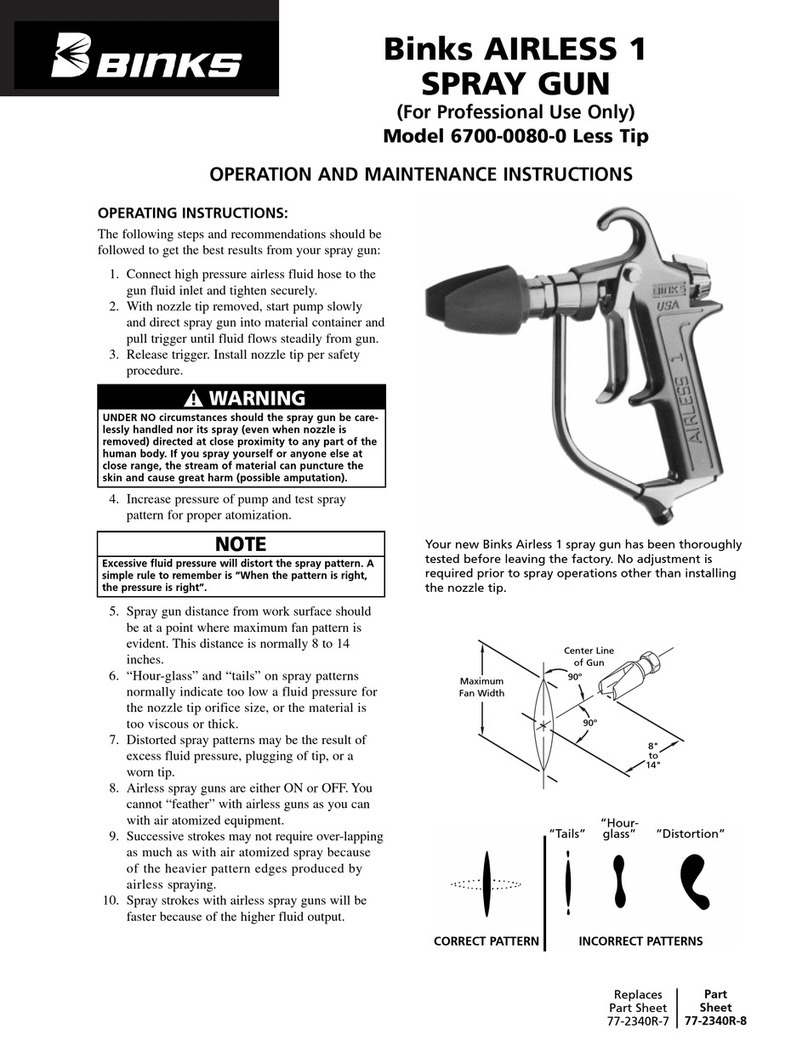

Binks 80-228 User manual

Other Binks Paint Sprayer manuals

Binks

Binks 95SL User manual

Binks

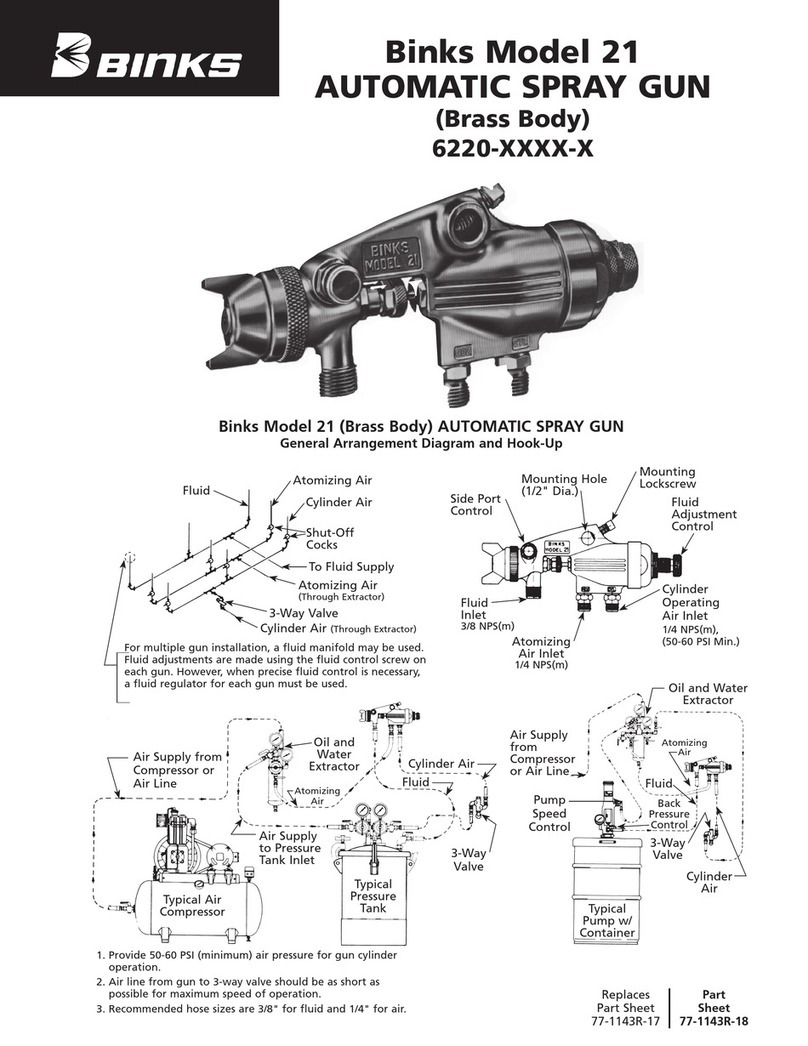

Binks 21 User manual

Binks

Binks Airless 75 User manual

Binks

