BioSure EOS8131-CL User manual

INSTALLATION & OPERATION MANUAL

Model: EOS8131-CL [G3]

EOS8132-CL [G6]

EOS8134-CL [G9]

Thank you for purchasing BioSure Professional product

Please read the instructions carefully and follow the safety precautions when using this

product.

General Information

2

Installation

7

Operation

12

Maintenance

20

Troubleshooting

24

1

4

2

5

3

The illustrations used in this Instruction Manual may vary from the actual

product that you have purchased.

EOS816X-ENG_V1.0

Table of Contents

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

Read this manual completely before attempting installation, operation or servicing.

•Follow all applicable electrical codes.

•Electric shock hazard. Be sure to turn power OFF before servicing. Failure to do so

could result in serious injury or death.

•Do not operate with any panels or covers removed.

•Hazardous levels of ozone may be trapped in the system after a fault condition or when

power is turned off during operation. Always ensure ozone has been purged by allowing

Ozone Generator to complete its shutdown sequence before servicing.

•Short term inhalation of high concentrations of ozone and long term inhalation of low

concentrations of ozone can cause serious harmful physiological effects. DO NOT inhale

ozone gas produced by this device.

•Do not store or use gasoline, chemicals or other flammable liquids or vapors near this or

any other appliance.

SAVE THESE INSTRUCTIONS

CAUTIONS AND GENERAL NOTES

This manual covers all BioSure Professional G Series Electrolytic Ozone Generators,

Models G-3/6/9.

Any variations in system operation or configuration between models are noted in the text.

BioSure Professional reserves the right to make changes to the product covered in this

manual. Use this manual only with its original product. Although every effort has been

made to ensure accuracy of the information contained in this manual, BioSure

Professional assumes no responsibility for inadvertent errors.

WARRANTY SUMMARY

•Two (2) years on entire Ozone Generator.

•One (1) year on replacement parts.

•To prevent voiding warranty, follow all installation instructions and ensure that an

authorized BioSure Professional technician has commissioned the unit prior to first start-

up. After commissioning, the end user is responsible for all routine maintenance outlined

in Section 4 of this manual.

1

1.1 Production Description

The G series Ozone Generators described in this manual applies BioSure Professional’s

Indirect Electrolytic Ozone Generation (iEOG) technology to generate ozone gas in high

concentrations. This advanced ozone technology enables ozone to be formed steadily

from water with NOx-free and 28wt% high purity results. They are designed to support

modular application so that they can be easily integrated into all types of systems for

ozone applications.

The G series systems contain all elements necessary for the production ozone

electrolytically from municipally treated and filtered tap water. They are designed to

operate under vacuum, typically engaging with suction provided by a self-priming mixing

pump or venturi injector in a side stream of the process flow.

Follow the instructions in this manual carefully to ensure safe and reliable operation of the

G Series Ozone Generator Systems.

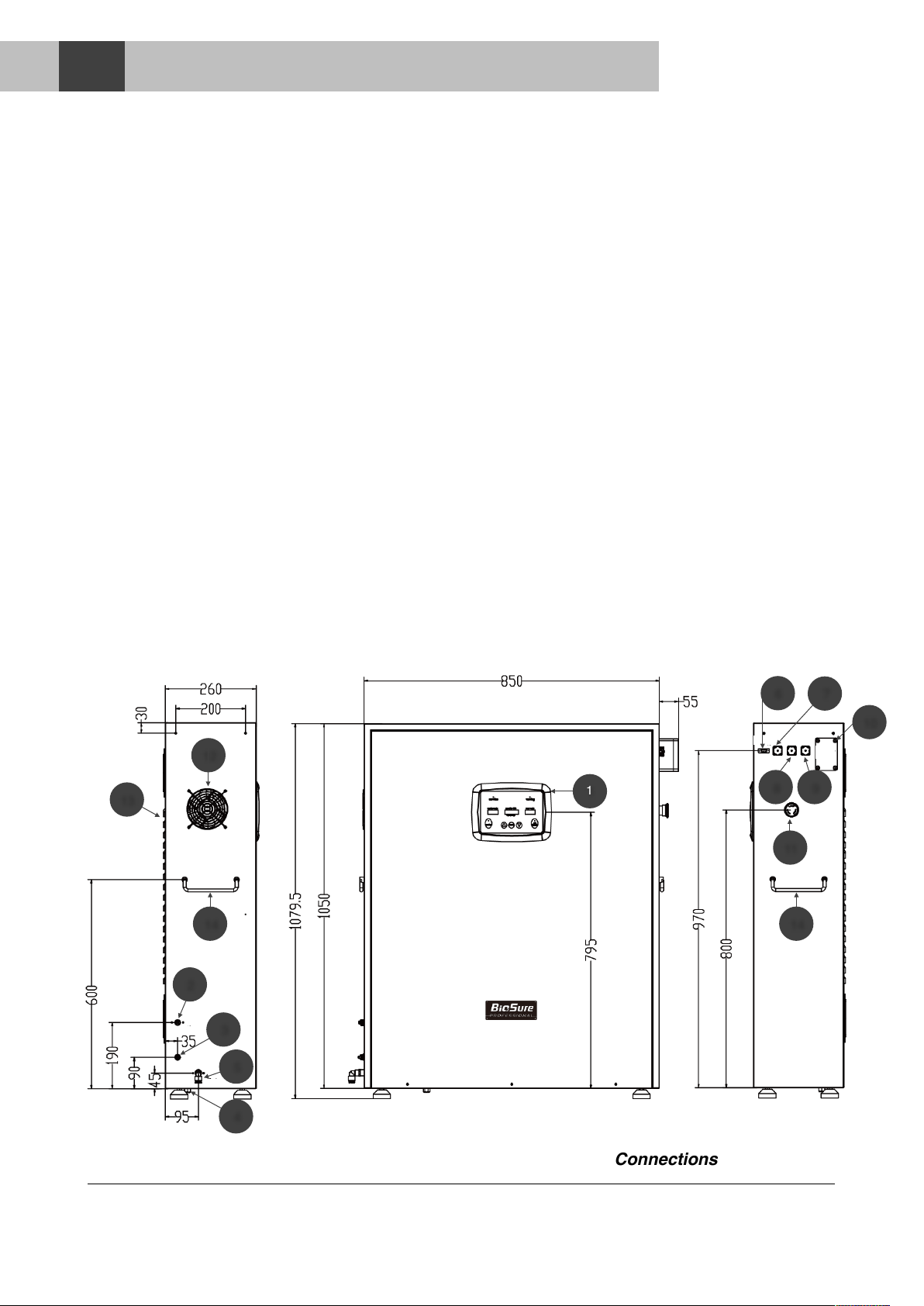

1.2 Ozone Generator Overview

Refer to Figure 1 & 2 below for an overview of the G Series Ozone Generator, system

connections and panel descriptions. Labels are provided on the Ozone Generator near

selected connections to assist in proper installation.

