BGS technic 8717 User manual

Other BGS technic Tools manuals

BGS technic

BGS technic 569 User manual

BGS technic

BGS technic 1773 User manual

BGS technic

BGS technic 9010 User manual

BGS technic

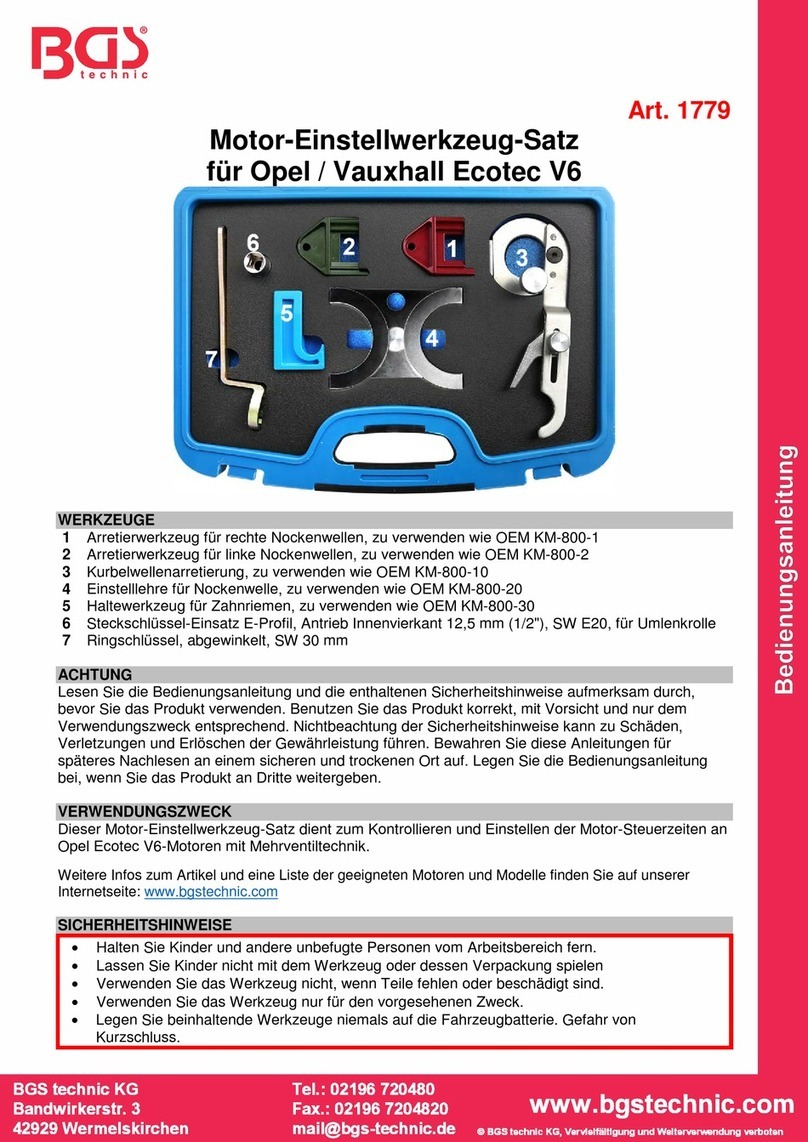

BGS technic 1779 User manual

BGS technic

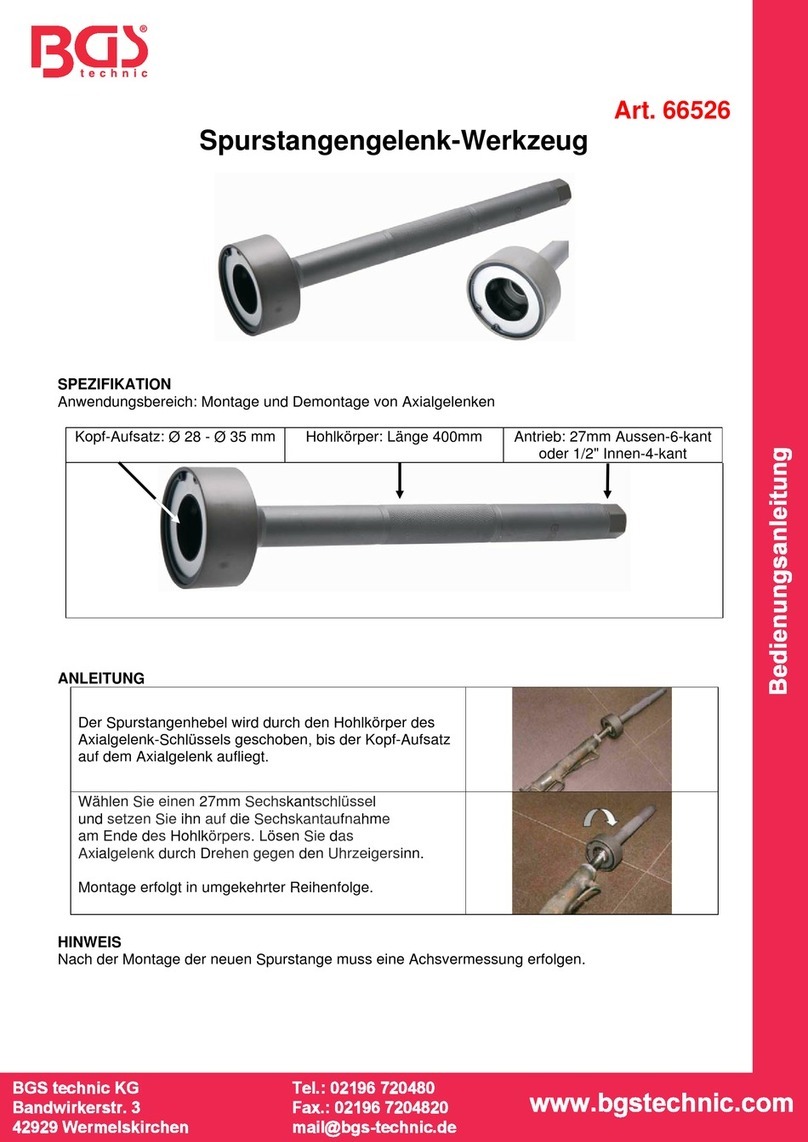

BGS technic 66526 User manual

BGS technic

BGS technic 70205 User manual

BGS technic

BGS technic 8261 User manual

BGS technic

BGS technic 9605 User manual

BGS technic

BGS technic 9754 User manual

