws (Figure 4)

Tighten screw to leg.

Repeat for each leg.

The following fixings are recommended:

Timber Staircase - 3 x 50mm screws.

Concrete Staircase -3 x 50mm screws & 3 x

rawlplugs.

Other Staircases - Installation

requirements must be assessed during

Survey.

BE AWARE OF HIDDEN DANGERS SUCH

AS; WIRING, PIPEWORK ETC.

RAIL FIXING

8

Finally ensure all rail dimensions are

in accordance with the rail installation

drawing.

Carry out any final adjustment to the

bases as required using the 3 x Grub

Screws then tighten once the rail position

is correct.

RAIL FIXING

9

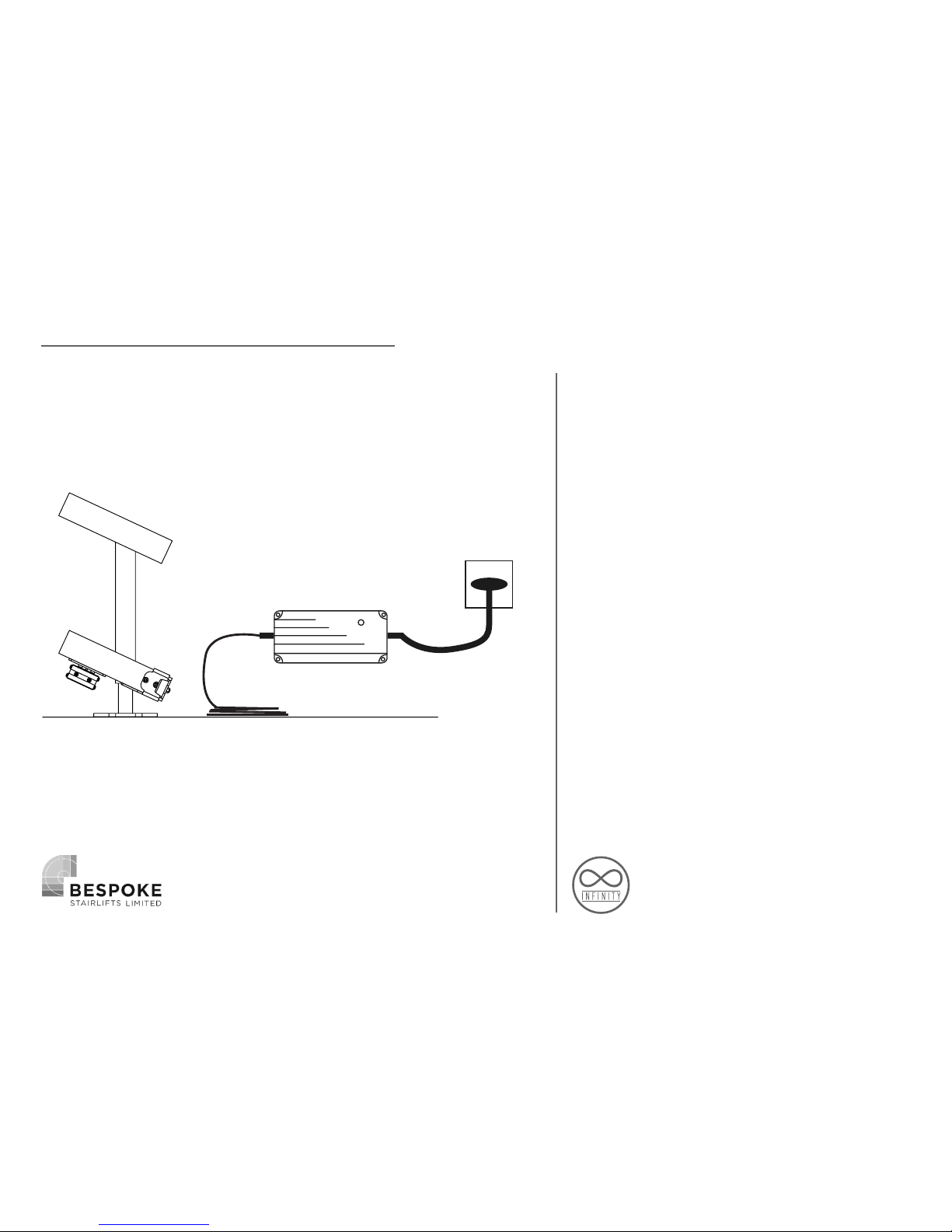

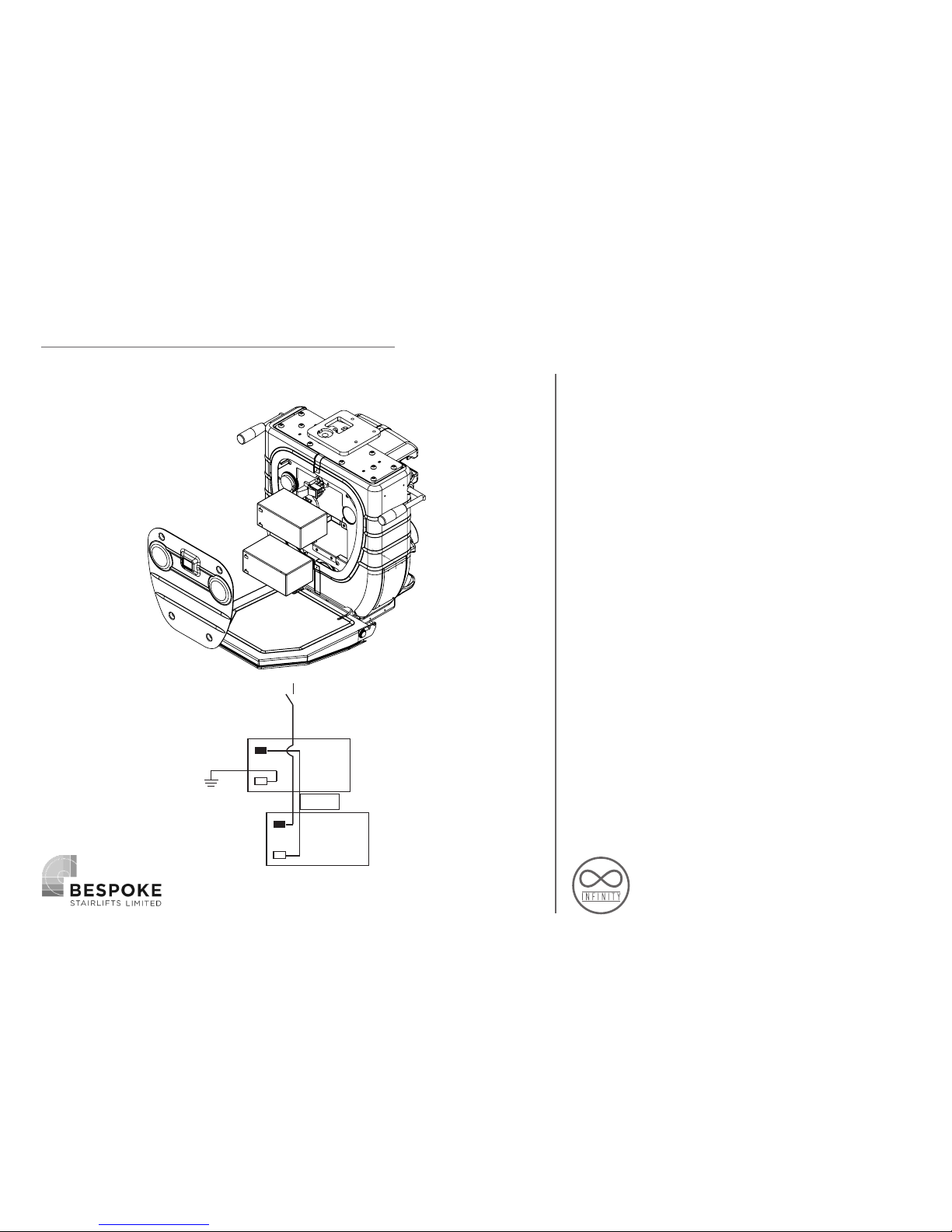

MOUNTING THE CHARGER

Find a suitable power supply as close as

possible to either the top or bottom of the

stairs.

Mount the charger in a suitable position

near the power supply using the screws

supplied. Please ensure the charger is

mounted level and secure.

Leave sufficient length on the power

output to enable easy connection to the

rail charge points.

