Page 5 z 25

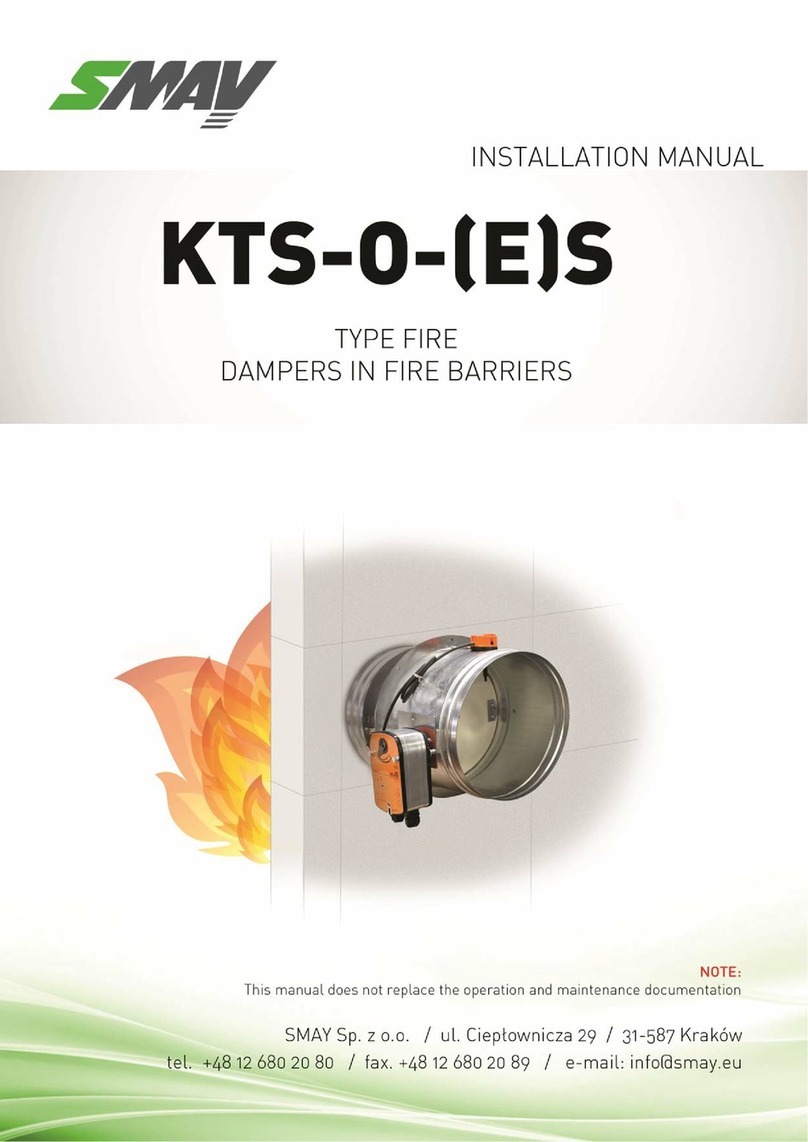

•EI 60 (ve i↔o) S

ostandard walls, thickness 75 mm or more and in fire resistance EI60 or

higher,

origid walls, thickness 75 mm or more and in fire resistance EI60 or higher

(e.g. concrete walls, non-hollow brick walls, cellular concrete block walls,

hollow masonry unit walls or concrete slab walls),

•EI 30 (ve i↔o) S

ostandard walls, thickness 75 mm or more and in fire resistance EI30 or

higher (thicker, greater density, more slab layers),

origid walls, thickness 75 mm or more and in fire resistance EI30 or higher

(e.g. concrete walls, non-hollow brick walls, cellular concrete block walls,

hollow masonry unit walls or concrete slab walls),

where:

E– integrity,

I– insulation,

S– smoke leakage,

120/90/60/30 – duration of fulfilment of E, I and S criteria, expressed in minutes,

ve – damper mounted directly in the wall,

ho – damper mounted directly in the ceiling,

i↔o– operating effectiveness criteria are fulfilled from the inside to the outside (fire

inside), and from the outside to the inside (fire outside).

