BMB Technology Nova Pro Instruction manual

Installation, Operation & Maintenance

Manual

For the Following Product-

*2021 MODEL- BMB Nova Pro + Biocera A-A-

Index-

Page 1 - 2, …..……….. Introduction to Nova Pro

Page 3 –10, ………….. Nova Pro water purification technology

and stages explained.

Page 11 –15, ………… Nova Pro Technical information and

component locations.

Page 16, ..…………….. Tools required for installation

Page 17- 18, ………….. Nova Pro basic set up diagrams

Page 19 –20, …………. Use of push fits

Page 21, ………………. Installation components

Page 22 - 23, …………. Installation steps

Page 24 –26, ………… RO Membrane installation

Page 27,……………….. Tank Installation

Page 28 -29, ………….. Start up and commissioning

Page 30 - 31, …………. Digital interface instructions

Page 31, …………….... Maintenance

Page 33, ………………. Going on holiday

Page 34, ………………. Trouble shooting table

Page 35 –36, …………. Pre & post filter change

Page 37, ………………. Service/filter change log

Page 38, ……………….. Warranty registration

Page 39, ……………….. Limited warranty

Page 1of 44

Introduction

The purpose of the Installation, Operation & Maintenance Manual is to give users a

reference for Technical Specifications, Connection Diagrams, Installation Procedures,

System Operation and System Maintenance of their BMB Technology Reverse Osmosis

System.

The essential information contained in this manual will allow the user to make full use of the

system. In the interest of brevity, an attempt has been made to include only that information

which will be used under normal operating circumstances. For special situations, it is

recommended that the user contact their authorized dealer or BMB Technology

(www.bmbtechnology.com).

Reverse Osmosis is the most advanced technology of water purification in use today. The

technique uses a nanotechnology enabled semipermeable membrane which can reduce or

remove most harmful impurities found in water including: microorganisms, nitrates, heavy

metals, insecticides and much more (see Figure 1 on page 3 for a comparison of different

filtration technologies).

Fig 2, on page 3 lists a more detailed filtration performance of specific materials. These

materials are only a partial list of the virtually hundreds of thousands of molecules that

Reverse Osmosis can filter out.

Osmosis is defined as the process of molecules passing through a semipermeable

membrane, from a less-concentrated solution to a more-concentrated solution. An example

of Osmosis is the roots of plants drawing water from the soil. Reverse osmosis is simply the

opposite of this process where molecules are forced through a semipermeable membrane to

form a less-concentrated solution.

