Smoke control dampers

Specification text

08/2017

EK-JZ

– DE/en

This specification text describes the general

properties of the product.Texts for variants can be

generated with our Easy Product Finder design

programme.

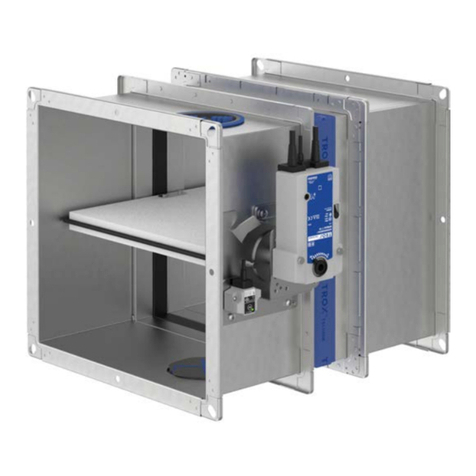

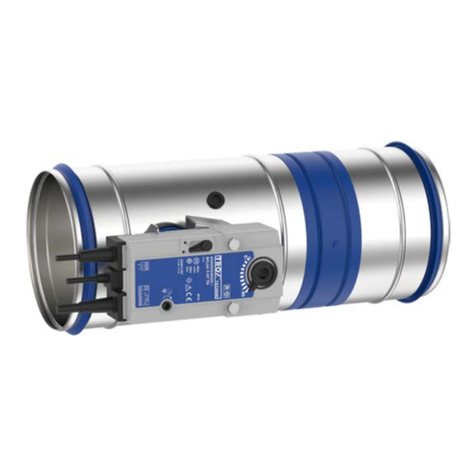

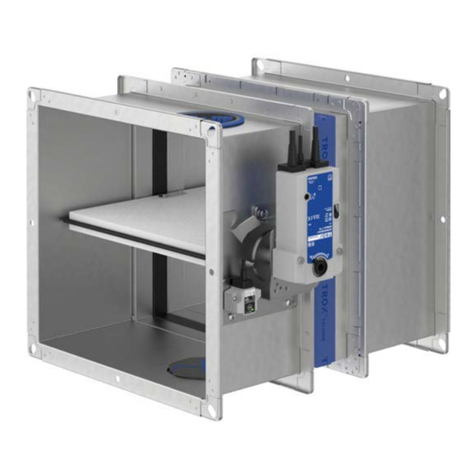

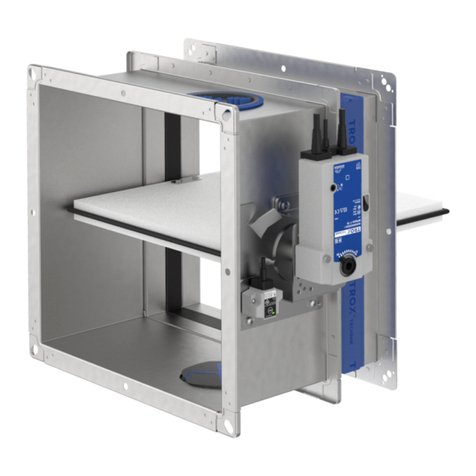

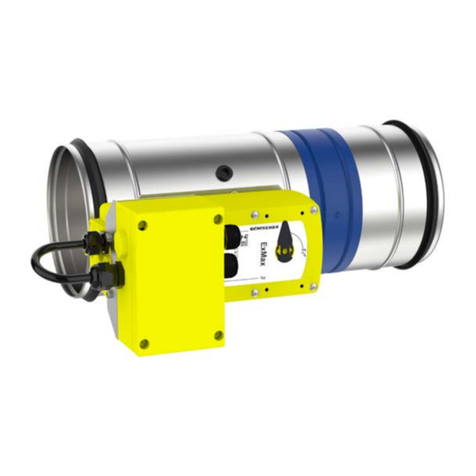

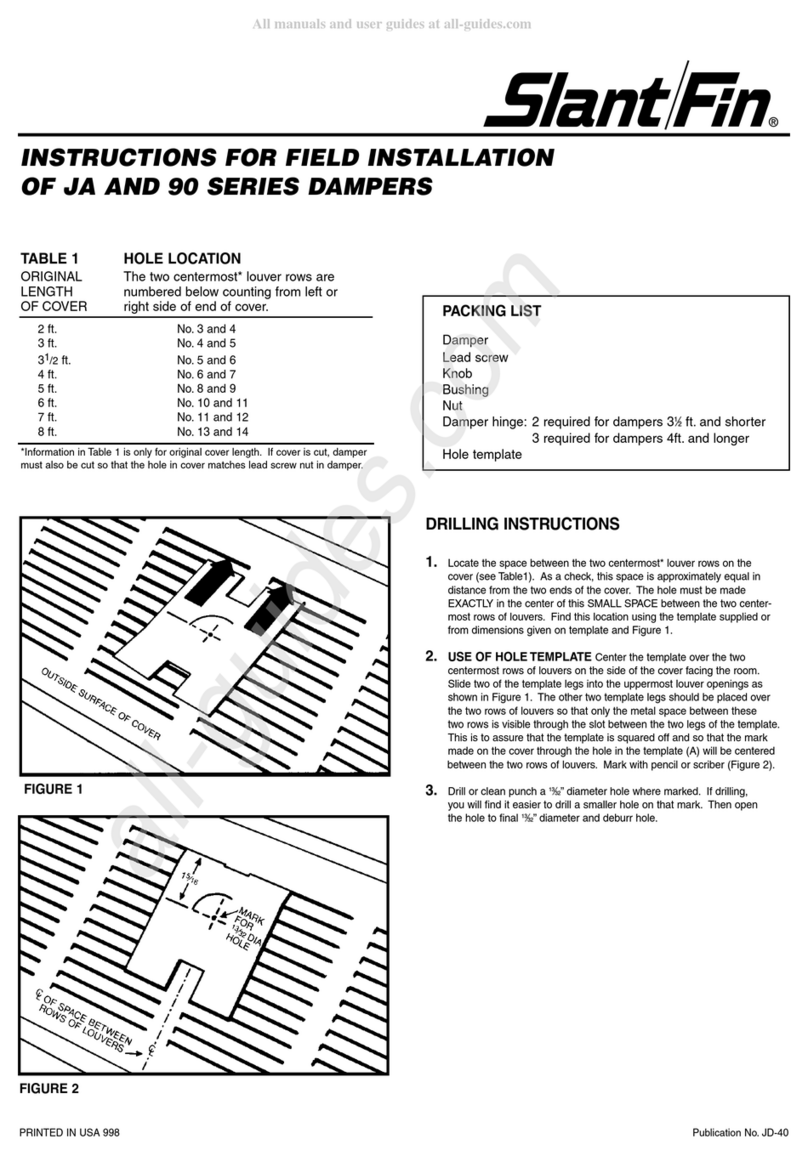

Rectangular or square smoke control dampers to

product standard EN 12101-8, tested to EN 1366-

10 and EN 1366-2, for use in smoke extract

systems. Smoke control dampers are not only

used for the exhaust of smoke, heat and

combustion products, but also for the controlled

removal of dangerous and toxic fire suppression

gases.

EK-JZ smoke control dampers can also be used

in pressurisation systems and as pressure relief

dampers in gas fire extinguishing systems. Also

for extracting smoke gases and for providing

additional supply air to one or more fire

compartments.

EK-JZ can be used in combined smoke exhaust

systems which have been approved for controlled

ventilation.The fire-resistant smoke control

damper for multiple compartments is suitable for

installation in and on fire-resistant smoke extract

ducts and in fire-resistant standard supporting

constructions. It is controlled with open/close

actuators that can be combined with control

modules that are factory wired and fitted inside