Do not connect or switch on the power

supply until the rail charge points have

been connected. (See Page 31)

Power Supply

Charging Unit

Power Output

Cable

10

CARRIAGE PREPARATION

11

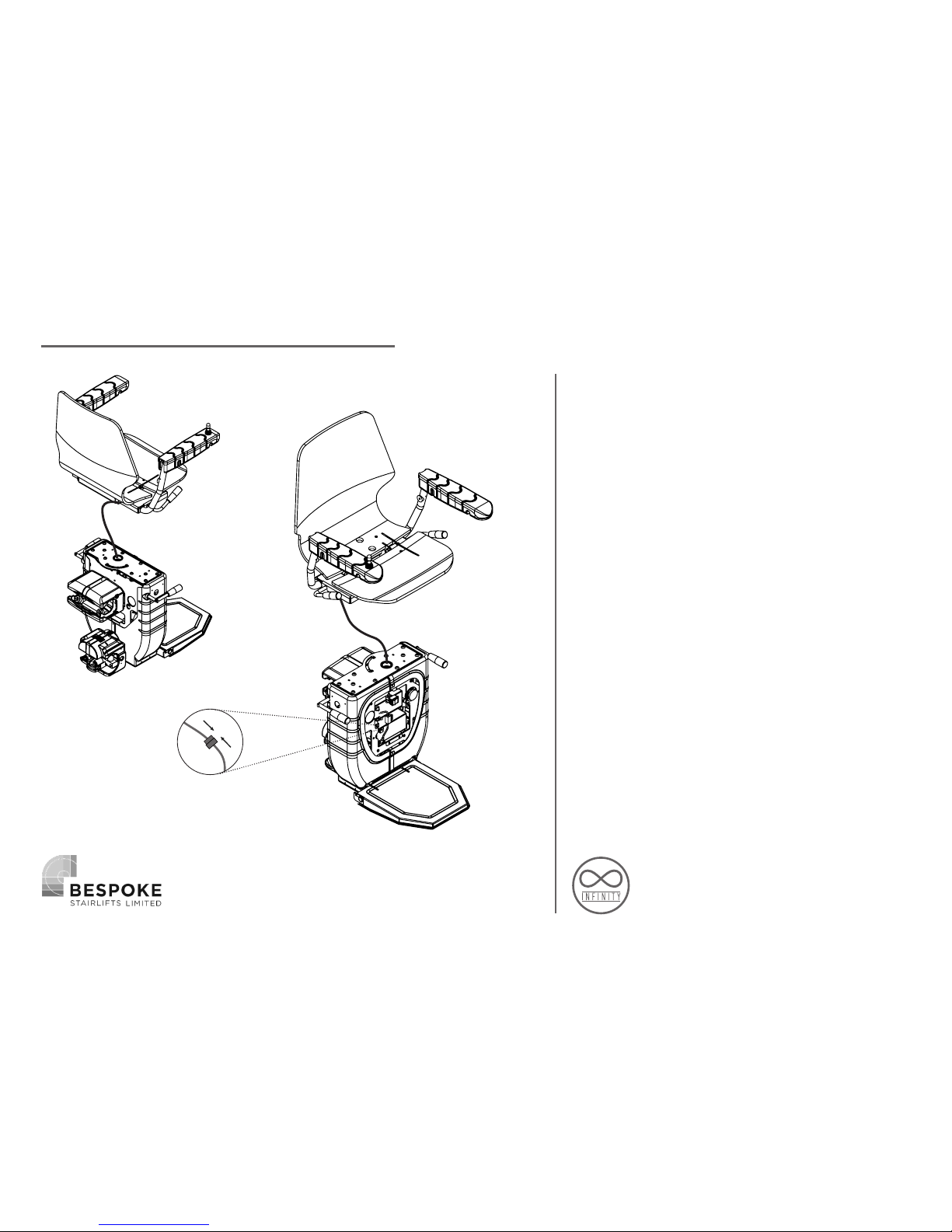

First unpack all the pre-assembled units

from their packaging, taking care not to

place the carriage on the floor, avoiding

damage. Your carriage will arrive already

pre-assembled as either a manual swivel

option or powered swivel option as per

your order.

CARRIAGE PREPARATION

CARRIAGE & FOOTREST SEAT & ARMREST ASSEMBLY

12

INSTALLING THE BATTERIES

To install the batteries first remove the

front panel by unscrewing the 4 main

screws. Once you’re have inserted the

batteries consult figure 2, making sure the

battery circuit is correct.

CARRIAGE ASSEMBLY

+

-

+

-

FUSE

Fig 1

Fig 2

13

CARRIAGE PREPARATION

LOADING ONTO THE RAIL

Next insert the long loading bar into the

top skate of the carriage and insert the

small cone stopper in the bottom rail tube.