2

Figure 1. G Series Dimension Drawing Showing Connections

1

2

3

5

6

7

8

9

10

11

14

14

12

13

4

GENERAL INFORMATION

1

Captions

1. Operator Interface Panel (OIP)

2. iEOG Feed Water Inlet, 3/8”

3. Ozone Gas Outlet, 3/8”

4. Exhaust Outlet (Oxygen)

5. Drain Outlet, 7x10

6. Programming Port (DB9)

7. OWS Parallel Communication Port

8. External Signal Control Port (DC 5-12V)

9. External Circuit Control Port (ON/OFF)

10. Electrical Terminal Box

11. Mains Switch / Emergency Stop Switch

12. Side Air Inlet

13. Rear Air Outlet

14. Carry Handle(s)!

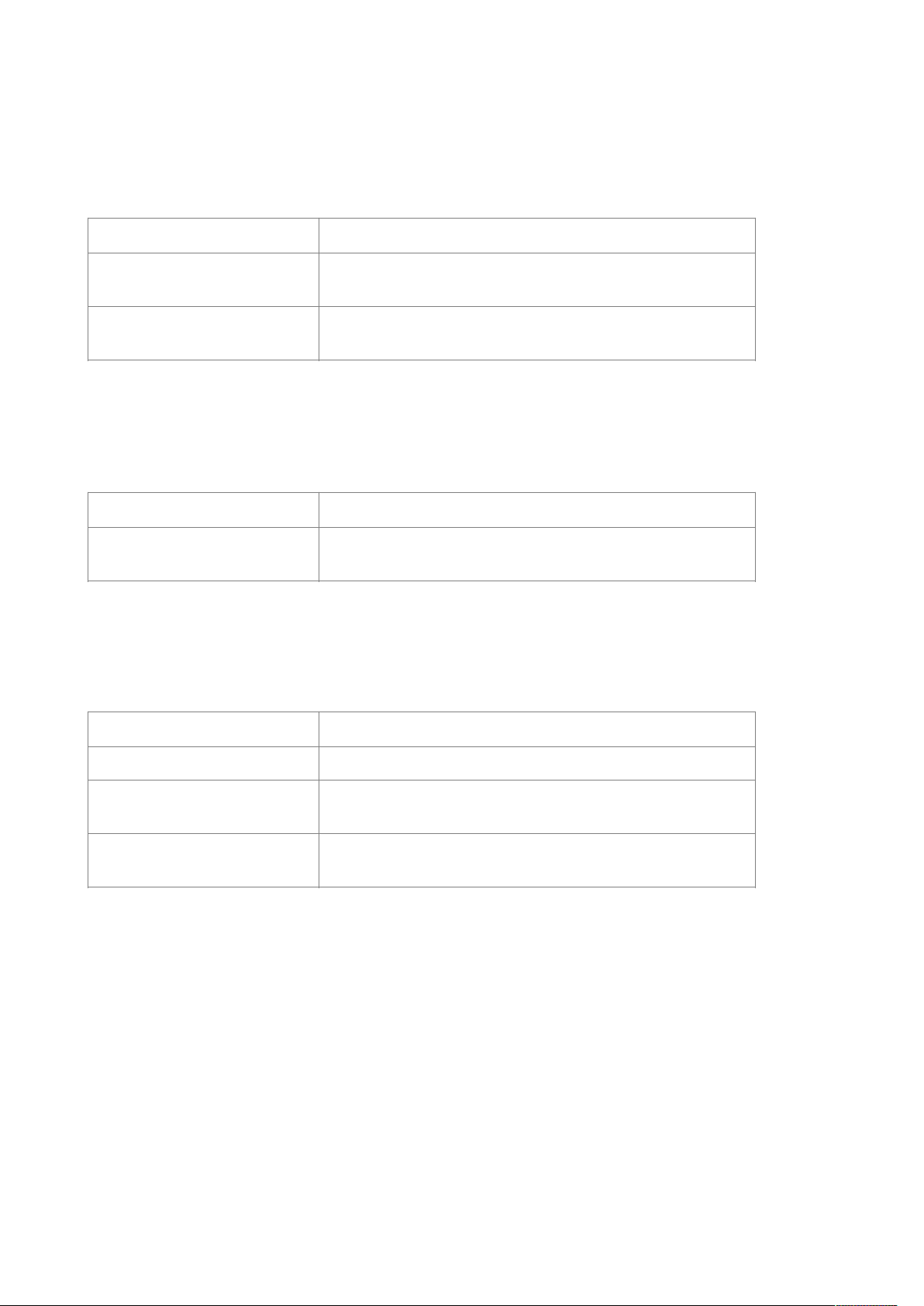

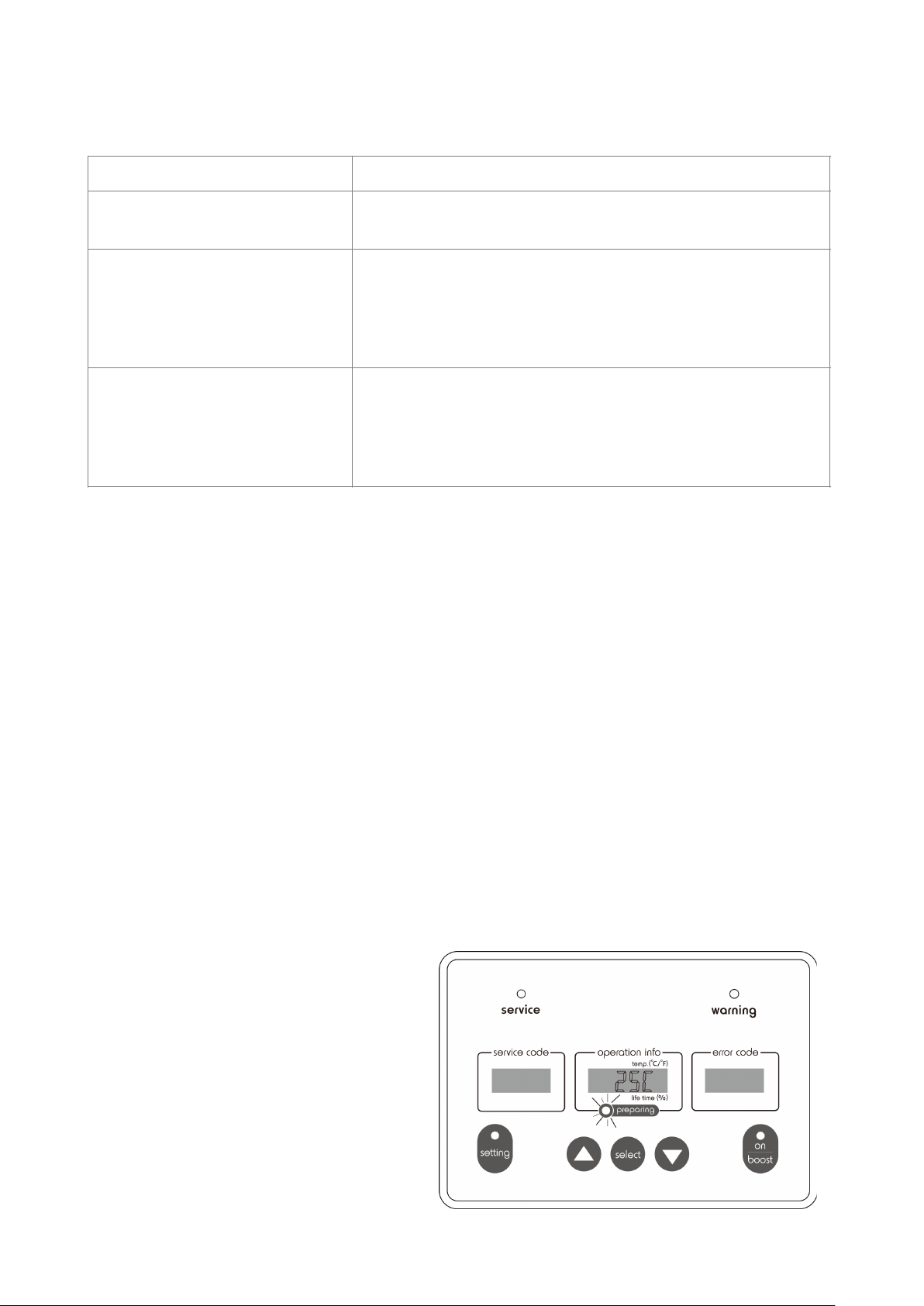

Captions

1. Service Indicator (Yellow)

2. Warning Indicator (Yellow)

3. Preparing Indicator (Green)

4. Service Code Screen

5. Operation Information Screen

6. Error Code Screen

7. Operation Indicator (Green)

8. [Cancelled Button]

9. Page-Down Key

10. Select/Enter Key

11. Page-Up Key

12. Setting Key

13. Setting Indicator (Green)!

3

Figure 2. G Series Operator Interface Panel (OIP) Descriptions

1.3 Ozone Generator Specifications

Engineering Configurations

System Code

G3

G6

G9

Model Number

EOS8131-CL

EOS8132-CL

EOS8134-CL

Ozone Production

3 g/h

6 g/h

9 g/h

Output Proportion

20-28 wt% O3(with 72-80 wt% O2)

Type of Ozone Generator

Indirect electrolytic ozone generation (iEOG)

Ozone Generation Source

Water (municipally treated water)

Principle of Setup

Central, Stationary Type (Point of Entry, POE)

Start Control Method

Signal Control

Off-gas handling

Built-in thermal catalytic process

Cooling Configuration

Air cool

IP Code

IP-X2

Noise Level

Max. 45 bB (at 1 m or 3.3 ft)

Dimensions

Width

905 mm

Depth

260 mm

Height

1079.5 mm

Weight

Net

60 kg

68 kg

75 kg

Gross

90 kg

98 kg

105 kg

Ambient Requirements

Location

For use on a hard, level, and stable surface only

Temperature

5 ~ 40°C (41 ~ 104°F)

Ventilation

Min. 5 air changes per hour

Clearance

Min. 10 cm (4”) clearance around unit

Power Requirements

Applied Power

□AC 220-240V, 50/60Hz

Rated Power

G3

300W

G6

600W

G9

900W

4

1.4 Functional Descriptions

Ozone (O3) is an active and unstable molecule consisting of three oxygen atoms. It is a

strong oxidizing agent, which is classed as particularly environmentally friendly as it

breaks down into oxygen. It is used especially in water for sanitation and disinfection

purposes.

The BioSure Professional G Series System produces ozone from water. The water in the

system is purified by reverse osmosis and ion-exchange and then dissociated by

electrolysis, the electrolysis cell uses a solid polymer membrane as electrolyte.

Using this membrane technology ozone can be produced by electrolysis from

demineralized water.

The main advantages of ozone production with a BioSure Professional’s G-Series

electrolytic ozone generator are as follows:

•Steady and concentrated ozone output promotes ozone dissolution and reactions.

•No feed gas preparation, as the ozone is produced from water by electrolysis.

•Performance independent to air (air quality, humidity and flow).

•No Nitric Oxides (NOx) formation (or formation of Nitrous Acid in water).

•No pure water input, as the pure water is self-prepared by the systems.

•No ionic contamination, as the water is dissociated using a solid polymer electrolyte.

•Easy integration and operation.

1.5 Ozone in Practice

Ozone itself is a colorless gas with a pungent smell. It is one of the strongest known

oxidizing agents. It has an electrochemical oxidation potential of 2.08 V. The ozone

molecule is only moderately stable and has a half-life in pure water and under normal

operating conditions of about 20 minutes. In the absence of oxidizable substances,

ozone decays to oxygen. In the presence of oxidizable substances, traces of CO2 will