the temperature-resistant actuator encasing.

Classification

– EI 120/90 (vedw, i ↔ o) S1000 C10,000 MA multi

Special characteristics

– C10,000 for combined smoke extract and

ventilation systems

– Complies with the requirements of EN 12101-8

– Tested to EN 1366-2 and 1366-10 for fire

resistance properties

– Closed blade air leakage to EN 1751, class 3,

and casing air leakage to EN 1751, class C

– Low sound power level and differential

pressure

– Any airflow direction

– Manual release is also possible using

TROXNETCOM

– Integration into the central BMS with standard

bus systems

– Long-time testing to EN 1366-10 with a weight

being attached to the blades, 10,000 open/

close cycles

Materials and surfaces

– Casing, damper blade and actuator encasing

made of temperature-resistant calcium silicate

– Brass bearings

– Blade shafts, drive arm and external linkage

made of galvanised steel

Technical data

– Nominal sizes B × H:

200 × 430 mm – 1200 × 2030 mm

– Casing length: 250 mm

– Volume flow rate range: Up to 24361 l/s or

87700 m³/h

– Differential pressure range, pressure level 2:

–1000 to 500 Pa

– Operating temperature: –30 to 50 °C; the

temperature should not fall below the dew point

– Upstream velocity*: ≤ 10 m/s with the largest

size, > 10 – 15 m/s with smaller sizes;

87700 m³/h max.

* Data applies to uniform upstream and

downstream conditions for the smoke control

damper

Attachments

Connecting subframe and cover grille for the

operating side and/or installation side.