Binks HVLP 2001 Installation guide

Binks

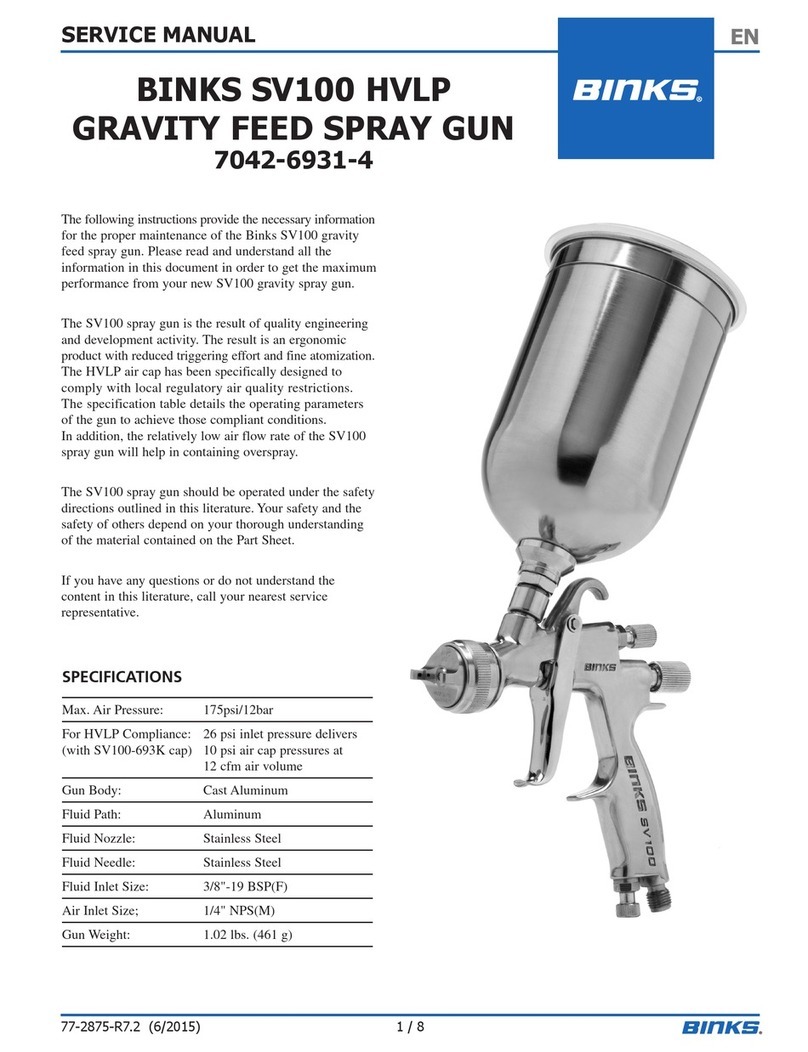

Binks 7042-6931-4 User manual

Binks

Binks TROPHY SERIES User manual

Binks

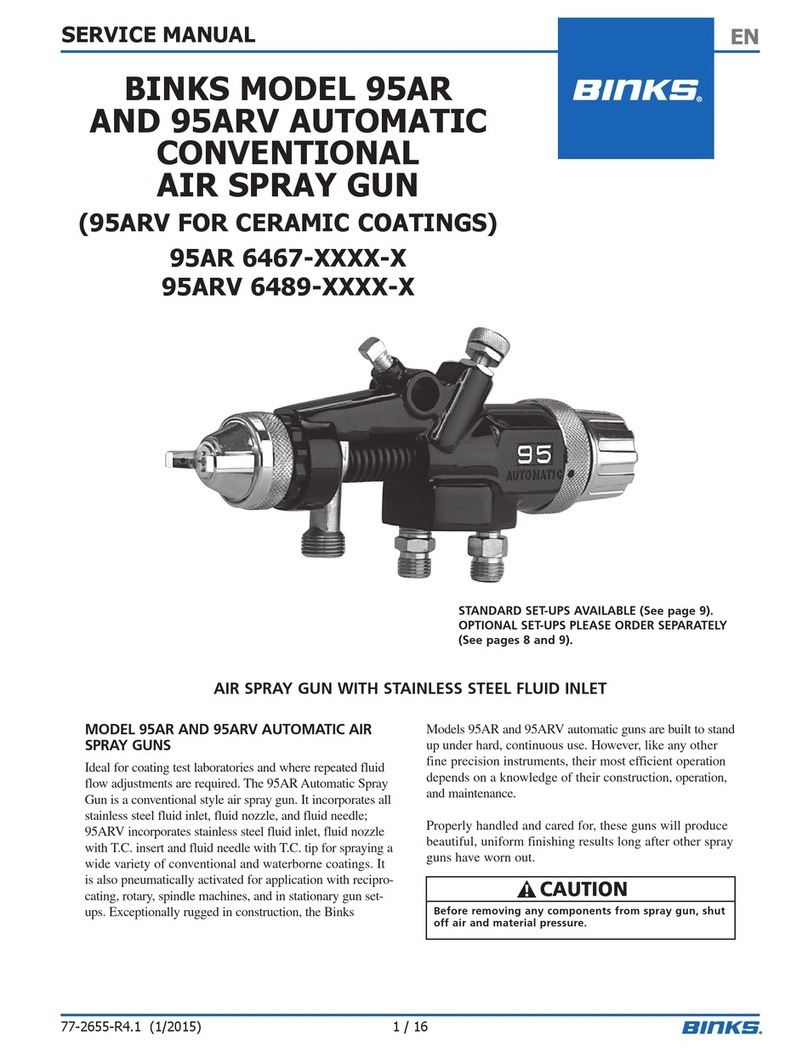

Binks 95AR User manual

Binks

Binks MACH 1AR HVLP User manual

Binks