also be formed.

Many years of experience show that an average ozone concentration of about 0.1 to 0.2

ppm (mg/L) is sufficient to maintain the colony forming unit (cfu) count in pure water

systems below 1 cfu per 100 ml.

Input Water Requirements - iEOG Feed Water

Conductivity

≤500μs/cm

Temperature

5 ~ 35 °C (41 ~ 95 °F)

Operating Pressure

2.0 - 7.0 kg/cm2(28.5 - 99.5 psi)

Flow Rate

≥300 LPH (1.3 GPM)

Others

pH 6~8; chlorine residual ≤0.1ppm; filtered to 1μm

5

1.6 Physical Properties of Ozone

*Normal conditions acc. to DIN1343: Pn = 1.01325 bar; Tn = 273.15°C, tn = 0°C

1.7 Intended Use

Applications

The BioSure Professional G Series ozone systems are used to produce ozone

electrolytically from water with promoted dissolution and disinfection performance and is

suitable for all types of industrial applications:

-Bottled Water Manufacturing

-Beverage Manufacturing

-Pharmaceutical Manufacturing

-Cosmetic Manufacturing

-Semi-Conductor Industry

-Personal Product Industry

-Foodstuffs Industry

-Industrial Cleaning Processes

-etc.

Ozone-containing gas or hydrogen should not be vented in an uncontrolled manner in

buildings or to atmosphere. The operator is responsible for the process and ensuring that

adequate safety precautions have been taken.

Molecular weight

47.9982

g/Mol

Density under normal conditions

2.144

g/L

Relative density

1.5582

g/L

Molecular volume under normal

22.387

m3/kMol

Boiling point (760 mm Hg)

-111.9 ± 0.3

°C

Melting point

-192.7 ± 0.2

°C

Critical temperature

-12.1 ± 0.1

°C

Critical pressure

54.6

atm.

Critical volume

111

cm3/Mol

Heat of vaporization

75.6

cal/g

Free energy (25 °C)

32.4

Kcal/Mol

6

Consult your local BioSure Professional dealer for installation arrangements. The

information described below in this section is intended for operator’s reference.

The most common configurations for common installation sites are discussed in this

section. For additional installation options or questions on your specific installation,

please contact your regional BioSure Professional dealer.

1. Pre-installation

Inspect the location for installation. Check for:

oSpace for the unit / Ventilation / ambient temperature

oWater supply flow and pressure

oDrain availability

oPower supply availability

Refer to the product specifications in Section 1.3 (P. 4-5) for all the requirements

and detail.

2. Location

The G-Series Ozone Generator is designed for location on the floor or support

plate. Place the unit on a flat and stable or similar placement surface to prevent

toppling and falling. Locate the unit out of reach of water splash and airborne

water with a degree of protection from dirt or other containments. Allow sufficient

access for maintenance and all piping. Other key requirements of the location are

as follows (Refer to Section 1.3, P. 4-5):

•Well ventilation - min. 5 air changes per hour

•A 10 cm (4”) minimum free air space must be maintained on all sides

•Climate-controlled, ambient temperature of 5° to 40°C (41° to 104°F)

3. iEOG Water Feed Pre-filtration

For water that enters the unit as input for iEOG water feed, the water quality must

meet our standards as follows:

oMunicipally treated tap water, 5 ~ 35 °C (41 ~ 95 °F)

oWater conductivity below 500 μs/cm, pH between 6 and 8

oFiltered to 1 μm with chlorine residual less than 0.1 ppm

BioSure Professional recommends that pre-filtration be installed on our products for

the input to the iEOG water feed. In most cases, treatment is needed to address

the removal of dirt, debris, sediment and chlorine residual. This stabilizes the iEOG

process resulting in maintained performance.$

The type of pre-filtration may vary with local water quality. Please see your local

BioSure Professional distributor for the best recommendation for your area.