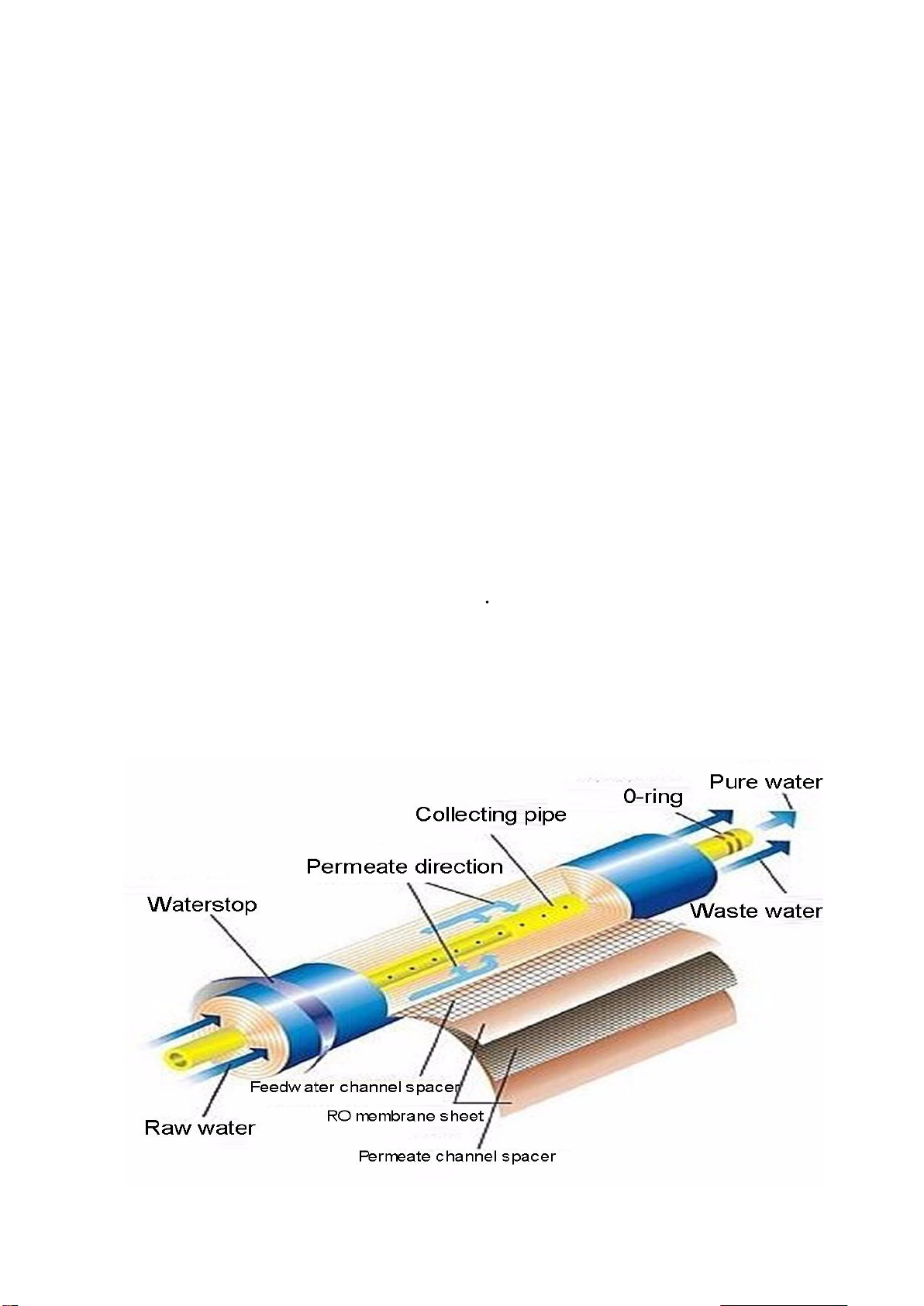

Essentially, the Reverse Osmosis filter (RO membrane or RO element) has nano sized

pores that help remove microscopic contaminants from the incoming water (more-

concentrated solution) to produce better quality water (less-concentrated solution). An

illustration of this process can be found page 4, Figure 3.

Page 2of 44

There is a bit more to the Reverse Osmosis process as it pertains to Reverse Osmosis

systems, however, this will be explained in more detail in the upcoming sections.

This BMB Technology system harnesses the power of Reverse Osmosis to purify the

incoming water. It was specifically designed to enhance the Reverse Osmosis process by

using sensors, pumps, probes, minerals, software and other components. This system will

be mainly used in residential and commercial applications to reliably produce high quality

water.

This BMB Technology Reverse Osmosis system is one of the most technologically advanced

water filtration systems in the world. It incorporates state of the art filters, easy Plug & Play

components and Quick-Change Filter Technology (QCFT) for low maintenance cost.

The system also comes equipped with a digital controller with Smart Water capabilities. It

continuously analyzes the purified water and displays the results on screen. The system will

know when water is consumed and will automatically flush the reverse osmosis filters

afterwards to maintain water quality and extend filter lifetime. The system works in the

background to track water temperature, errors and filter lifetime in order to give the highest

up time possible while delivering the best water quality and user experience.

Some of the significant features of this product line are as follows:

•

Elegant & compact design / LED light-up during operation

•

Standing bracket, no mounting required, easy installation

•

Locking quick change pre-filters for low maintenance cost

•

Nano zinc powder activated pre-filters for antibacterial performance

•

BIOCERA A-A Antioxidant, Alkaline, ORP, re-mineralizing Filter

•

High Capacity 600 GPD configuration

•

Direct flow (no tank required) option for maximum freshness

•

Smart capabilities optimize system performance and water quality

•

Set and track filter lifetime to maximize cost savings

•

Instantaneous analysis of water (TDS)