BGS technic

BGS technic BGS 8457 User manual

BGS technic

BGS technic 3229 User manual

BGS technic

BGS technic 69506 User manual

BGS technic

BGS technic 9101 User manual

BGS technic

BGS technic BGS 8691 User manual

BGS technic

BGS technic 6643 User manual

BGS technic

BGS technic 6250 User manual

BGS technic

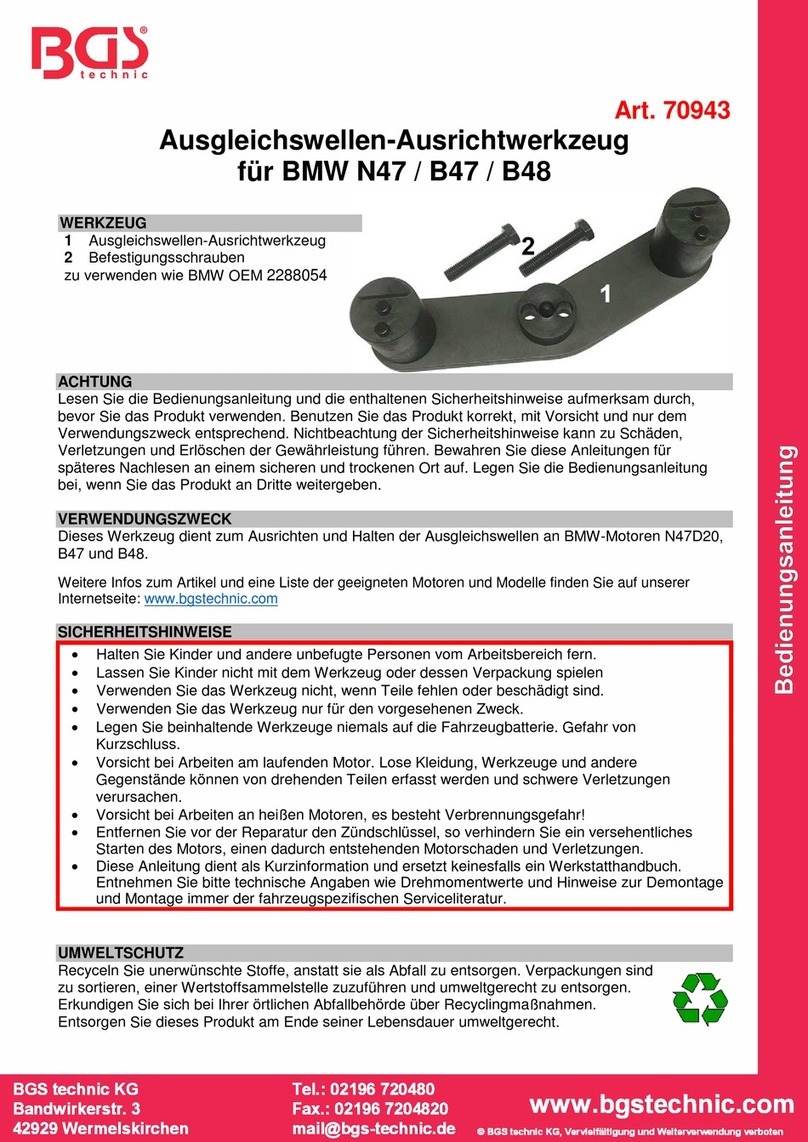

BGS technic 70943 User manual

BGS technic

BGS technic BGS 70009 User manual

BGS technic

BGS technic 8216 User manual

BGS technic

BGS technic PROFI User manual