i

Installation, Operation and Maintenance Manual

VCIOM-15345-EN Rev. 1

Table of Contents

February 2022

Table of Contents

Table of Contents

Section 1: Introduction

1.1 Scope............................................................................................................ 1

1.2 General Information...................................................................................... 1

1.3 Safety Information ........................................................................................ 3

1.4 Abbreviation Denitions ............................................................................... 4

Section 2: Installation

2.1 Preparation ................................................................................................... 5

2.2 Valve Preparation.......................................................................................... 6

2.3 Actuator Preparation..................................................................................... 6

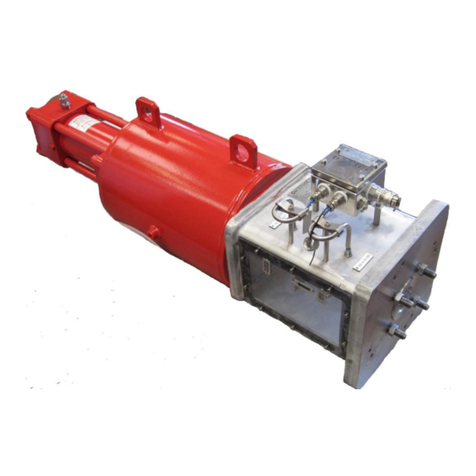

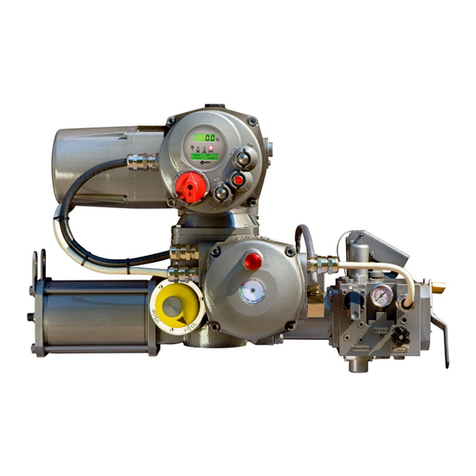

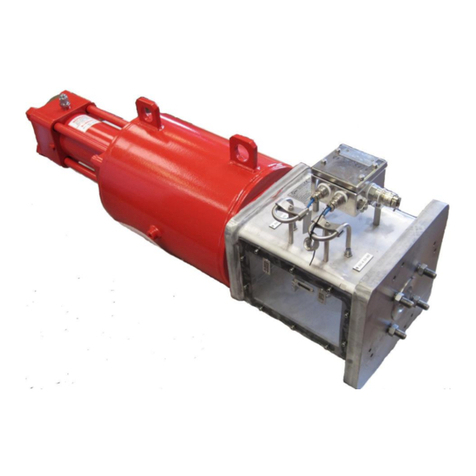

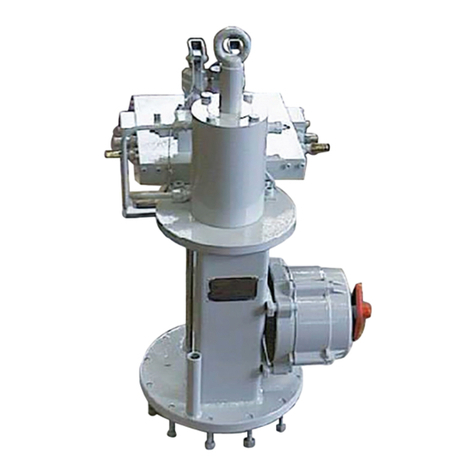

2.4 Lifting the Bif EHO Actuator ........................................................................ 7

2.5 Installing the Bif EHO Actuator on the Valve .............................................. 10

2.6 Setting the Stroke Limit Stops ..................................................................... 11

2.7 Hydraulic Fluid ............................................................................................ 12

2.8 Accumulator (Optional) .............................................................................. 13

Section 3: Electrical Connections

3.1 Remove Separate Terminal Chamber (STC) Cover........................................ 18

3.2 Sealing Cable/Conduit Entries ..................................................................... 19

3.3 Recommended Terminal Connections......................................................... 19

3.4 Separate Terminal Chamber (STC) Connections........................................... 20

3.5 Replace Terminal Chamber Cover ................................................................ 20

3.6 External Earth/Ground Connections............................................................ 20

3.7 Discrete Controlled Inputs Connection........................................................ 21

Section 4: Set-up/Start-up Procedure

4.1 Preparation ................................................................................................. 23

4.2 Initial Check of the Unit............................................................................... 24

4.3 Initial Connections ...................................................................................... 24

4.4 Handpump Operation................................................................................. 24

4.5 Hydraulic Test ............................................................................................. 25

4.6 Check Rotation ........................................................................................... 26

4.7 Self-Calibration ........................................................................................... 27

4.8 Limit Switch Adjustment (Optional) ............................................................ 28

4.9 Function Test with Local Controls................................................................ 31

4.10 Other Options............................................................................................. 32

Section 5: Communication Protocols

5.1 Modbus RTU ............................................................................................... 33

5.2 HART .......................................................................................................... 35

5.3 FOUNDATION™ Fieldbus............................................................................. 36