Note: Filtration, or treatment, must be sized properly to be effective.

Inadequate flow and pressure will cause problem with operation of the unit.

7

INSTALLATION

2

4. Electrical

The G-Series Ozone Generator is supplied with an electrical terminal box on the

side for Power and Ground Connections. A hole underneath the box is provided for

conduit fitting.

Refer to specifications of the unit (Refer to Section 1.3) and your local electrical

codes for information on proper electrical connection. All permanent electrical

connections should be made by a qualified electrician.

Note: The circuit must be protected by a GFCI (Ground fault Circuit

Interrupter) installed in accordance with electrical codes.

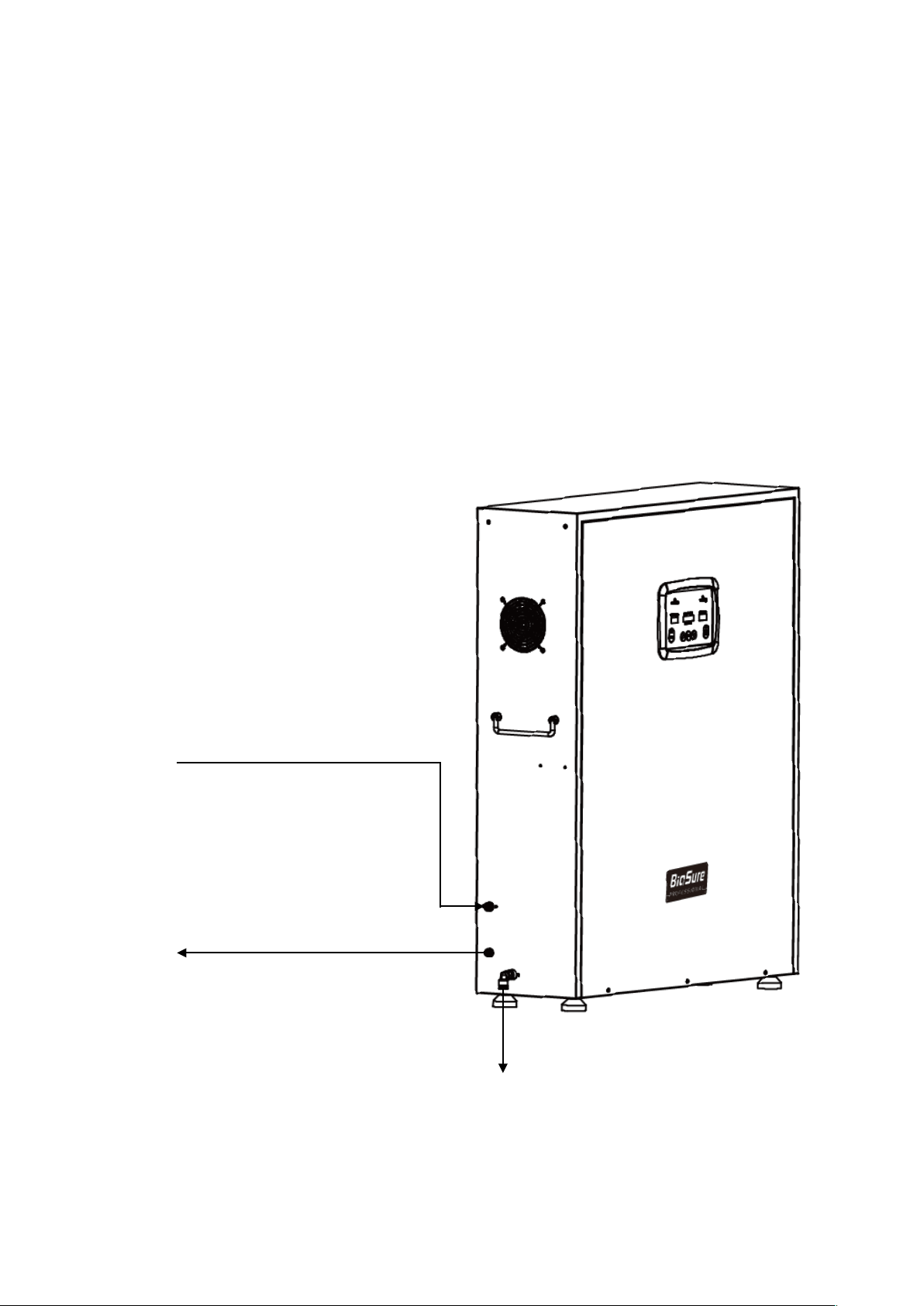

5. Connections

Water Input and Ozone Output

8

Water In

Ozone Out

•Press Connection.

•3/8” PE tube (white), included

accessory.

•Refer to specifications for

water quality requirements.

Drain

•Press Connection.

•3/8” PTFE tube, included

accessory.

•Quick Connection.

•7X10 PVC tube (black),

included accessory.