– Connecting subframe for calcium silicate and

sheet steel smoke extract ducts

– Cover grille – crimped wire mesh or square

perforated metal plate

– Cover grille – external weather louvre or

ventilation grille

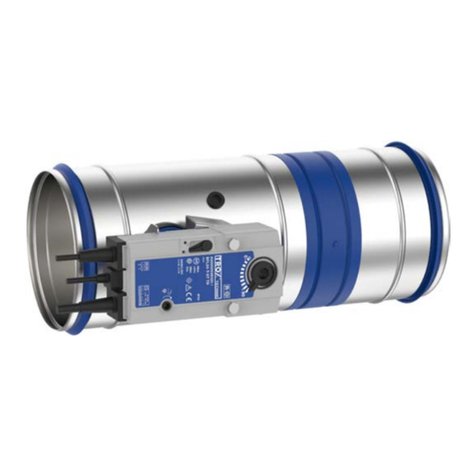

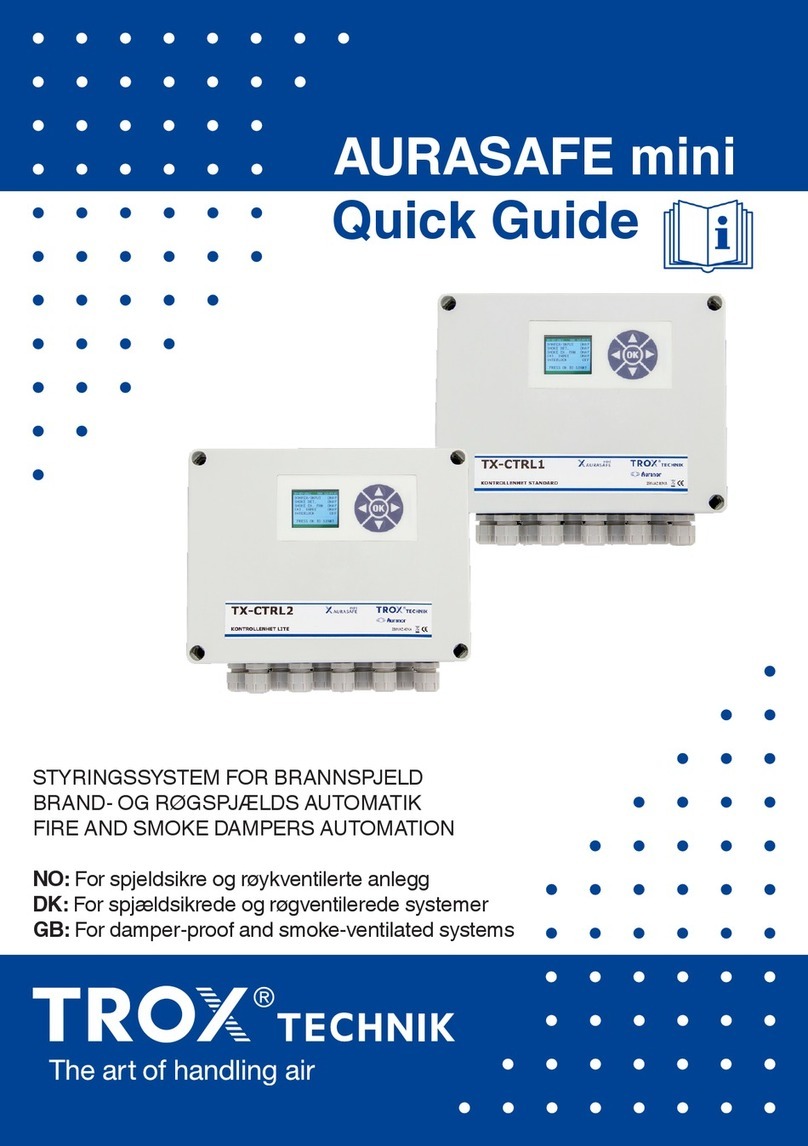

Open/Close actuators for the control of smoke

control dampers, with automatic (AA) or manual

release (MA).

Optional control or communication module for

integration with the central BMS.

– Supply voltage 24 V AC/DC or 230 V AC

– Limit switches for capturing the end positions

OPEN and CLOSED

– Override control for up to 25 minutes

– Module for the control of smoke control

dampers (optional)

– Indicator lights for indicating the damper blade

position

– Monitoring of signal reception

Sizing data

– ____________ _______________________

[m³/h]

– Δpst __________ _______________________

[Pa]

Air-regenerated noise

– LPA ___________ _______________________

[dB(A)]

PD – EK-JZ – 16