Binks TROPHY 2465 Series User manual

Binks

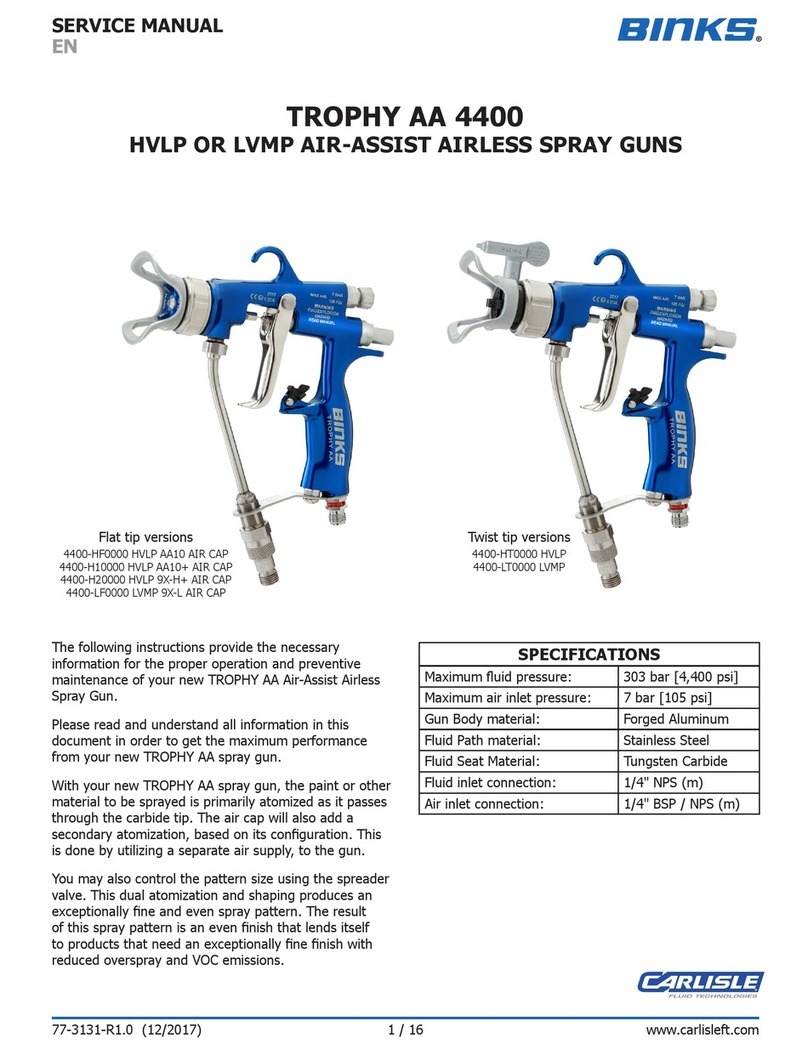

Binks 400-HF0000 HVLP AA10 AIR CAP User manual

Binks

Binks HAP 50 Series User manual

Binks

Binks 7N User manual

Binks

Binks TROPHY SERIES User manual

Binks