Figure 3. G-Series Water Input and Ozone Output Connections

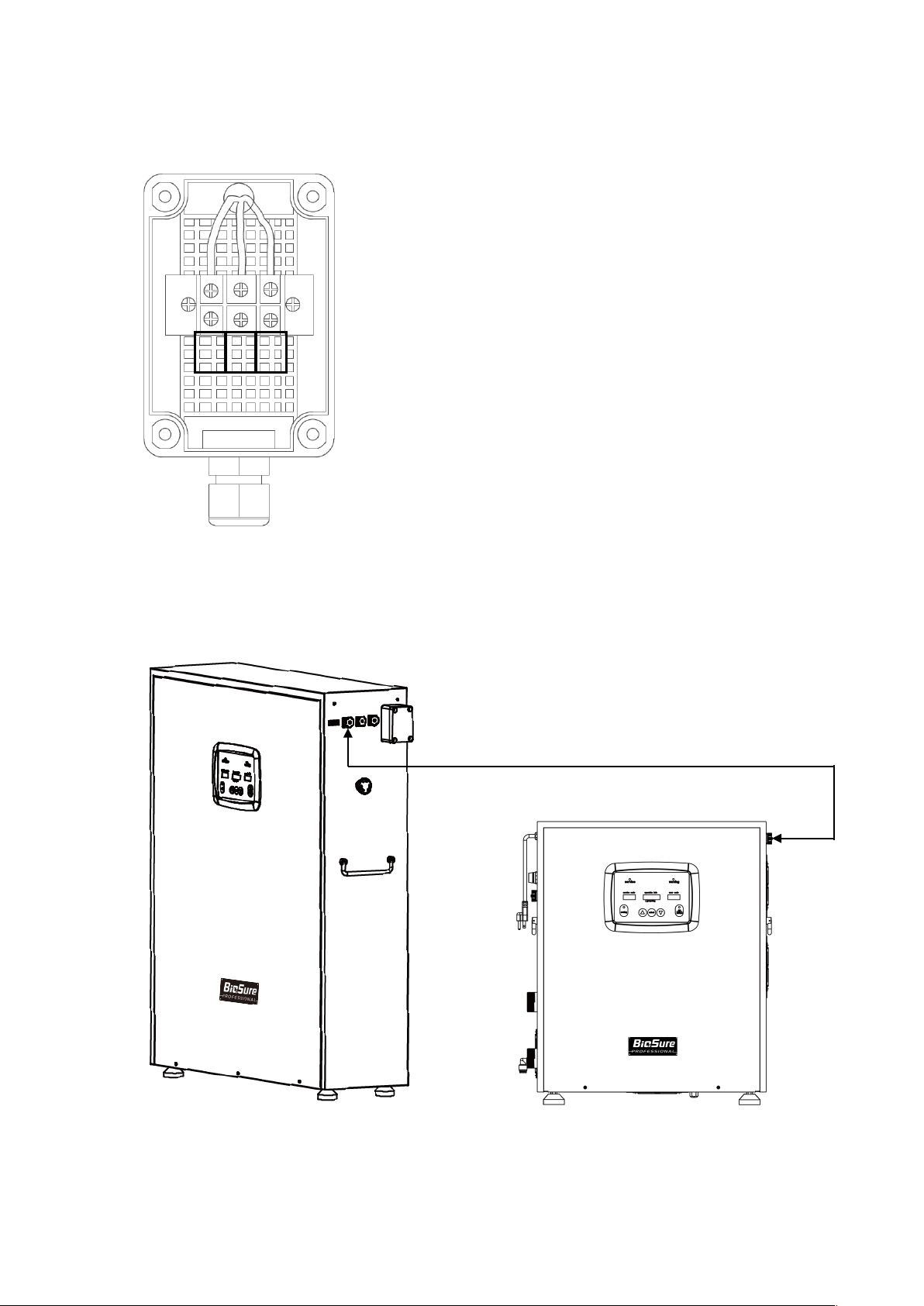

Electrical Connections

Control Connections

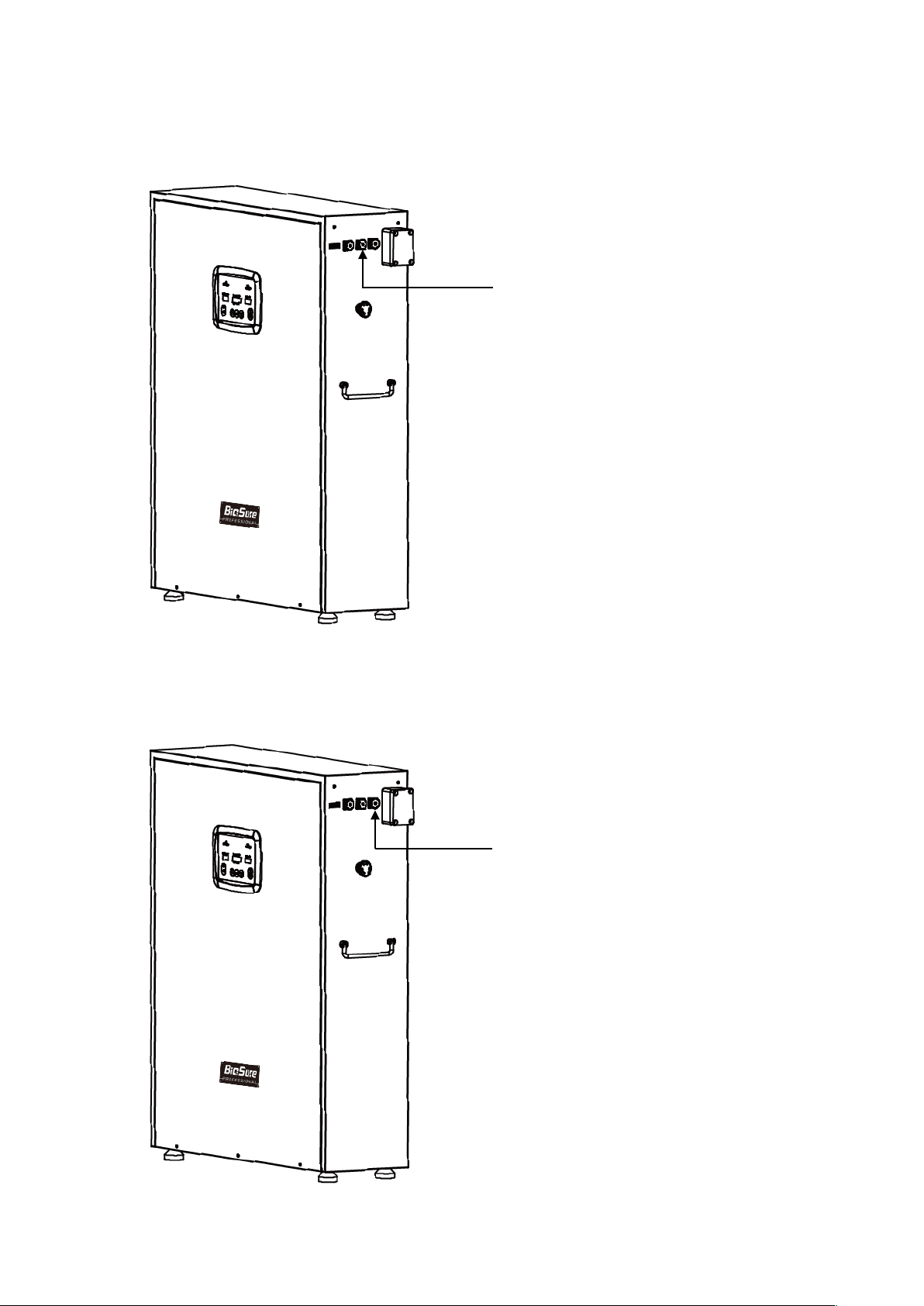

Model 1 - Operated with BioSure Professional OWS Series

9

N

L

E

Refer to Figure 3 for illustration of the Power

and Ground connections in the Electrical

Terminal Box.

Figure 4. G-Series Electrical

Terminal Box Power and

Ground Connections

Figure 5. G-Series Control Connection - Connecting with BioSure Professional

OWS-Series

OWS-1 (EOS8131-CD) Shown

Note: This complementary control wiring plug is

an optional accessory. Please contact your local

BioSure Professional distributor to order this

accessory if so needed.

