Blue Line VORTEX 8000Q User manual

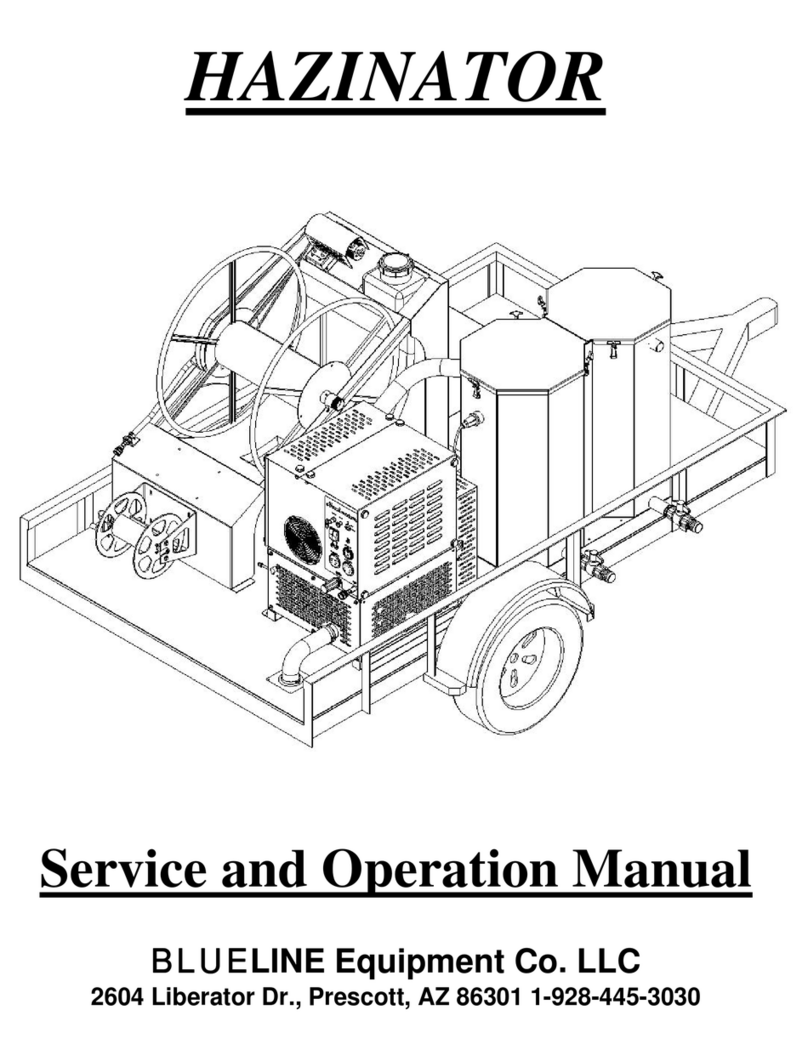

VORTEX 8000Q Mobile Cleaning

Unit

The Worlds Most Powerful Cleaning Machine

Service and Operation Manual

BLUELINE Equipment Co. LLC

2604 Liberator Dr., Prescott, AZ 86301 1-928-445-3030

BLUELINE VORTEX 8000Q I

Congratulations on your purchase of the

VORTEX MOBILE CLEANING UNIT.

This instruction/parts manual is a guide for

operating and servicing your BLUELINE

VORTEX 8000Q® mobile cleaning unit.

Proper operation and service are necessary to

ensure the outstanding performance of this unit.

When properly maintained, your mobile cleaning

unit will have a long and trouble-free life.

The following service methods outlined in this

manual are detailed in a manner that operation and

servicing may be performed properly and safely.

Because service levels vary due to the skill of the

mechanic, tools and parts availability, ensure that

prior to attempting any repair, you are familiar with

this equipment and have the proper tools. Any

questions regarding the operation, service, or repair

of this unit should be directed to your nearest

BLUELINE dealer.

The headings WARNING and CAUTION are

utilized to warn you that steps must be taken to

prevent personal injury or damage to the

equipment. Please make sure that you have read

and understand these instructions entirely before

proceeding with the operation of this unit.

Record your units vehicle identification number

here for future reference or if you should need to

contact the factory in the future for any reason.

VIN:

This service and operations manual is written

specifically for BLUELINE VORTEX 8000Q®

mobile cleaning unit manufactured by:

BLUELINE EQUIPMENT LLC

2604 Liberator Drive

Prescott, AZ 86301 USA

The information contained in this document is

subject to change without notice and does not

represent a commitment on the part of BLUELINE

EQUIPMENT LLC.