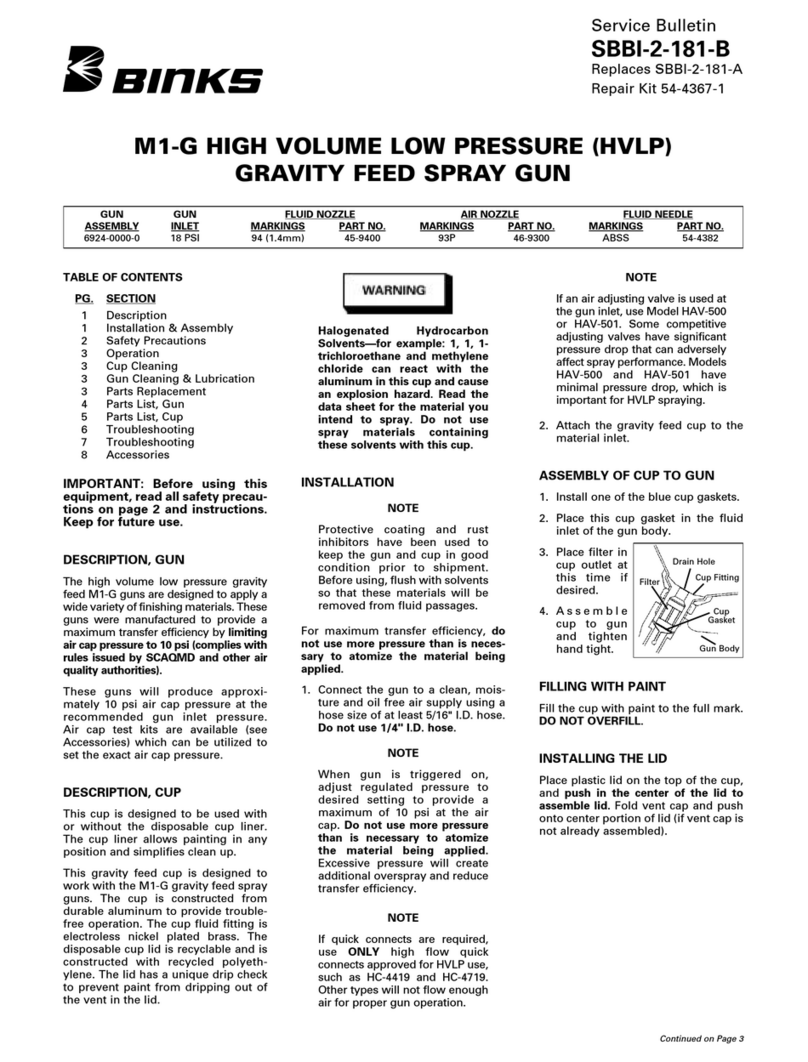

Binks M1-G HVLP Reference manual

Binks

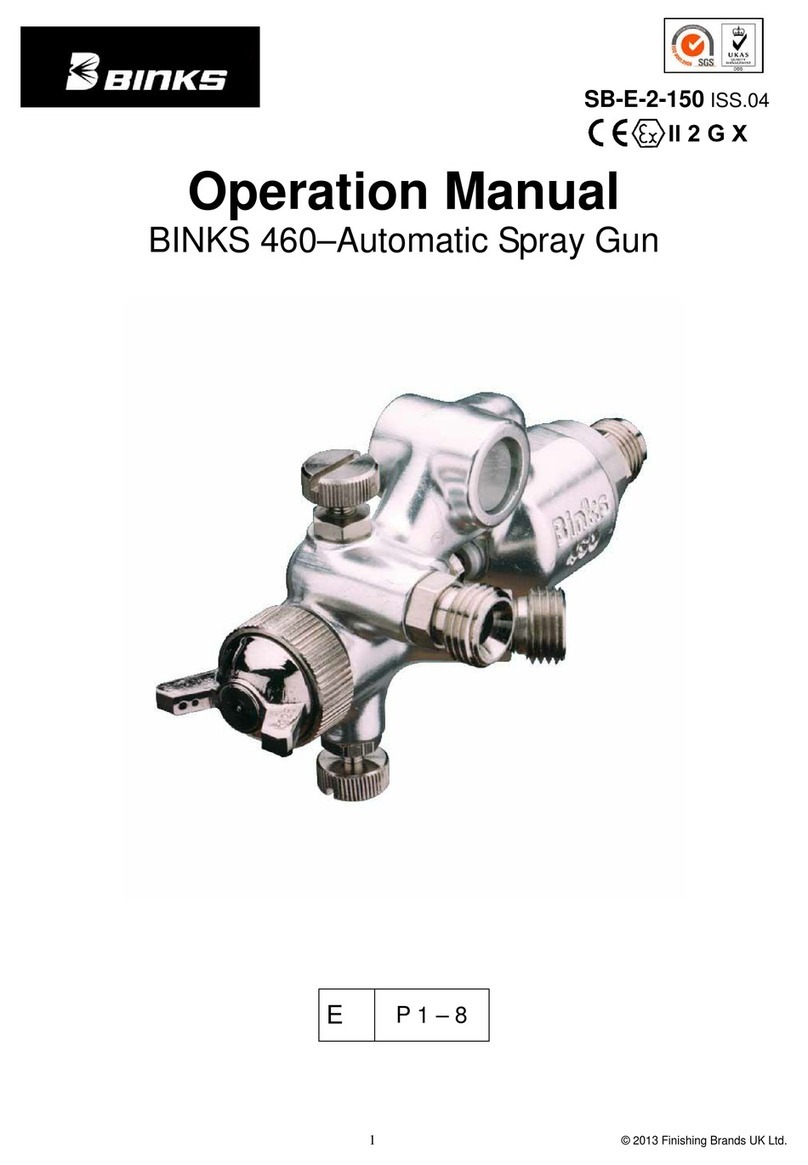

Binks 460 User manual

Binks

Binks TROPHY AA 4400 User manual

Binks

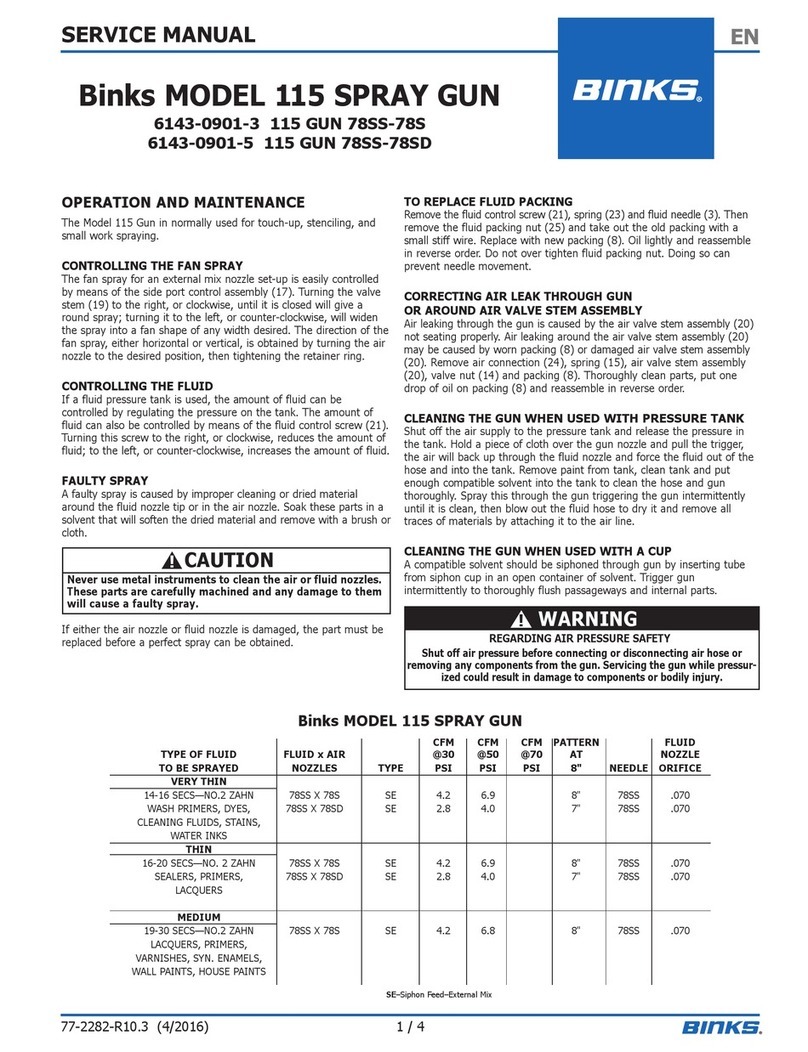

Binks Model 115 User manual

Binks