•

Automatic flush of membranes for water quality and max. filter lifetime

•

Quick Connect parts for easy service and maintenance

•

Dual manometers to track incoming and pump water pressure

•

1-2 LPM flow rate- 2.5 bar incoming pressure

•

Tank installation option available for low pressure or High demand situations

Page 3of 44

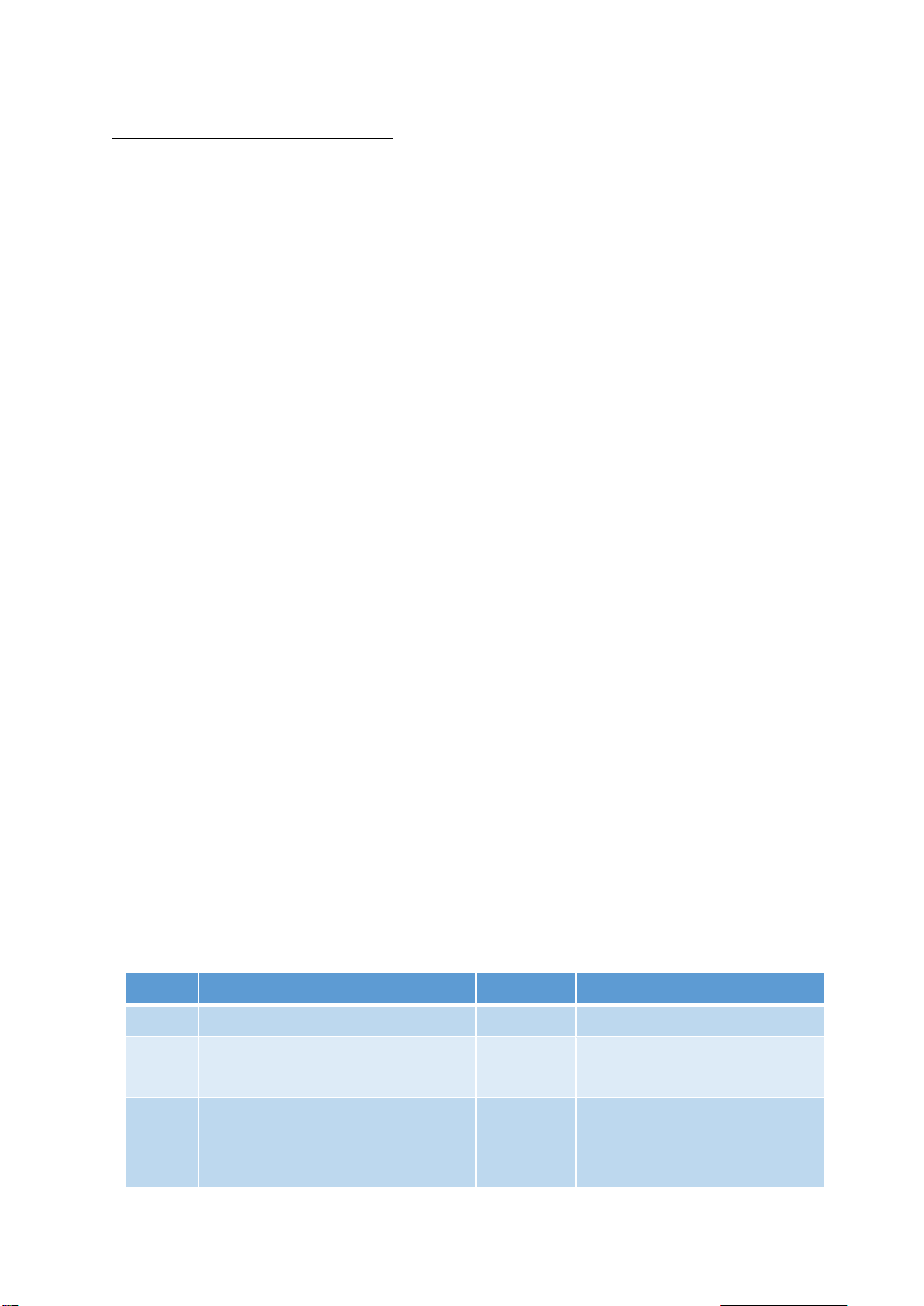

Fig1,

Water Filtration Technology’s spectrum

Fig 2,

Estimated Reverse Osmosis Rejection Percentages

* Figures given above are estimates of normal

BMB Technology

reverse osmosis membrane filter

performance, under normal conditions and water quality.