All rights reserved. Copyright 2006 by

BLUELINE EQUIPMENT LLC. No part of this

work may be used or reproduced in any form or

means without the express written consent and

permission of BLUELINE EQUIPMENT LLC.

Published by BLUELINE EQUIPMENT LLC.

First printing: April 2008

Printed in USA

VORTEX 8000Q® MANUAL

PART# 49-036

Revision 1

September, 2008

s

II BLUELINE VORTEX 8000Q

LIMITED WARRANTY

BLUELINE warrants your machine to be free of defects in material and workmanship. This

warranty shall extend to the designated parts for the specific period of time listed from the date

of delivery to the user. If BLUELINE receives notice of any defects during the warranty period,

BLUELINE will either, at its option, repair or replace products that prove to be defective. Any

transportation, related service labor, normal maintenance and diagnostic calls are not included.

Vacuum Pump (Through manufacturer or local dealer)_______ 18 months

Water Pump_________________________________________ 1 year

Oil Pump___________________________________________ 1 year

Waste Pump_________________________________________ 1 year

Engine Heat Exchanger________________________________ 1 year

Wands (Excluding shut off valve and orifices)______________ 1 year

Waste and Water Tanks________________________________ 1 year

Pressure Regulator____________________________________ 1 year

All Other Components_________________________________ 1 year

This warranty shall not apply to defects caused by improper operation, inadequate maintenance

by the customer, unauthorized modification or misuse, improper repair, freezing or damage due

to hard water scaling.

Electrical components, disposable filters, belts, hoses, fittings, o-rings and other service

maintenance items are not under warranty. Components supplied by BLUELINE, but provided

by other manufacturers, will only be warranted to the extent that they are warranted to

BLUELINE.

To receive warranty service, products must be returned to a BLUELINE designated service

facility. The customer shall prepay shipping charges for products returned to BLUELINE for

warranty evaluation and BLUELINE shall pay for the return of products to the customer.

BLUELINE makes no other warranty, expressed or implied, with respect to this product.

BLUELINE disclaims the implied warranties of merchantability and fitness for a particular

purpose. Any implied warranty of merchantability or fitness is limited to the specific duration of

this limited warranty.

This warranty gives the customer specific legal rights, and you may also have other rights that

may vary from state to state, or province to province.

The remedies provided herein are the customer’s sole and exclusive remedies. In no event shall

BLUELINE be liable for any direct, indirect, special, incidental, or consequential damages,

whether based on contract, tort, or any other legal theory.

BLUELINE VORTEX 8000Q III

Table of Contents

SECTION ONE: GENERAL INFORMATION 1

1. SAFETY 2

Safety, Specifications, Chemical, Water Requirements

2. RECEIVING YOUR MOBILE CLEANING UNIT 6

Dealer Responsibility, Acceptance of Shipment, Equipment Listing, Optional Equipment

SECTION TWO: SYSTEMS/OPERATION 8

3. SYSTEMS 11

Water Pumping System, Heat Transfer System, Vacuum System, Chemical System

4. OPERATION 15

Equipment setup, Instrumentation, Starting Your Unit, Priming the Chemical Pump, Waste

Pump, Operation, Cleaning, Upholstery Cleaning, Stair Tool Cleaning, Flood Restoration,

Shut Down and Daily Maintenance, Freeze Protection.

SECTION THREE: MAINTENANCE and SERVICE 24

MAINTENANCE CHART 26

5. MAINTENANCE 29

6. GENERAL SERVICE ADJUSTMENTS 32

7. TROUBLESHOOTING 35

SECTION FOUR: PARTS and ACCESSORIES 43

9. ILLUSTRATED PARTS LISTINGS 44

10. ACCESSORIES 75

SECTION FIVE: SERVICE BULLITENS 84

BLUELINE VORTEX 8000Q 1

SECTION 1:

GENERAL INFORMATION

1. SAFETY

Safety 2

Specifications 5

Chemical requirements 6

Water requirements 6

2. RECEIVING YOUR TRUCK MOUNT UNIT

Dealer responsibility 6

Acceptance of shipment 6

Equipment listing 7

Optional equipment 7

SECTION 1

2 BLUELINE VORTEX 8000Q

1. SAFETY

For Your Safety!

