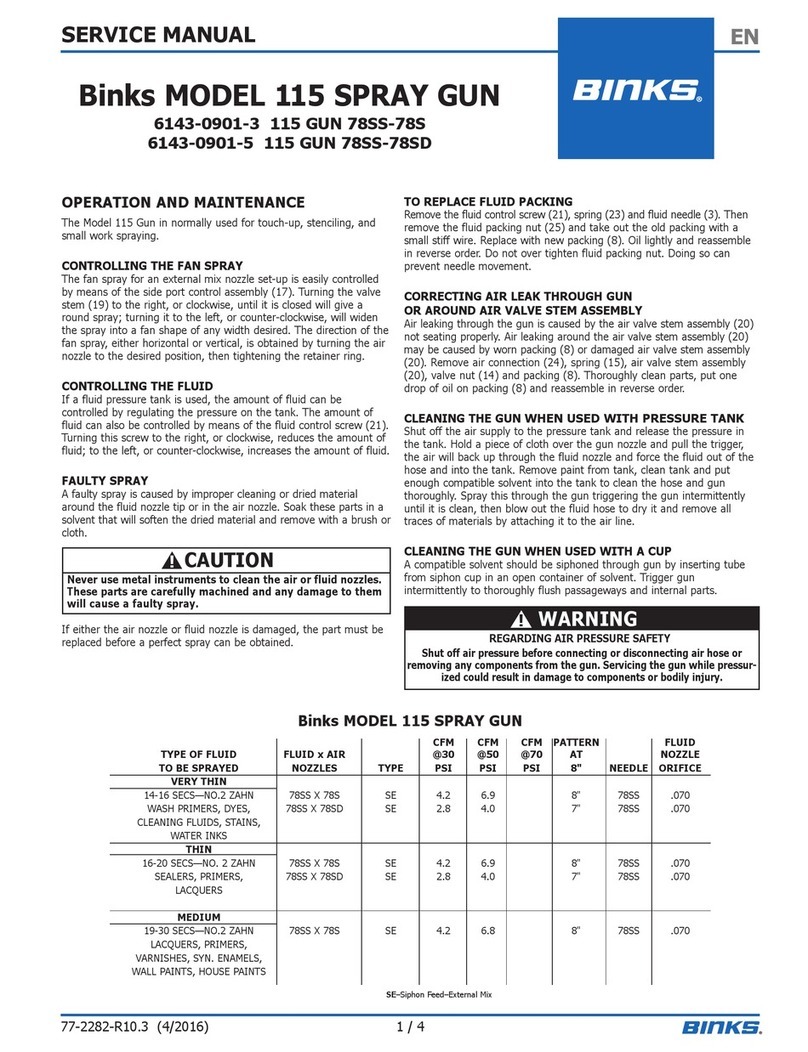

2

INJECTION HAZARD

1. The Mavrick gun is capable of spraying

coatings at high pressure. If you spray

yourself or anyone else at close range, the

stream of material can puncture the skin and

cause great harm (possible amputation).

2. NEVER point the gun at yourself or anyone

else. NEVER point the gun at your hands,

fingers, or body. ALWAYS keep the gun

trigger safety catch locked in the OFF

position when not in use.

3. DO NOT cover the tip and attempt to "blow

back" fluid. This is not an air sprayer.

4. If injury occurs, see your doctor

immediately! DO NOT TREAT THIS AS A

SIMPLE CUT. Inform your doctor

specifically of what fluid was injected.

AVOID STATIC SPARKING

Static electricity charge builds up by high

velocity liquid flowing through a hose during

flushing, cleaning, or spraying operations.

Proper grounding of the airless system safely

dissipates this charge.

GROUNDING THE PUMP

Installation of the ground wire attachment to a

metallic portion of the pump must insure a

secure metal-to-metal contact. The ground wire

must be 12 gauge minimum. A clamp must be

attached to a true earth ground and an

instrument test must be done to verify a

ground. Mounting is the user’s responsibility.

All high pressure airless systems must be

grounded to avoid dangerous static sparking,

explosion, or fire when spraying or flushing

with flammable liquids.

1. Use Binks NO-WIRE conductive hose in all

airless spraying operations. Be sure the gun

and hose have continuity. Check continuity

weekly with ohmmeter. Overall (end to end)

resistance of un-pressurized hose must not

exceed 29 mega ohms (max.) for any

coupled length or combination of hose

lengths.

2. Make sure the pump is grounded. NEVER

operate the unit when it is on a non-

grounded platform.

3. When flushing or cleaning with a

combustible solvent, always use an open

metallic container for receiving the waste

solvent. Ground the solvent receptacle.

4. Bond the spray gun to the waste container

with a grounding wire. Be sure there is good

metal to metal contact.

5. ALWAYS remove spray tip when flushing

the system. Operate the pump at the lowest

possible pressure.

PERSONAL SAFETY

CONSIDERATIONS

1. NEVER leave a pressurized sprayer

unattended.

2. DO NOT use fluids, coatings, or chemicals

which are not compatible with nylon hoses.

3. Periodically inspect all hoses for leaks and/

or abrasions and tighten all connections

before use. DO NOT ATTEMPT TO

REPAIR a defective hose. REPLACE it

with another conductive hose.

4. Follow all warnings and precautions of the

coating and solvent manufacturers.

