BIFFI RPHD User manual

Table of contents

Other BIFFI Controllers manuals

BIFFI

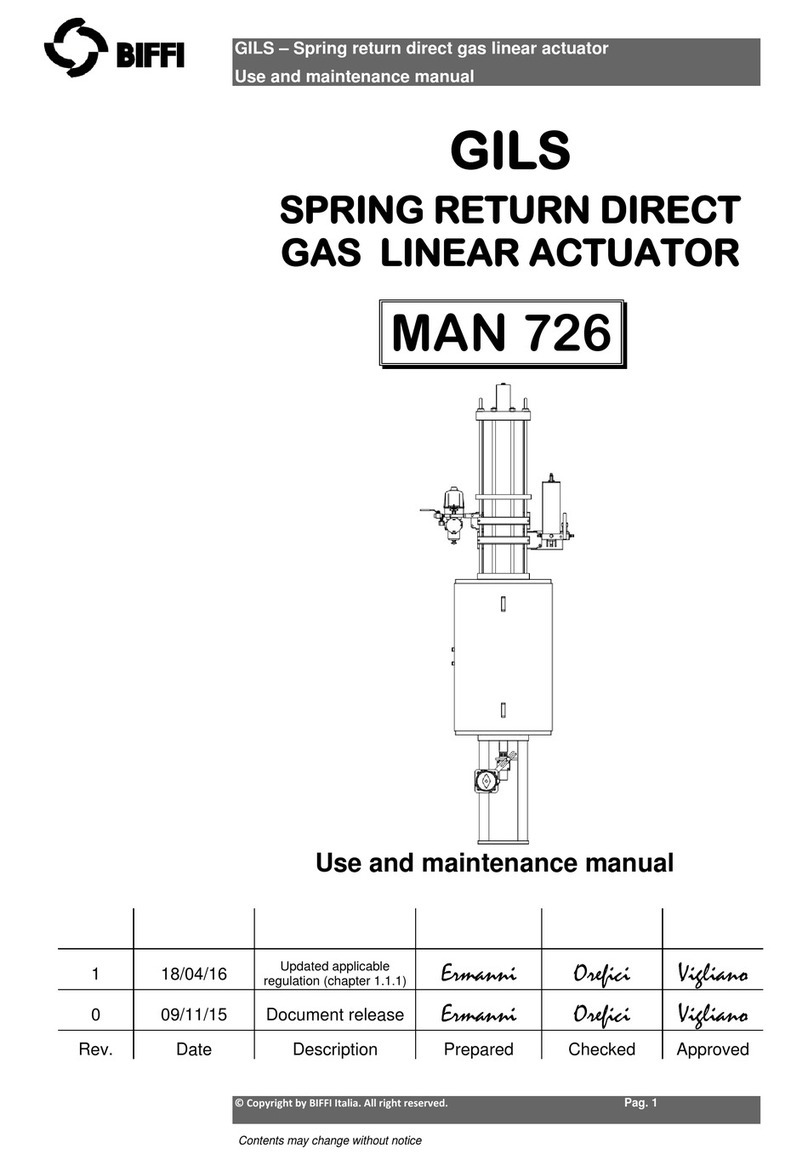

BIFFI GIGS Series User manual

BIFFI

BIFFI F01-2000 Parts list manual

BIFFI

BIFFI RP14 User manual

BIFFI

BIFFI EHO User manual

BIFFI

BIFFI ICON3000 Series Setup guide

BIFFI

BIFFI OLGAS-H User manual

BIFFI

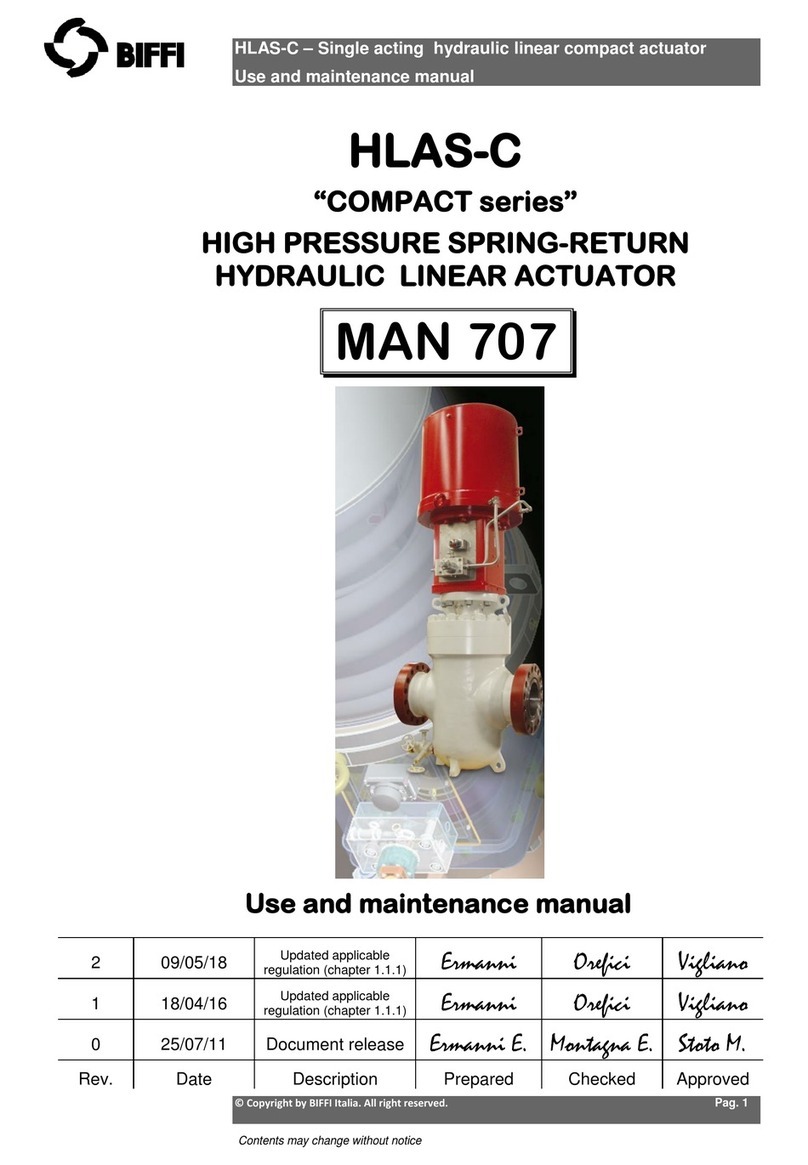

BIFFI HLAS User manual

BIFFI

BIFFI ALGAS User manual

BIFFI

BIFFI HLAS User manual

BIFFI

BIFFI ALGAS-QA Series Manual

BIFFI

BIFFI RPS Series User manual

BIFFI