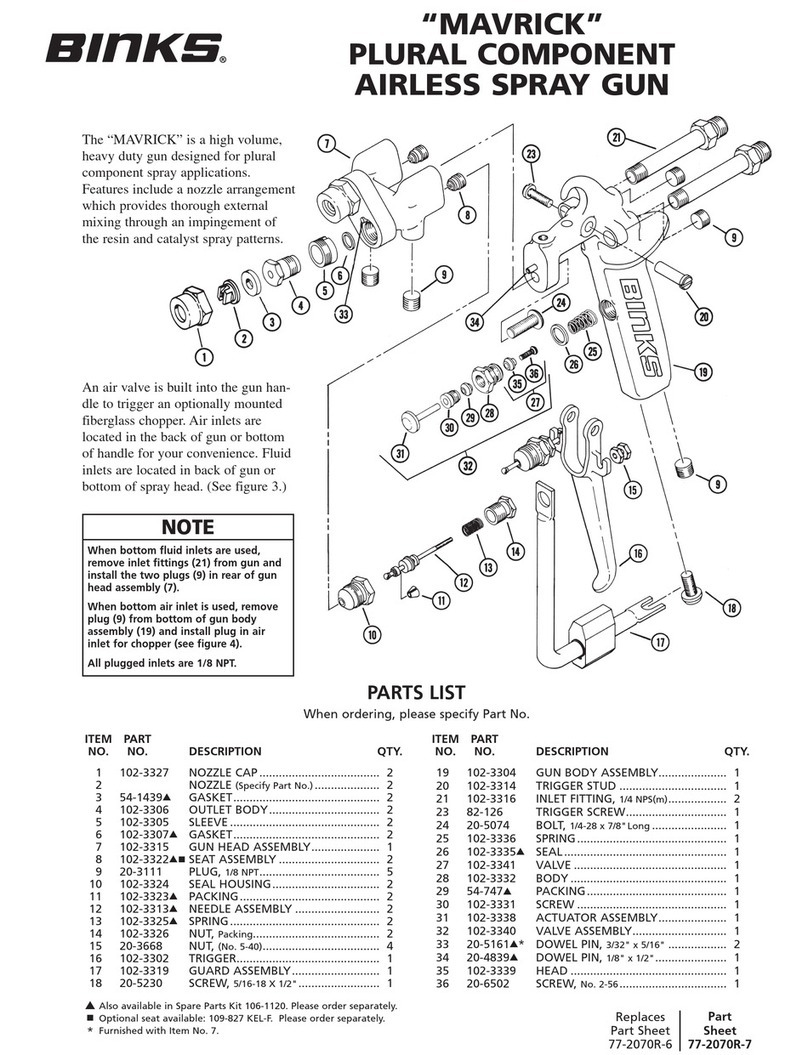

Binks MAVRICK User manual

Binks

Binks 2100 gw User manual

Binks

Binks SG-2 PLUS 80-600 User manual

Popular Paint Sprayer manuals by other brands

KISANKRAFT

KISANKRAFT KK-KBS-165 Operation manual

Matrix

Matrix SG 650 Translation of the original instructions

Anest Iwata

Anest Iwata SGA-3 Installation, use & maintenance instruction manual

paasche

paasche VV Instructions and parts list

Carlisle

Carlisle DeVilbiss JGA-510 Service manual

Gardena

Gardena 11120 Operator's manual