Page 4of 44

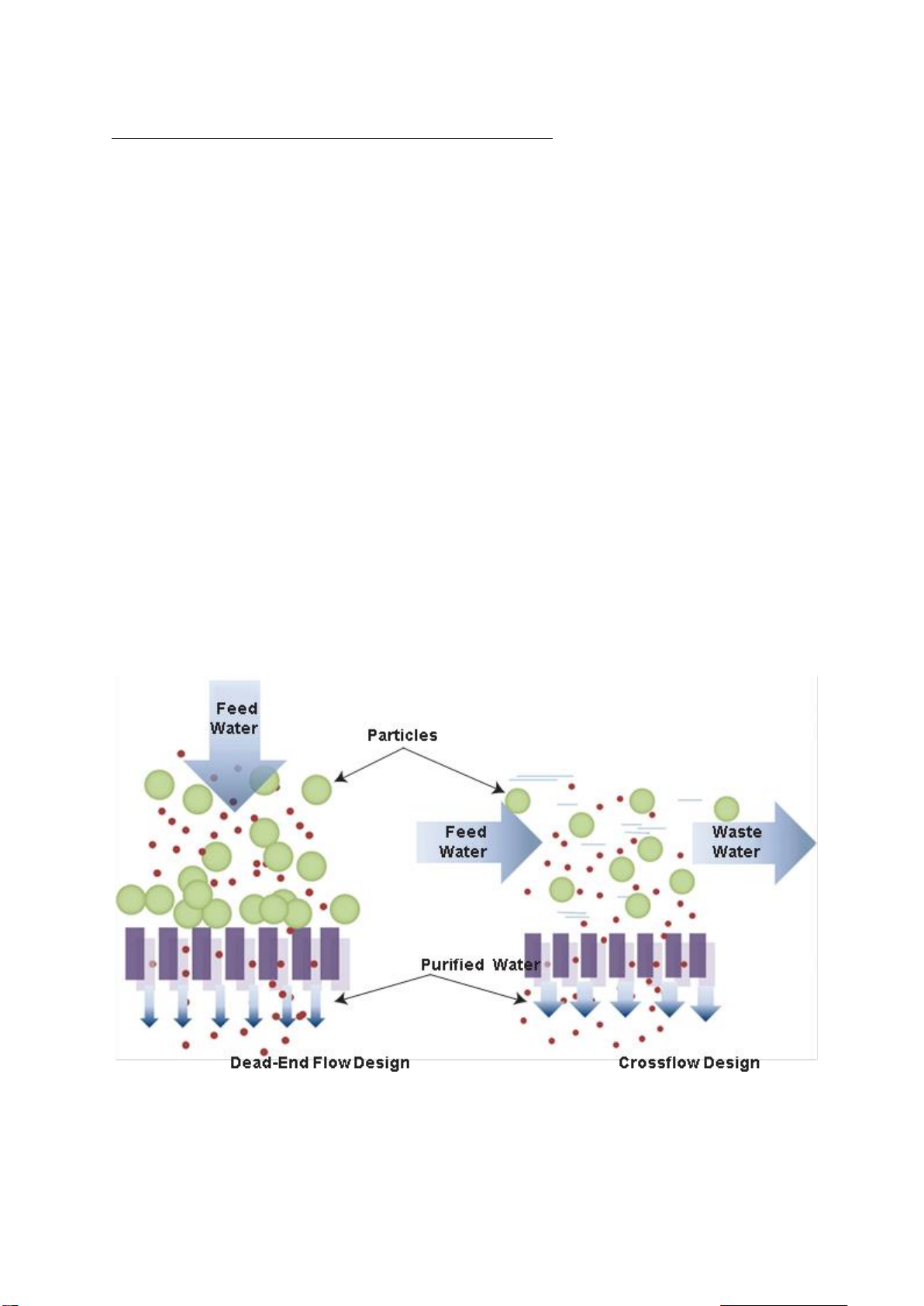

Fig 3,

Reverse Osmosis Membrane –

Nova Pro + Biocera A-A Filtration process,

The most essential part of any Reverse Osmosis system is its filters. It is also a

misconception that all filters remove materials from the incoming water, some filters actually

add materials into water to improve the taste, increase the mineral content and other health

benefits. Although a Reverse Osmosis system can consist of many filters, they all fall into

one of three categories with each category having a very specific purpose:

•

Pre-Filters

•

Reverse Osmosis Membrane

•

Post-Filters BIOCERA A-A , Antioxidant Alkaline

Page 5of 44

Pre-filtration before Reverse osmosis

The main purpose of the pre-filters is to protect the more expensive Reverse Osmosis

membrane filter from specific contaminants.

