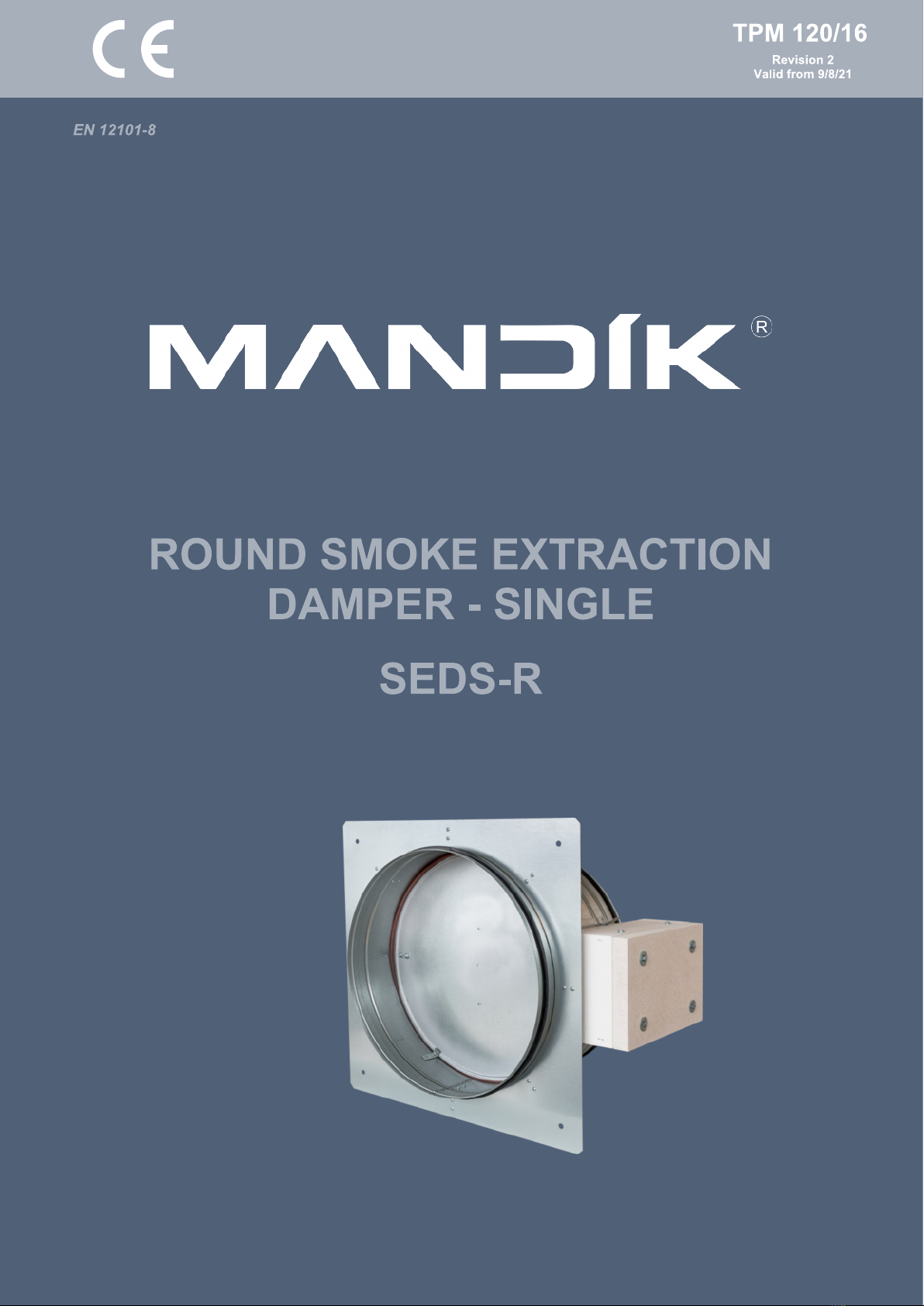

Mandik SEDS-R User manual

Other Mandik Fire And Smoke Damper manuals

Mandik

Mandik FDMS Series User manual

Mandik

Mandik SEDM User manual

Mandik

Mandik MSD Square Configuration guide

Mandik

Mandik FDMA-PM User manual

Mandik

Mandik FDMB User manual

Mandik

Mandik SEDS User manual

Mandik

Mandik SEDM-L User manual

Mandik

Mandik MSD User manual

Mandik

Mandik FDMR 60 User manual

Mandik

Mandik FDMB User manual

Popular Fire And Smoke Damper manuals by other brands

HVC

HVC NCA 700 Series Operation and maintenance manual

Wildeboer

Wildeboer FR90 user manual

FläktGroup

FläktGroup ETCE Instructions for installation, operation and maintenance

Tamco

Tamco 1000 SM Series manual

Greenheck

Greenheck Vektor-MD Installation, operation and maintenance manual

Lindab

