EC DECLARATION OF CONFORMITY

Manufactured By: DeVilbiss Ransburg de Mexico S. de R.L. de C.V

Via Gustavo Baz #3990, Col.Barientos

C.P.54110 Tlalnepantla, Estado de Mexico.

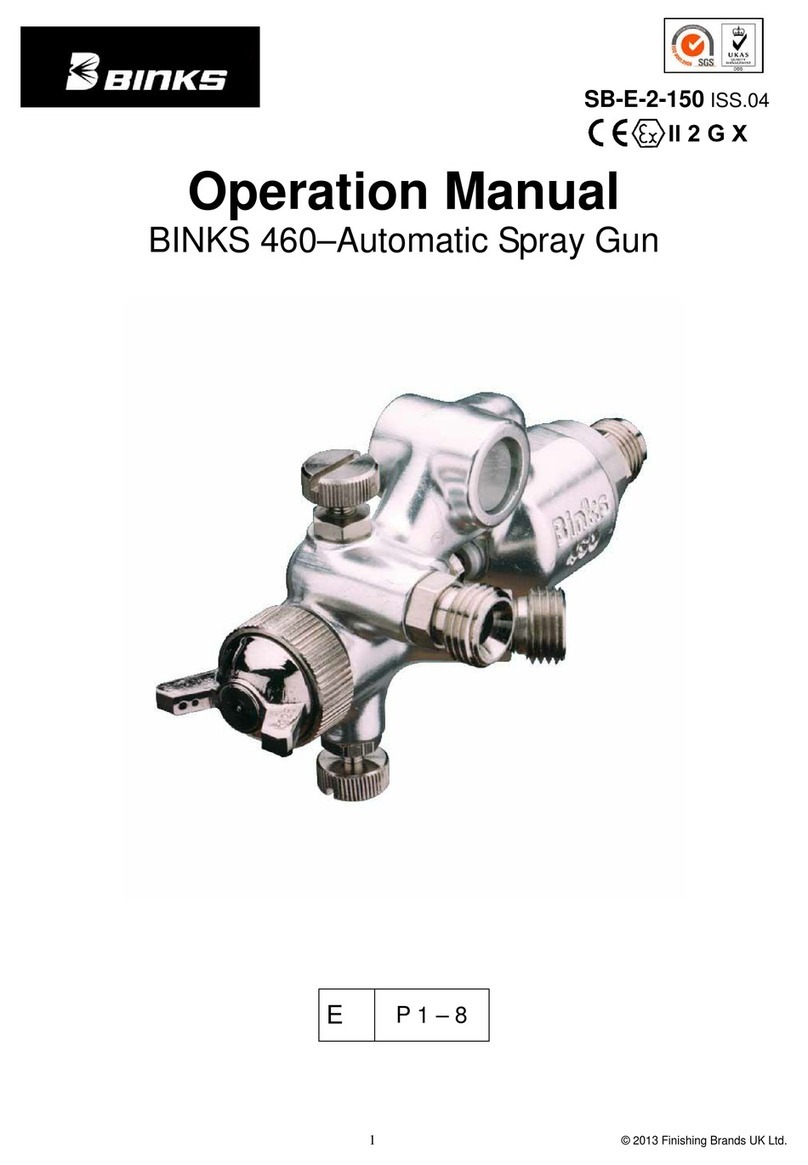

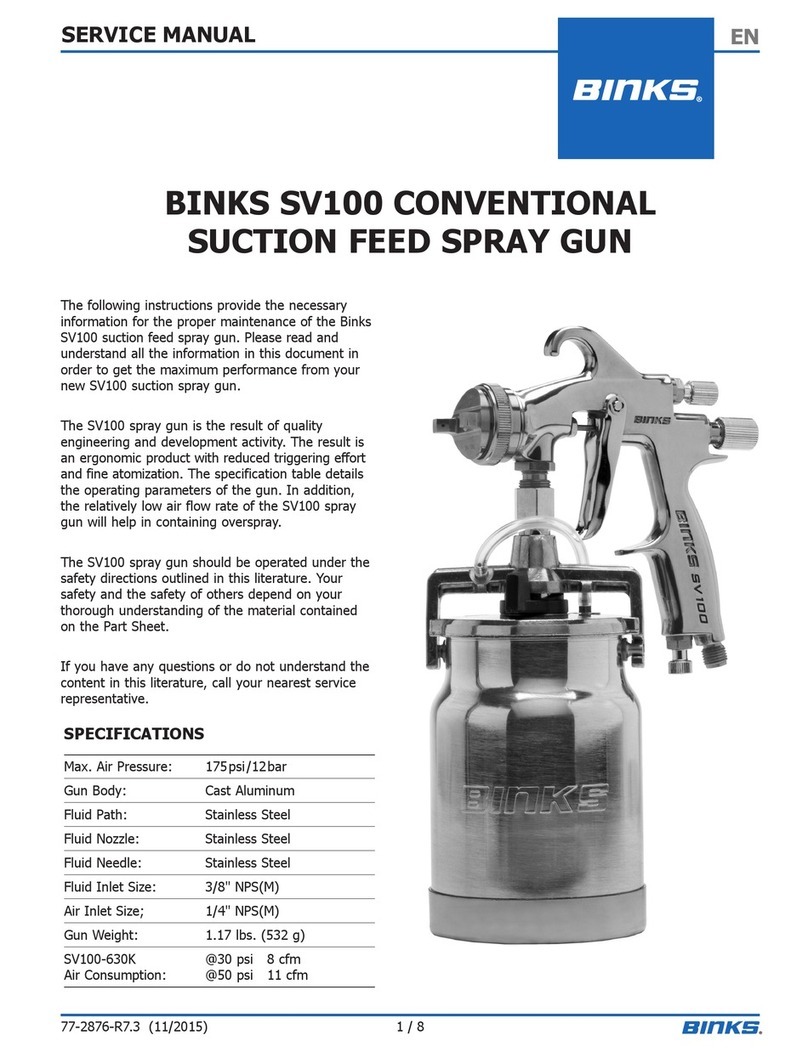

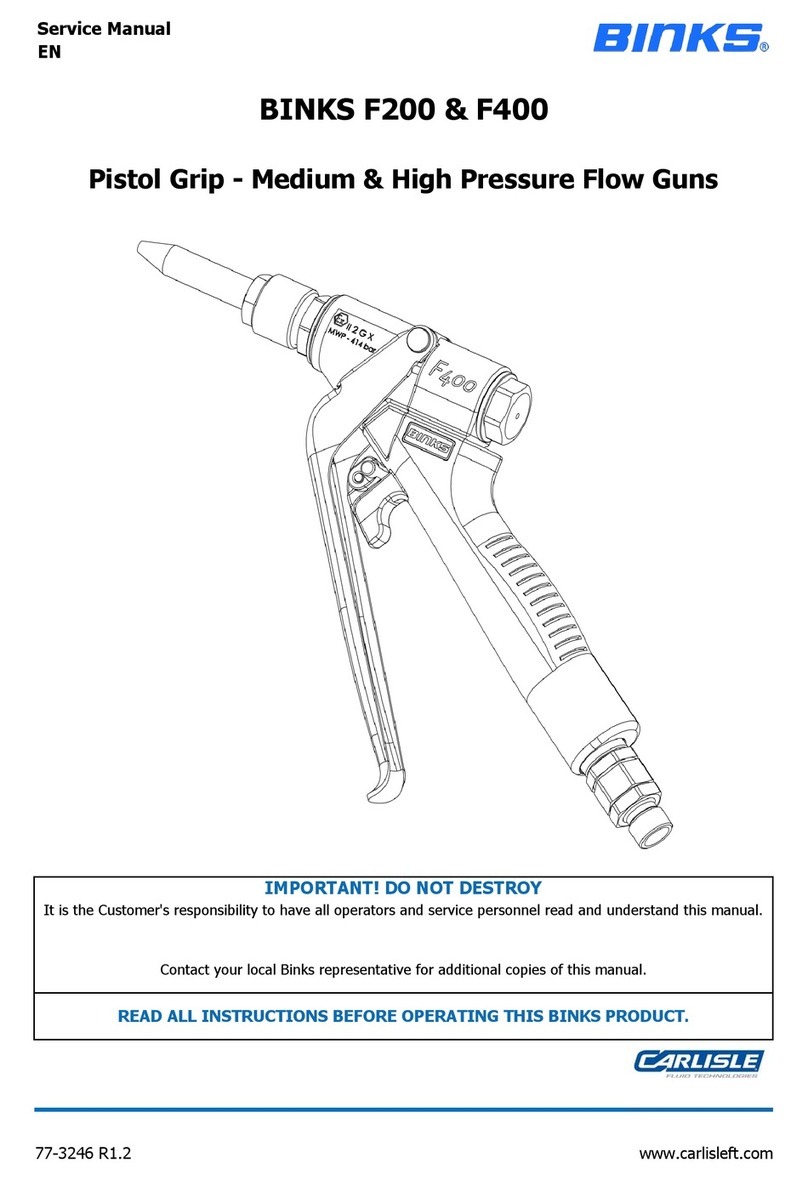

Type/Series: Handheld Spray Guns

Model: Binks “EMG SeriesTM”

The equipment to which this document relates is in conformance with the following standards or other

normative references:

BS EN 12100:2010 and BS EN 1953:2013; and thereby conform to the protection

requirements of Council Directive 2006/42/EC relating to Machinery Safety Directive, and;

EN 13463-1:2009, Council Directive 94/9/EC relating to Equipment and Protective Systems

intended for use in Potentially Explosive Atmospheres protection level II 2 G X.

Approved By: Gerardo Perez Carpy (General Manager)

Date: 11th December 2013

KNOW WHERE AND HOW TO SHUT OFF THE

EQUIPMENT IN CASE OF AN EMERGENCY

PRESSURE RELIEF PROCEDURE

Always follow the pressure relief procedure in the equipment

instruction manual.

NEVER MODIFY THE EQUIPMENT

Do not modify the equipment unless the manufacturer provides

The spray gun must be earthed to dissipate any electrostatic

charges which may be created by fluid or air flows. This can

be achieved through the spray gun mounting, or conductive

air/fluid hoses. Electrical bond from the spray gun to earth

should be checked with an Ohm meter. A resistance of less

than 106Ohms is recommended.

You may be injured by loud noise. Hearing protection may be

required when using this equipment.

PROP 65 WARNING

WARNING: This product contains chemicals known to the State

of California to cause cancer and birth defects or other

FIRE AND EXPLOSION HAZARD

Never use 1,1,1-trichloroethane, methylene chloride, other halogenated

hydrocarbon solvents or fluids containing such solvents in equipment with

aluminium wetted parts. Such use could result in a serious chemical reaction,

with the possibility of explosion. Consult your fluid suppliers to ensure that the

fluids being used are compatible with aluminium parts.