Traditional Reverse Osmosis systems have pre-filters which target sediment and chlorine as

they can damage the reverse osmosis filter and cause it to fail early. Additionally, traditional

systems have a significant health risk where although the filters are changed periodically, the

outside casing (housing) for these filters stay the same usually throughout the lifetime of the

system. This can result in unhygienic conditions as contaminants will accumulate on the

inside surface of the housing over time and can be gradually released into the incoming

water.

This BMB Nova Pro Reverse Osmosis System has three state-of-the-art pre-filters. The filter

element and housing are a single unit. Consequently, during filter replacement periods they

are changed at the same time in order to maintain system hygiene. Also, all of the pre filters

are easy to change and have a click-and-lock mechanism in order to reduce the risk of

leaks. Once the filter is being changed, simply keep twisting it into place slowly until a click is

heard. To remove the filter, turn and hold the lock to open position with one hand while

twisting the filter with the other hand until it is removed from the system.

Although the RO membrane filters used in this system are fully efficient in removing

microorganisms, the first and last pre-filters are equipped with Nano Zinc powder for

antibacterial effects. This prevents biofilm buildup on the membrane sheet surface which can

lead to fouling of the membrane filter. In addition to particles and chlorine, the pre-filters in

this system are designed to reduce heavy metals (iron, manganese and other rust), dust and

very fine particles down to 0.5 microns. This will allow the membrane filters to work with less

effort to produce high quality water. Please see the table below for a detailed list of the pre-

filters.

Position

Filter

Type

Filtration

1

5 Micron Antibacterial Sediment

Meltblown

Microorganisms, particles

2

CTO Block Coconut Shell Carbon

CTO Block

Chlorine, Chloramines and

other organic compounds

3

0.5 Micron Antibacterial Nano

Carbon

Meltblown +

GAC

All of the above + fine particles,

heavy metals such as iron,

manganese and other rust

Page 6of 44

Pre-filters

Filter 1

Antibacterial 1 Micron Sediment

The two-stage filter is made from nano zinc powder infused, NSF certified polypropylene

fibers. The fibers have a +97% efficiency of filtering particles that are 5 microns or larger

while the nano zinc powder acts as an antibacterial agent for any microorganisms in the

incoming water supply. Although zinc is an element that humans cannot live without, it is

lethal to microorganisms such as bacteria, virus, algae, fungi, etc.

Contaminants Reduced or Removed:

Sediment, particles, dust, rust, iron, manganese, microorganisms (bacteria, algae, fungi,

etc.)

Filter 2

Chlorine Tase Odour (CTO) Block, Coconut Shell carbon

The two-stage filter is made from NSF Certified Coconut Shell Carbon which has a very high

capacity to reduce taste and odor compared to charcoal filters. With a higher absorbent

level.

Contaminants Reduced or Removed:

Chlorine, chloramine, pesticides, herbicides, nitrate, phosphate, lithium, pharmaceuticals,

microplastics, arsenic, asbestos, lead, zinc, copper, mercury and other heavy metals

Filter 3

Antibacterial 0.5 Micron Sediment

The two-stage filter is made from nano zinc powder infused, NSF certified polypropylene

fibers. The fibers have a +97% efficiency of filtering particles that are 0.5 microns or larger

while the nano zinc powder acts as an antibacterial agent for any microorganisms in the

incoming water supply. Although zinc is an element that humans cannot live without, it is

lethal to microorganisms such as bacteria, virus, algae, fungi, etc.

Contaminants Reduced or Removed:

Sediment, particles, dust, rust, iron, manganese, microorganisms (bacteria, algae, fungi,

etc.)

Page 7of 44

Reverse osmosis Membrane- filters 4 & 5 Total - 600 GPD

At the heart of every Reverse Osmosis system is the membrane filter’s. The membrane filter

consists of microporous, semipermeable membrane sheets. The sheets are glued to each

other around three edges with a thin spacer in between (prevents the sheets from sticking to

each other) to form a “leaf”. Next, depending on the desired capacity of the membrane filter,

multiple leaf’s with mesh spacers in between (to allow the water to pass between leaf’s) are

stacked on top of each other. The stack is then spirally wound with the open end of the leaf

adhered to a perforated tube that runs up and down the center.