At the top of the stairs lift the carriage

with the loading strap and insert the

loading bar into the top rail tube, slowly

run the carriage along until the small cone

is through the bottom skate. Once the

carriage is securely located on rail it is

safe to let go of the loading strap.

(Loading bar & cone are part of the

separate installation kit.)

Small cone

Loading Bar

Loading strap

Fig 1

Fig 2

14

CONNECT THE SEAT BASE WITH ARMS

TO THE CARRIAGE

You can now begin to install the seat to

the carriage. First, lift the seat above

the carriage and feed the joystick cable

down through the hole located in the

seat boss plate, before lowering the seat

down onto the plate ensure to feed all the

cable through when doing so, to prevent

the cable getting trapped under the seat

frame. If the lift is a Manual Swivel, you

must ensure the locator on the swivel lever

is passing through the aperture in the boss

– this is not required on a powered swivel.

CARRIAGE ASSEMBLY

15

Now line the holes up on the seat frame

down to the boss plate below. Fix with the

2 shorter bolts towards the front of the

seat, the 2 longer ones to the back. Please

ensure the correct screws are positioned in

the correct holes as incorrect installation

will result in damage. Then connect the

joystick cable to the PCB cable which is

located inside the chassis above the upper

battery (Fig 1), making sure the 2 cables

are free to move as the chair rotates, then

the front battery cover can now be fixed

back on. Insert the key into the arm and

turn to the in position, the carriage is now

ready to run down the rail.