Control Connections

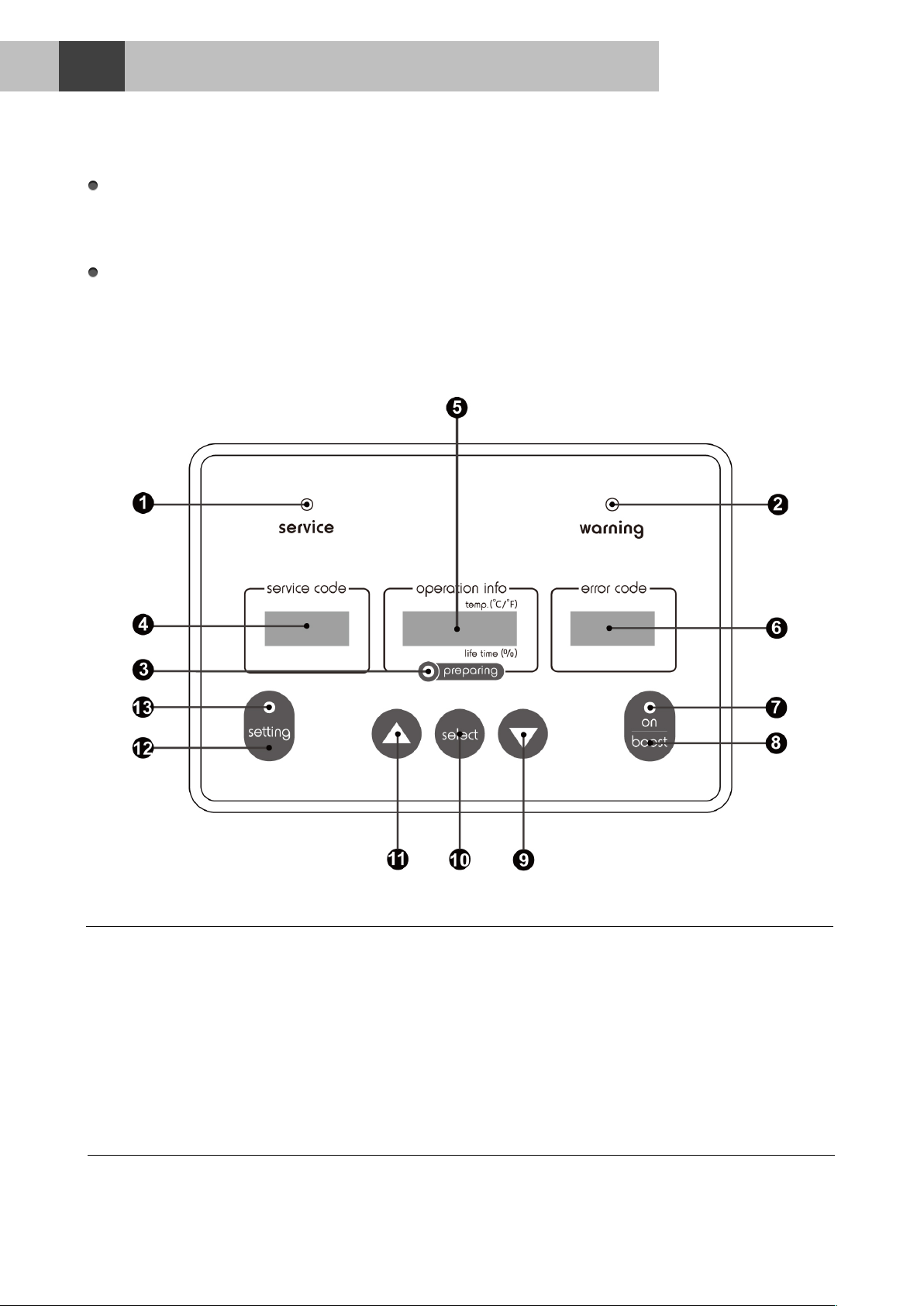

Model 2 - Operated with an External Signal DC 5-12V

Control Connections

Model 3 - Operated with a Closed Contact Switch (ON/OFF)

10

Figure 6. G-Series Control Connection -

Connecting with a DC Signal for switching off

Supply DC 5-12V to switch off

operation.

Application: Safety control from ambient

ozone monitor

Note: This complementary control wiring

plug is an optional accessory. Please

contact your local BioSure Professional

distributor to order this accessory if so

needed.

Supply a closed contact for normal

operation.

Application: Remote Main switch or

timer control

Figure 7. G-Series Control Connection -

Connecting with a closed contact for normal

operation.

Note: This complementary control wiring

plug is an optional accessory. Please

contact your local BioSure Professional

distributor to order this accessory if so

needed.

6. Material Compatibility

In order to avoid ozone leaks, all materials coming into contact with ozone must be

completely ozone compatible. Acceptable materials include stainless steel, glass,

Hypalon, Teflon (PTFE), PVDF, etc.

As a general rule, the following minimum material qualities are recommended:

•Stainless steel ASTM 316 L for wet ozone gas

•PTFE, PVDF or Viton Gaskets for wet and dry ozone gas

11

3.1 Correct and Proper Use

The G-Series Ozone Generator MUST remain connected to the supply of power and

water AT ALL TIMES. This is because the stability and sustainability of the iEOG’s

performance is highly reinforced by the continuance of connected power and water

supply to the system.

Installation in an environment where temperatures may exceed 40°C can impair cooling

performance and may result in system overheat. The system will shut down

automatically for protection once inside temperature exceeds 44°C.

3.2 Descriptions of OIP Display and Button Functions

Captions

1. Service Indicator (Yellow)

2. Warning Indicator (Yellow)

3. Preparing Indicator (Green)

4. Service Code Screen

5. Operation Information Screen

6. Error Code Screen

7. Operation Indicator (Green)

8. [Cancelled Button]

9. Page-Down Key

10. Select/Enter Key

11. Page-Up Key

12. Setting Key

13. Setting Indicator (Green)!

12

OPERATION

3

“Service” Indicator (Yellow)

At the top-left corner is the “Service Indicator”, flashing in two modes to indicate the

service is required and the degree of urgency to the requirement:

“Warning” Indicator (Yellow)

At the top-right corner is the “Warning Indicator”, flashing to indicate an error and the unit

has stopped operating:

“Preparing” Indicator (Green)

The “Preparing Indicator” will light solid-on or flash to indicate three different status for

iEOG’s preparation conditions:

“Service Code” Screen

When service is due, together with flashing service indicator, this screen displays service

code to notify the required item(s) for replacement.

In addition, it will also display a number from 1 to 6 together with display of “Operational

Code” in “Operation Info” screen. As the “Operation Code” are divided and displayed in

groups of 6, here this number from 1 to 6 is displayed for identification of the group

numbers (Refer to Service Manual in addition).

LED Mode

Interpretation

Slow Flashing Yellow

[On 0.5S/Off 0.5S]

Servicing parts approaching the end of lifecycle (2%

remaining).

Quick Flashing Yellow

[On 0.1S/Off 0.2S]

Servicing parts reached the end of lifecycle.

LED Mode

Interpretation

Quick Flashing Yellow

[On 0.1S/Off 0.2S]

Error encountered and operation is stopped.

LED Mode

Interpretation

Solid ON Green

iEOG preparation in process (pure water refilling).

Slow Flashing Green

[On 0.5S/Off 0.5S]

iEOG re-start protection (30 min suspended).

Quick Flashing Green

[On 0.1S/Off 0.2S]

iEOG preparation failure (PS. plus flashing warning).

13

“Operation Info” Screen

In the middle of the three screens is for “Operation Information” that can provide

information about various operational data:

“Error Code” Screen

On the far right of the three screens is for “Error Code” that will display error codes to

notify the occurrence of any self-detectable problems.

“ON” Indicator (Green)

At the right-bottom corner, on the “On/Boost” button is the “On” Indicator that will light

solid on when the unit is running under normal conditions:

Readings/Display

Display Conditions

Service Code

Indicate which part is required for replacement when

Service Indicator starts flashing.