The membrane is constructed in this manner because unlike the pre-filters which are

designed as “dead-end filtration”, Reverse Osmosis membranes are designed as “crossflow

filtration”. In dead-end filtration, the feed water is passed perpendicular to the filter surface in

order to trap large particles. However, in Crossflow filtration the feed water is passed

tangential to the filter surface so the more-concentrated solution (particles) exits at the end

of the filter while the less-concentrated solution (purified water) permeates through the

membrane surface, gets trapped between the sheets and exits out of the perforated tube.

Figure 4 below shows the difference between dead-end filtration and crossflow filtration.

Page 8of 44

The membrane pores are so small that if the Reverse Osmosis filter was designed as dead-

end, the pores would be clogged up in a matter of few litres due to the abundant number of

dissolved solids found in the feed water and the extremely small membrane pore size.

The membrane filter has one water inlet and two exits. The feed water first travels through

the pre-filters and then to the membrane filter. At the exit of the membrane filter one of the

ports is the waste water (more-concentrated solution) which is connected to the drain, while

the other port is the purified water (less-concentrated solution) which is plumbed to the post-

filters. Figure 5 on page 9 shows a detailed schematic of the membrane filter.

BMB Technology Reverse Osmosis membranes are made of the highest quality Thin Film

Composite (TFC) polyamide and are designed to remove a wide variety of both aesthetic

and health related contaminants. Additionally, the following have been, considered when

designing the membrane filter:

•

Average membrane pore size of 0.0005 m

•

Ultra Low Pressure (ULP) membrane (min. 2 bar feed water pressure)

•

Included system pump for optimum osmotic pressure

ReverseOsmosis Membrane Filter

Page 9of 44

Semipermeable Membrane

Purified Water

Post Filtration, multi stage –BIOCERA A-A FILTERS 6 & 7

Page 10 of 44

Page 11 of 44

Nova Pro Specifications

Parameter

Value

Electricity

100 - 240 VAC / 50-60 Hz

Feed Water Pressure

2.5 Bar Min. - 6 Bar Max.*

Feed Water Temperature

4 - 40

o

C

Feed Water Connection

3/8"

System Dimensions (L x W x H)

42 cm x 30 cm x 49 cm

System Weight (no water)

16 KG

Tank Dimensions (L x W x H)

24 cm x 24 cm x 37 cm

**

The supply water requirements for this system can be found in

Table below.

If the water supply does not meet these requirements, the filter lifetime and output water

quality of the system can be affected. Please see section 7.1 for the recommended filter

lifetime of this system. This duration should be reduced depending on how much the water

quality exceeds the limits. Please also see section 7.2 on how to adjust the filter change

duration in the user interface.

If the feed water is supplied with raw well water, laboratory test of the water should be done

before installing the system. If there is a significant exceeding of these limits, a well water

treatment system at the source should be considered to correct the water quality.

The main components for this system can be found on the next page.

Parameter

Value

pH

6.5 - 8.5

Turbidity

< 5 NTU

TDS

< 500 PPM

Hardness

< 500 PPM CaCO3(50 oF) (28 odH)

Chloride

< 250 PPM

Free Chlorine

< 0.7 PPM

Iron

< 0.1 PPM

Manganese

< 0.1 PPM

Silica

< 0.1 PPM

Chemical Oxygen Demand

< 5 PPM O2

Total Bacteria Count

< 50 CFU / mL

E. Coli

< 3 CFU

Page 12 of 44

1

2

5

6

3

7

8

14

13

4

9

10

11

12

Page 13 of 44

List of system components and functions

System Filter locations

Pre filters

No:

Component

Function

1

Power Supply

Supplies 24V / 3.7A to the system

2

Low Pressure Switch

Prevents water production at low inlet water pressure in order to protect the system from overheating, will

give a "No Water" alarm on the digital controller

3

Inlet Water Solenoid Valve

Closes feed water supply when system goes into standby or alarm mode

4

LED Strip

Acts as a visual guide, lights during water production

5

Inlet Water Pressure Manometer

Measures feed water pressure

6

Pumping Pressure Manometer

Measures pumping pressure

7

Pump

Increases feed water pressure to supply the reverse osmosis membrane filters at optimum osmotic pressure

8

Digital Controller

Controls all system components, measures TDS and regulates filter lifetime

9

Auto-Flush Solenoid Valve

Activates in between water production and standby mode to flush the reverse osmosis membrane filters for