5. ALWAYS relieve pressure in the system by

turning bypass valve to BYPASS or

triggering spray gun before disassembly of

any component parts.

6. Exhausting air from a motor cycling with the

mufflers removed can exceed OSHA limits.

Thus, never operate the pump without proper

muffling.

7. NEVER attempt to loosen or remove fluid

hoses, or to disassemble the pump without

first performing the pressure relief procedure

as listed in the pumping equipment part sheet.

8. NEVER perform any disassembly procedure

unless the air motor air supply has been

turned off, the residual air has been

exhausted, and pressure in the air motor and

fluid ends have been relieved. Should air

pressure remain within the motor chamber,

the motor could cycle at any time.

9. Keep hands and fingers clear of the pump

manifold fluid inlet and the individual inlets.

The powerful suction can cause serious

bodily injury, and any breaks in the skin can

allow exposure to the chemicals in the

formulation being pumped.

10. Pressure relief procedure must be followed

whenever the pump is shut-off for cleaning,

servicing, or repairing any part of the air or

fluid system. This includes removing or

installing or cleaning spray gun tips or

nozzles. See the pressure relief procedure

in the pumping equipment part sheet.

REPLACEMENT PARTS

The spray gun is designed to use authorized

parts only. When using this gun with parts that

do not comply with the minimum specifications

and safety devices of Binks, the user assumes

all risks and liabilities.

Warning

HIGH PRESSURE CAN CAUSE SERIOUS INJURY IF EQUIPMENT IS INSTALLED OR USED INCORRECTLY—

REAd, UNdERSTANd, ANd ObSERVE ALL WARNINGS AND INSTRUCTIONS IN THIS MANUAL.

FOR GENERAL SAFETY INFORMATION CONCERNING BINKS EQUIPMENT, SEE SAFETY BOOKLET 5300.

INSTALL, OPERATE OR SERVICE THIS EQUIPMENT ONLY AFTER

ALL INSTRUCTIONS ARE CLEARLY UNDERSTOOD.

It is the responsibility of the employer to place this information into the hands of the operator.

!

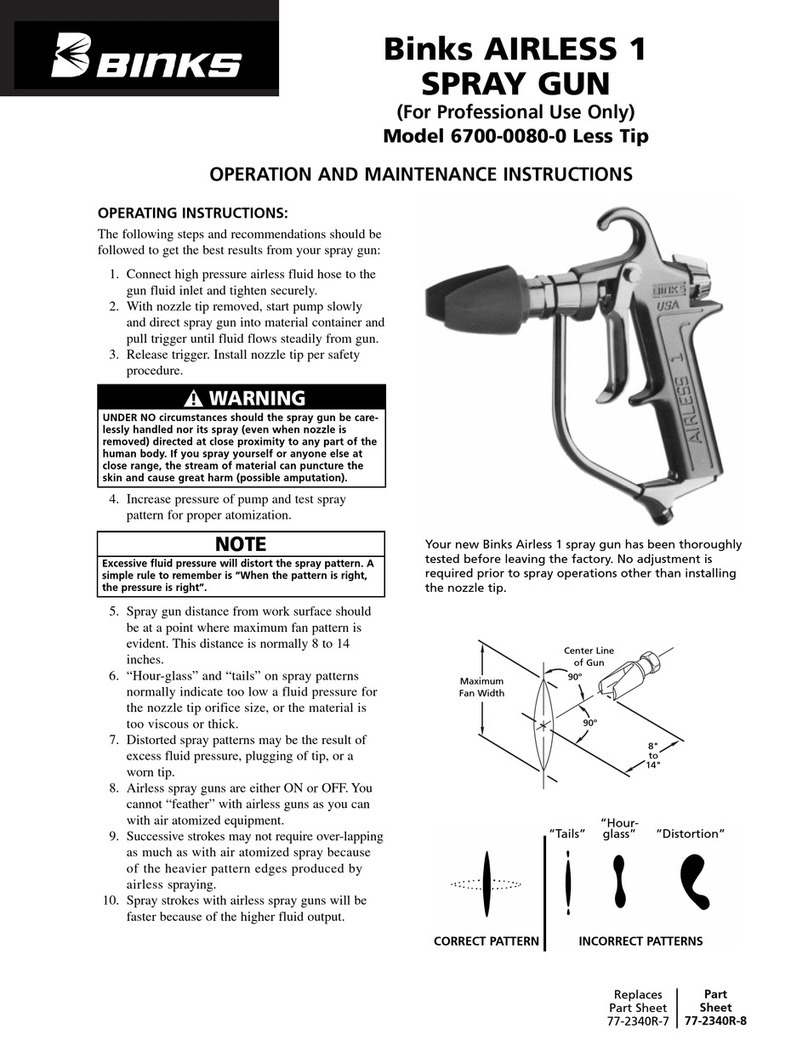

Bonding Wire,

Gun To Solvent Container

Conductive Hose

To Airless Pump

Open

Metallic

Waste Solvent

Container,

Grounded

CAUTION

Hazards or unsafe practices which could

result in minor personal injury, product

or property damage.

!

WARNING

Hazards or unsafe practices which could

result in severe personal injury, death or

substantial property damage.

!

NOTE

Important installation, operation or

maintenance information.

CA PROP

65

PROP 65 WARNING

WARNING: This product contains

chemicals known to the State of

California to cause cancer and birth

defects or other reproductive harm.