The following WARNING labels are on your VORTEX 8000Q mobile cleaning unit. These

labels point out important Warnings and Cautions, which must be followed at all times.

Failure to follow warnings could result in personal injury, fatality, to yourself and/or others

or property damage. Please follow these instructions carefully!

DO NOT remove these decals.

SECTION 1

BLUELINE VORTEX 8000Q 3

!

1. Read the operator's manual before

starting this unit.

Failure to adhere to instructions could result in

severe personal injury, property damage, or

could be fatal.

2. Operate this mobile cleaning only in a

well- ventilated area.

Exhaust fumes contain carbon monoxide,

which is an odorless and deadly poison that can

cause severe injury or death. DO NOT operate

this unit in an enclosed area. DO NOT operate

this unit where the exhaust may enter a

building doorway, window, vent or other

opening.

3. DO NOT place hands, feet, hair, clothing or

any body parts near rotating or moving parts.

Rotating machinery can cause severe injury or

death.

4. NEVER operate this unit without belt and

safety guards. High speed moving parts, such

as belts and pulleys, should be avoided while

the unit is running. Severe injury, fatality or

damage may result.

5. NEVER service this unit while it is running.

High speed mechanical parts as well as high

temperature components may result in injury or

severed limbs.

6. The engine and other components will be

extremely hot from operation. To prevent

severe burns, DO NOT touch these areas while

the unit is running or shortly after the unit is

shut off.

7. DO NOT touch the exhaust diverter valve or

any part of the exhaust system while the system

is running or for 20 minutes after the unit is

shut off. Severe burns could result.

8. Water under high pressure at high

temperature can cause burns, severe

personal injury, or fatality. Shut down unit,

allow to cool down and relieve system of all

pressure before removing caps, valves, plugs,

fittings, filters or hardware.

9. Battery acid contains sulfuric acid. To

prevent acid burns, avoid contact with skin,

eyes and clothing. Batteries also produce

explosive hydrogen gases while charging. To

prevent fire or explosion, charge batteries only

in a well ventilated area. Keep sparks, open

flames, as well as other sources of ignition

away from battery at all times. Remove all

jewelry prior to servicing batteries. Keep

batteries out of the reach of children.

Before disconnecting the negative (-) ground

cable, ensure that all switches are in the off

position. If on, a spark could occur at the

ground connection terminal which could cause

an explosion if hydrogen gas or gasoline

vapors are present. ALWAYS disconnect the

negative (-) terminal first.

10. DO NOT exceed your vehicles weight

limit. GVW (Isuzu NPR) 14,250 lbs. This will

prevent unsafe or hazardous driving conditions.

11. Always keep your vehicle clean and

orderly. Wands, tools and accessories must be

securely stowed while driving the vehicle.

12. All high-pressure hoses must be rated at

3000 PSI and have a heat rating of 250° F.

Thermoplastic hoses do not meet this criteria,

and should never be used. Severe burns,

damage to property or fatality could result if

hoses do not meet these requirements.

13. Ensure that you have received proper

training from the distributor that you purchased

the unit from prior to operation.

14. This unit produces high pressure and high

temperatures. Improper use could result in

serious injury or fatality.

SECTION 1

4 BLUELINE VORTEX 8000Q

15. DO NOT modify this unit in any manner.

Any modification could result in serious injury

or fatality, and will void your warranty.

16. California Proposition 65 Warning: Engine

exhaust from this product contains chemicals

known by the State of California to cause

cancer, birth defects, or other reproductive

harm.

SECTION 1

BLUELINE VORTEX 8000Q 5

SPECIFICATIONS

Truck Isuzu NPR HD

Allowable Truck Gross Weight 14,250 lbs.

*Refer to owners’ manual for allowable axle load ratings.

Engine Speed 700-1700 rpm (Manual Control Cleaning Mode)

600-700 rpm (Idle)

Water Pump RPM 1400 rpm

Vacuum Pump RPM 3000 max rpm @ 900 cfm

Water Flow Rate 6.5 GPM (maximum) Optional 4.5 GPM

Water Pump Pressure 1750 PSI (maximum) Optional 2750 PSI

Vacuum Relief Valve 17 in. HG

Waste Tank Capacity 210 Gallons at shutoff

TANKS

Fresh Water 220 Gallons.