BIFFI ALGA - EAC User manual

BIFFI

BIFFI COMPACT Series User manual

BIFFI

BIFFI HLA Series User manual

BIFFI

BIFFI RPD Series User manual

BIFFI

BIFFI OLGA-H User manual

BIFFI

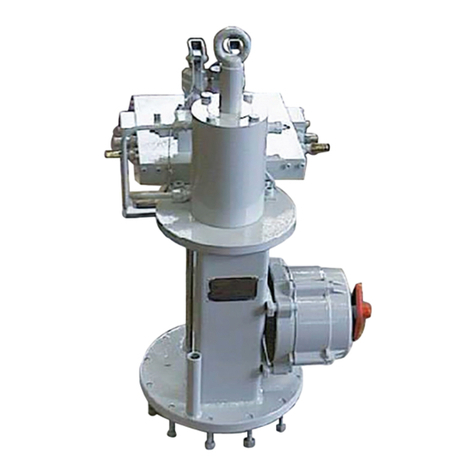

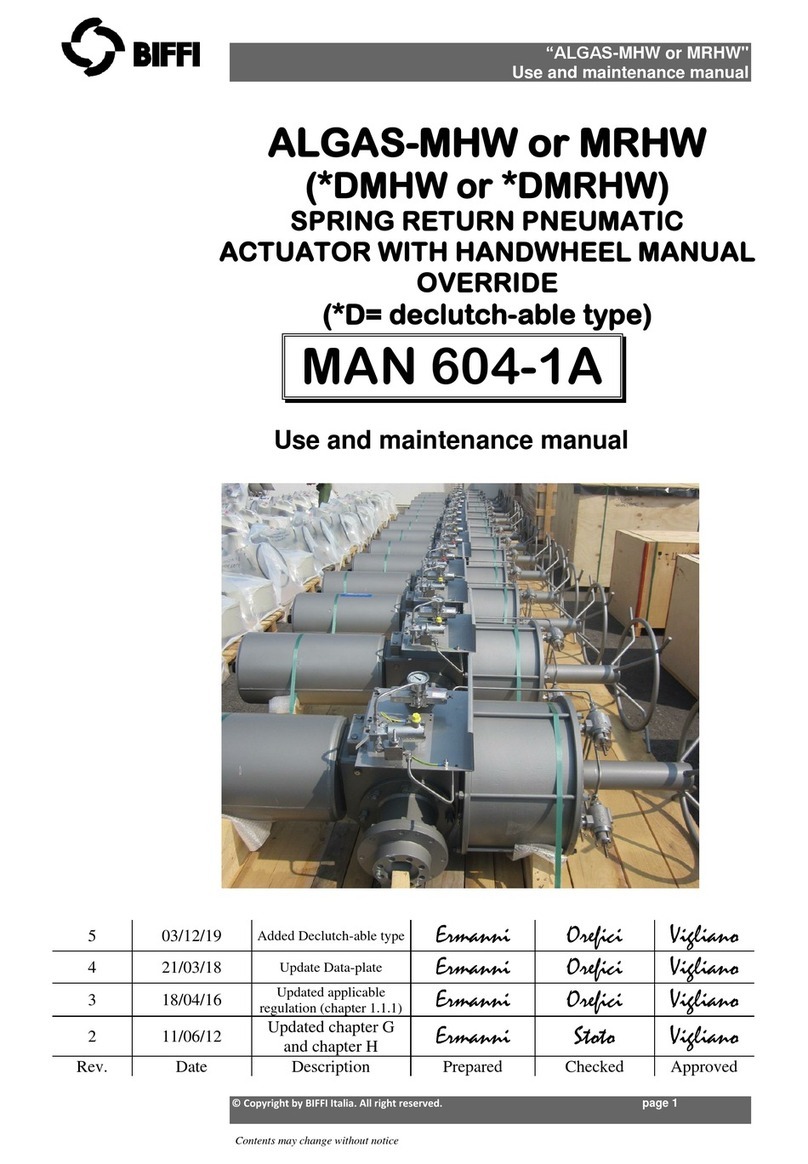

BIFFI ALGAS-MHW User manual

BIFFI

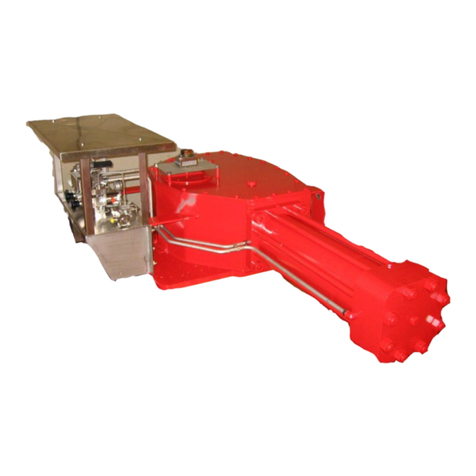

BIFFI ALGAS-MHP User manual

BIFFI

BIFFI RPHD-10 User manual

BIFFI

BIFFI ICON3000 Series User manual

Popular Controllers manuals by other brands

Logitech

Logitech TAP Setup guide

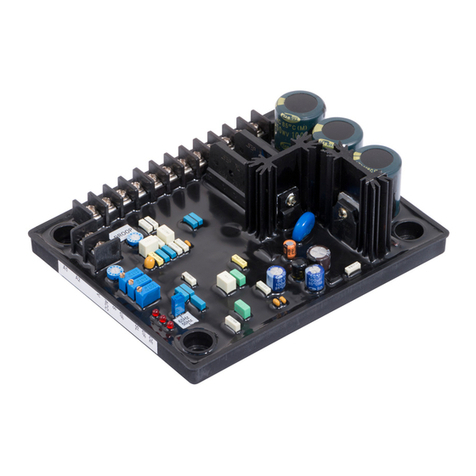