10 seconds in order to protect them from caking

10

Flow Restrictor

Controls ratio of produced water to waste water for optimum reverse osmosis membrane filter performance

11

High Pressure Switch

Activates pump during low pressure, stops pump and sends system to standby mode during high pressure

12

Check Valve

Prevents production of waste water during standby mode

13

TDS Probe

Measures produced water TDS before remineralization

14

LED On/Off Button

Turns system on or off

Page 14 of 44

post filters

Reverse osmosis membranes

Page 15 of 44

System on Board Water Ports

This system comes with four water ports on the side for easy installation and maintenance.

Since the system is wet tested after assembly, it is shipped with plugs on all of the ports in

order to prevent any potential leaking in the box from residue water that may be left after

testing. It is important to note that if the system does not require a tank, the plug on the

“Tank” connection should be left intact.

Page 16 of 44

Planning the Installation

The following tools will be needed for the installation of this system. Please see Table below

Tools Required

Installation Function

Electric Drill

Open hole on sink to mount the faucet*

5 mm or 1/8” diamond tip drill bit

Pilot hole for faucet*

12 mm or 1/2” diamond tip drill

bit

Main hole for faucet stem*

7 mm or ¼ tip drill bit

Tubing hole for drain saddle

Adjustable Wrench

Installing feed water diverter valve, metal ball valve and

faucet

Phillips Screw Driver

Mount drain saddle

Sharp Scissors or Knife

Shorten tubing if needed

BMB Nova Pro does not ship with a tank and unless the water pressure is below 2 bar or the

consumption is high (more than 300 liters / day), it will not require one.

Page 17 of 44

Nova Pro connection diagram

Below a connection diagram can be found for the BMB Nova Pro Model. The BMB Nova Pro

model is a system that can be used for both residential and commercial applications. The

system is a direct flow model (tankless) that does not ship with a tank. Consequently, all

purified water is instantaneously generated and consumed (without waiting in a tank) which

will increase the purified water health and quality benefits.