Waste Recovery 220 Gallons

JET SIZING

BLUELINE recommends that the total floor tool tip size does not exceed .12”. Using

larger jet sizes on your VORTEX 8000Q® unit may reduce cleaning temperatures.

Example: Four-jet wand uses four 95015 jets. (95 deg. Spray angle w/015 orifice)

.015 x 4 = .06

When using two wands while cleaning with this unit, BLUELINE recommends that the

tip size in each tool does not exceed a total of .18”.

Example: Four-jet wand uses four 9501 jets. (95 deg. Spray angle w/01 orifice)

.01 x 4 = .04 .04 x 2 tools = .08

Upholstery tool jet size: 80015 Stair tool jet size: 9502

Spray lance jet size: 3.5 GPM maximum

SECTION 1

6 BLUELINE VORTEX 8000Q

FUEL REQUIREMENTS

Use ultra low sulfur diesel fuel (15ppm) ONLY.

Refer to vehicle owners' manual for use of additives

and bio-diesel recommendations.

ENGINE OIL REQUIREMENTS

Refer to vehicle owners' manual for

recommended oil type and maintenance

schedules.

CHEMICAL REQUIREMENTS

The BLUELINE VORTEX 8000Q® mobile truck

cleaning unit’s unique last step chemical injection

system can be used with a wide variety of water

diluted chemical compounds, either acidic or

alkaline, depending on the work to be performed.

We recommend using only the highest quality

chemistry.

WATER REQUIREMENTS

Because hard water deposits will damage the

plumbing and heat exchange systems on this unit,

BLUELINE recommends that a high quality water

softener be used in areas where the water hardness

exceeds 3-1/2 grains. If a water softener is used, it

must have a flow capacity of at least five (5) GPM

or greater, without any hose constrictions.

The use of a water softening system will reduce

maintenance and reduce down time caused by hard

water scaling. It will also enhance the performance

of cleaning chemicals, which will result in greater

efficiency in lower concentrations.

2. RECEIVING YOUR

TRUCK CLEANING UNIT

DEALER RESPONSIBILITY

THE BLUELINE DEALER THAT YOU

PURCHASED THIS MOBILE TRUCK

CLEANING UNIT FROM IS RESPONSIBLE

FOR THE PROPER INITIAL TRAINING OF

YOUR OPERATORS AND MAINTENANCE

PERSONNEL.

ACCEPTANCE OF SHIPMENT

Your VORTEX 8000Q® mobile truck cleaning

unit was thoroughly tested, checked and inspected

in its entirety prior to leaving our manufacturing

facility. When receiving your mobile cleaning

unit, please make the following acceptance

check:

1. The unit should not show any signs of damage. If

there is damage, notify your dealer immediately.

2. Carefully check your equipment and packing list.

The standard BLUELINE VORTEX 8000Q® unit

SECTION 1

BLUELINE VORTEX 8000Q 7

should arrive with the following items as well as

any optional accessories:

EQUIPMENT LISTING

A. Operation and Service manual

B. Hose reel

C. 400 ft. 2” vacuum hose

D. 220 Gallon fresh water tank

E. 220 Gallon waste tank

F. Pre-Filter box with stainless steel strainer.

G. Waste tank filters.

H. 2 Chemical solution reels.

I. 400 ft. of 1/4 in. high pressure solution hose with

quick connects

J. 2 vacuum hose adaptors

K. 50 ft. water supply hose with quick connect

L. Vortex marketing materials package.

OPTIONAL EQUIPMENT

8 BLUELINE VORTEX 8000Q

SECTION 2:

SYSTEMS/OPERATION

3 SYSTEMS/OPERATION

Mobile Truck Unit Layout 9

Battery 10

Fire extinguisher 10

Water pumping system 11

Heat transfer system 11

Vacuum system 13

Chemical pumping system 14

4. OPERATION

Preparation 15

Starting the unit 19

Priming the chemical pump 20

Automatic waste pump 21

Operation 21

Automatic Diverter System 21

Cleaning 21

Upholstery cleaning 22

Stair tool cleaning 22

Flood restoration/extraction 22

Shut down and daily maintenance 22

Freeze protection 23

SECTION 2

BLUELINE VORTEX 8000Q 9

SECTION 2

10 BLUELINE VORTEX 8000Q

BATTERY CONNECTION

!

Explosive gases, Dangerous gases!

