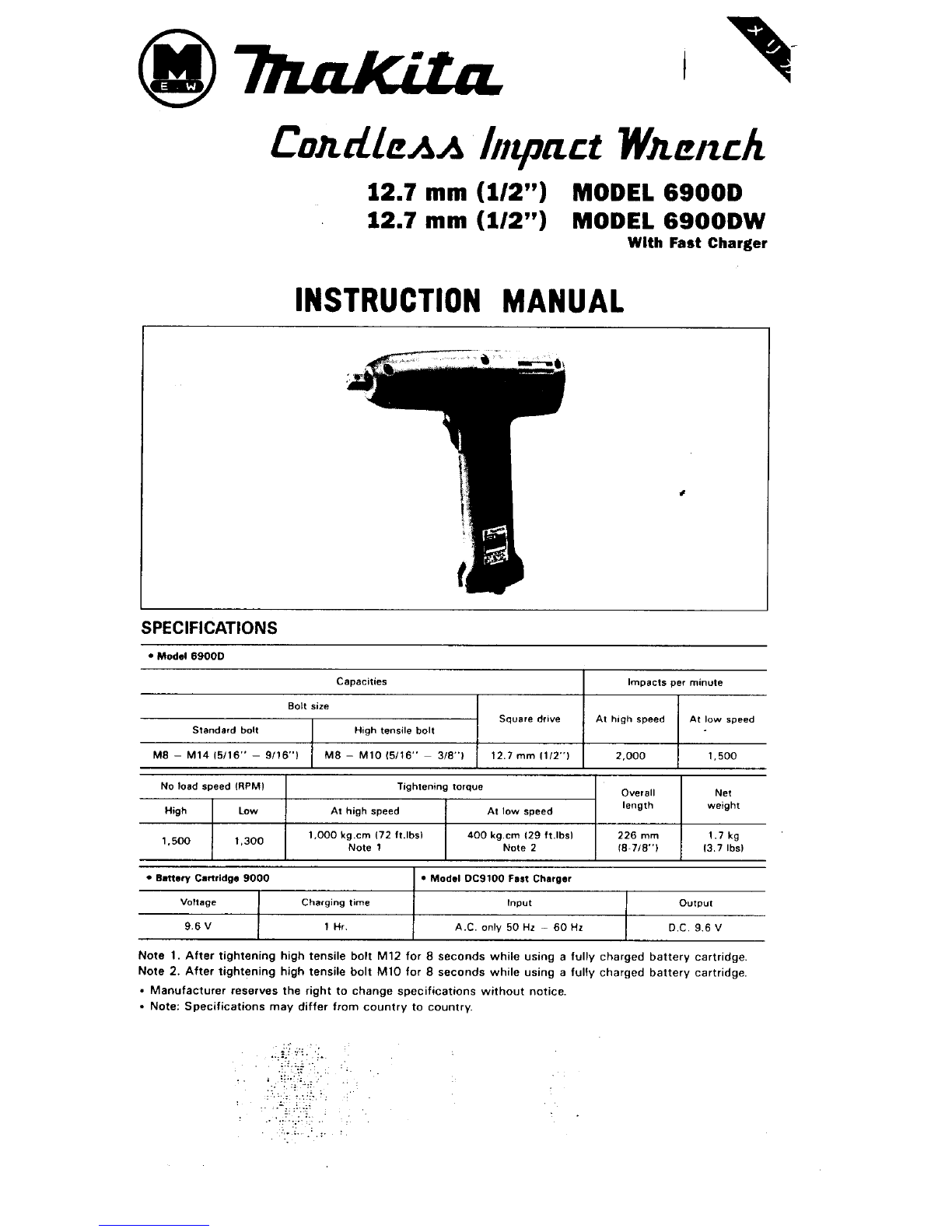

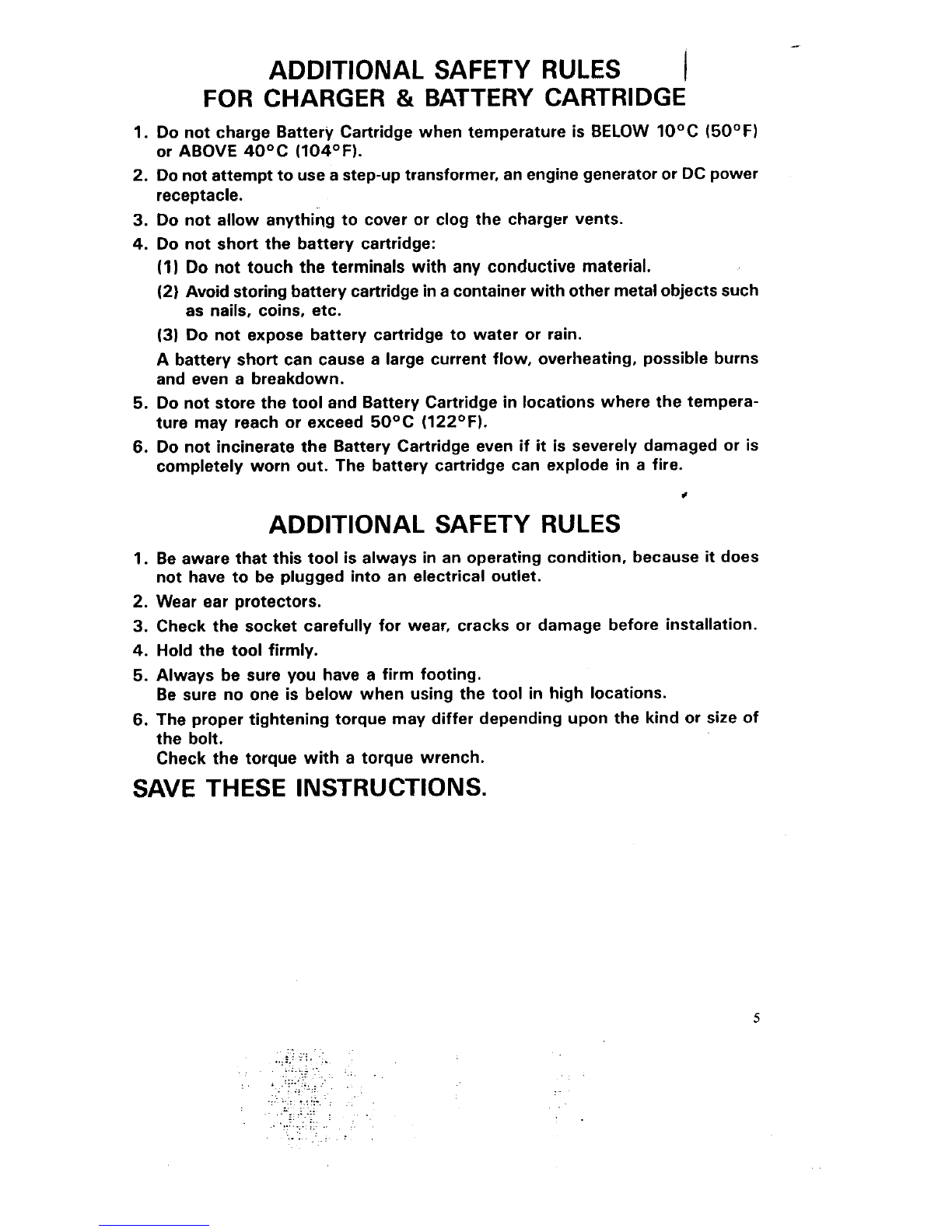

Installingor removing battery cartridge

Always switch off the tool before insertion

To

remove the battery cartridge, pull out

the

set

plate on the tool and grasp both

sides of the cartridgewhile withdrawing it

from the barrel.

To insert the battery cartridge, align the

tongue

on

the battery cartridge with the

groove in the housing and

slip

it

into

place. Snap the set plate back into place.

Be sure to close the set platefully before

usingthe tool.

or removalof the battery cartridge.