Operational Code

Group Number

Associated with Operational Code, display numbers

from 1 to 6 to identify the groups.

Readings/Display

Display Conditions

Temperature

Under normal conditions (including normal standby

and running), display water temperature inside the unit.

Use “▲” (page-up) or “▼” (page-down) key under

standby mode to switch between degree Celsius (°C)

and Fahrenheit (°F) in the display based on preference.

Part’s Remaining

Life-span

Press “select” to display the remaining life span for

each consumable part. Use “▲” (page-up) or

“▼” (page-down) key under standby mode to roll up or

down. Press “select” again to return.

Operational Code

Press “setting” (hold 15 sec) to display the Operation

Codes for operating history. Refer to P.xx for further

detail.

LED Mode

Interpretation

Solid ON Green

System running.

14

“Select” Key

This button is used for operators to switch the display between the “Temperature” and

“Part Remaining Life-time”. Also, it can be used to cancel the display of “Operational

Code”:

“Setting” Key

The “setting” button is used for operators to activate the display of “Operational Code”:

“Setting” indicator (Green)

At the left-bottom corner, on the “setting” button is the “Setting Indicator” that will flash

slowly when the “Operational Code” is displayed.

Function

Conditions / Outcomes

Part Remaining

Life Span Display

(Press 0.3S)

To display the Part Remaining Life-Time in the

“Operation Info” screen. Use “▲” (page-up) or

“▼” (page down) key to switch the display of between

each part. Press the “select” again to return to standby

with temperature display.

Operational Code

Display Cancellation

(Press 0.3S)

To cancel the Operational Codes display.

Function

Conditions / Outcomes

Operation Code

(Press 15S)

Press and hold on the key for 15 seconds to activate

the display of Operation Codes. Use “▲” (page-up) or

“▼” (page down) key to switch between each

displayed codes group (6 groups in total). Press

“select” to return.

LED Mode

Interpretation

Slow Flashing Green

[On 0.5S/Off 0.5S]

Indicate “Operational Code” is being displayed.

15

Summary of Button Functions

3.3 Pre-Commissioning Check

Confirm all below points prior to start-up:

•All inputs, output and drain are correctly installed to their corresponding connections.

•The power supply meets the requirements as indicated in the product specifications.

•Input water pressure is 2-7 kg/cm2.

•The area of operation is well ventilated (Min. 5 air changes per hour).

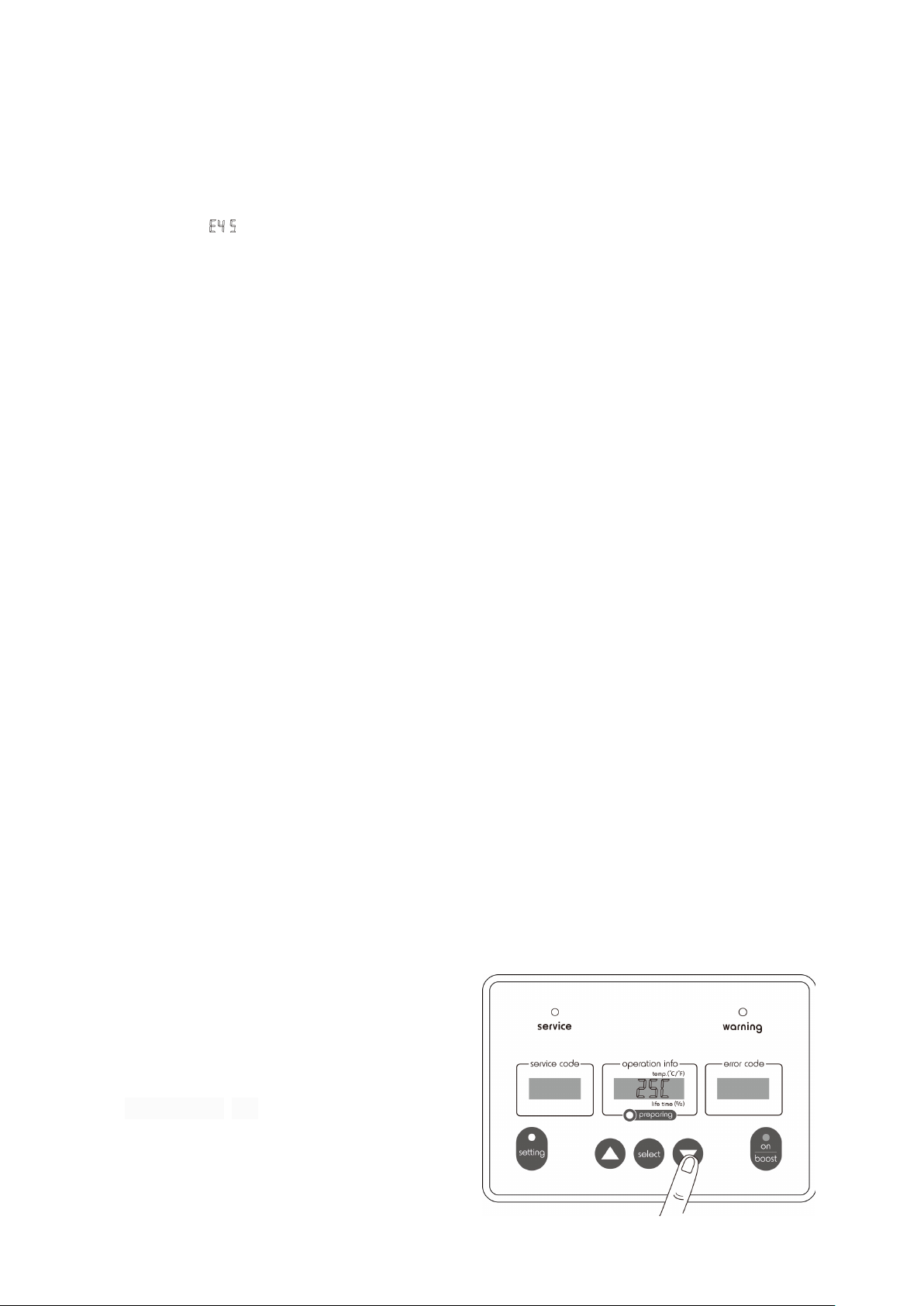

3.4 Initial Start-Up

The system is switched ON either controlled by OWS-Series or an external closed contact

switch. To use the machine at the first time, connect the machine to your selected signal

source for switching on and the “preparing” light will begin to flash slowly. At this point,

the machine is in preparation stage refilling water for iEOG start-up. This process will

take about 40 to 90 minutes depending on models, ambient and water temperature and

on-site water pressure.

Note: System draining during this stage is normal.

Functions

Operation Instructions

Switch temperature between °C

and °F

•Press “▲” (page-up) or “▼” (page-down) key under

standby mode.

Display part remaining life-time

information

•Press “select” key under standby mode (Temperature

display).

•Use “▲” (page-up) or “▼” (page-down) key to display

data.

•Press “setting” key to return.

Display operational code

•Press and hold on the “setting” key for 15 seconds to

display the system operation codes.

•Use “▲” (page-up) or “▼” (page-down) key to switch

between each displayed codes group.

•Press “select” key to return.

16

Once this preparation phase is complete, the “preparing” light will go out automatically,

and the system is now ready for normal operation. At this point, the panel displays the

detected water temperature inside the system on the “Operation Info” screen.