CARRIAGE ASSEMBLY

Fig 1

2x Long Screws

2x Short Screws

16

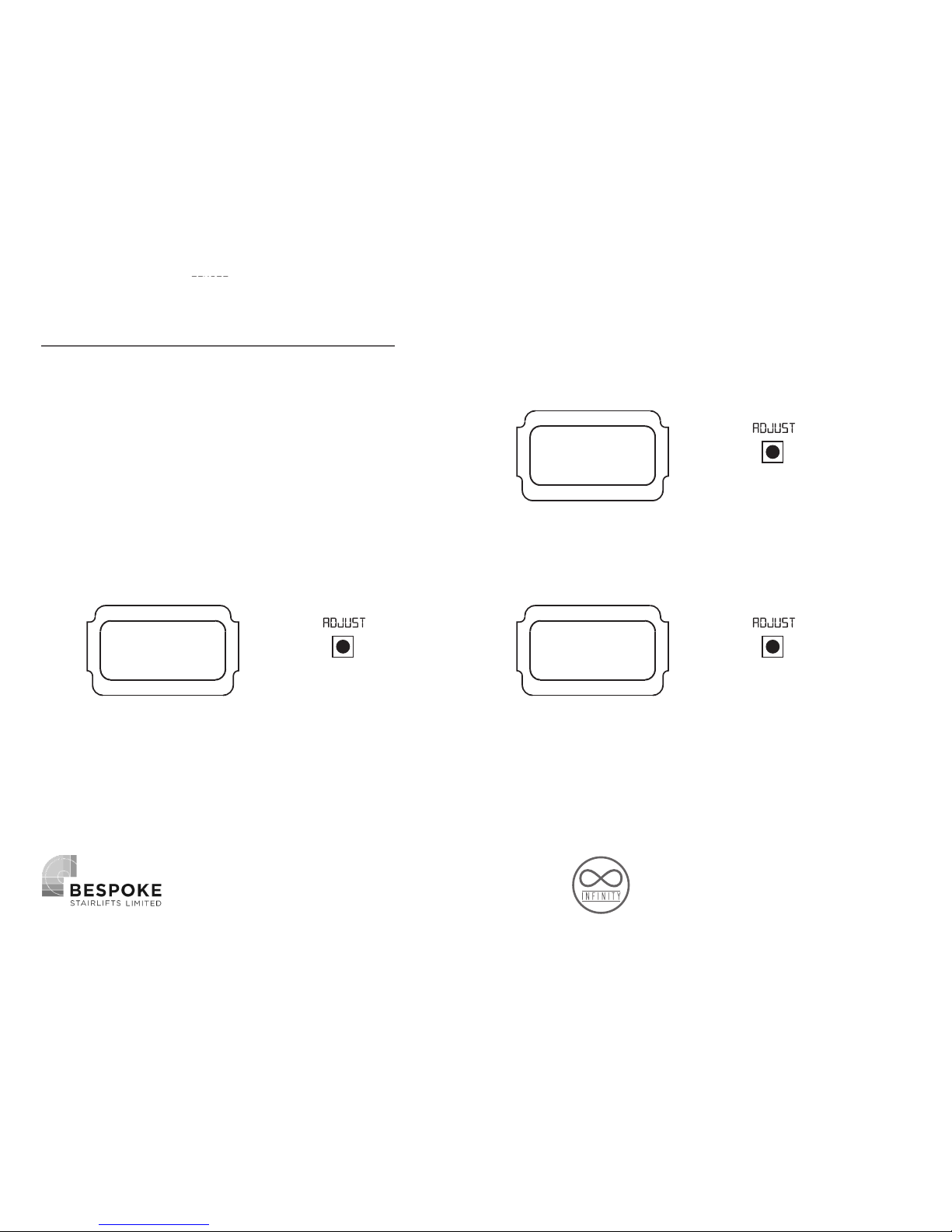

Switch on the lift by pressing the orange

switch on the front of the carriage to the

on position. Remove the PCB cover for

access to the programming buttons and to

have a clearer view of the LCD screen. The

lift should already come set up correctly

ready for programming, but this can be

checked by going through the menu

function on the screen.

The lower ‘SCROLL’ button is used to cycle

through the menu options and the top

‘ADJUST’ button to change an option. For

example, scroll to the Swivel option and

press the adjust button to choose Manual

or powered. It is best to check through all

these beforehand to make sure everything

is set up correctly.

RUNNING THE CHAIR ON

MANUAL

17

The lift will not run unless in program

mode or already programmed to the rail.

To put the lift into Program mode, Press

the scroll button until you see ‘POSITION’

(this is the first option you come to if

scrolling from the home screen), then

press and HOLD the scroll button and this

will change to ‘Program LO 1500’ – you are

now in program mode and able to drive

the lift onto the rail. Run the chair to a

desired position on the rail so you are now

able to start mounting the charging points.

RUNNING THE CHAIR ON

Position

PROGRAM

Lo 1500

HOLD

18

Return to the rail and fit the charge points

to both the top and bottom connecting

the core cable at both ends, use the

diagram in the installation guide to ensure

correct polarity (+ to the lower charging

strip and - to the top) once you are happy

with the positions fasten the final end stop

brackets at the top and bottom of the rail.

When placing the final end stops and

charging points please ensure;

1. The lower skate of the carriage does not

touch the floor before engaging with the

final end stop. This could result in damage

to the skate mechanism. If the distance

is incorrect you may need to adjust the

charging terminal.

2. When the charging terminals are

engaged make sure there is ONLY 5mm-

10mm gap between the end stop and

the skate cover, if for any reason the lift

overruns the charge points it will ensure

the lift is still on charge.

INSTALL RAIL CHARGE POINTS

+

+- -

+ -

+

-

19

PROGRAMMING

HAND

This is to determine the hand of the lift

LEFT / RIGHT

MODE

Used for different lift types as will both Curved

and Straight lifts will use the same PCB &

software. *Straight lift not yet available*

CURVED/STRAIGHT

POSITION

Used for programming the lift to the rail (press

and hold scroll button to get in/out of Program

mode), also shows the encoder count once

programmed.

NO FUNCTION

Below is breakdown and explanation

of each of the menu options shown

on the display when using the scroll

/ adjust button. The home screen will

show lift status, for example, ‘LIFT

READY’ or OFF CHARGE’ before you

scroll through the menu, the display

will automatically go back to the

lift status after 5 seconds of neither

button being pressed.

20

INT.CP

When the lift has an Intermediate Charging Point

(INT. CP) the lift will always park here from the remote

controls, but you have the option for the joystick,

PASS – to always pass the charge point when using the

joystick (when the lift only requires the charge point

STOP – To stop on the charge point when using the

joystick (usually required where the customer has an

intermediate landing they need to be able dismount

the lift).

PASS / STOP

TRAVEL

Option for the lift to BEEP when travelling up or

down the rail

QUIET / ALARM

LANGUAGE

Choose 1 of 7 language options;

English, Spanish,French,

German, Italian, Portuguese & Dutch

SELECT LANGUAGE

SWIVEL

This option is to set up whether the lift has a

manual or powered swivel

MANUAL / POWERED

PROGRAMMING

Other manuals for Infinity

2

Table of contents

Other Bespoke Stairlift manuals