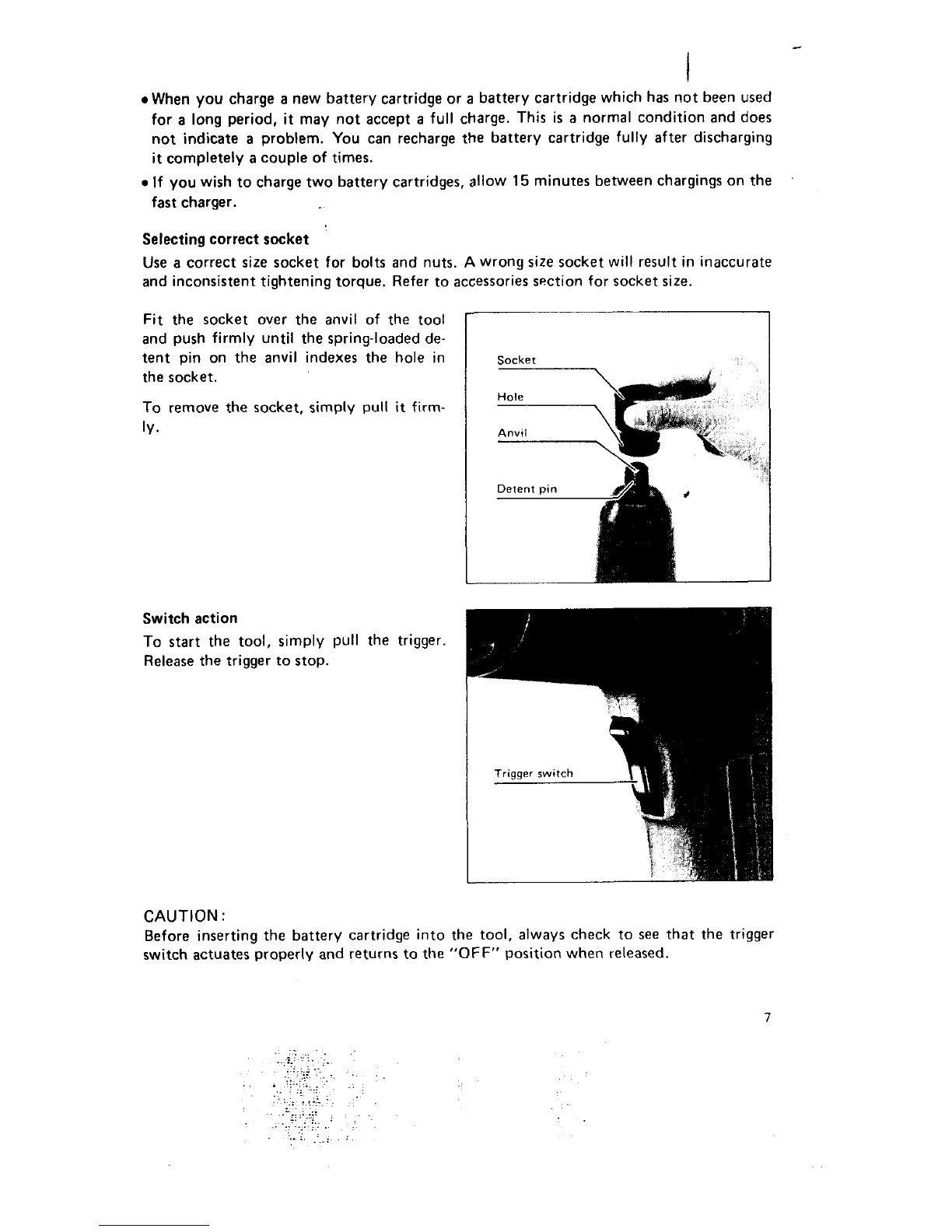

Set

plate

I

/

Battery

cartridge

I

k

Do

not use force when insertingthe battery cartridge.

If the cartridgedoes not slide ineasily, it

is

not being inserted correctly.