Feed

Faucet

Other BMB Technology Water Filtration System manuals

Popular Water Filtration System manuals by other brands

American Water Service

American Water Service PTE-8 Installation, operation and maintenance manual

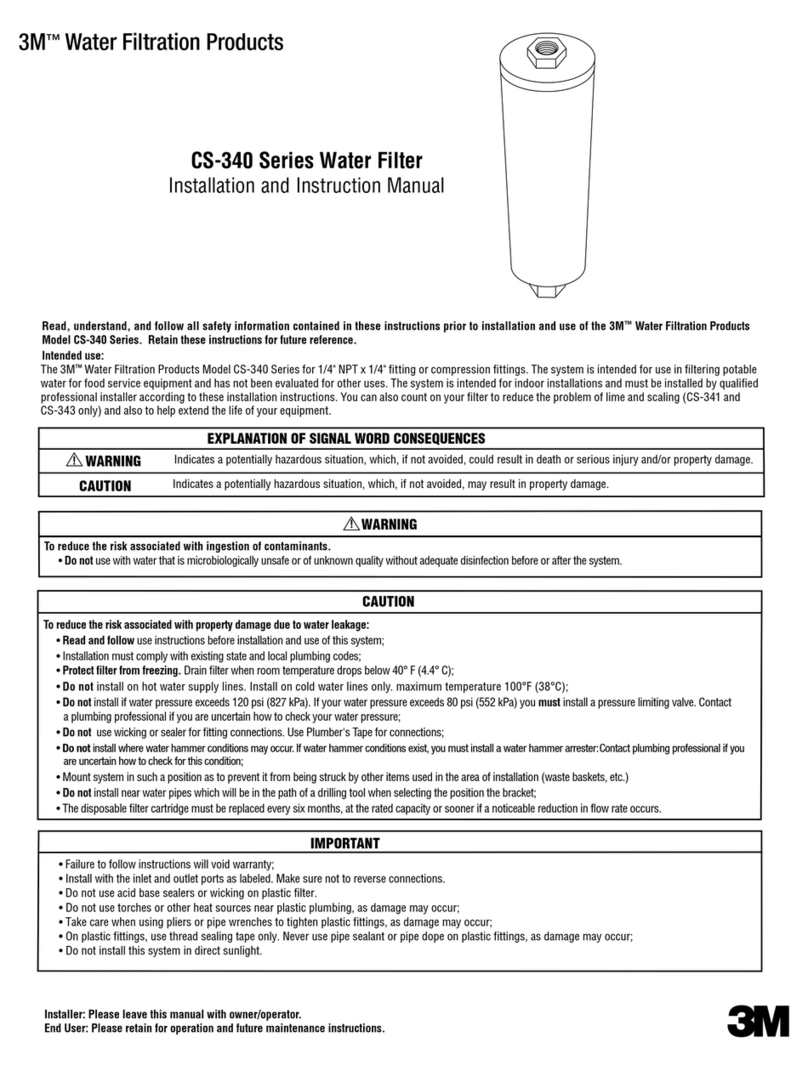

3M

3M CS-340 Series Installation and instruction manual

A.O. Smith

A.O. Smith AOS-HERO-CHR owner's manual

MTE

MTE Matrix E-Series Technical reference manual

Insignia

Insignia NS-LGLT5531 Quick setup guide

Donaldson Torit

Donaldson Torit WSO M Installation and operation manual

BLUGARDA

BLUGARDA BluPressure manual

Biotage

Biotage Flash 75 user manual

EHEIM

EHEIM Biopower Series manual

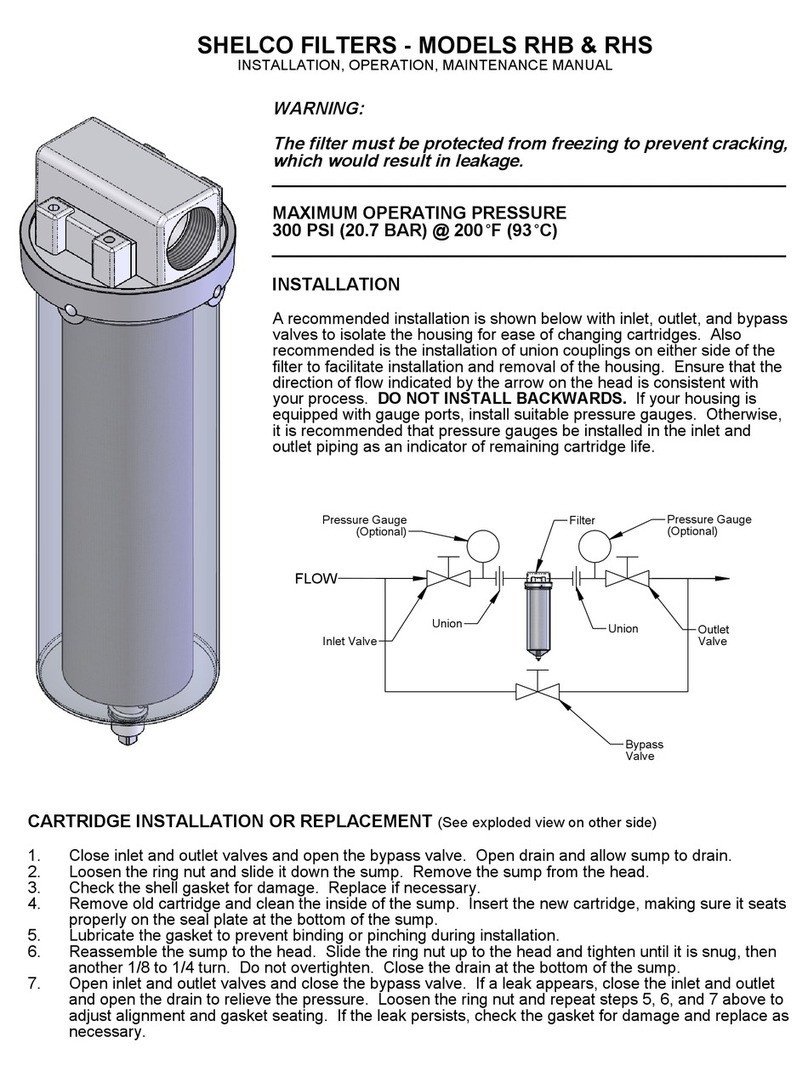

SHELCO FILTERS

SHELCO FILTERS RHB Installation, operation & maintenance manual

Hague Quality Water

Hague Quality Water WaterMax H6000 Owner's manual and installation guide

IST

IST MRO001 instruction manual