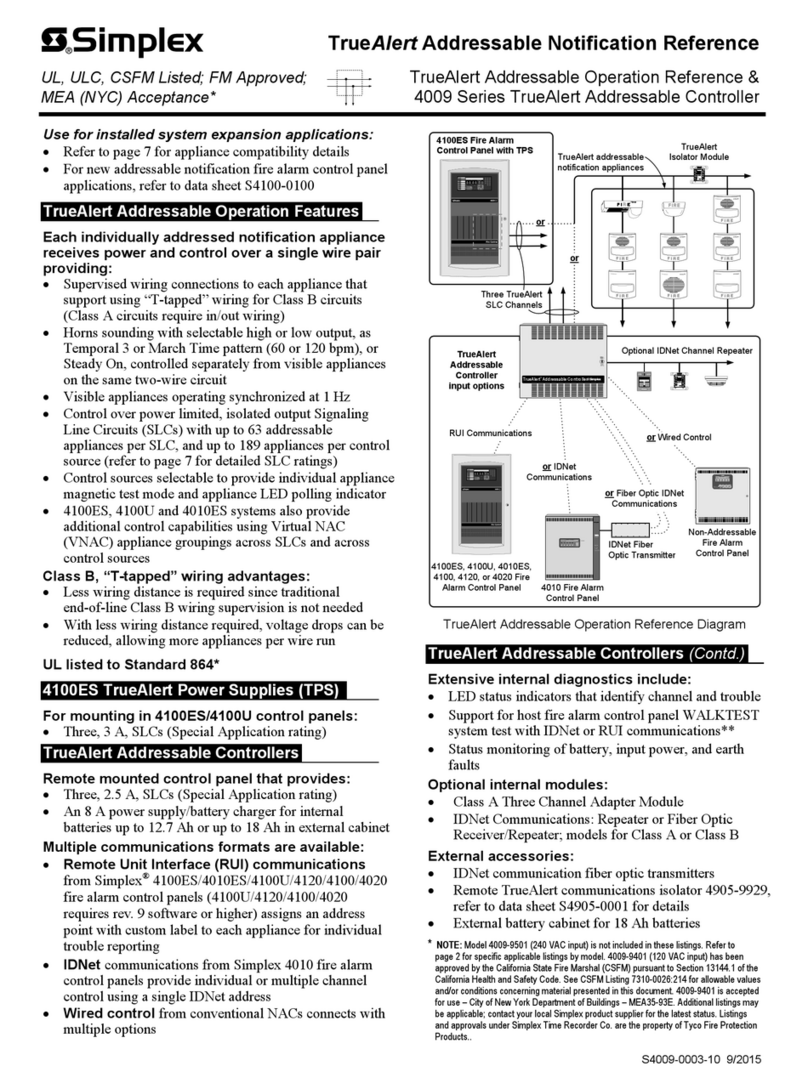

19

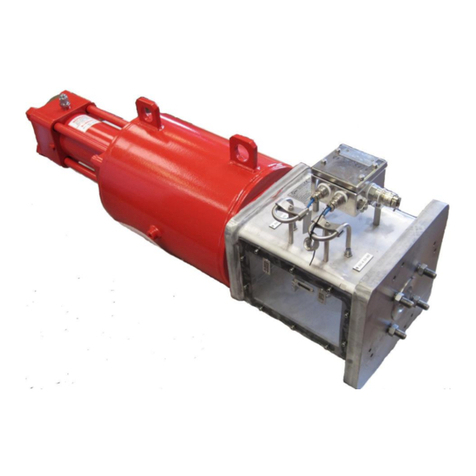

Replacement of seals for actuators with Biffi

manual hand-pump (see figure 27)

If there are leaks in the hydraulic cylinder or a

malfunction in the mechanical components, or

in case of scheduled preventive maintenance,

the actuator must be disassembled and

seals must be replaced with reference to the

sectional drawing and adopting the following

procedures:

1� Remove the nuts (item 16) and the washers

(item 15) from the tie rods (item 10) at the

end flange (item 13) side�

2� Slide off the end flange and the tube

(item12)�

3� Remove the screws (item 2-fig� 26) and the

cover (item 1-fig� 26)�

4� Unscrew the piston rod (item 6) threaded

end from the adaptor bush (item 32-fig� 26)

of guide block (item 14-fig� 26)�

5� Slide off the piston rod from the head flange

(item 2)�

6� Disassemble the head flange from the

mechanism housing (item 8-fig� 26) by

removing the screws (item 7- fig� 26) only

if the gasket (item 39-fig� 26) has to be

replaced because damaged�

Seals replacement

Prior to reassemble check that the actuator

components are in good conditions and clean�

Lubricate all the surfaces of the parts, which

move in contact with other components, by

recommended grease� If the O-ring must be

replaced, remove the existing one from its

groove, clean the groove carefully and lubricate

it with protective oil or grease film� Assemble

the new O-ring into its groove and lubricate it

with a protective oil or grease film�

1� Replace the O-rings (3) of the head flange

(2)�

2� Replace the O-ring (3) of the end flange (13)�

For replacement of piston rod seal ring (4) and

of the O-ring (5) proceed as follows:

1� Remove the existing PTFE seal ring (4) and

the O-ring (5) from their groove�

2� Clean the groove carefully and lubricate it

with a protective oil or grease film�

3� Assemble the new O-ring into its groove and

lubricate it with a protective oil or grease

film�

4� Assemble the new PTFE seal ring (4) into

the flange groove, on the rubber O-ring (5),

by bending it: take care that the bending

radius is as large as possible to avoid

damaged the seal� Then enlarge the seal

ring with your fingers so as to restore its

round shape: pay attention not to utilize any

tools, which can damage the seal ring�

To replace the piston dual-seal ring (9) proceed

as follows :

1� Remove the existing dual-seal ring (9) from

its groove�

2� Clean the groove carefully and lubricate it

with a protective oil or grease film�

3� Assemble the new dual-seal ring (9) by

introducing one side of it into the groove

and then enlarge it with your fingers so as

to introduce it into the groove: take care

to enlarge it uniformly without any tools

which could possibly damage it� The elastic

memory of the kind of PTFE type the seal

ring is made of allows the ring to shrink

back to its previous dimension after a short

time�

4� If the O-ring (17) has to be replaced,

measure the protrusion of the stop screw

(11) with reference to the end flange (13)

surface, so as to be able to easily restore

the setting of the actuator mechanical

stop in the open valve position, once

the maintenance procedures have been

completed�

5� Loosen the protection cover (14) and

unscrew the stop screw (11) until it is

removed�

6� Replace the O-ring (17) from the stop screw

cover (14)�

7� Screw the stop screw into the threaded hole

of the end flange until it reaches its original

position (the same protrusion with reference

to the flange surface)�

8� Tighten the protection cover (14)�

Reassemble

1� Assemble the new gasket (item 39-fig�26)

after cleaning the surfaces of housing

(item8-fig� 26) and head flange (item 2)

which are in contact�

2� Assemble the head flange and tighten the

screws (item 7- fig� 26) to the recommended

torque�

3� Clean and lubricate the piston rod (item 6)

surface, particularly that of the bevel, with

a protective oil or grease film and introduce

it into the head flange hole, taking care not

to damage the PTFE seal ring (item 4): the

piston rod bevel has to enlarge smoothly the

seal ring�

4� Carefully clean the threaded end of the

piston rod and the threaded hole of the

adaptor bush (item 32-fig� 26) of guide block

(item 14-fig� 26)� Spread some sealant

LOCTITE 452, or equivalent, on the rod

threaded end and screw into the adaptor

bush threaded hole and tighten�

5� Carefully clean the inside of the tube

(item12) and check that the entire surface,

particularly that of the bevels, is not

damaged� Lubricate with protective oil or

a grease film the tube inside surface and

the bevels at the ends� Slide the tube onto

the piston taking cares not to damaged the

dual-seal ring (item 9): the tube bevel has to

smoothly compress the seal ring�

6� Take care also not to damage the head

flange O-ring (item 3)�

7� Assemble the end flange (item 13) by

centring it on the inside diameter of the

tube, taking cares not to damage the O-ring

(item 3)�

8� Assemble the washers (item 15) and the

nuts (item 16) onto the tie rods (item 10)�

Tighten the nuts to the recommended

torque, alternating between opposite

corners�

9� Restore a generous coating of grease on

the contact surfaces of the yoke (item 11-

fig� 26) and the bushings (item 13-fig� 26),

on the yoke grooves, on the sliding blocks

(item5-fig� 26), on guide bar (item 9-fig� 26)�

10� Assemble the new gasket (item 39-fig� 26)

after cleaning the surfaces of the housing

(item 8-fig� 26) and cover (item 1-fig� 26)

11� Lubricate with protective oil or grease the

O-ring (item 34-fig� 26)�

12� Assemble the cover (item 1-fig� 26) and the

screws (item 2-fig� 26)� Tighten the screws

to the recommended torque�

IMPORTANT

AFTER MAINTENANCE OPERATIONS CARRY OUT

A FEW ACTUATOR OPERATIONS TO CHECK THAT

ITS MOVEMENT IS REGULAR AND THAT THERE

IS NO AIR LEAKAGE THROUGH THE SEALS.

BIFFI OLGA-H HIGH PRESSURE DOUBLE ACTING HYDRAULIC ACTUATOR

INSTALLATION, OPERATION AND MAINTENANCE MANUAL