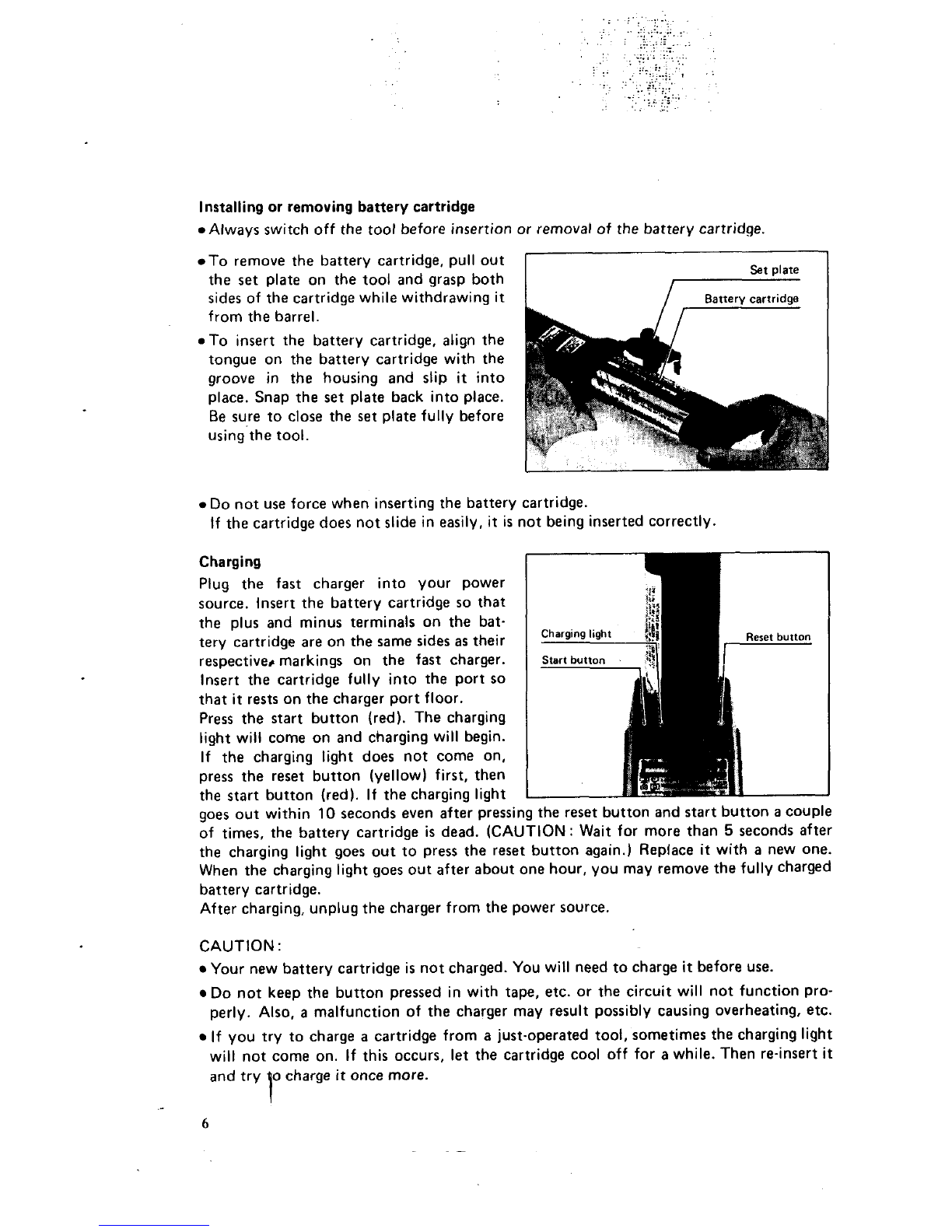

Charging

Plug the fast charger into your power

source. Insert the battery cartridge

so

that

the plus and minus terminals on the bat-

tery cartridge are on the same sides

as

their

respective#markings on the fast charger.

Insert the cartridge fully into the port

so

that itrests on the charger port floor.

Press the start button (red). The charging

light will come on and charging will begin.

If the charging light does not come on,

press the reset button (yellow) first, then

the start button (red). If the charging light

Charging light

Start

button

tit\

goes out within

10

seconds even after pressingthe reset button and start button

a

couple

of times, the battery cartridge

is

dead. (CAUTION

:

Wait for more than

5

seconds after

the charging light goes out to press the reset button again.) Replace

it

with

a

new one.

When the charging light goes oat after about one hour, you may removethe fully charged

battery cartridge.

After charging, unplugthe charger from the power source.

CAUTION

:

Your new battery cartridge

is

notcharged. You will need tocharge

it

beforeuse.

Do

not keep the button pressed in with tape, etc. or the circuit will not function pro-

perly. Also,

a

malfunction of the charger may result possibly causing overheating, etc.

If you try to charge

a

cartridge from

a

just-operatedtool, sometimes the charging light

will not come on. If this occurs,

let

the cartridge cool off for

a

while. Then re-insert

it

and try

o

charge

it

oncemore.

1

6