SW-Stahl und Werkzeugvertriebs GmbH Tel. +49 (0) 2191 / 46438-0

F56essartSresukreveL ax +49 (0) 2191 / 46438-40

ed.lhatsws@ofni:liaM-EdiehcsmeR79824-D

Instruction Manual

BGS technic KG

Bandwirkerstr. 3

42929 Wermelskirchen

Tel.: 02196 720480

Fax.: 02196 7204820

www.bgstechnic.com

© BGS technic KG, Copying and further use not allowed

Art. 8856

Torque Wrench

SPECIFICATION

Range: 6 – 30 Nm

Division: 0,2 Nm

Drive: 6,3 (1/4)

Length: 280 mm

Head Sizes:

7, 8, 9, 10, 11,

12, 13, 14 mm

Accuracy: +- 4%

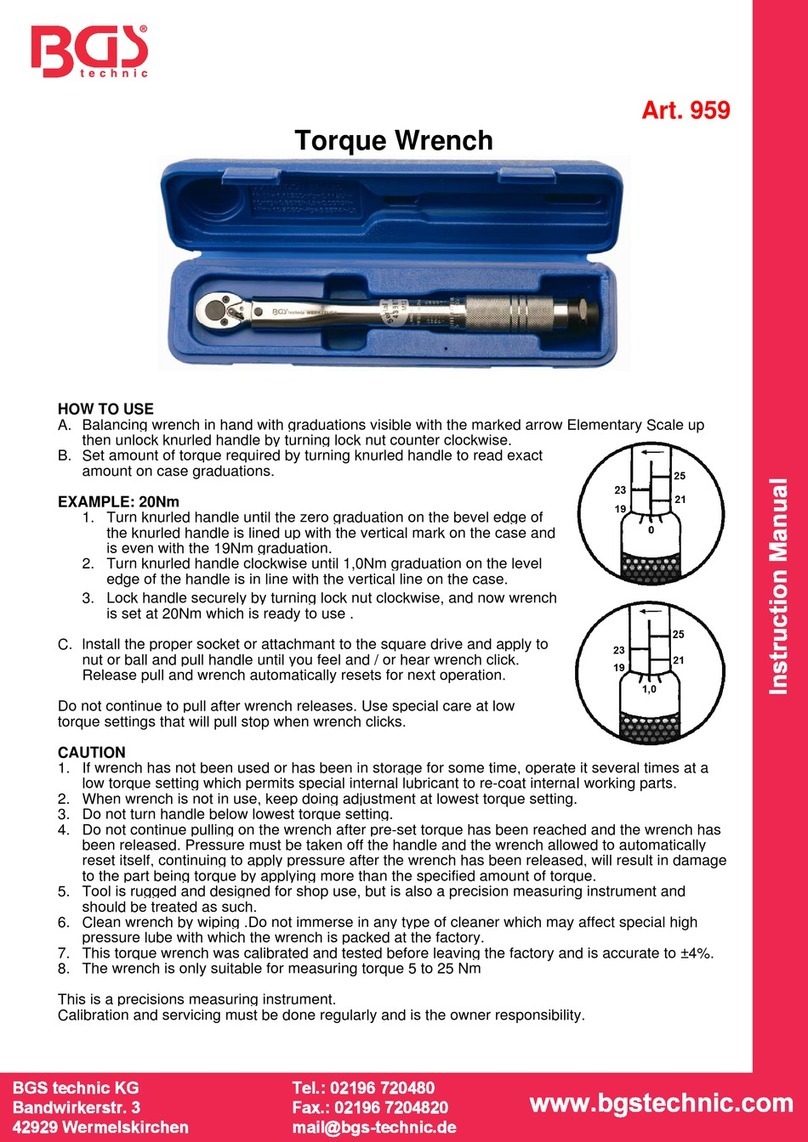

USING (Example: 146 Nm)

Unlock the handle by sliding the locking sleeve backwards.

Turn the upper edge of adjusting handle to 140Nm and meantime, the

reading "0" on the handle must align with the centerIine of scale

perpendicularly so as to acquire 140 Nm.

Then turn clockwise to align the reading of "6" on the adjusting handle with

the centerline of scale so as to acquire 146 Nm. Smaller torque wrench can

be set alike. Please refer to the smallest possible division, these can be

found under specification.

Lock the handle by pushing the locking sleeve forward. Now an adjustment is

no longer possible.

Mount an appropriate socket onto the square drive and put the wrench onto

the bolt. Turn the torque wrench slowly and evenly until a clicking sound is

heard, then finish tightening immediately.

Caution: At low torque values, the clicking noise is quieter and can not be

heard in a noisy environment.

CAUTION

1. If wrench has not been used or has been in storage for some time, operate it several times at a

low torque setting which permits special internal lubricant to re-coat internaI working parts.

2. When wrench is not in use, keep doing adjustment at lowest torque setting.

3. Do not turn handle below lowest torque setting.

4. Do not continue pulling on the wrench after pre-set torque has been reached and the wrench has

been released. Pressure must be taken off the handle and the wrench allowed to automatically

reset itself, continuing to apply pressure after the wrench has been released, will result in damage

to the part being torque by applying more than the specified amount of torque.

5. Tool is rugged and designed for shop use, but is also a precision measuring instrument and

should be treated as such.

6. Clean wrench by wiping .Do not immerse in any type of cleaner which may affect special high

pressure lube with which the wrench is packed at the factory.

7. This torque wrench was calibrated and tested before leaving the factory and is accurate to ±3%.

8. The key is only suitable for a permissible torque, which can be found in the table above.

This is a precisions measuring instrument.

Calibration and servicing must be done regularly and is the owner responsibility.

.