Leroy-Somer

Leroy-Somer Nidec R180 Installation and Maintenance

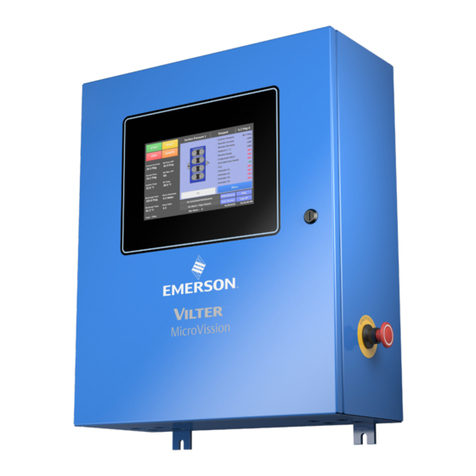

Emerson

Emerson Vilter MicroVission Operation and service manual

Desoutter

Desoutter ESP-CA 230 Original instructions

Danfoss

Danfoss MCX08M2 installation guide

Tridium

Tridium JACE-6 Series Mounting and wiring instructions

YASKAWA

YASKAWA YRC1000 Operator's manual

Derale Performance

Derale Performance 16795 installation instructions

oventrop

oventrop EnOcean Aktor MH CON B Installation and operating instructions

HEIDENHAIN

HEIDENHAIN ND 2100G - V2.59.0 Quick reference guide

Invertek

Invertek Optidrive VTC user guide

Bosch

Bosch AMC2 Series installation manual

Centork

Centork Centronik user manual

Siemens

Siemens SIRIUS 3RM1 manual

Emerson

Emerson AVENTICS 651 Series Installation and maintenance instructions

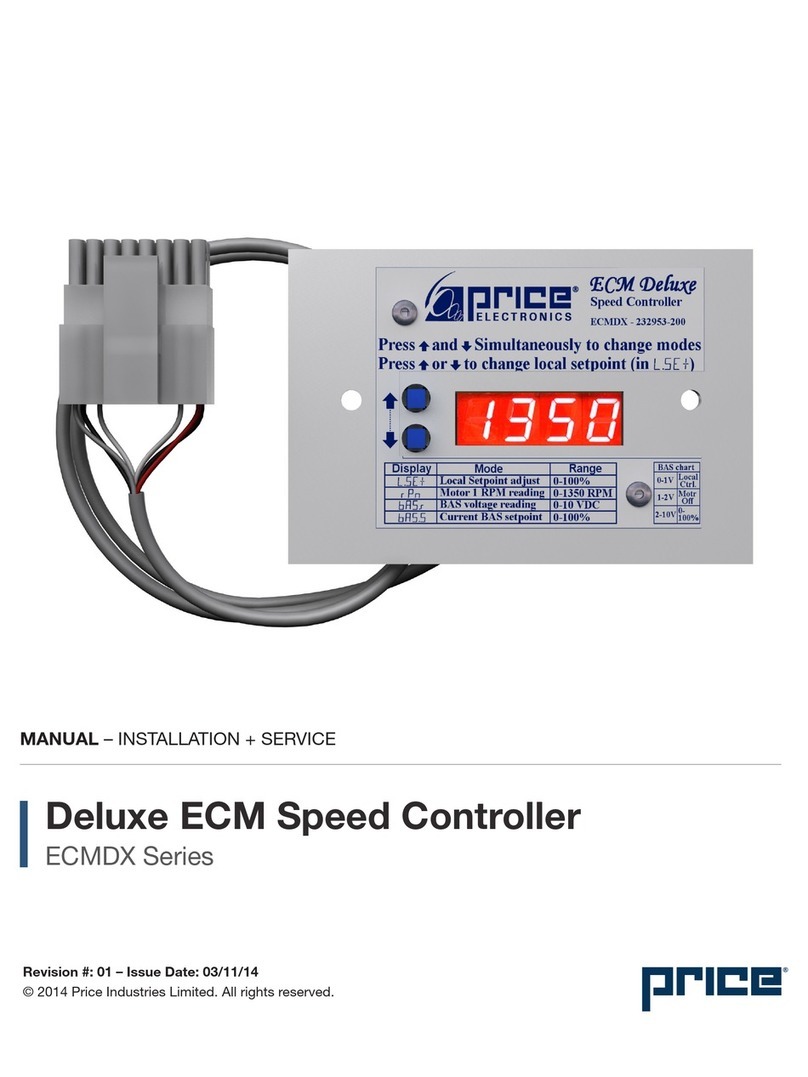

Price

Price ECMDX Series Installation and service manual

Moxa Technologies

Moxa Technologies ioPAC 8600 Series Quick installation guide

Erreka

Erreka VIVO-M203 Quick installation and programming guide