KWP-L fire dampers may also be installed in space dividers having a smaller fire

resistance. In this case, the damper`s fire resistance is equal to the space divider`s

fire resistance, considering the smoke leakage criterion.

KWP-L fire dampers may be installed in vertical space dividers with both horizontal

and vertical rotation axis of damper blade, with any actuator location.

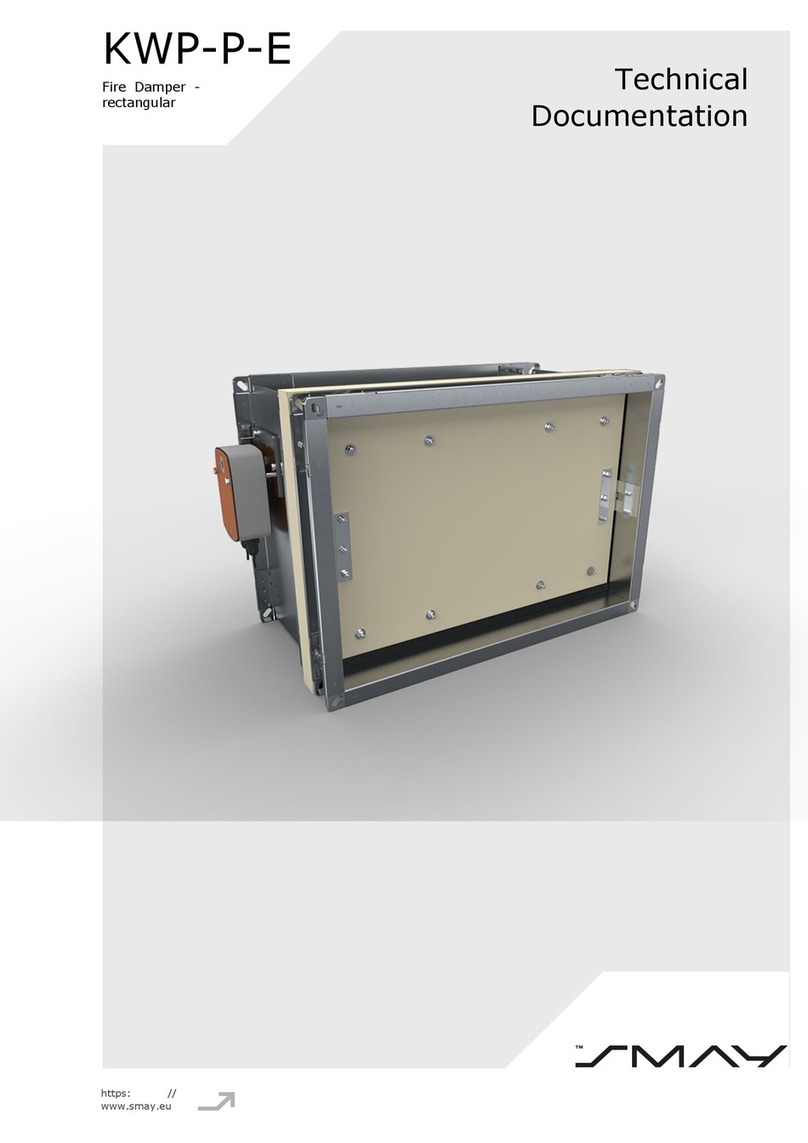

4. TECHNICAL DESCRIPTION

KWP-LS dampers (with a spring mechanism) and KWP-LE dampers (with

electric actuator and return spring) comprise a housing, square in profile, moving,

single-axis isolating baffle and actuating mechanism with a release device.

The damper housing and its interacting elements are made of galvanised steel

sheet. Both ends of the housing are terminated with connection flanges, allowing easy

connection between the duct and the damper.

There are intumescent seals on the outer and inner surface of the housing, in

the place of perforation around the closed isolating baffle. Their characteristic feature

is the fact that their volume increases at high temperatures, tightly filling all leaks

between the baffle and the body.

The isolating baffle of the damper is made of calcium-silica board, and a bubble

seal is installed on its perimeter, ensuring the damper’s integrity in the ambient

temperature.

The KWP-L damper is provided with a spring mechanism, comprising e.g. the

actuating spring, manual release device, and a thermal fuse whose nominal activation