Batteries contain sulfuric acid. To prevent acid

burns, avoid contact with skin, eyes and

clothing. Batteries also produce explosive

hydrogen gases while charging. To prevent fire

or explosion, charge batteries only in a well

ventilated area. Keep sparks, open flames, as

well as any other sources of ignition away from

batteries at all times. Remove all jewelry prior

to servicing batteries. Keep batteries out of the

reach of children.

Refer to vehicle owners’ manual for specific

instructions on the maintenance, removal or

replacement of vehicles batteries.

Before disconnecting batteries, ensure that all

the mobile cleaning units’ switches are in the

OFF position. If ON a spark could occur at the

ground connection terminal, which could cause

an explosion if hydrogen gas, or other explosive

vapors are present.

FIRE EXTINGUISHER

BLUELINE, and many government agencies,

recommend that a fire extinguisher rated for A, B,

and C type fires be installed into any commercial

vehicle.

SECTION 2

BLUELINE VORTEX 8000Q 11

3. SYSTEMS

NOTE: Read and understand this section of the

manual entirely before proceeding.

This portion of the manual divides the unit up into

systems and describes how each system works.

Prior to proceeding into the operations and

maintenance sections of this manual it is

recommended that you acquire a basic

understanding of how the unit functions.

WATER PUMPING SYSTEM

See figure 2-1. Water flows from the fresh water

tank, through a wye strainer to the water pump

where it is pressurized. The pressurized water is

pumped to the pressure regulator, which maintains

the desired pressure setting. The pump discharge

manifold is equipped with a nitrogen charged

accumulator, which helps reduce pressure

fluctuations.

Water flows from the pressure regulator through

the engine coolant heat exchanger, through the

vacuum exhaust heat exchanger and then through

the upper xentherm heat exchanger.

Water then flows through the metering valve

located on the control panel. At this point, the

chemical injection takes place.

The hot solution mixture of water and chemicals

then flows to the cleaning tool.

HEAT TRANSFER SYSTEM

See figure 2-1 Water is heated through a multi-

stage heat exchange system that utilizes engine

coolant, vacuum exhaust and engine exhaust. Stage

one utilizes hot engine coolant, where the

temperature is maintained at or near 195°F by the

engine thermostat. The engine coolant flows

through the engine heat exchanger heating the

pressurized water supplied by the water pump.

Water then flows through the vacuum exhaust heat

exchanger and into the upper xentherm heat

exchanger. Where oil heated by the engine exhaust

in the lower xentherm heat exchanger is circulated

in a closed loop system, heating the water to the

desired temperature, set with the oil temperature

control located on the control panel.

This unit is equipped with an automatic diverter

valve system located behind the engine muffler.

This system incorporates an electronic rotary

solenoid with an exhaust diverter valve. When the

water temperature reaches the desired setting, the

solenoid automatically positions the diverter valve

into the direct exhaust mode.

The low water level switch located on the water

tank will automatically shut off the water pump

clutch, disengaging the water pump when the fresh

water supply is low. A water tank empty indicator

light, located on the control panel, will then be

illuminated.