However, if in two hours the initial water filling process for iEOG start-up cannot be

completed, a “ ” error code will be displayed, indicating that the water filling process

was unsuccessful. All functions will remain suspended. Please check the input water

pressure and refer to the troubleshooting section on P.25 if the symptom is identified.

3.5 Shut-down, Re-Start & Power Disconnection Protection

The G-Series Ozone Generator is intended for being power connected and switched on

at all times, unless in necessary situations, such as to stop the unit for service or

relocation. The unit can be switched OFF by disconnecting the power supply or switching

off the Mains Switch / Emergency Stop Switch. Before shutting down the unit, the water

supply to the unit should be completely turned off.

Note: Disconnecting the power too often may cause unexpected impacts on the

iEOG module, which may result in degradation to the product performance.

To re-start the unit, simply reconnect the unit to power or switching on the Mains Switch

for switching on. However, after re-start all functions will be suspended for 30 minutes.

This is a standard protection procedure to minimize the impacts on the iEOG-working

module. During this “PROTECTION” period, system is running program for check and

maintenance.

3.6 Operation States

Starting and Running

The G-Series units are signal-controlled systems. Once a selected signal is available

(mastered by OWS-Series or a contact type ON/OFF circuit), the unit enters the “Running

State” automatically, which is also indicated on the OIP with “On” indicator lighting solid

on green. In this state, the electrolytic ozone generator module is running and ozone is

being delivered to the output. This ozone delivery will continue unless the signal is off to.

During the OFF period the ozone is destructed within the unit and discharged through

exhaust in the form of oxygen.

The G-Series units measure system temperature inside the unit and displays it on the

“Operation Info” screen for operator’s

reference. This display under all states as a

primary display comes as default in any new

unit. You can press “▲” (page-up) or

“▼” (page-down) under standby mode to

switch the unit between degree Celsius (°C)

and Fahrenheit (°F).

17

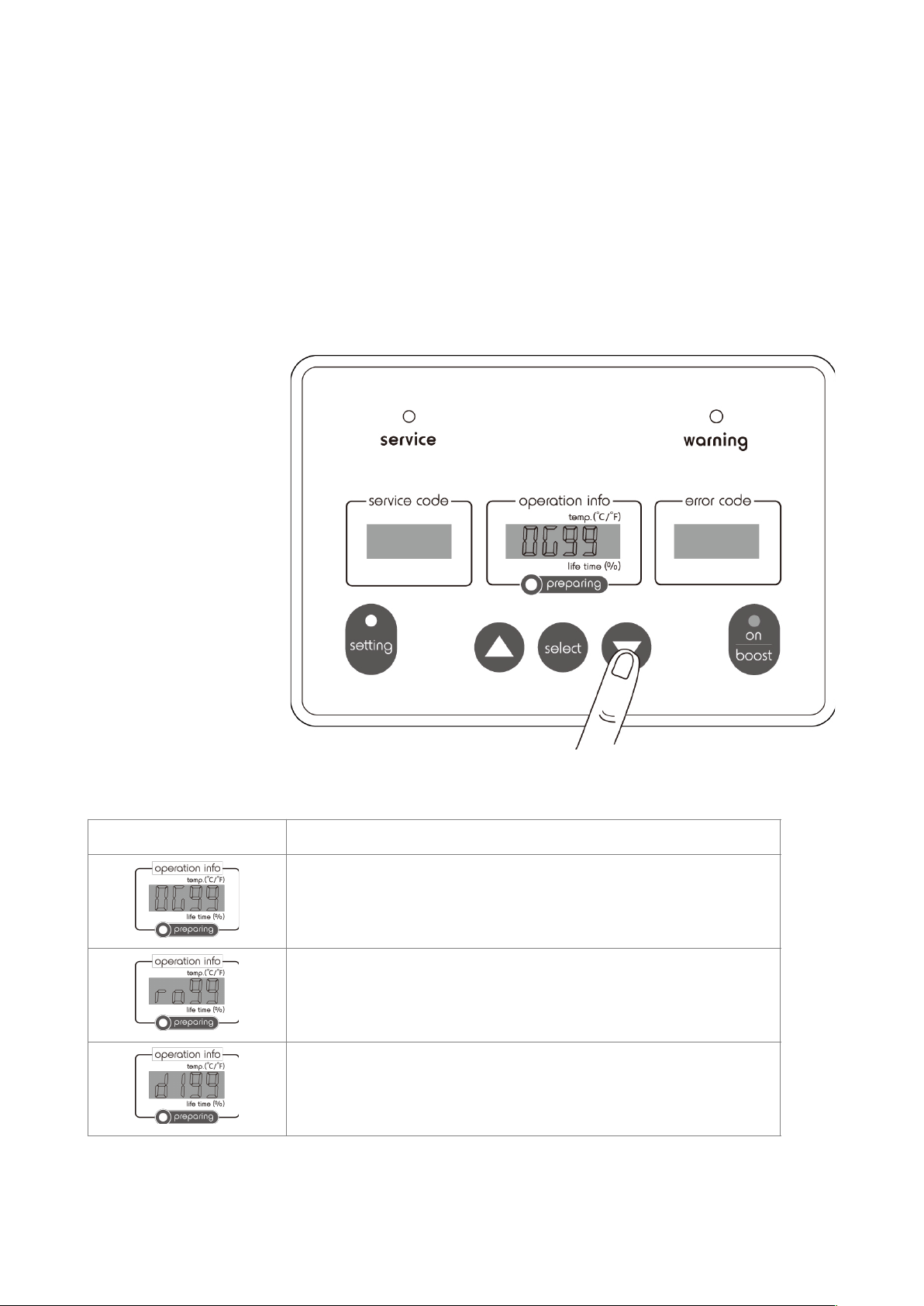

Display of Parts Life Cycle

The G-Series units record Remaining Life Cycle of each consumable part for operator’s

reference. The information is displayed on the “operation info” screen. Under standby

mode, press “select” button to switch the display for between the measured water

temperature and Remaining Life Cycle Information of each consumable part. The first

two codes represent the part and the following two indicate the Remaining Life Cycle in

percentage (%). Press “▲” (page-up) or “▼” (page-down) to switch the display for each

of the consumable parts equipped in the units for regular check purpose.

The coding system for the Remaining Life Cycle display is interpreted as follows:

Coding

Interpretation

Wording translation: OG99

Indicated part: EOG Cell(s)

Interpretation: Remaining life 99% for EOG Cell(s)

Wording translation: ro99

Indicated part: Reverse Osmosis (RO) Module

Interpretation: Remaining life 99% for RO Module

Wording translation: dI99

Indicated part: Resin Deionizer (DI) Module

Interpretation: Remaining life 99% for DI Module

18

This manual suits for next models

2

Table of contents

Other BioSure Cleaning Equipment manuals

Popular Cleaning Equipment manuals by other brands

Suevia

Suevia 130.5011 EASYCLEANER Mounting instructions

i-MO

i-MO Öko 2000 user guide

unGer

unGer Hydro Power Ultra UNP01 operating instructions

Black & Decker

Black & Decker BHPC130 Original instructions

Uni-ram

Uni-ram UG5000E operating manual

Axi

Axi MTC HC-300 Installation, operating and maintenance manual