Lindab FBC2 Installation booklet

EKOVENT

EKOVENT EKO-SRB1 Installation, operating and maintenance instructions

Greenheck

Greenheck HBS Series Installation, operation and maintenance instructions

Advanced Air

Advanced Air 0160 Series Installation, operation and maintenance manual

Greenheck

Greenheck CRD-1WT Installation, operation and maintenance manual

Swegon

Swegon Actionair CSS Series installation guide

TAKACHIHO

TAKACHIHO FYN-M 1 Series manual

Valmet

Valmet Flowrox Expulse Series Installation, operation and maintenance instructions

ETS NORD

ETS NORD NORDfire FDMB manual

AMS

AMS CR2 manual

Arzel

Arzel RegiDamper installation instructions

mercor

mercor mcr S-THERM C Operation and maintenance manual

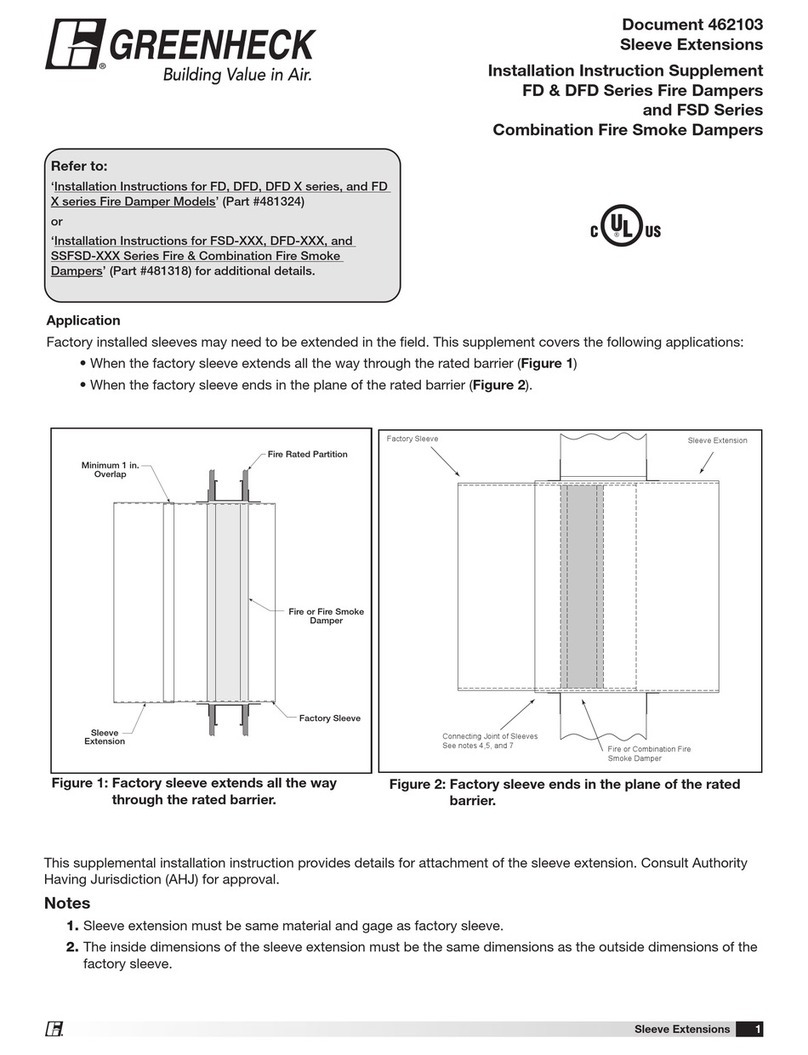

Greenheck

Greenheck FD Series Installation instruction supplement