SECTION 2

12 BLUELINE VORTEX 8000Q

Water System

2-1

SECTION 2

BLUELINE VORTEX 8000Q 13

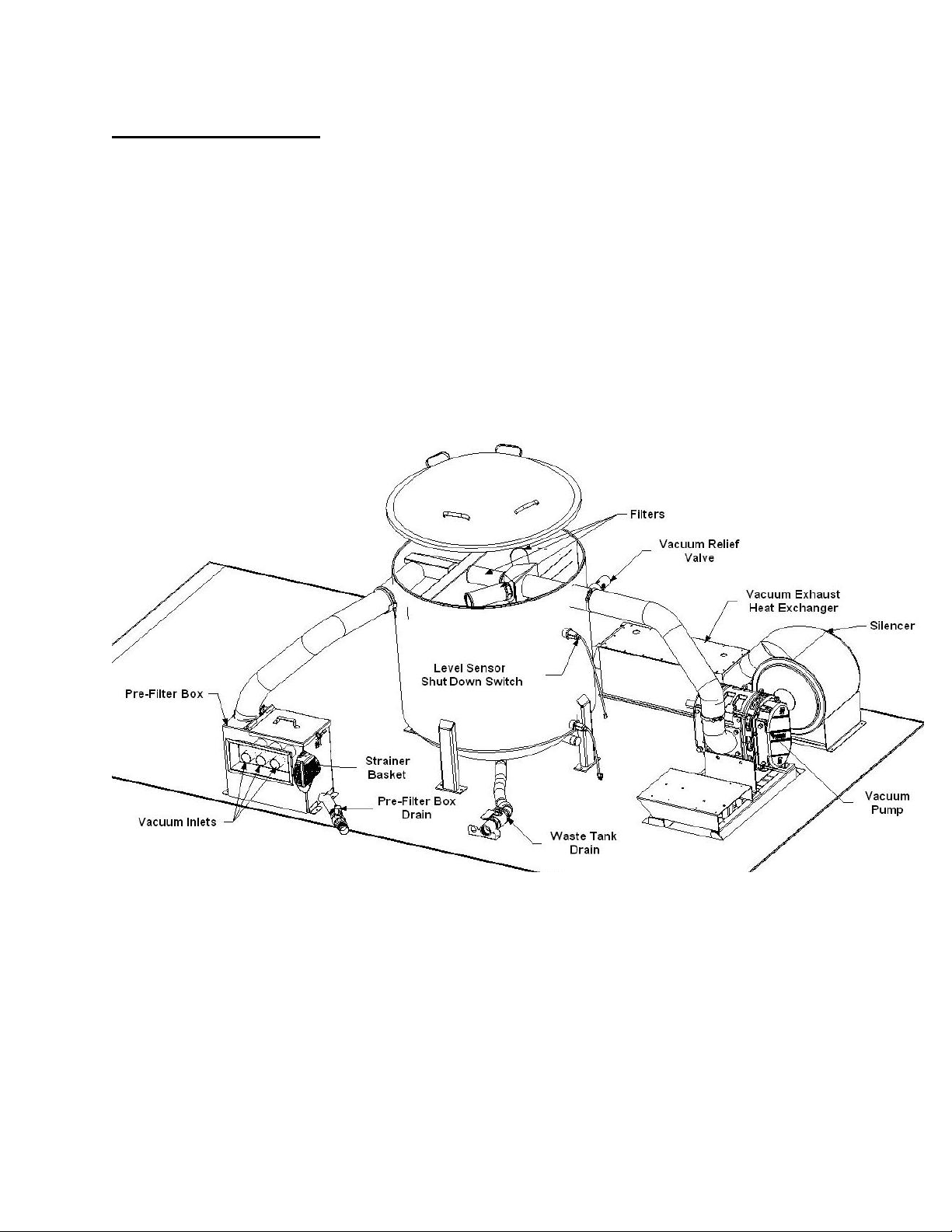

VACUUM SYSTEM

See figure 2-2. The vacuum flow is initiated by the

vacuum pump, or blower. An air and water mixture

is drawn into the vacuum inlet on the side of the

truck. The mixture flows through a strainer basket

in the pre-filter box, and then into the waste tank.

The air exits the waste tank through a 100 mesh

filtration system, into the vacuum pump. A

vacuum pump relief valve is installed for vacuum

pump protection.

The air is discharged from the vacuum pump

through a spiral silencer, then through a vacuum

exhaust heat exchanger.

A level shut off sensor is located near the top of

the waste tank and will shut down the PTO (power

take off) unit before the tank is at full capacity. A

waste tank full indicator light, located on the

control panel, will then be illuminated. This

protects the vacuum pump from water damage.

Note: Waste tank level shut off sensor will not

shut the unit off due to high levels of foam. The

use of a quality defoamer is recommended.

2-2

SECTION 2

14 BLUELINE VORTEX 8000Q

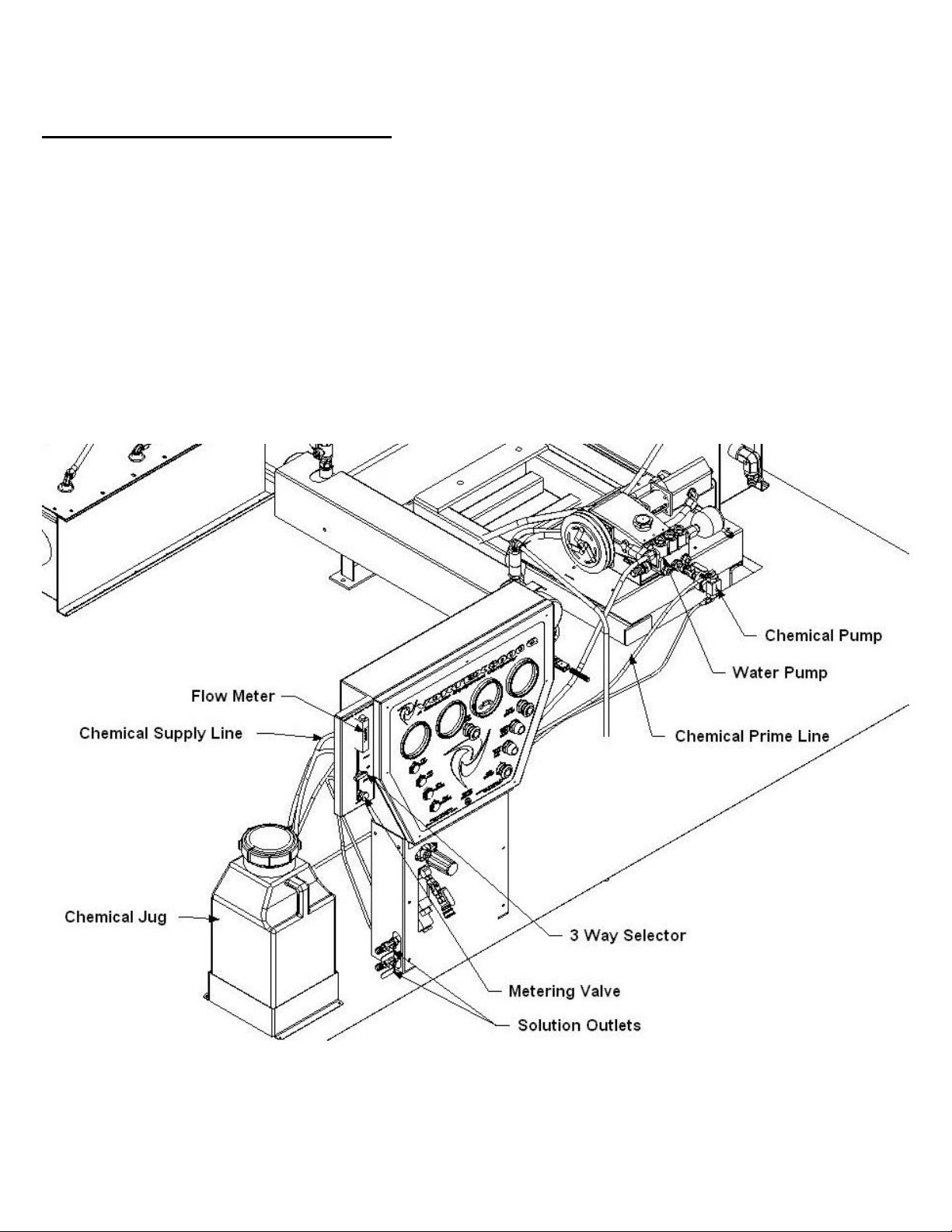

CHEMICAL PUMPING SYSTEM

See figure 2-3. The chemicals are drawn from the

chemical jug through a strainer into the flow meter.

The flow meter indicates the rate of chemical flow.

The chemicals then flow into the stainless steel

pulsation chemical pump. The chemical pump

injects the chemicals to the three way selector

valve located on the front panel. This valve may be

used to turn the chemical flow to PRIME, OFF, or

METER.

The chemicals then flow through the chemical

metering valve to the solution outlet. This valve

controls the rate of chemical flowing into the

cleaning solution, which is indicated by the flow

meter.

2-3

SECTION 2

BLUELINE VORTEX 8000Q 15

5. OPERATION

PREPARATION

This section of the operator’s manual explains how

to prepare, start, operate, shut down and maintain

your BLUELINE VORTEX 8000Q® mobile

cleaning unit. The VORTEX 8000Q® unit is easy

to operate, however only trained operators should

proceed.

!

Operate this unit and equipment only in a well

ventilated area. Exhaust fumes contain carbon

monoxide, which is an odorless and deadly

poison that can cause severe injury or death.

DO NOT run this unit in an enclosed area. DO

NOT operate this unit where the exhaust may

enter a building doorway, window, vent or any

other opening.

Water under high pressure at high temperature

can cause burns, severe personal injury, or

fatality

Table of contents

Other Blue Line Cleaning Equipment manuals